Polyoxymethylene (POM), a high-performance thermoplastic, is renowned for its exceptional properties in precision engineering. Its high crystallinity results in a tensile strength of approximately 60 MPa, a low friction coefficient (~0.2), and excellent dimensional stability. POM’s chemical and thermal resistance make it ideal for demanding applications, such as automotive fuel system valves and electronic connectors. Its processability allows for the creation of complex, high-tolerance components, enhancing manufacturing efficiency. This article delves into POM’s melting characteristics, processing advantages, and its critical role in high-stress industrial applications.

Key Properties of POM

Polyoxymethylene (POM) delivers exceptional performance in engineering applications due to its highly crystalline (CH₂O)ₙ structure, offering a unique combination of mechanical, chemical, and processing properties.

Mechanical and Physical Performance

- Tensile strength: 60-70 MPa (ASTM D638), ensuring rigidity for load-bearing components like automotive gears.

- Flexural modulus: 2,800-3,100 MPa (ASTM D790), supporting precision parts.

- Impact resistance: Notched Izod values of 6.5-7.5 J/m (ASTM D256), maintaining toughness at -40°C.

- Fatigue resistance: Supports millions of stress cycles, ideal for dynamic parts like conveyor rollers.

- Low thermal expansion: 80-110 × 10⁻⁶ m/m°C, and minimal water absorption (<0.8%, ASTM D570), ensuring dimensional stability for high-tolerance parts like electronic connectors.

Chemical and Environmental Durability

- Resists solvents such as gasoline, ethanol, and hydraulic fluids (pH 4-9), suitable for fuel system valves and industrial cleaning equipment.

- Copolymers offer enhanced chemical stability compared to homopolymers, supporting use in harsh environments.

Processing and Electrical Advantages

- Heat deflection temperature: 110-165°C (ASTM D648), with a melting point of ~175°C (homopolymers) or ~165°C (copolymers), performing reliably from -40°C to 100°C.

- Melt flow index: ~10-30 g/10min, enabling precise molding of complex shapes.

- High volume resistivity: >10¹⁴ Ω·cm, and low dielectric constant (~3.7), suitable for electrical insulators in high-frequency electronics.

- Low friction coefficient (~0.2) and superior wear resistance reduce maintenance in sliding components like bearings.

These properties, combined with POM’s recyclability and competitive edge over materials like nylon (higher moisture absorption) and ABS (lower chemical resistance), make it a cornerstone for precision engineering. The following sections explore POM’s melting characteristics and their impact on processing efficiency and application performance.

| Property Category | Typical Value | Test Method | Engineering Significance |

|---|---|---|---|

| Tensile Strength | 60-70 MPa | ASTM D638 | Supports high-stress structural components |

| Flexural Modulus | 2,800-3,100 MPa | ASTM D790 | Ensures rigidity in precision parts |

| Water Absorption | <0.8% | ASTM D570 | Maintains tight tolerances in humid conditions |

| Heat Deflection | 110-165°C | ASTM D648 | Enables use in elevated-temperature applications |

| Impact Strength | 6.5-7.5 J/m | ASTM D256 | Prevents failure under sudden loads |

| Coefficient of Friction | ~0.2 | ASTM D1894 | Reduces wear in sliding mechanisms |

Melting Characteristics of POM

Polyoxymethylene (POM)’s melting and crystallization behaviors are critical for optimizing processing and ensuring high-quality parts in precision engineering. Its narrow melting range and rapid crystallization enable efficient molding, while its flow and thermal stability properties demand precise control to achieve consistent results.

Melting and Flow Behavior

- Melts at 175-185°C for homopolymers and 165-175°C for copolymers (ASTM D3418), requiring processing temperatures of 195-215°C for smooth molding.

- Copolymers offer a wider processing window. The melt flow index (2-25 g/10min for homopolymers, 5-30 g/10min for copolymers, ASTM D1238) varies with molecular weight, enabling tailored flow for parts like gears (low MFI) or valve housings (high MFI).

- Temperatures above 230°C risk degradation, releasing formaldehyde.

Crystallization and Cooling

- Rapid crystallization (5-10 seconds at 150-160°C) forms a highly crystalline structure (up to 80%), enhancing strength and dimensional stability.

- Homopolymers crystallize faster, with slightly higher shrinkage (2.0-2.5%) than copolymers (1.8-2.2%).

- Optimized cooling cycles minimize warpage, ensuring tight tolerances.

These properties enable POM to deliver consistent, high-strength parts when processed with precise temperature and cooling control. Its versatility supports applications in automotive, electronics, and industrial components, as explored in subsequent sections.

Processing Parameter Table

| Processing Parameter | Homopolymer POM | Copolymer POM | Impact on Processing |

|---|---|---|---|

| Melting Temperature Range | 175-185°C | 165-175°C | Ensures smooth molding |

| Melt Flow Index | 2-25 g/10min | 5-30 g/10min | Tailors flow for part design |

Processing Techniques for POM

Polyoxymethylene (POM) granules require precise processing to leverage their high crystallinity and melt flow properties, ensuring high-quality parts for applications like automotive fuel systems. Optimized injection molding and extrusion techniques enhance part strength and dimensional accuracy.

Injection Molding

Injection molding, the primary method for POM parts, uses barrel temperatures of 195-215°C (ASTM D3418) to ensure smooth flow without degradation. Copolymers allow a wider temperature window than homopolymers. Mold temperatures of 80-120°C improve surface finish and precision, while injection pressures of 80-120 MPa (ASTM D955) ensure complete mold filling, minimizing sink marks in parts like fuel pump gears. Drying granules at 80-100°C for 2-4 hours to <0.02% moisture prevents hydrolysis and surface defects.

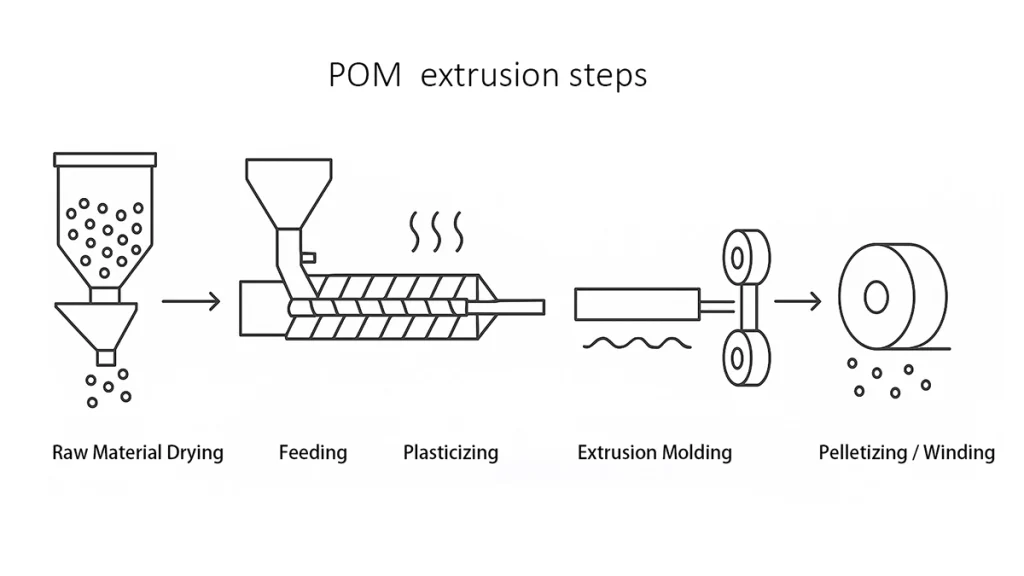

Extrusion

Extrusion produces POM profiles and sheets, requiring a gradual temperature increase from 180°C (feed zone) to 210°C (die) and a screw compression ratio of 2.5:1 to 3:1 for uniform melting. Streamlined die designs with short land lengths reduce thermal degradation, ensuring consistent flow for products like conveyor belts. Copolymers are preferred for their enhanced thermal stability.

Post-Processing and Quality Control

Annealing at 140-160°C for 1-2 hours relieves internal stresses, enhancing dimensional stability in precision components like electronic connectors. Real-time monitoring of melt temperature and injection pressure prevents defects like warpage or short shots. Compared to nylon, POM’s lower moisture absorption simplifies processing, reducing drying times. These techniques ensure reliable, high-performance parts, as explored in subsequent application sections.

Processing Parameter Table

| Processing Method | Temperature Range (°C) | Pressure Range (MPa) | Impact on Processing |

|---|---|---|---|

| Injection Molding | 195-215 | 80-120 | Ensures precise molding |

| Extrusion | 180-210 | 15-35 | Maintains uniform flow |

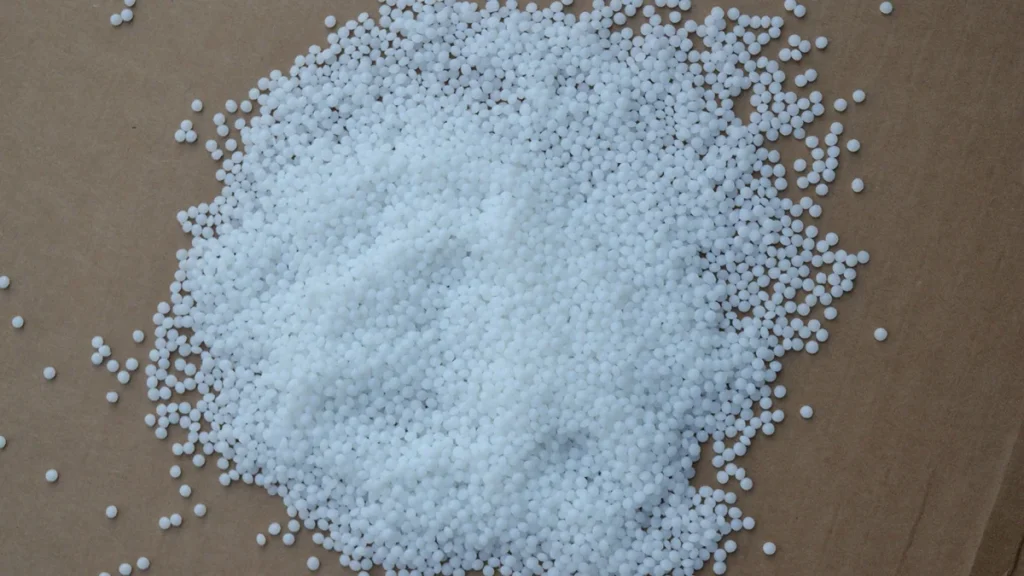

Sourcing and Quality Control of POM Granules

Effective supply chain management for POM granules ensures consistent quality and cost-efficient delivery. Strategic sourcing involves partnering with ISO 9001-certified suppliers to meet specifications for molecular weight and melt flow index (MFI 2-30 g/10min, ASTM D1238). Diversifying suppliers mitigates disruptions and secures competitive pricing.

Quality assurance includes batch testing for MFI, thermal stability (melting point 165-185°C), and moisture content (<0.02%) to prevent defects like hydrolysis. Global sourcing requires managing lead times and customs, while moisture-proof packaging is essential. Compared to nylon, POM’s lower moisture absorption simplifies logistics.

High-quality POM granules are characterized by type: homopolymers offer high tensile strength (60-70 MPa, ASTM D638) and chemical resistance for load-bearing parts like gears, while copolymers provide better thermal stability for intricate components like electronic connectors. Key properties include melt flow index (MFI 2-30 g/10min, ASTM D1238) for processing consistency and low moisture absorption (<0.8%, ASTM D570) for dimensional stability.

Reliable suppliers ensure consistent granules with stable MFI and thermal properties. Incoming inspections verify specifications through tests for MFI, tensile strength, and moisture content. Statistical process control ensures batch consistency, preventing defects in precision parts.

For high-quality POM granules tailored to your manufacturing needs, contact us to explore reliable supply solutions.

Applications and Advantages of POM

Polyoxymethylene (POM) delivers exceptional performance in precision engineering, leveraging its low friction, high strength, and rapid crystallization for applications in automotive, electronics, industrial, medical, and food sectors. Its processing efficiency supports high-quality, cost-effective components.

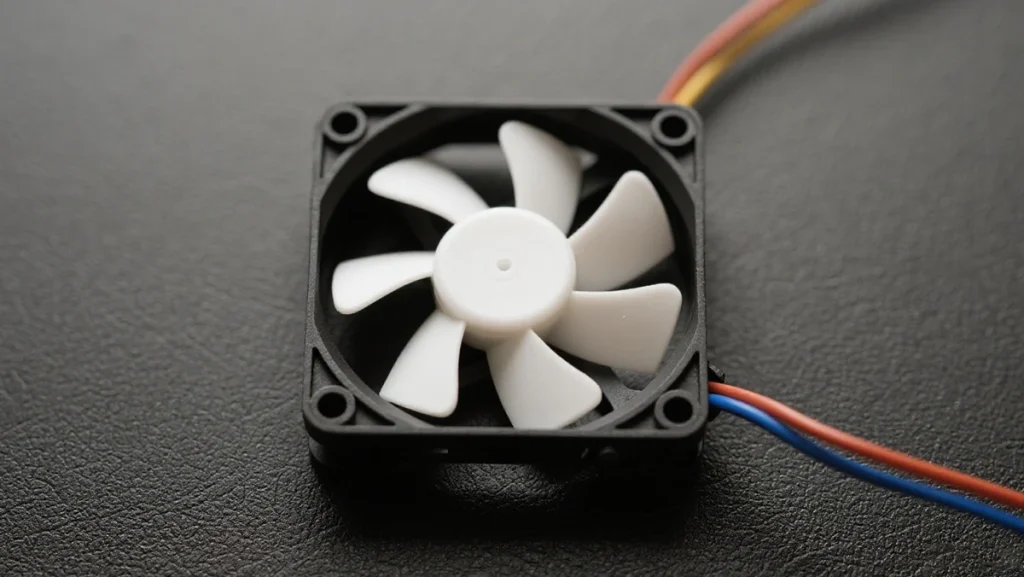

Automotive and Electronics

POM’s low friction coefficient (~0.2, ASTM D1894) and high tensile strength (60-70 MPa, ASTM D638) make it ideal for automotive fuel system valves and transmission gears, resisting corrosion and extending service life. In electronics, its dimensional stability (<0.8% moisture absorption, ASTM D570) ensures precision in connectors and camera module housings, supporting miniaturization. Homopolymers excel in high-stress automotive parts, while copolymers suit intricate electronic components.

Industrial and Mechanical

POM’s wear resistance and self-lubricating properties enable quiet, durable gears and bearings in industrial machinery, such as conveyor systems. Its rapid crystallization (5-10 s at 150-160°C) supports efficient molding of complex shapes with tight tolerances, reducing maintenance costs compared to nylon, which has higher creep.

Medical and Food Processing

Specific POM grades, FDA-compliant for food contact, resist sterilization and chemicals, making them suitable for surgical tools and food conveyor parts. Copolymers offer enhanced thermal stability for reusable medical devices. POM’s recyclability aligns with sustainability goals, unlike PP with lower chemical resistance.

Updated Application Table

| Application Sector | Key Advantages | Typical Components | Performance Benefits |

|---|---|---|---|

| Automotive | Chemical resistance, low friction | Fuel valves, gears | Extended durability, energy efficiency |

| Electronics | Dimensional stability, insulation | Connectors, housings | Precision, miniaturization |

| Industrial | Wear resistance, self-lubrication | Gears, bearings | Quiet operation, low maintenance |

| Medical/Food | Biocompatibility, FDA compliance | Surgical tools, conveyor parts | Safety, sterilization resistance |

Environmental and Safety Considerations

Effective environmental and safety management in polyoxymethylene (POM) manufacturing ensures worker protection and sustainability, supporting high-quality production for applications like food-grade components. Optimized protocols align with POM’s high-temperature processing needs.

Workplace Safety

Robust ventilation systems capture formaldehyde emissions (<0.1 ppm) during POM melting (165-185°C), protecting workers. Mandatory protective gear, including gloves and masks, mitigates risks when handling hot granules. Comprehensive training covers safe lifting, emergency shutdowns, and chemical exposure protocols, guided by OSHA standards and material safety data sheets.

Environmental Management

Energy-efficient heating systems reduce consumption by 10-20% during POM processing, lowering carbon footprint. Closed-loop recycling systems recover ~80% of POM waste, minimizing raw material use. Copolymers, with lower formaldehyde release than homopolymers, enhance environmental performance, outperforming nylon’s higher energy demands in production.

Regulatory Compliance and Sustainability

POM grades comply with FDA food-contact standards, REACH, and RoHS for global markets, ensuring safety in medical and electronic applications. ISO 14001-certified facilities promote circular economy practices, designing recyclable parts. Lifecycle assessments optimize transport and disposal, reducing environmental impact.

Summary and Future Trends

Polyoxymethylene (POM) stands out in precision engineering with its high crystallinity, tensile strength (60-70 MPa, ASTM D638), low friction coefficient (~0.2, ASTM D1894), and dimensional stability (<0.8% moisture absorption, ASTM D570). Its melting range (165-185°C, ASTM D3418) and rapid crystallization support efficient processing for automotive fuel valves, electronic connectors, and medical devices. Market demand for POM remains robust, fueled by automotive lightweighting and electronics miniaturization, with global production expected to grow steadily through 2030 (per industry reports).

Innovations in bio-based POM grades and enhanced copolymers boost thermal stability and recyclability, aligning with sustainability goals. POM’s low energy consumption (10-20% less during processing) and compliance with FDA, REACH, and RoHS standards position it for growth in renewable energy components and 3D-printed medical tools. As high-tech industries demand durability and precision, POM’s versatility ensures its pivotal role in next-generation engineering. For tailored POM granule solutions to meet your manufacturing needs, contact us to explore high-quality supply options.

Email: jerry@salesplastics.com

Phone: +8618657312116

Frequently Asked Questions (FAQ)

A:POM’s melting point is 175-185°C for homopolymers and 165-175°C for copolymers (ASTM D3418). This narrow range supports precise molding for components like gears and connectors, ensuring dimensional stability and strength.

A:POM is produced via catalytic polymerization of formaldehyde, forming a crystalline (CH₂O)ₙ structure. Homopolymers offer high strength (60-70 MPa, ASTM D638); copolymers enhance thermal stability. Precise reaction control ensures consistent melt flow index (2-30 g/10min, ASTM D1238), as noted in the article’s “Key Properties”.

A:Homopolymers provide higher crystallinity and strength (60-70 MPa, ASTM D638), ideal for gears. Copolymers, with a lower melting point (165-175°C vs. 175-185°C, ASTM D3418), resist thermal degradation, suiting connectors.

A:Uniform wall thickness prevents warpage in POM parts due to rapid crystallization (5-10 seconds at 150-160°C). Thin walls (1-3 mm) ensure dimensional stability (<0.8% moisture absorption, ASTM D570).

A:Controlled melting (195-215°C) and rapid crystallization create POM’s crystalline structure (up to 80%), enhancing wear resistance (friction coefficient ~0.2, ASTM D1894). As noted in “Melting Characteristics”, uniform cooling ensures smooth surfaces for bearings, per the “Applications”section.

A:Optimal processing involves controlling temperature (195-215°C), pressure (80-120 MPa, ASTM D955), and drying (<0.02% moisture). Match melt flow index (2-30 g/10min) to part design.