Polyamide 6 with 30% glass fiber reinforcement (PA6 GF30) has become an industry-standard engineering thermoplastic, valued for its exceptional balance of performance and cost. By expertly compounding PA6 with glass fibers, this material achieves a dramatic boost in tensile strength, stiffness, and thermal stability over the base polymer. As industries increasingly require components that are both lighter and stronger, PA6 GF30 provides a critical solution that drives innovation across the automotive, electrical, and mechanical engineering sectors.

This comprehensive guide delves into the core properties, processing considerations, and versatile applications of PA6 GF30, equipping engineers, procurement specialists, and researchers with the insights needed to make informed material selections.

Introduction to PA6 GF30

PA6 GF30 is a precisely engineered composite, integrating the fundamental properties of Polyamide 6 (Nylon 6) with a 30% glass fiber reinforcement by weight. The base Polyamide 6 polymer, derived from caprolactam via ring-opening polymerization, offers inherent toughness and excellent processability. The strategic addition of glass fibers fundamentally transforms the material, delivering a measurable increase in tensile strength, rigidity, and dimensional stability.

The “GF30” designation is more than just a specification; it represents the industry’s most proven composition for achieving an optimal balance. At a 30% loading, the glass fibers maximize mechanical performance gains while maintaining excellent flow characteristics and avoiding the brittleness or processing difficulties associated with higher fiber contents. This precise formulation makes PA6 GF30 the go-to solution for applications demanding a perfect blend of durability and ease of molding.

Facing a Specific Technical Challenge?

Our team of material experts is ready to help. Stop guessing and start collaborating. Contact us to discuss your unique project requirements, optimize material selection, and overcome your most complex engineering challenges with personalized, expert guidance.

Key Properties and Benefits

PA6 GF30 is not just a material; it’s a high-performance solution whose properties are precisely engineered to meet the most rigorous demands. The synergy between the PA6 polymer matrix and glass fiber reinforcement results in a dramatic leap in mechanical, thermal, and chemical performance.

Mechanical Properties

The addition of 30% glass fibers fundamentally transforms the mechanical profile of Polyamide 6, making PA6 GF30 a preferred choice for load-bearing and structural components.

| Property | PA6 GF30 | Unreinforced PA6 |

| Tensile Strength | 150-180 MPa | 70-85 MPa |

| Flexural Modulus | 8,500-9,500 MPa | 2,800-3,200 MPa |

| Impact Strength (Charpy) | 10-12 kJ/m² | 5-7 kJ/m² |

| Wear Resistance | Excellent | Good |

- Tensile Strength: The tensile strength of PA6 GF30 is more than double that of its unreinforced counterpart, providing the resilience needed for high-stress applications.

- Flexural Modulus: With a flexural modulus up to three times higher, the material exhibits exceptional stiffness, minimizing deformation under load.

- Wear Resistance: Its superior wear properties make it an ideal material for gears, bearings, and other parts subject to friction and abrasion.

Thermal Properties

PA6 GF30’s enhanced thermal properties enable it to withstand continuous exposure to high temperatures, making it a reliable solution for demanding environments.

- Melting Point: 220-225°C

- Heat Deflection Temperature (HDT): A high HDT of 200-210°C at 1.8 MPa ensures dimensional stability where unreinforced plastics would fail.

- Continuous Service Temperature: The material maintains its integrity up to 180°C, making it perfect for applications under the hood of a car or in electrical enclosures.

Chemical Resistance

The semi-crystalline structure of PA6 GF30 gives it robust resistance to common industrial fluids.

High Resistance To:

- Hydrocarbons (fuels, oils, greases)

- many organic solvents

- weak bases

- This makes it an ideal choice for components that face direct contact with automotive fluids or industrial cleaners.

Limited Resistance To:

- Strong acids

- Strong oxidizing agents

- Certain chlorinated hydrocarbons

Crystalline Structure

The glass fibers in PA6 GF30 serve as a nucleating agent, promoting a higher degree of crystallinity in the base PA6 polymer. This more organized crystalline structure is the key factor behind the material’s superior mechanical strength, dimensional stability, and chemical resistance. It ensures that the enhanced properties are consistently maintained throughout the component’s service life.

Advantages and Key Considerations

While PA6 GF30 offers a powerful combination of benefits, it is crucial for engineers and designers to understand its complete property profile, including certain characteristics that require careful management to ensure optimal performance.

Advantages

- Exceptional Mechanical Strength & Stiffness: The material’s high tensile strength and flexural modulus make it a top choice for demanding structural applications.

- Superior Thermal Stability: PA6 GF30 maintains its integrity at elevated temperatures, outperforming many other thermoplastics in high-heat environments.

- Excellent Chemical Resistance: It stands up to hydrocarbons, oils, and greases, making it ideal for automotive and industrial components.

- Dimensional Stability: The glass fiber reinforcement provides excellent resistance to creep and warpage, ensuring parts maintain their shape under continuous load.

- Outstanding Wear & Abrasion Resistance: This property makes it a go-to solution for parts subject to friction, like gears and bearings.

Key Considerations

- Moisture Management:Hygroscopic nature requires pre-drying (80-90°C for 4-6 hours) to ensure consistent properties and dimensional stability.

- Reprocessing Complexity:Recycled material may have slightly reduced mechanical properties due to glass fiber length degradation.

- Specialized Tooling:The abrasive nature of glass fibers may require hardened steel molds for high-volume production.

- Machining Challenges:Machining can be more difficult than with unreinforced plastics, requiring sharp tools to avoid fiber pull-out.

- Reduced Impact Strength:While tough, it may have lower impact resistance than specialized, rubber-modified nylon grades.

Overcome Material Limitations

Speak with our technical experts about specialized PA6 GF30 formulations designed to address specific application challenges.

Comparison with Other Materials

Understanding how PA6 GF30 compares to alternative materials is crucial for making informed material selection decisions. The following comparisons highlight key differences between PA6 GF30 and other commonly used engineering plastics.

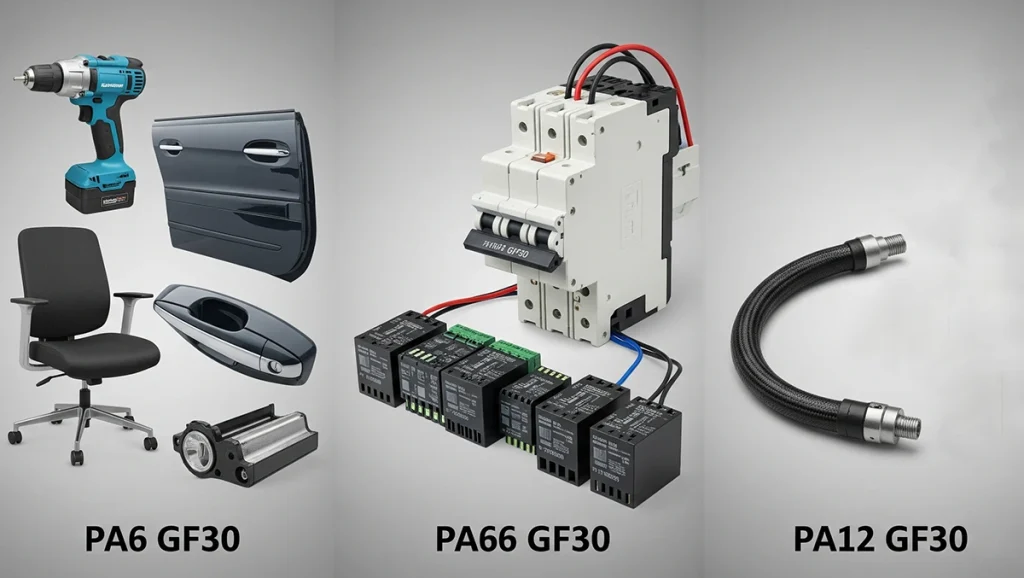

PA6 GF30 vs. PA66 GF30

| Property | PA6 GF30 | PA66 GF30 | Key Difference |

| Chemical Structure | From caprolactam | From hexamethylenediamine and adipic acid | Different monomer composition |

| Melting Point | 220-225°C | 255-265°C | PA66 has higher thermal resistance |

| Moisture Absorption | 1.5-1.8% | 1.0-1.3% | PA6 absorbs more moisture |

| Processing Temp. | 270-290°C | 280-300°C | PA6 processes at slightly lower temperatures |

| Surface Quality | Better | Good | PA6 typically yields a better surface finish |

PA6 GF30 vs. PA12 GF30

PA12 GF30 is a high-performance alternative, but it comes with a significantly higher price tag, typically 1.5 to 2 times more expensive than PA6 GF30. The premium cost delivers:

- Superior dimensional stability due to much lower moisture absorption (0.7-0.9%).

- Enhanced chemical resistance, particularly against hydrolysis.

- Greater flexibility and lower density.

However, if your application demands high mechanical strength and stiffness, PA6 GF30 is the clear winner, providing superior tensile and flexural properties at a fraction of the cost. The choice between the two is a direct trade-off between absolute performance and budget.

PA6 GF30 vs. PBT GF30

PBT GF30 is another glass fiber-filled thermoplastic that competes with PA6 GF30, particularly in electrical and automotive applications. The main differentiator lies in their moisture sensitivity:

- PBT GF30 has exceptionally low moisture absorption (0.2-0.3%), ensuring stable electrical and dimensional properties even in humid conditions.

- PA6 GF30, by contrast, offers superior impact and wear resistance, making it a better choice for parts that face mechanical stress, friction, and abrasion.

While both are dimensionally stable, PA6 GF30’s excellent toughness often makes it the preferred material for components that require robust mechanical performance in non-humid environments.

Manufacturing and Processing

Achieving flawless part quality with PA6 GF30 begins with a precise and disciplined processing strategy. Adhering to these guidelines is key to unlocking the material’s full potential and ensuring reliable, high-performance end products.

Pre-Processing Requirements

Due to its hygroscopic nature, proper drying is the single most critical step to prevent defects like splay marks, bubbles, and inconsistent mechanical properties.

- Recommended Drying Conditions: 80-90°C for 4-6 hours.

- Target Moisture Content: <0.1%.

- Best Practice: Utilize desiccant dryers for superior results. Ensure the dried material is processed immediately or stored in a sealed, moisture-proof container.

Injection Molding Parameters

Adhering to the correct parameters ensures uniform melt flow and optimal crystallization, which are essential for dimensional stability and strength.

| Parameter | Recommended Range | Why It Matters |

| Melt Temperature | 270-290°C | Maintain this range to prevent material degradation while ensuring proper flow. |

| Mold Temperature | 80-90°C | Higher temperatures promote better crystallinity, leading to improved dimensional stability and mechanical properties. |

| Injection Pressure | 80-120 MPa | Varies based on part geometry; sufficient pressure ensures full mold cavity filling. |

| Injection Speed | Medium to high | Helps prevent premature material freeze-off and ensures a consistent fill, especially for thin-walled parts. |

| Holding Pressure | 60-90% of injection pressure | Crucial for compensating for material shrinkage and maintaining dimensional accuracy. |

| Cooling Time | Varies | Sufficient cooling time is essential to prevent part warpage and internal stress. |

Equipment and Tooling

The abrasive nature of glass fibers can cause significant wear on standard equipment. Using the right components protects your investment and maintains product consistency.

- Wear-Resistant Components: Opt for hardened steel screws, barrels, and nozzles.

- Screw Design: A general-purpose screw with an L/D ratio of 18:1 to 22:1 and a compression ratio of 2:1 to 3:1 is recommended for efficient plasticizing.

- Hot Runner Systems: Should be properly sized and feature shut-off nozzles to prevent drooling and stringing.

Post-Processing Considerations

Proper post-processing ensures the finished component meets all performance specifications.

- Annealing: Annealing at 160-180°C for 2-4 hours can further enhance dimensional stability and reduce residual stress.

- Machining: Use sharp, carbide-tipped tools to combat the abrasive nature of the material.

- Storage: Store finished parts in a controlled environment to prevent moisture absorption and maintain their specified properties over time.

Applications of PA6 GF30

PA6 GF30 isn’t just a versatile material; it’s a critical solution engineered to meet the toughest challenges across key industries. By leveraging its superior strength, thermal stability, and durability, manufacturers are able to produce high-performance components that are both lighter and more reliable.

Automotive Applications

PA6 GF30 is a cornerstone material for automotive engineering, helping to reduce vehicle weight, improve fuel efficiency, and enhance component reliability. Its resistance to heat, oil, and chemicals makes it the ideal choice for demanding under-the-hood environments.

Under-the-Hood Components

- Engine covers, air intake manifolds, cooling system parts, and oil pans.

Exterior & Interior Parts

- Mirror housings, door handles, and structural components that require both strength and a good surface finish.

Electric Vehicle (EV) Solutions

- With the rise of EVs, PA6 GF30 is increasingly used for battery housings, high-voltage connectors, and thermal management systems, where its excellent mechanical properties and electrical insulation are paramount.

Electrical and Electronic Applications

The material’s high dielectric strength and heat resistance make it an invaluable material for protecting sensitive electrical components from thermal and mechanical stress.

- Enclosures and Housings: Switch housings, terminal blocks, and connector bodies.

- Circuitry Components: Circuit breaker parts and insulating elements.

- Structural Elements: Strong and rigid housings for consumer electronics and power tools.

Industrial and Mechanical Applications

PA6 GF30’s exceptional wear resistance and dimensional stability make it a go-to solution for power transmission and fluid handling systems, where parts must endure continuous friction and pressure.

Motion & Power Transmission

- Gears, bearings, pulleys, and coupling components.

Fluid Handling

- Pump housings, valve bodies, and filter housings that require high pressure resistance and chemical stability.

Consumer and Sporting Goods

For products where strength-to-weight ratio is crucial, PA6 GF30 offers the perfect blend of performance and processability.

- Equipment Frames: High-performance sporting equipment and luggage frames.

- Tool Components: Durable housings and handles for power tools.

- Durable Components: Furniture components and structural elements requiring high load-bearing capacity.

Explore Application-Specific Solutions

Request material samples of PA6 GF30 for testing in your specific application.

Specialized Variants and Sustainability

While standard PA6 GF30 is a high-performance workhorse, specific applications often require an added dimension of capability. To meet these unique demands, manufacturers have engineered specialized variants.

- Flame-Retardant Grades: Formulated to achieve high flame ratings like UL94 V-0, essential for electrical enclosures and connectors. Halogen-free and low-smoke emission variants are also available.

- Impact-Modified Grades: Incorporate elastomeric modifiers to dramatically boost the material’s toughness and impact strength, especially at low temperatures.

- Heat-Stabilized Grades: Designed for long-term service in elevated temperatures, ensuring that mechanical properties are maintained up to 180°C.

- Laser-Markable Grades: Formulated with specialized additives for crisp, high-contrast laser marking, essential for traceability and branding.

As industries accelerate their push toward a circular economy, the demand for sustainable material solutions is growing rapidly. We offer advanced PA6 GF30 variants that meet this challenge, providing a path to reduced environmental impact without compromising on performance.

- Post-Industrial Recycled (PIR) PA6: Incorporates high-quality PA6 from manufacturing waste streams.

- Bio-Based Polyamides: Feature a polymer matrix derived from renewable resources, lowering their carbon footprint.

- Recycled Grades: Leveraging innovative recycling technologies to use post-industrial and, in some cases, post-consumer recycled content.

These sustainable variants are engineered to maintain the same high level of mechanical, thermal, and chemical performance as their virgin counterparts.

Market and Practical Considerations

Navigating the market for engineering plastics requires more than just technical knowledge. Understanding the business dynamics, from global trends to cost factors, is essential for a successful material strategy.

Global Market Trends

The PA6 GF30 market is undergoing rapid evolution, driven by innovation and shifting global demands.

- Asian Growth Engine: The market is experiencing significant growth in the Asia-Pacific region, fueled by expanding manufacturing hubs in China and India.

- The EV Revolution: The rapid rise of electric vehicles is a major catalyst, as manufacturers increasingly turn to PA6 GF30 for lightweight yet durable battery housings and thermal management systems.

- Sustainability as a Standard: A global push towards a circular economy is accelerating the adoption of sustainable and recycled PA6 GF30 grades, which are key to meeting corporate environmental goals.

Cost Factors

- Material Cost Premium: While PA6 GF30 is typically 20-30% higher than unreinforced PA6, this initial cost is offset by its superior performance.

- Processing Efficiencies: The material’s excellent processability can lead to reduced cycle times and lower energy consumption.

- Part Consolidation: PA6 GF30’s strength allows for the consolidation of multiple components into a single, molded part, significantly reducing assembly costs and complexity.

- Long-Term Savings: Its durability and longevity reduce the need for replacements and maintenance, leading to substantial lifecycle cost advantages.

Future Outlook

The PA6 GF30 market is not standing still. It’s an arena of continuous innovation, with cutting-edge developments that promise to unlock new applications and redefine what’s possible in material science. Staying ahead of these trends is key to future-proofing your projects.

The next generation of PA6 GF30 is focused on pushing the boundaries of performance and sustainability.

- Hybrid Reinforcements: The rise of hybrid systems, such as combining glass fibers with carbon fibers or minerals, allows for a more tailored balance of high strength, rigidity, and weight reduction to meet highly specific application needs.

- Bio-Based Alternatives: With a growing focus on sustainability, new PA6 variants are being developed with a bio-based polymer matrix, offering a lower carbon footprint without compromising on the material’s core mechanical properties.

Frequently Asked Questions (FAQs)

What Are the Key Features of PA6 GF30?

PA6 GF30 is characterized by high mechanical strength (150-180 MPa tensile strength), excellent thermal stability (HDT of 200-210°C), good chemical resistance to hydrocarbons, superior wear resistance, and dimensional stability under load. The 30% glass fiber reinforcement provides a significant improvement in stiffness and strength compared to unreinforced PA6 while maintaining reasonable processability.

What Are the Common Applications of PA6 GF30?

PA6 GF30 is widely used in automotive components (engine covers, cooling systems, mirror housings), electrical applications (switch housings, connector bodies), industrial machinery (gears, bearings, pump housings), and consumer goods requiring high strength and durability. Its combination of mechanical properties, thermal stability, and chemical resistance makes it particularly suitable for demanding environments where metal replacement is desired.

Are There Other Types of Glass-Filled PA6 Available?

Yes, PA6 is available with various glass fiber contents ranging from 10% to 60%. Common variants include PA6 GF15 (15% glass fiber), PA6 GF30 (30% glass fiber), and PA6 GF50 (50% glass fiber). Higher glass content increases stiffness and strength but reduces impact resistance and processability. There are also hybrid reinforcement systems combining glass fibers with minerals or carbon fibers for specialized applications.

Can PA6 GF30 be 3D printed?

Yes, PA6 GF30 can be 3D printed. Specialized PA6 GF30 filaments are available for Fused Filament Fabrication (FFF) printers, enabling the creation of strong, rigid parts. It’s a popular choice for functional prototypes and industrial tooling due to its high strength, stiffness, and excellent dimensional stability.

Does PA6 GF30 Absorb Water?

Yes, PA6 GF30 is hygroscopic and absorbs moisture from the atmosphere. At equilibrium in standard conditions (23°C, 50% relative humidity), it typically absorbs 1.5-1.8% moisture by weight. This moisture absorption affects dimensional stability and mechanical properties, with water acting as a plasticizer that reduces stiffness and strength while increasing ductility. Pre-drying before processing and proper storage are essential to manage moisture-related issues.

Is PA6 GF30 food safe?

PA6 GF30 is not inherently food safe. Its suitability for food contact depends entirely on the specific formulation and its compliance with relevant food safety regulations, such as those from the FDA in the U.S. or the European Union.

Can PA6 GF30 Be Recycled?

Yes, PA6 GF30 is technically recyclable, but several factors complicate the recycling process. The primary challenges include glass fiber length reduction during reprocessing (which affects mechanical properties), potential contamination in recycling streams, and the complex separation of glass fibers from the polymer matrix. While mechanical recycling is possible, the recycled material typically shows reduced performance compared to virgin material and is often downcycled into less demanding applications.

What Material Is PA6 GF30 Similar To?

PA6 GF30 is most similar to PA66 GF30, with both materials offering comparable mechanical properties and applications. It also shares similarities with PBT GF30 (polybutylene terephthalate with 30% glass fiber), particularly in terms of stiffness and dimensional stability. For metal replacement applications, PA6 GF30 can sometimes substitute for aluminum alloys in non-structural components, offering weight reduction while maintaining adequate mechanical performance.

What Makes Certain Brands of PA6 GF30 Special?

Major manufacturers differentiate their PA6 GF30 offerings through proprietary formulations and processing technologies. For example, BASF’s Ultramid® B3WG6 features optimized fiber-matrix adhesion for enhanced mechanical properties. DuPont’s Zytel® offers specialized surface treatments for improved paintability. These brand-specific features can significantly impact performance in specific applications and should be considered during material selection.

How Is PA6 GF30 Used in Electric Vehicles?

In electric vehicles, PA6 GF30 is increasingly used for battery housing components, charging port structures, high-voltage connector housings, and thermal management systems. Its combination of mechanical strength, flame retardancy (in FR grades), electrical insulation properties, and dimensional stability makes it well-suited for EV applications. Specialized formulations with enhanced thermal stability and flame retardance are being developed specifically for the growing EV market, where safety and reliability are paramount concerns.

Conclusion

PA6 GF30 stands as a foundational high-performance material, consistently delivering an unmatched balance of strength, durability, and cost-effectiveness across a diverse range of applications. Its proven track record in demanding industries from automotive to electrical engineering makes it a trusted solution for challenging projects.

To harness the full potential of this material, a holistic understanding is paramount. Recognizing its key properties, managing processing parameters, and staying ahead of market trends are all critical steps. This guide has provided the foundational insights needed to navigate these complexities and make a truly informed material choice.

As the industry continues to evolve with new demands for sustainability and specialized performance, PA6 GF30 is perfectly positioned to remain a cornerstone of modern engineering. We are committed to staying at the forefront of these innovations, ensuring our clients have access to the latest grades and expertise.

Let us be your strategic partner in unlocking the full potential of PA6 GF30 for your next project.

Need Expert Material Selection Guidance?

Contact our technical team for personalized assistance in selecting the optimal PA6 GF30 grade for your specific application requirements.