Polyoxymethylene (POM) M25 High-Flow Abrasion-Resistant is a specialized engineering material crafted to resolve a fundamental trade-off in polymer design: achieving superior melt processability without sacrificing robust long-term mechanical performance.

This grade delivers an exceptional melt flow rate optimized for the reliable manufacturing of complex, thin-wall components that demand both precise dimensional stability and rapid cycle times. Crucially, POM M25 integrates a proprietary additive package to maintain its mechanical integrity and inherent low-friction properties, providing superior resistance against wear and abrasion essential for dynamic applications.

This technical and buyer guide provides product designers and engineers with the specific performance data, processing parameters, and targeted application insights necessary to effectively leverage POM M25 for their most demanding projects, from high-speed gears to critical automotive mechanisms.

Material Overview

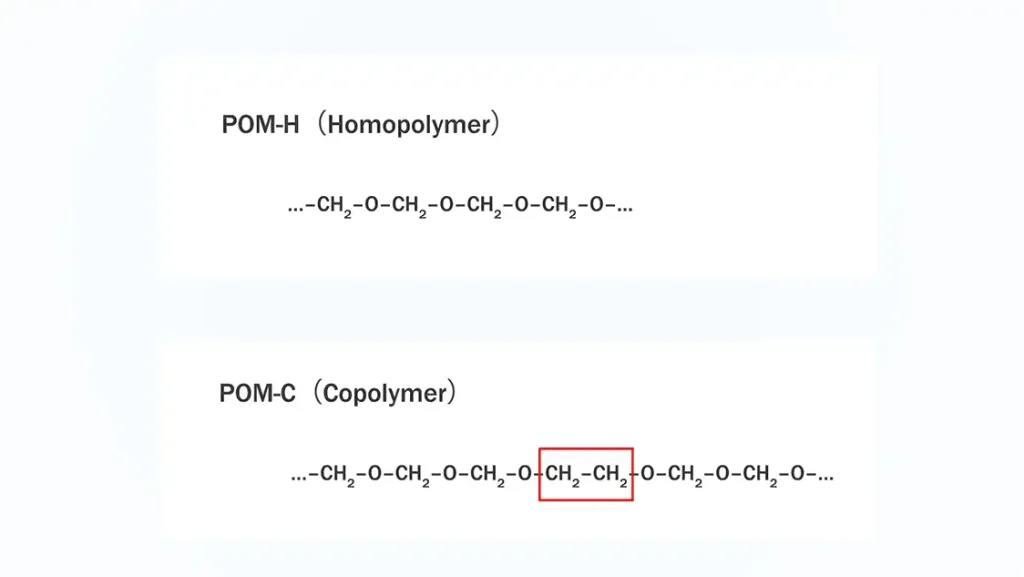

Polyoxymethylene (POM), defined by its repeating -CH₂O- backbone, is an essential engineering polymer. To specify the correct grade, engineers must first understand the structural differences that govern performance.

Chemical Structure: Homopolymer vs. Copolymer

POM is primarily categorized by two structures, each with distinct benefits:

Homopolymer (POM-H)

Characterized by high crystallinity, leading to maximized mechanical properties, hardness, and stiffness. However, POM-H can exhibit a more limited processing window and lower resistance to hot water and strong alkaline environments.

Copolymer (POM-C)

Incorporates comonomer units into the backbone, which significantly enhances thermal stability and chemical resistance, particularly against hydrolysis and strong alkalis, offering greater processability and a wider melt temperature range.

The choice balances required mechanical strength against environmental and processing demands. POM M25, designed for enhanced stability and flow, is typically based on the structural flexibility of POM-C.

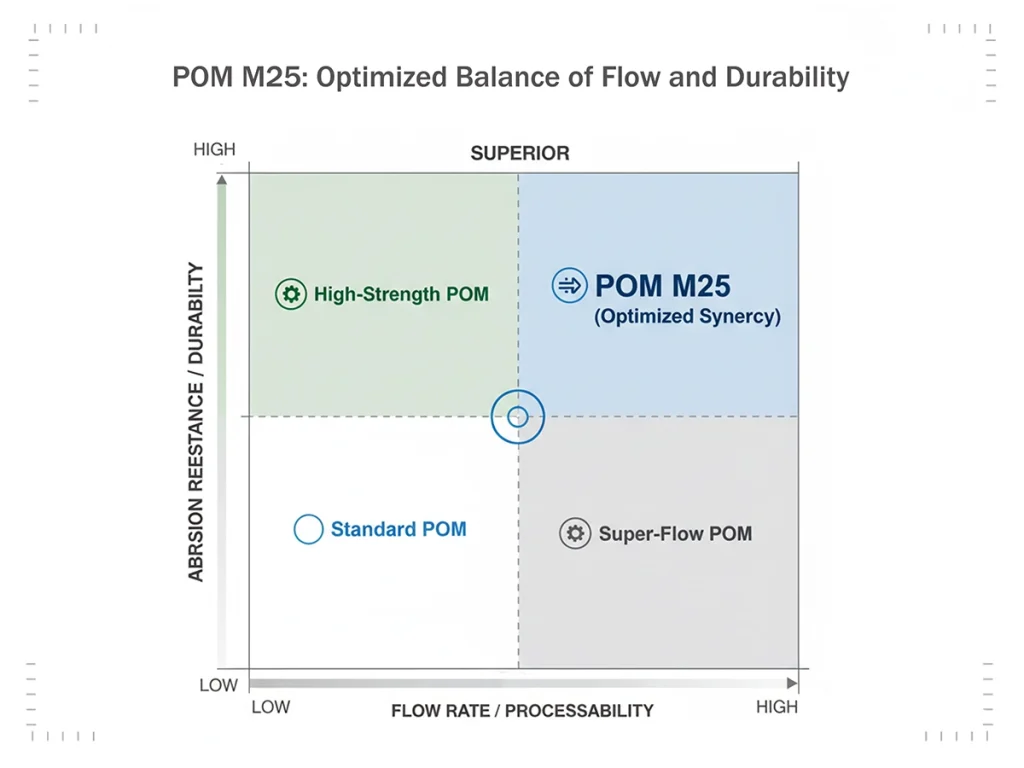

Why M25 Grade Stands Out: Optimized Flow & Tribological Synergy

The POM M25 grade is specifically engineered to transcend the limitations often associated with general-purpose POM by focusing on two critical, synergistic properties: optimized processability and enhanced abrasion resistance.

Optimized Processability for Durability

The M25 polymer’s controlled molecular structure results in a viscosity profile optimized for the injection molding of durable parts. The controlled flow rate (typically Melt Flow Rate (MFR) ≈ 2.5 g/10 min at 190℃/2.16 kg) is balanced to ensure:

- Thorough Mold Filling: Reliable filling of intricate, thin-walled, or thick sections.

- Preserved Mechanicals: The flow is controlled to preserve the high toughness and mechanical integrity essential for long-term functional components.

(Note: The ‘M25’ designation often directly correlates to the MFR of 2.5 g/10 min, signifying a specific engineering target for flow.)

Tribological Enhancement

Unlike standard variants, POM M25 integrates a specialized additive package for superior performance in dynamic contact. This formulation significantly:

- Lowers the Coefficient of Friction

- Dramatically Boosts Resistance to Wear and Abrasion

This enhancement ensures a long service life for high-contact components like precision gears, bearings, and sliding mechanisms, making it ideal for self-lubricating, dry-running applications.

Core Technical Specifications

The reliability of high-performance components relies on verified technical data. These specifications provide the quantitative baseline necessary for Finite Element Analysis (FEA), mold design validation, and processing optimization.

Physical Properties

| Property | Test Method | Duracon® M25-44 | Duracon® M25S | Celcon® M25 | Celcon® M25UV | Unit |

|---|---|---|---|---|---|---|

| Density | ISO 1183 | 1.41 | 1.41 | 1.41 | 1.41 | g/cm³ |

| Melt Flow Index (MFI) | ISO 1133 190°C/2.16kg | 2.5 | 2.5 | 2.5 | 2.2 | g/10min |

| Water Absorption (23°C/24h) | ISO 62 | 0.50% | 0.60% | 0.75% | 0.75% | % |

| Linear Mold Shrinkage (Flow) @2mm | ISO 294-4 | 2.7% | — | 2.2% | 2.2% | % |

| Linear Mold Shrinkage (Transverse) @2mm | ISO 294-4 | 2.3% | — | 1.8% | 1.8% | % |

Mechanical Properties

| Property | Test Method | Duracon® M25-44 | Duracon® M25S | Celcon® M25 | Celcon® M25UV | Unit |

|---|---|---|---|---|---|---|

| Tensile Strength | ISO 527 | 59 | 59 | 63 | 62 | MPa |

| Elongation at Break | ISO 527 | 40% | 40% | 12% | 12% | % |

| Tensile Modulus | ISO 527 | 2.50 | 2.50 | 2.46 | 2.50 | GPa |

| Rockwell Hardness (M) | ISO 2039 | 80 | 80 | — | — | — |

| Notched Charpy Impact | ISO 179/1eA | 0.80 J/cm² | 8.0 kJ/m² | 0.91 J/cm² | 0.85 J/cm² | — |

Thermal Properties

| Property | Standard | Duracon® M25-44 | Duracon® M25S | Celcon® M25 | Celcon® M25UV | Unit |

|---|---|---|---|---|---|---|

| Heat Deflection Temperature (HDT) (1.8 MPa) | ISO 75 | 90 | 90 | 94 | 93 | °C |

Wear Resistance

| Property | Standard | Duracon® M25-44 | Duracon® M25S | Celcon® M25 | Celcon® M25UV | Unit |

|---|---|---|---|---|---|---|

| Dynamic Friction Coefficient (vs Steel, 0.98MPa) | JIS K7218 | 0.40 | 0.23 | — | — | — |

| Wear Rate (vs Steel, Material Side) | JIS K7218 | 30.0 × 10⁻⁸ mm³/N·m | 0.0002 mm³/(N·km) | — | — | — |

Need Complete Technical Data?

Access our comprehensive technical documentation for detailed property information and testing methodologies.

Performance Advantages

The rigorous technical specifications of POM M25 translate directly into measurable benefits across manufacturing, component reliability, and operational lifespan. These advantages set M25-class materials apart from commodity plastics and standard POM grades.

Enhanced Processability & Dimensional Integrity

The optimized melt viscosity of POM M25 ensures consistent manufacturing and high-precision parts:

- Complex Molding: The controlled flow allows for rapid and complete filling of intricate mold cavities, mitigating weld-line weakness and incomplete parts.

- Dimensional Stability: Predictable, low mold shrinkage (approx. 2.2%–2.7%) ensures high-precision parts with minimal warpage—essential for mating components.

- Manufacturing Efficiency: Lower required injection pressures can contribute to reduced machine wear and extended tool life.

Unmatched Tribological Longevity

M25’s specialization in tribology directly addresses wear in dynamic assemblies:

- Extended Service Life: Enhanced abrasion resistance dramatically reduces material loss in sliding and rotating contacts, minimizing replacement frequency.

- Lower Frictional Energy: A low and stable coefficient of friction (≈ 0.20 vs steel) reduces heat generation and energy consumption in mechanical systems.

- Self-Lubrication: M25 provides reliable operation in many dry-running applications without external lubricants.

Inherent Material Robustness

POM M25 inherits and enhances the key structural strengths of the POM backbone:

- Creep Resistance: The material resists deformation under sustained load, maintaining tight tolerances over time, even at elevated temperatures.

- Chemical Compatibility: Excellent resistance to automotive fluids, fuels, oils, and industrial solvents.

- Low Moisture Sensitivity: Low water absorption (typically 0.50% to 0.75% over 24 hours) guarantees reliable geometry regardless of ambient humidity.

Design Limitations for Informed Selection

Engineers must account for the following limitations inherent to POM:

- UV Resistance: Standard M25 grades require a UV-stabilized variant (e.g., M25UV) or protective coating for prolonged outdoor exposure.

- Chemical Vulnerability: POM is not recommended for use with strong oxidizing agents, strong inorganic acids, or strong bases.

- Cost Position: As a specialized, high-performance grade, M25 typically commands a higher material price than general-purpose POM.

Experience POM M25 Performance Firsthand

Evaluate how POM M25 performs in your specific application environment with a material sample.

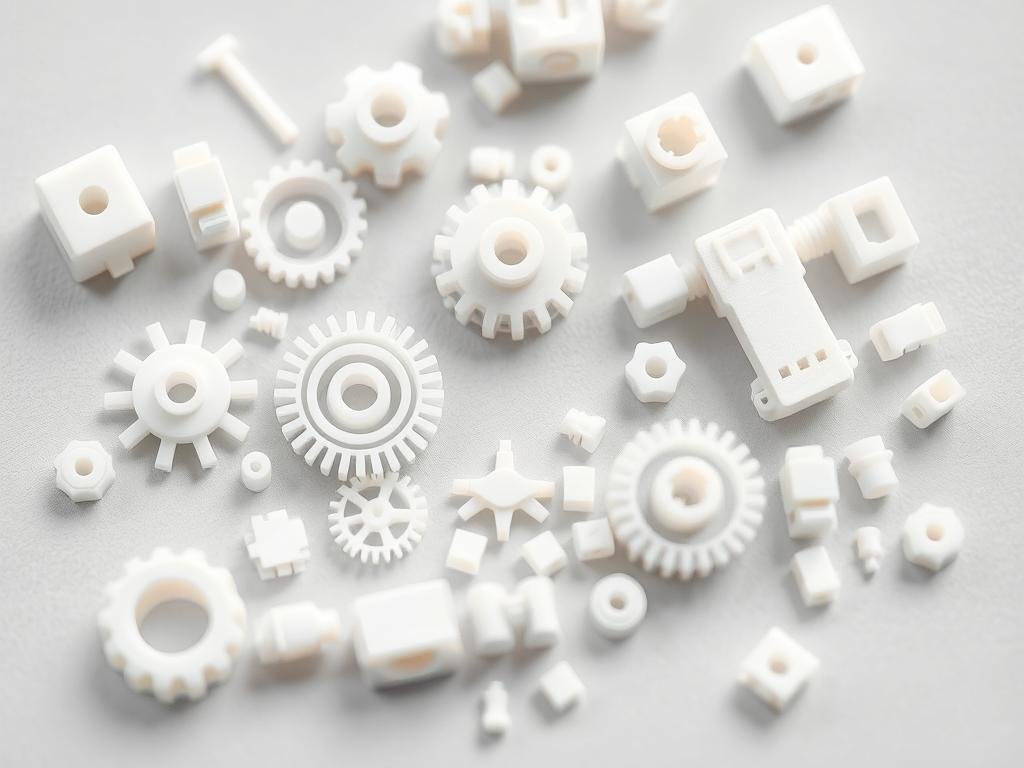

Typical Application Scenarios

The engineered synergy of high-flow processability and superior abrasion resistance makes POM M25 a reliable solution for components facing dual demands: intricate molding requirements and sustained dynamic stress.

Automotive Systems

- Gear Systems & Bushings: Window regulators, seat adjusters (low friction, quiet operation).

- Fuel System Components: Valves and fasteners (resistance to hydrocarbons).

- Precision Actuators: Door lock mechanisms (high dimensional stability).

Industrial & Mechanical Engineering

- Conveyor Components: Rollers and wear strips (resisting continuous sliding abrasion).

- Precision Gears & Cams: Automated equipment (minimizing friction loss and fatigue).

- Pumps & Valve Housings: Fluid handling (stability under pressure, chemical compatibility).

Consumer Electronics & Precision Devices

- Miniature Gears: Cameras and printers (high-flow capability for intricate, small-pitch features).

- Sliding Mechanisms: Mobile device trays (resistance to frequent surface contact).

- Precision Connectors: Utilizing M25’s dimensional stability to ensure accurate mating and consistent force.

Plumbing Systems

- Valve Bodies and Cartridges: Faucets and mixing valves (stability under pressure and resistance to chlorinated water).

- Sealing Components: Specialized fittings (low creep and maintaining a reliable, long-term seal).

Medical and Healthcare

- Drug Delivery Systems: Inhaler and insulin pen mechanisms (tight dimensional tolerances for controlled dosing).

- Surgical/Diagnostic Equipment: Components requiring excellent material consistency and minimal particle generation.

Sports & Recreation

- Binding Mechanisms: High-stress ski and snowboard equipment (withstanding repeated impact and high loads).

- Fishing Reels: Precision gear sets (utilizing low friction for smooth operation).

- Adjustable Components: Equipment requiring durability against frequent, high-cycle wear.

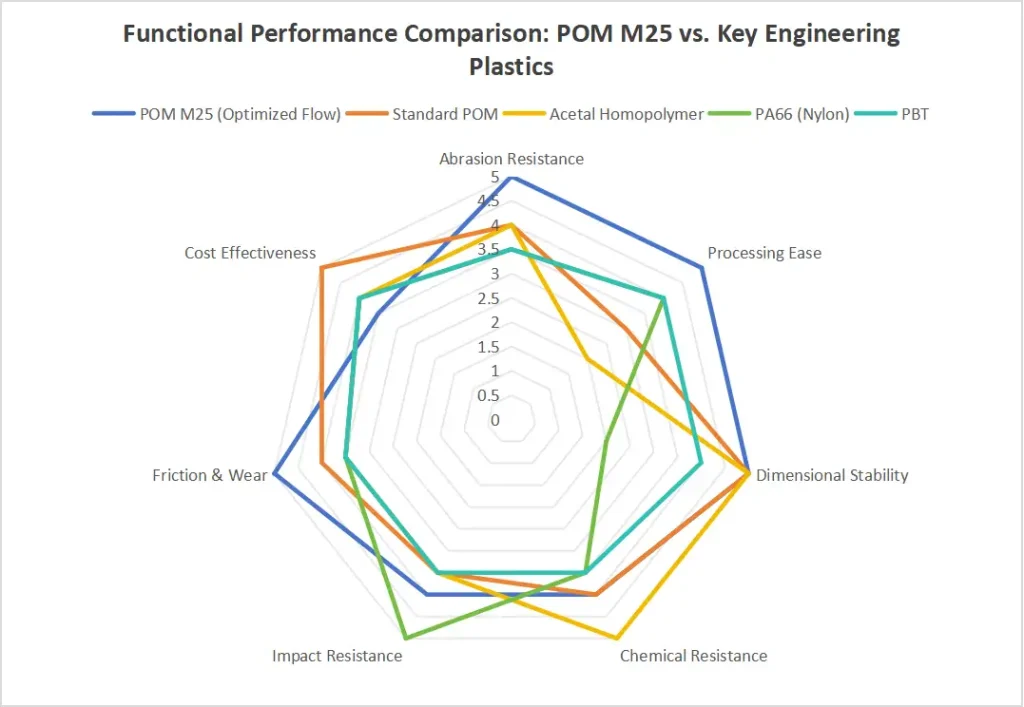

Comparison with Competitors

Accurate material comparison is fundamental to minimizing risk and optimizing performance in engineering design. The following table provides a high-level, functional comparison of POM M25 against standard POM grades and major competing engineering thermoplastics.

| Property | POM M25 (Optimized Flow) | Standard POM | Acetal Homopolymer | PA66 (Nylon) | PBT (Polybutylene Terephthalate) |

| Abrasion Resistance | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ |

| Processing Ease | ★★★★★ | ★★★☆☆ | ★★☆☆☆ | ★★★★☆ | ★★★★☆ |

| Dimensional Stability | ★★★★★ | ★★★★★ | ★★★★★ | ★★☆☆☆ | ★★★★☆ |

| Chemical Resistance | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | ★★★☆☆ |

| Impact Resistance | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★★★ | ★★★☆☆ |

| Friction & Wear | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ |

| Cost Effectiveness | ★★★☆☆ | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★★☆ |

M25 achieves a rare five-star rating in both Processing Ease and Abrasion Resistance, a combination standard POM often cannot deliver simultaneously. Furthermore, M25 matches the superior Dimensional Stability of high-crystallinity acetals, significantly exceeding the performance of hygroscopic polymers like PA66 in precision assemblies.

– Engineering Insights: M25’s Strategic Advantage

Processing Guidelines

Achieving maximum mechanical and dimensional performance from POM M25 requires adherence to specific protocols, capitalizing on its optimized flow characteristics while preventing thermal degradation.

Pre-Processing Requirements and Handling

While POM exhibits low hygroscopicity, drying is essential to ensure maximum part integrity:

- Drying Temperature/Time: 80 ℃ for 3–4 hours, or 100℃ for 2 hours.

- Target Moisture Content: <0.1% (Optimal performance <0.05%).

- Contamination Warning: Crucially, avoid contact with Polyvinyl Chloride (PVC). Trace PVC at POM’s processing temperatures can cause rapid, corrosive mold degradation and gas release.

Injection Molding Parameters

The parameters below are tailored to utilize M25’s high-flow characteristics while optimizing part crystallinity and stability.

| Parameter | Recommended Range | Optimal Value | Notes |

| Melt Temperature | 190℃ – 210℃ | 200℃ | Use the lower range to maximize stability; avoid exceeding $220^\circ\text{C}$. |

| Mold Temperature | 80℃- 100℃ | 90℃ | Higher temperature promotes optimal crystallinity and better dimensional stability. |

| Injection Pressure | 80 – 120 MPa | 100 MPa | Pressure is dependent on geometry; M25’s flow allows for reduced pressure. |

| Holding Pressure | 70% – 90% of injection | 80% of injection | Critical for controlling part shrinkage and preventing sink marks. |

| Injection Speed | Medium to High | High | High speeds fill intricate molds quickly, leveraging the high flow. |

| Back Pressure | 5 – 10 MPa | 7 MPa | Use low back pressure to minimize material shear and degradation risk. |

Mold Design Considerations

- Venting: Vent depth should be precise (0.02 – 0.03 mm) to prevent gas entrapment and surface burn marks, particularly with high-speed injection.

- Wall Thickness: Maintain uniform walls (1.5 – 3.0 mm) where possible. M25’s flow capability supports minimum thicknesses down to 0.8 mm for complex features.

- Assembly: M25 is compatible with snap-fits and ultrasonic welding but generally performs poorly with conventional adhesive bonding.

Purchase Considerations

Sourcing POM M25 High-Flow Abrasion-Resistant material is a strategic decision that requires assessing the total value proposition—not just the unit price. Engineers and purchasing teams must evaluate both the material quality and the supplier’s capability to ensure project success.

Supplier Capability and Verification

The supplier must demonstrate a commitment to quality and technical partnership.

- Quality System: Verify ISO 9001 certification and relevant industry-specific standards (e.g., IATF 16949).

- Technical Partnership: Ensure access to application engineers for design guidance and troubleshooting.

- Material Verification: Always request a Certificate of Analysis (CoA) for each batch. Review material traceability documentation to ensure lot-to-lot consistency.

Cost-Performance Analysis

Evaluate the material cost against the financial benefits derived from M25’s specialized properties:

- Manufacturing Efficiency: Factor in savings from reduced cycle times (due to high flow) and lower tooling stress.

- Component Longevity: Calculate savings from extended lifespan and reduced maintenance frequency resulting from superior abrasion resistance.

Regulatory and Compliance Due Diligence

Compliance verification is non-negotiable, particularly for components in regulated industries.

- Key Regulations: Confirm compliance with international standards such as EU RoHS and REACH.

- Industry Standards: Verify required flammability ratings (UL 94) and specific standards like ISO 10993 (for medical use) or FDA clearance.

- Documentation: Ensure all required documentation and safety data sheets (SDS) are provided.

Storage and Handling Recommendations

Proper material handling protects the investment and ensures processing reliability.

- Storage Environment: Store in a cool, dry environment, away from direct sunlight (below 40℃).

- Packaging: Keep material in its sealed, original packaging until use to prevent contamination.

- Inventory Control: Implement a First-In, First-Out (FIFO) system to maintain optimal quality.

Conclusion

POM M25 High-Flow Abrasion-Resistant POM offers a compelling solution for demanding engineering applications. The material’s strategic value lies in three core areas:

- Manufacturing Efficiency: Optimized melt flow enables the reliable production of high-precision, intricate components, supporting efficient cycle times and reduced tooling stress.

- Component Longevity: Superior tribological properties ensure extended service life and reliable low-friction operation in critical dynamic mechanisms.

- Total Value: Its dimensional stability and durability ultimately translate into a lower Total Cost of Ownership (TCO) compared to standard polymers or metal alternatives.

This guide provides the necessary technical confidence and data to integrate POM M25 into your most demanding projects. We are ready to move beyond specification to implementation.

Ready to Optimize Your Material Selection?

Our technical team is available to help you evaluate POM M25 for your specific application requirements.