The drive for lighter, smaller, and more integrated components requires polymers capable of filling increasingly intricate mold cavities. Meeting this demand, M270-44 (POM) is specifically engineered as a high-flow specialty grade of Polyoxymethylene. Its core value proposition lies in its exceptionally optimized melt characteristics, which significantly reduce melt viscosity and injection pressures compared to standard POM grades. This superior flow ability makes M270-44 the material of choice for the reliable, large-scale production of high-precision parts, especially those featuring challenging ultra-thin wall sections and complex geometries.

Design engineers are leveraging M270-44’s unique balance of flow and mechanical integrity across critical applications, including micro-electronic components, precision gearing systems, intricate functional connectors, and delicate medical devices. The following sections will delve into how this grade transforms design possibilities and manufacturing efficiency.

Material Properties and Performance

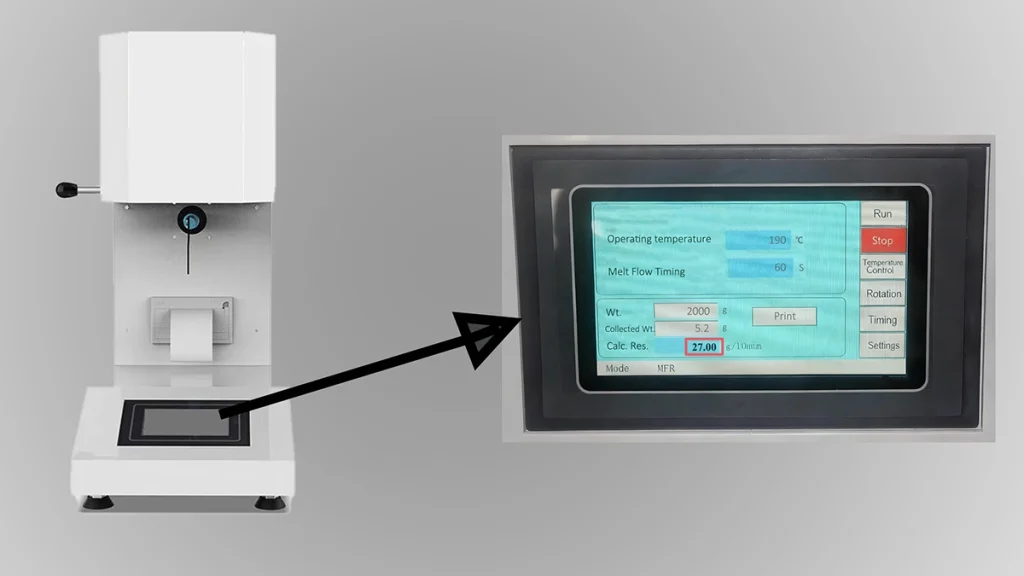

The high-performance molding capability of M270-44 is rooted in its unique material formulation. This material is defined as a low-viscosity copolymer polyacetal grade (often categorized as Super Flow POM) with a melt index (MI) of 27 g/10min (tested at 190℃}, 2.16kg per ISO 1133). To achieve this, M270-44 incorporates specialized internal lubricants and release agents that effectively lower the melt’s intrinsic viscosity without significant degradation to the base polymer’s strength. This ensures that while offering superior processability, the material maintains the high toughness and dimensional stability essential for demanding engineering applications.

Key Physical and Mechanical Properties

The following table confirms the robust mechanical integrity M270-44 maintains, setting it apart from other generic high-flow materials:

| Property | Test Standard | Value | Unit |

| Density | ISO 1183 | 1.41 | g/cm³ |

| Melt Index (190°C, 2.16kg) | ISO 1133 | 27 | g/10min |

| Tensile Modulus | ISO 527 | 2800 | MPa |

| Tensile Strength | ISO 527 | 63 | MPa |

| Flexural Modulus | ISO 178 | 2550 | MPa |

| Elongation at Break | ISO 527 | 30 | % |

| Heat Deflection Temperature (1.8MPa) | ISO 75 | 100 | °C |

Key Physico-Chemical Properties Analysis

The M270-44 grade excels by combining high flowability with the established performance of POM.

- Exceptional Flowability (High MFR): Core advantage. Ensures rapid filling of thin-wall and complex multi-cavity molds, effectively resolving short shots.

- Mechanical Integrity: Maintains high strength and rigidity (high flexural modulus), ensuring reliable performance in miniature precision components.

- Dimensional Stability: Low shrinkage and high creep resistance guarantee strict dimensional tolerances, crucial for gears and connectors.

- Wear & Friction: Excellent self-lubrication provides low friction and outstanding abrasion resistance, ideal for transmission parts.

- Chemical Resistance: Good resistance to oils and solvents, suitable for automotive and diverse industrial environments.

Evaluate M270-44(POM) for Your Application

Experience the exceptional flow properties firsthand with a material sample for testing in your specific application.

Advantages of Precision Molding

The highly specialized formulation of M270-44 (POM) directly translates its material properties into profound operational advantages. These benefits address critical bottlenecks in high-precision molding, ensuring improved part quality, expanded design freedom, and optimized throughput.

Superior Cavity Fill and Detail Replication

M270-44’s ultra-low viscosity allows it to effortlessly fill extremely thin sections (as low as 0.5mm and below) and complex geometric features. This remarkable flow performance significantly reduces the incidence of common defects such as short shots and incomplete fills, ensuring near-perfect replication of intricate mold details, even in parts with a high length-to-wall thickness ratio.

Stress Mitigation and Dimensional Stability

The need for lower melt viscosity fundamentally allows processing at reduced injection pressures. This action minimizes the input of shear heat and mechanical stress on the polymer melt. The result is a reduction in residual internal stress within the molded part, which is key to achieving and maintaining superior long-term dimensional stability and minimizing the risk of post-molding warping.

perational Efficiency and Equipment Longevity

Optimized Tooling and Equipment Life

Operating at consistently lower injection pressures places less mechanical strain on both the molding machine and the tooling. This reduction in load directly translates to decreased mold wear, potentially extending equipment longevity, and reducing the overall maintenance required for the injection molding system.

Accelerated Cycle Times

Versatility for Complex Systems

M270-44 is the optimal solution for complex production setups. Its consistent, high-flow behavior makes it uniquely suitable for applications utilizing high-cavitation molds and sophisticated hot runner systems, ensuring uniform filling and balanced pressure distribution across all cavities.

Optimize Your Manufacturing Process

Our technical specialists can analyze your current injection molding process and identify opportunities for improvement using M270-44(POM).

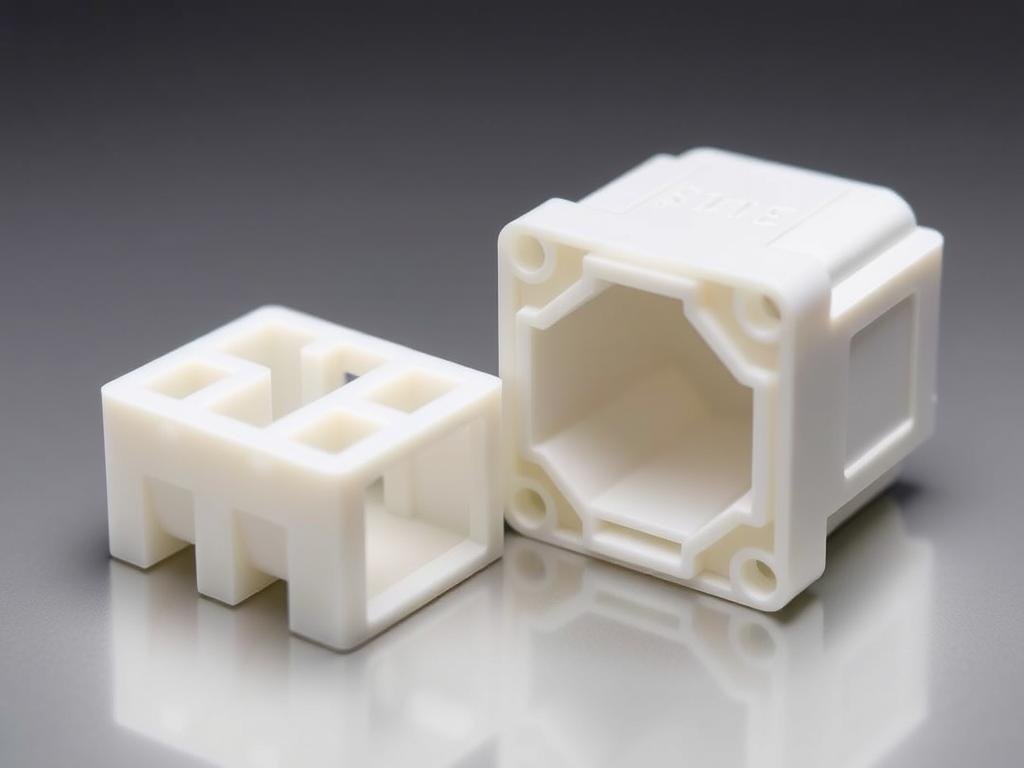

Typical Applications

The unique balance of ultra-high flow and robust mechanical integrity makes M270-44 (POM) a key material enabler for achieving precise dimensions and complex geometries in challenging operational environments. This specialized grade is instrumental in realizing next-generation designs that were previously constrained by the limitations of standard engineering plastics.

Automotive Components

M270-44 addresses the automotive sector’s need for durable, high-precision components that operate reliably under varying thermal and mechanical stress. The grade is specifically utilized where design freedom is critical for system miniaturization:

- Thin-Walled Fuel System Components: Facilitating complex internal channels and fine features required for optimized fluid dynamics.

- Precision Gears and Actuator Systems: Enabling intricate tooth profiles and low-friction sliding mechanisms for reduced wear and precise control.

- Electrical and Sensor Connector Housings: Producing components with fine, deep-drawn snap-fit features while ensuring dimensional stability under thermal cycling.

- Window and Door System Mechanisms: Utilizing the material’s inherent lubricity and low creep for reliable, long-term performance.

Electronics and Electrical Components

In the electronics industry, M270-44 is valued for its ability to produce highly miniaturized, thin-walled parts that demand extreme dimensional fidelity and consistent electrical properties:

- Miniaturized Connector and Switch Housings: Achieving complex internal geometries and ultra-thin walls essential for high-density, small-form-factor devices.

- Precision Components for Office and Printing Equipment: Molding small, intricate parts (such as paper feed mechanisms) that require consistent actuation forces and minimal friction.

- Structural Components in Telecommunications: Used in housings and components where high stiffness and dimensional control over wide temperature ranges are necessary.

Medical and Consumer Applications

M270-44’s non-toxicity, stability, and precision make it an ideal choice for sensitive and high-cycle applications across medical and consumer markets.

Medical Devices

- Precision Components for Drug Delivery Systems: Manufacturing intricate metering and mechanical components with tight tolerances.

- Precision Components for Drug Delivery Systems: Manufacturing intricate metering and mechanical components with tight tolerances.

- Intricate Mechanical Components in Surgical Instruments: Utilizing the material’s strength and low friction for smooth, reliable operation.

Consumer Products

- Complex Gearing in Timepieces and Actuators: Achieving the fine tooth profiles required for high-accuracy and high-cycle performance.

- Thin-Walled Components in Writing Instruments and Lifestyle Products: Allowing for sophisticated designs that prioritize aesthetics and reduced weight.

- Precision Components in Sporting Equipment: Where complex, thin-walled structural parts require toughness and dimensional repeatability.

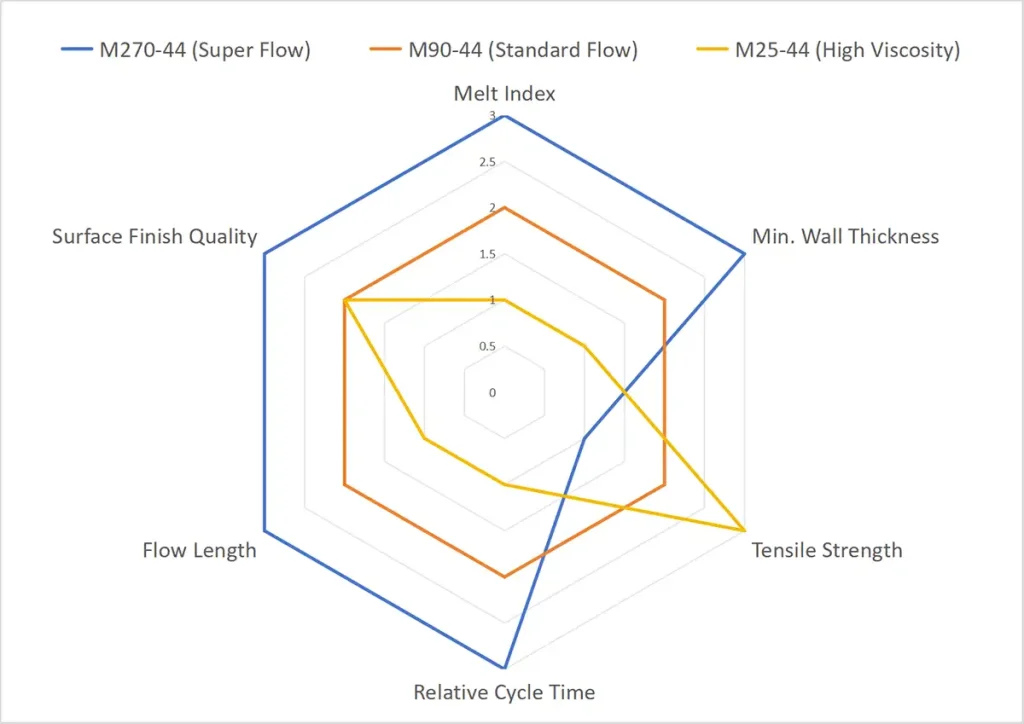

Comparison with Other Grades

M270-44 represents a highly specific, low-viscosity choice within the polyacetal family. To demonstrate its unique positioning, the following comparison highlights the strategic trade-offs in processing efficiency versus mechanical performance across key POM grades.

Comparison with Standard POM Grades

The data below illustrates how M270-44’s formulation prioritizes melt flow for complex geometry filling and rapid cycle times, while carefully minimizing the impact on core mechanical strength:

| Property | M270-44 (Super Flow) | M90-44 (Standard Flow) | M25-44 (High Viscosity) |

| Melt Index (g/10min) | 27 (Highest Flow) | 9 | 2.5 (Lowest Flow) |

| Minimum Wall Thickness (mm) | 0.5 (Thin-Wall Capability) | 0.8 | 1.2 |

| Tensile Strength (MPa) | 63 | 65 | 67 |

| Flexural Modulus (MPa) | 2550 | 2600 | 650 |

| Relative Cycle Time | 1.0(Baseline) | 1.2 | 1.4 |

| Flow Length in Thin Sections | Excellent | Good | Limited |

| Surface Finish Quality | Excellent | Good | Good |

Advantages Over Alternative Engineering Plastics

M270-44(POM) Advantages

M270-44 offers distinct advantages over alternative engineering plastics such as PC, PA, and PBT:

- Superior flow in thin sections.

- Better dimensional stability than PA and ABS.

- Higher stiffness and strength than commodity plastics (PP/PE).

- Excellent fatigue resistance.

- Superior chemical resistance (vs. ABS/PC).

- Better wear resistance and lower friction.

- Maintains mechanical properties across a wide thermal range.

Considerations

Users should be aware of the following technical considerations to ensure optimal results with this specialized grade:

- Requires proper drying before processing.

- More sensitive to precise processing conditions.

- Higher material cost compared to commodity plastics.

- Limited UV resistance without specific additives.

- Not suitable for continuous use above 100°C

- Slightly reduced strength/modulus versus high-viscosity POM.

In summary, M270-44’s value proposition is clear: the marginal trade-off in ultimate mechanical strength is far outweighed by the significant, enabling advantages in processability and thin-wall capability. This makes it the definitive choice when design complexity and production efficiency are the primary engineering drivers.

Summary and Outlook

M270-44 (POM) stands as a strategic solution within the injection molding landscape. It successfully resolves the traditional dichotomy between processability and mechanical integrity, enabling manufacturers to achieve previously challenging designs while fully maintaining the robust performance profile of polyoxymethylene materials. By delivering ultra-high flow without a significant sacrifice in strength, this specialized grade is a critical enabler for advancing miniaturization, complexity, and weight reduction across key industries.

Key Takeaways

As detailed throughout this analysis, M270-44 provides measurable advantages:

- Thin-Wall Feasibility: Enables reliable wall thicknesses down to 0.5mm while ensuring structural integrity.

- Precision and Detail: Facilitates the production of complex geometries with excellent surface finish and reduced cosmetic defects.

- Operational Efficiency: Delivers significant production improvements via reduced cycle times and lower energy and material consumption.

- Balanced Performance: Retains the fundamental mechanical, wear, and chemical resistance properties that define POM as a preferred engineering plastic.

Future Developments

The evolution of design complexity demands materials that can adapt to future manufacturing techniques. M270-44 is strategically positioned to support emerging industry trends:

Multi-Material Integration

Its stable processing window supports advanced co-molding and overmolding techniques to create complex functional assemblies.

Micro-Molding Applications

The exceptional flow properties are critical for increasingly miniaturized components required in diagnostics and advanced electronics.

Sustainable Processing

The reduced injection pressure and faster cycle times directly contribute to lower energy consumption, supporting industry sustainability targets.

M270-44 (POM) is more than just a material; it is a tool for design freedom. To explore how this specialized grade can revolutionize your most complex injection molding challenges, we invite you to engage directly with our technical application specialists.

Ready to Optimize Your Injection Molding Process?

Contact our technical team to discuss how M270-44(POM) can help you achieve your design and manufacturing objectives.