Polyoxymethylene with 25% Glass Bead reinforcement (POM GB-25) represents a critical niche in engineering thermoplastics. By bridging the gap between the ductility of standard Acetal and the rigidity of glass fiber-reinforced grades, this technical compound offers a solution for precision components requiring high dimensional stability and isotropic mechanical properties.

For engineers and procurement specialists, understanding the nuances of POM GB-25—specifically its spherical reinforcement technology—is essential for specifying the correct material for high-tolerance applications.

Core Definitions and Ingredients

This guide establishes a precise understanding of POM GB-25, primarily distinguishing it from standard unfilled POM and the more common Glass Fiber (GF) reinforced grades.

The Material Composition

At its foundation, POM GB-25 is a technical compound defined by two core components:

Matrix (Base Resin)

Matrix (Base Resin): Polyoxymethylene (POM)—typically a POM Copolymer due to its superior processing stability.

Reinforcement

Reinforcement: 25% Glass Beads (spherical glass microspheres).

The Critical Difference: Geometry and Isotropy

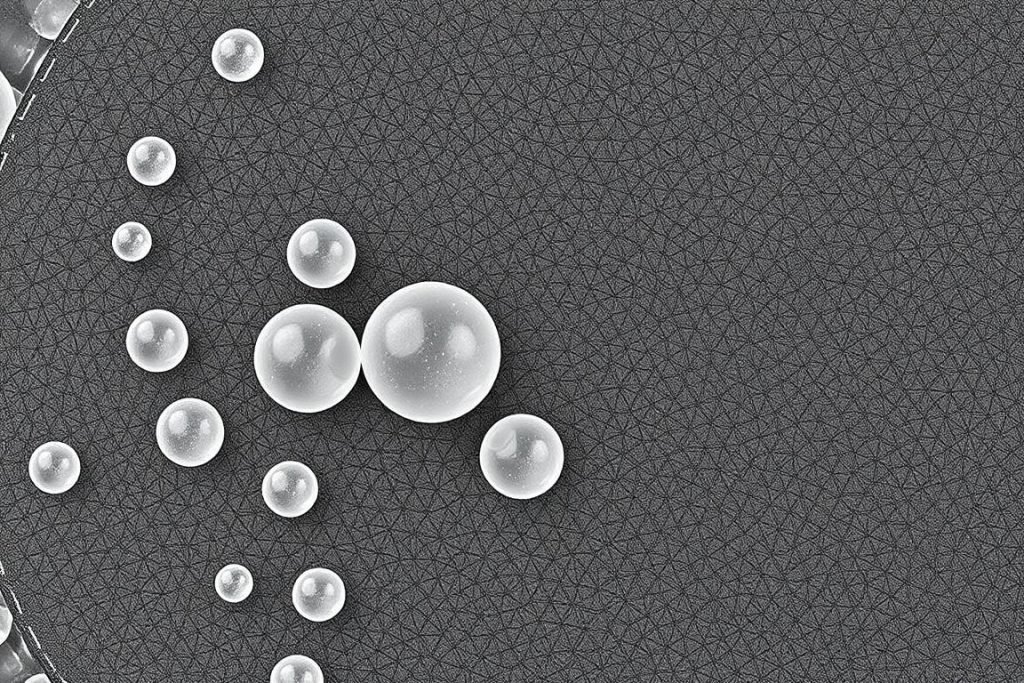

The compound’s unique performance profile is rooted in the filler’s spherical morphology. Unlike Glass Fiber (GF), which uses long, directional strands, the reinforcement in POM GB-25 consists of spherical microspheres.

This spherical shape inherently promotes superior isotropic performance in the finished part:

- Isotropy: Material properties are nearly uniform regardless of the direction of measurement (X, Y, or Z axis).

- Result: Drastically minimized internal stresses and differential shrinkage during the molding process.

Consequently, the primary value proposition of POM GB-25 is its significantly lower warpage and enhanced dimensional stability—a non-negotiable factor for high-precision components.

| Comparison Point | POM GB-25 (Glass Beads) | POM-GF (Glass Fiber) |

| Filler Shape | Spherical | Strand-like, Directional |

| Material Property | Highly Isotropic | Highly Anisotropic |

| Primary Benefit | Low Warpage / Stability | High Stiffness / Strength |

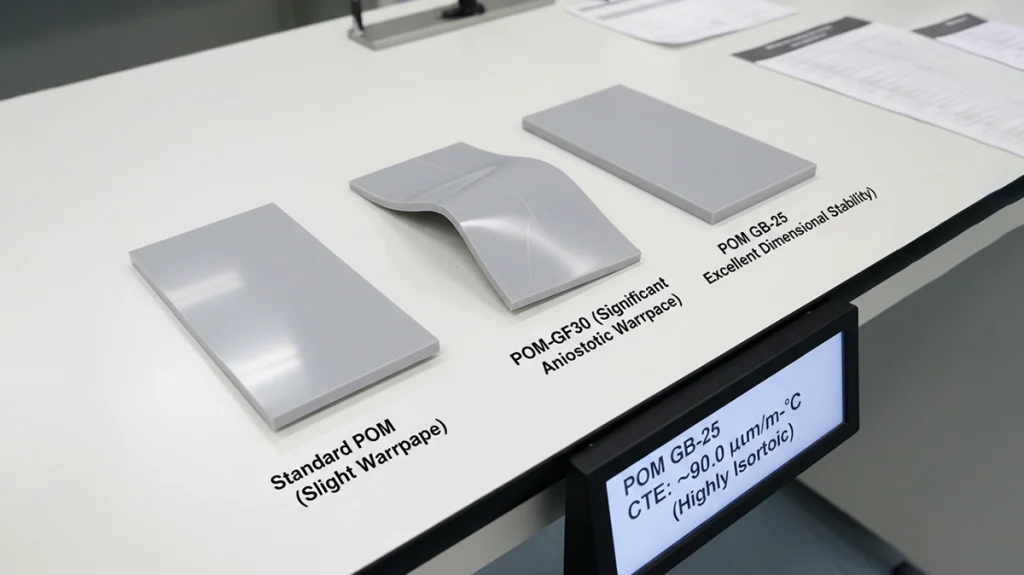

This contrasts sharply with Glass Fiber (POM-GF) reinforced compounds. While GF boosts tensile strength and stiffness, the fiber alignment inevitably leads to high anisotropy, resulting in considerable mold shrinkage differences and higher warpage. Therefore, POM GB-25 is the specialist material when dimensional stability is paramount.

Performance Characteristics

When engineers evaluate materials, the decision hinges on a clear understanding of the trade-offs between mechanical, thermal, and surface properties. POM GB-25 is not designed for ultimate strength; rather, it is positioned as the specialist for applications demanding dimensional integrity and isotropic behavior.

Core advantages

The unique spherical morphology of the glass beads translates directly into the following critical benefits for precision components:

- Exceptional Low Warpage: The non-directional reinforcement ensures shrinkage after molding is uniform (isotropic), significantly minimizing product deformation and supporting reliable part design simulation.

- Superior Dimensional Stability: The rigid internal support from the 25% glass beads, combined with POM’s low water absorption, guarantees stability across varying environmental and temperature conditions.

- Favorable Abrasion Resistance and Surface Finish: The smooth surface of the glass microspheres complements the self-lubricating properties of the base POM polymer, providing good abrasion resistance and a surface finish superior to fibrous compounds (minimal fiber protrusion).

Mechanical properties

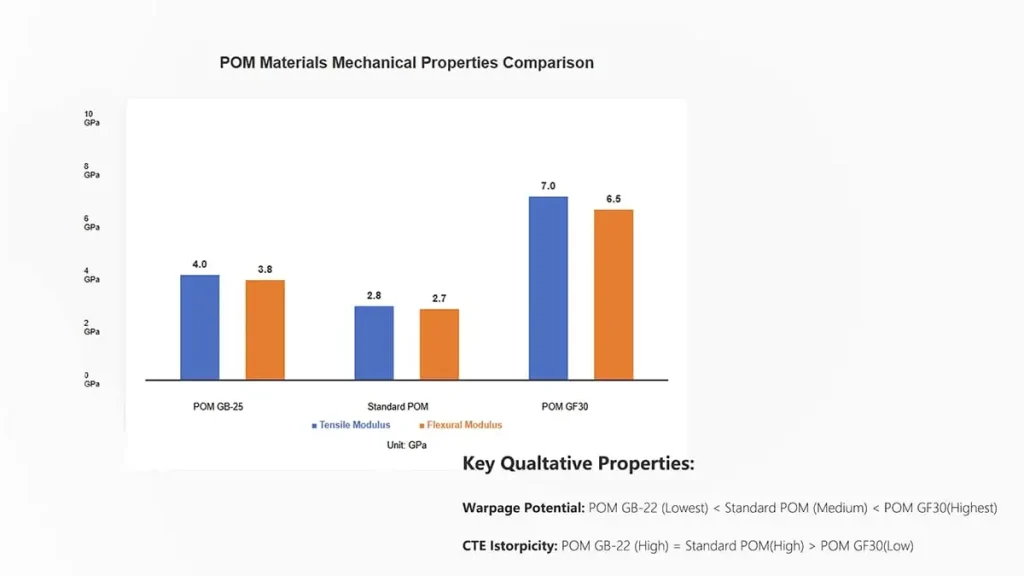

While POM GB-25 compromises ultimate tensile strength compared to high-fill POM GF, it provides a robust structural foundation. Using a benchmark grade (e.g., Polyplastics DURACON® GB-25) to illustrate its profile:

Material Positioning: Stiffness vs. Stability

While POM GB-25 compromises ultimate tensile strength compared to high-fill POM GF, it provides a robust structural foundation. Using a benchmark grade (e.g., Polyplastics DURACON® GB-25) to illustrate its profile:

| Property | POM GB-25 | Standard POM | POM GF30 | Unit |

| Tensile Modulus (Stiffness) | 4.00 | 2.8 | ~ 7.0 | GPa |

| Flexural Modulus | 3.80 | 2.7 | ~ 6.5 | GPa |

| Warpage Potential | Lowest | Medium | Highest | – |

| CTE Isotropicity | High | High | Low | – |

- Evidence of Isotropic Control: A key technical confirmation is the Coefficient of Thermal Expansion (CTE). Critical data demonstrates the CTE is uniform both parallel and transverse to the flow (e.g., 90.0 μm/m-℃), confirming the material’s true non-directional stability.

- Creep Resistance: The rigid network significantly enhances resistance to deformation under sustained load over time.

The material is optimized for stability over ultimate toughness. Its Notched Charpy Impact strength is typically lower than that of pure POM (e.g.,≈ 0.360 J/c㎡), which must be factored into dynamic load bearing designs.

Need Detailed Technical Data?

Request our comprehensive technical datasheet for POM GB-25 with complete property profiles and comparative analysis against other engineering materials.

Application Scenarios

POM GB-25’s unique combination of properties—isotropic dimensional stability, controlled mechanical strength, and favorable surface characteristics—makes it a specialized solution across various industries. The material is strategically deployed in components where standard unfilled POM exhibits unacceptable warpage, or where glass fiber reinforced grades (POM GF) introduce surface finish defects or noise issues.

Automotive Applications

POM GB-25 is a critical material in automotive systems, valued for its stability under fluctuating temperatures and resistance to automotive fluids. Its isotropic nature is essential for maintaining tight tolerances in assemblies.

- Drivetrain & Pumps: Impellers and housings where uniform thermal expansion is required to maintain seal integrity.

- Interior Mechanisms: Window regulators and door latch components. The material reduces the “stick-slip” noise often generated by rougher fiber-filled materials.

- Fuel Systems: Structural flanges that require resistance to hydrocarbons while maintaining flatness to prevent leakage.

Consumer Electronics

The material provides the necessary dimensional stability and electrical insulation for complex electronic mechanisms where components must maintain precise geometry over long service cycles.

- Camera lens mechanisms and focusing housings.

- Precision gear trains within printers, scanners, and electronic devices.

- Laptop hinge mechanisms and small electrical connector housings.

Industrial Machinery

The combination of mechanical support, wear resistance, and chemical compatibility makes it suitable for dynamic and functional parts operating under moderate stress.

- Precision gears and cams requiring low noise and good surface wear.

- Valve bodies and components in fluid systems (suitable for non-aggressive chemicals).

- Wear pads and conveyor system components that benefit from smooth surfaces.

Medical Devices

Medical-grade versions of POM GB-25 are utilized in specialized applications demanding high dimensional stability and biocompatibility, often subject to sterilization requirements.

- Mechanisms in drug delivery devices.

- Surgical instrument components requiring long-term reliability.

- Diagnostic equipment components where tolerance stacking is critical.

Comparative Application Advantages

The table below summarizes the technical advantages of POM GB-25, clearly establishing its niche relative to the two primary POM alternatives:

| Application Requirement | POM GB-25 Advantage | Vs. Standard POM | Vs. POM GF30 |

| Dimensional Stability | Excellent – Non-directional shrinkage | Superior | Comparable |

| Isotropic Properties | High uniformity across all axes | Similar | Superior |

| Surface Finish | Good – Minimal filler protrusion | Slightly Lower | Superior |

| Wear Resistance | Very Good – Maintains low friction | Superior | Comparable |

| Mechanical Strength | Moderate Stiffness | Slightly Lower | Lower |

Brands and Competitors

The global supply of POM GB-25 is concentrated among major chemical manufacturers, each with distinct formulation nuances.

Major Global Manufacturers and Grade Profiles

The primary suppliers of POM offer grades tailored to specific end-use requirements:

| Brand | Representative Grade | Key Strength | Relative Cost Positioning | Regional Focus |

| Celanese | Celcon® GB25 | Excellent processability; Industry-standard dimensional stability. | Medium | Global |

| DuPont | Delrin® 525GR | Optimized for wear resistance and enhanced thermal stability. | Premium | Global |

| BASF | Ultraform® N2320 G5 | Consistent batch quality; Optimized for high-tolerance automotive use. | Medium | Europe, Asia |

| Polyplastics | Duracon® GB-25 | Benchmark dimensional stability and low warpage control. | Medium-High | Asia-Pacific |

| Kolon Plastics | Kocetal® K300G6 | Cost-effectiveness and competitive mechanical performance. | Economy | Asia |

As a dedicated supplier of high-performance POM materials, our core expertise lies in the Polyplastics Duracon® GB-25 grade. This focus allows us to provide specialized technical support and reliable supply logistics tailored to the material’s specific characteristics, ensuring optimal performance for your low-warpage applications.

Processing and Technology

Injection molding of POM GB-25 requires specific parameter adjustments compared to standard POM, primarily to maintain the material’s dimensional stability and minimize damage to the glass bead reinforcement.

Key Parameters

The presence of 25% glass beads necessitates controlling both temperature and pressure to achieve the compound’s superior dimensional characteristics.

| Parameter | Key Recommendation | Engineering Rationale |

| Melt Temperature | 180-200°C | Standard POM range; avoid overheating to prevent degradation. |

| Mold Temperature | 90-120°C (High) | Critical for low warpage. Higher temperature promotes full and uniform crystallization. |

| Injection Speed | Slow to Moderate | Reduces shear stress and minimizes damage/breakage to the glass beads. |

| Back Pressure | ≤ 2.0 MPa (Low) | Minimizes shear heating and premature filler wear. |

Pre-Drying Note: Although moisture absorption is low, pre-drying at 180-100°C for a minimum of 3 hours is recommended to eliminate surface defects.

Mold Design and Cooling Essentials

Proper mold design must support the GB-25’s focus on non-directional stability:

Gate and Runner Design

Use full round runners and avoid sharp corners. Fan gates are preferred for wide parts as they ensure a uniform flow front, which is crucial for maintaining isotropic properties.

Cooling System

A highly uniform cooling system is essential. The high mold temperature requirement means consistent channel spacing and water flow are needed to regulate the crystallization rate and prevent differential shrinkage.

Tooling

Glass beads are abrasive. Mold components should utilize abrasion-resistant steel to ensure long tool life.

Post-Processing and Quality Control

POM GB-25 is compatible with standard assembly techniques (snap-fits, welding). Quality assurance should focus primarily on Dimensional Verification (the material’s primary selling point) and Visual Inspection for defects like surface knit lines, ensuring reliable component performance.

Processing Challenges with POM GB-25?

Our technical team can provide expert guidance on optimizing your processing parameters for POM GB-25. Get personalized recommendations for your specific application and equipment.

Conclusion

POM GB-25 is not a generic replacement for standard acetal; it is a specialized instrument for precision engineering. It resolves the conflict between structural rigidity and warpage that plagues many plastic component designs.

Summary of Value:

- Precision: Isotropic shrinkage allows for predictable tolerances.

- Surface: Superior finish compared to glass fiber grades.

- Stability: Rigid performance under thermal and mechanical stress.

Next Steps for Engineering Teams: If your current design is experiencing warpage with standard POM, or if you are over-engineering with expensive high-performance polymers to hold tolerance, POM GB-25 (specifically high-consistency grades like Duracon®) may be the optimal value engineering solution.

Need Technical Assistance with POM GB-25?

Our materials engineers can help you determine if POM GB-25 is right for your application. Get personalized technical consultation and material recommendations.