25% Glass-Bead Reinforced Polyoxymethylene (POM GB-25) is specified when dimensional stability criteria surpass the capabilities of standard unfilled or glass-fiber-reinforced grades. This compound delivers near-isotropic shrinkage (anisotropy typically <0.2% MD/TD), ultra-low warpage, and a superior, non-fibrous surface finish. Key applications include precision gears, camera lens barrels, and actuation components.For a detailed understanding of the material's core properties, applications, brands, and supply chain, please consult our main guide: POM GB-25: From Properties to Supply – Comprehensive Technical Guide .

Market Context: Polyplastics Duracon GB-25 established itself as a global benchmark in this segment, known for its consistency and reliability. While recent market shifts highlight the need to evaluate cost-effective alternatives, material selection must prioritize performance continuity and supply security, warranting a direct comparison against the established Duracon standard.

Core Performance

- Near-Isotropic Shrinkage (<0.2%)

- Ultra-Low Warpage

- Non-Fibrous Surface Finish

- High Tensile Modulus (6000+ MPa)

Commercial Grades, Key Properties, and Comparison

The table below summarizes critical engineering properties for leading global and cost-effective commercial POM GB-25 grades. Tensile Modulus and Shrinkage Anisotropy determine fitness for high-precision use. All property values are typical; confirmation via specific data sheets remains necessary.

| Grade (Manufacturer) | Tensile Modulus (MPa) | MVR (190°C/2.16kg) (cm³/10min) | Relative Price Level |

|---|---|---|---|

| Duracon GB-25 (Polyplastics) | 6000 | 5 | High(Benchmark) |

| Celcon GB25 (Celanese) | 6000 | 4.5–6 | High |

| Kepital GB-25 (KEP) | 6200 | 5 | Mid-Low |

| Hostaform C 2521 GBS (Celanese) | 5900–6100 | 5-6 | High |

| Tenac GA510 (Yunnan Yuntianhua) | 5800 | 6 | Mid-to-Low |

Observation: The striking uniformity of key physical properties across top-tier grades confirms that multiple suppliers are now meeting the stringent dimensional requirements established by the industry benchmark.

Value Proposition: Tensile Modulus vs. Cost

Performance Validation and Cost Analysis

Performance Parity Achieved

Performance gaps between traditional imported grades and advanced domestic alternatives have significantly narrowed due to market maturation and manufacturing process refinement. Top-tier alternatives, exemplified by the Yuntianhua Tenac GA510 series, consistently meet the stiffness requirement with a Tensile Modulus of 6000–6500 MPa. Crucially, their shrinkage consistency and warpage control are validated as equivalent to the imported benchmark, guaranteeing the required dimensional stability.

Economic Advantage

These high-performance alternatives offer a 20–35% lower unit cost and provide enhanced supply-chain resilience (shorter lead times, reduced dependency on specific regions). This enables significant BOM reduction without compromising core performance parameters.

Subtle Trade-offs:

Some mid-range domestic grades may exhibit minor deviations in batch-to-batch color consistency or marginal differences in long-term creep performance under extreme, non-standard loading conditions. Nevertheless, these grades remain fully viable for the majority of non-appearance-critical, general-purpose applications.

Key Applications & Compliance

Precision Gears

Required: High stiffness, low wear, and perfect tooth profile retention due to isotropic shrinkage.

Camera Lens Barrels

Required: Extreme dimensional stability to maintain optical axis alignment across temperature variations.

Actuation Components

Required: Low warpage and consistency for reliable, high-cycle movement in automotive/industrial systems.

Industry Compliance & Quality Assurance

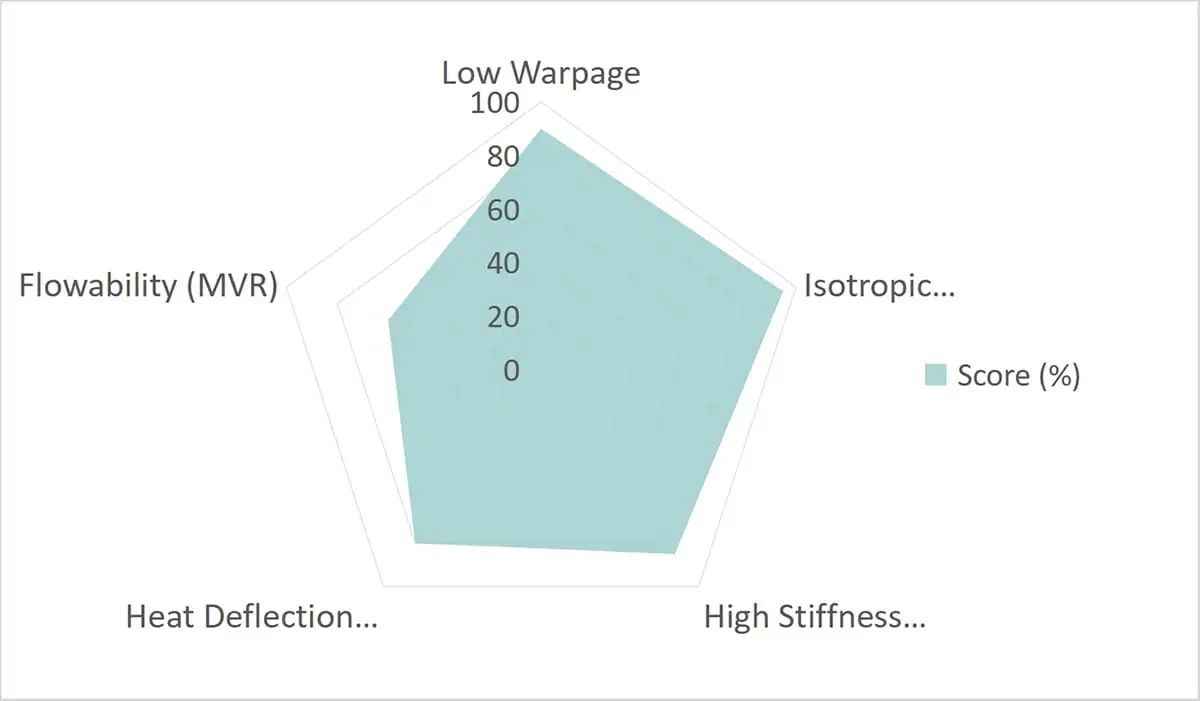

Performance Profile: Dimensional Stability

The radar chart highlights the balanced, high-performance profile of POM GB-25, excelling in dimensional criteria.

Conclusion

When selecting POM GB-25, the engineer’s goal remains achieving dimensional precision and low warpage. While validated, cost-competitive grades now match the headline mechanical properties of the best materials, Polyplastics Duracon GB-25 remains the industry's reliable standard for consistency and technical assurance. Engineers must conduct thorough validation, prioritizing Duracon GB-25 for the most demanding applications where proven, long-term reliability outweighs immediate cost reduction.