Duranex 3300 PBT is a specialized, 30% glass fiber reinforced (GF30) Polybutylene Terephthalate (PBT) engineering thermoplastic manufactured by the Polyplastics Group. This specific grade is formulated to provide a robust combination of exceptional mechanical strength, thermal stability, and superior electrical insulation characteristics. Owing to these properties, Duranex 3300 PBT is a primary material specification for structural parts in the automotive, electrical/electronic, and industrial sectors.

This technical article provides engineers, product designers, and procurement specialists with essential data and processing insights crucial for material specification.

Key Material Properties and Technical Specifications

Duranex 3300 PBT is characterized by its ability to deliver a crucial trifecta of high mechanical rigidity, thermal resistance, and excellent dimensional stability. The strategic incorporation of 30% glass fiber reinforcement significantly expands the base PBT resin’s performance envelope, fundamentally upgrading its load-bearing capacity and structural integrity under elevated temperatures.The following tables provide detailed technical specifications, derived from standardized ISO and IEC test methods, serving as the essential quantitative basis for engineering and design specification.

| Mechanical Properties | Value | Unit | Test Method |

| Tensile Strength | 140 | MPa | ISO 527 |

| Strain at Break | 2.2 | % | ISO 527 |

| Flexural Modulus (23°C) | 9030 | MPa | ISO 178 |

| Flexural Strength | 220 | MPa | ISO 178 |

| Charpy Notched Impact (23°C) | 10.5 | kJ/m² | ISO 179/1eA |

| Rockwell Hardness | M 100 | – | ISO 2039-2 |

| Thermal Properties | Value | Unit | Test Method |

| Heat Deflection Temperature (1.80 MPa) | 213 | °C | ISO 75 |

| Linear Thermal Expansion (Parallel) | 20 | E-6/K | ISO 11359-1/-2 |

| Linear Thermal Expansion (Normal) | 90 | E-6/K | ISO 11359-1/-2 |

| Burning Behavior | HB | class | IEC 60695-11-10 |

| Electrical Properties | Value | Unit | Test Method |

| Volume Resistivity | 5×10¹⁶ | Ω.cm | IEC 60093 |

| Electric Strength | 23 | kV/mm | IEC 60243-1 |

| Comparative Tracking Index | 375 | – | IEC 60112 |

| Physical Properties | Value | Unit | Test Method |

| Density | 1530 | kg/m³ | ISO 1183 |

Need Complete Technical Specifications?

Access our comprehensive technical data sheet for detailed property information, including chemical resistance data, processing parameters, and application-specific performance metrics.

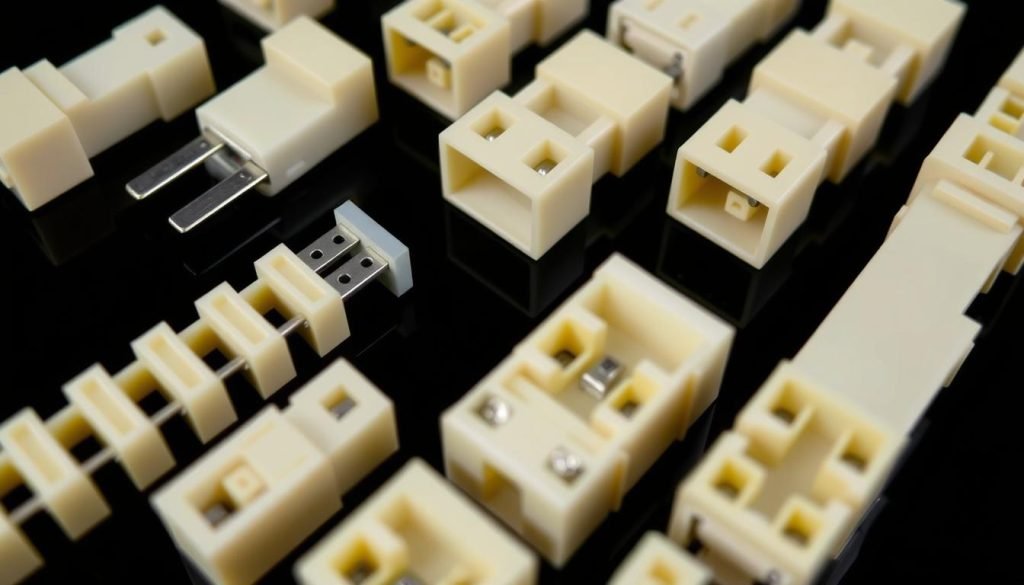

Major Application Fields

Duranex 3300 PBT is rigorously specified for structural and functional components across key industrial verticals where strength, thermal performance, and electrical integrity are non-negotiable. The material’s balanced property profile provides reliability in harsh operating environments, particularly in three major sectors:

Automotive Applications

The high Heat Deflection Temperature (HDT) and robust mechanical strength of Duranex 3300 secure its use in critical under-hood components that endure high operating temperatures. Specific applications include:

- Electrical connectors and housings

- Sensor components and modules

- Fuel system components

- Electric vehicle (EV) charging infrastructure parts

Electrical/Electronic Applications

Superior dielectric strength and high comparative tracking index (CTI) make this grade an essential insulator for high-voltage and power delivery systems. Precision is ensured by the material’s inherently low moisture absorption. Key parts include:

- Circuit breaker components and switch housings

- Terminal blocks and high-precision connectors

- Relay components and motor/transformer bobbins

Industrial Applications

In industrial settings, the material’s excellent chemical resistance allows prolonged exposure to various fluids, lubricants, and cleaning agents. Its mechanical rigidity and dimensional stability maintain critical alignment and performance over time in high-cycle components:

- Pump and valve components

- Precision gears and bearings

- Structural machine components

- Chemical processing equipment parts

This GF30 PBT variant is thus validated for precision components requiring tight dimensional tolerances across varying thermal and humid conditions. Its inherent resistance to automotive fluids and aggressive industrial substances further expands its functional lifespan in harsh service.

Exploring Duranex 3300 PBT for Your Application?

Our materials experts can help determine whether Duranex 3300 PBT meets your specific application requirements.

Processing and Injection Molding Guidelines

Achieving the full mechanical potential of Duranex 3300 PBT mandates stringent adherence to specific processing conditions. The following technical guidelines outline essential parameters for injection molding operations, ensuring optimal part performance and surface quality, though adjustments will be necessary based on specific equipment and component geometry.

Material Handling and Pre-Drying

Proper drying is non-negotiable for Duranex 3300 PBT to prevent hydrolysis, which leads to polymer degradation and a critical loss of mechanical properties during the melt phase. Moisture content must be rigorously controlled before processing.

| Material Drying | Requirement | Details |

| Drying Temperature | 120-130℃ | Maintain consistency to prevent material sticking. |

| Drying Time | 4–8 hours | Duration depends on initial moisture level. |

| Target Moisture | <0.04% | Maximum acceptable moisture content. |

| Equipment | Dehumidifying Dryer | Recommended for precise moisture control. |

Injection Molding Parameters

Controlling melt temperature and shear is crucial to ensure both good flow and preserve the integrity and dispersion of the 30% glass fibers.

| Processing Parameter | Recommended Range | Notes |

| Barrel Temperature | 240-260°C | Requires a consistent, smooth temperature profile. |

| Mold Temperature | 60-100°C | Higher temperatures enhance surface finish and crystallinity. |

| Injection Pressure | 80-120 MPa | Adjust based on cavity packing and flow resistance. |

| Injection Speed | Medium to High | Use higher speeds for rapid filling of thin sections. |

| Holding Pressure | 60-100 MPa | Typically 50-80% of the peak injection pressure. |

| Screw Speed | 40-80 rpm | Moderate speeds are necessary to minimize shear heating and fiber breakage. |

| Back Pressure | 5-10 MPa | Moderate pressure aids optimized dispersion and melt uniformity. |

Mold Design Considerations

Mold geometry must account for the high fiber content to manage shrinkage anisotropy and stress concentration.

- Gate Design: Full-round gates are preferred. Gate diameter should be 50–80% of the nominal wall thickness.

- Runner System: Full-round runners with polished surfaces minimize pressure drop and fiber misalignment.

- Venting: 0.025-0.040 mm depth is necessary to prevent air entrapment and resultant burning.

- Draft Angles: Minimum 1° per side;1.5° to 2 ° recommended for easier ejection.

- Wall Thickness: Maintain thickness uniformity (minimum 0.8 mm) to control shrinkage variation.

- Radii: Minimum 0.5 mm is essential for reducing molded-in stress concentrations.

Post-Processing Considerations

Specific post-molding steps may be required to relieve residual stresses and prepare parts for final assembly or surface finishing.

- Annealing: Optional heat treatment at 170-190℃ for 2-4 hours, used to relax molded-in stresses and stabilize dimensions for critical applications.

- Assembly: Compatible with common techniques, including ultrasonic welding, thermal welding, and mechanical fastening systems.

- Surface Treatment: Accepts industry-standard processes (metallization, painting, printing) following appropriate surface preparation.

- Machining: Conventional techniques are applicable; sharp, well-maintained tooling and sufficient cooling are advised.

Need to Validate Processing Parameters?

Request material samples to conduct processing trials and validate performance for your specific application requirements.

The Duranex 3300 Family & Derivatives

Duranex 3300 functions as the baseline 30% glass-reinforced platform within Polyplastics’ robust family of PBT engineering thermoplastics. This comprehensive portfolio offers design engineers significant flexibility, providing application-specific grades that retain the core PBT advantages while addressing highly specialized performance requirements such as heat aging, flame safety, or moisture exposure.

| Grade | Description | Key Differentiating Properties | Primary Applications |

| Duranex 3300 | Standard 30% glass fiber reinforced | Benchmark mechanical, thermal, and electrical balance | General purpose load-bearing and structural parts |

| Duranex 3300H | High heat stabilized | Superior long-term thermal aging performance | Engine compartment and under-hood components |

| Duranex 3300FR | Flame retardant | UL94 V-0 certification at 0.8 mm wall thickness | High-voltage electrical housings and safety connectors |

| Duranex 3300HR | Hydrolysis resistant | Proven stability in hot and humid service environments | Automotive cooling systems and water-contact components |

| Duranex 3300IM | Impact modified | Significantly enhanced toughness and low-temperature impact strength | Components exposed to shock loading or vibration |

| Duranex 3300LW | Low warpage | Optimized dimensional stability and reduced molded warpage | Precision assemblies requiring tight tolerance mating |

Compliance, Certifications, and Sustainability

Adherence to global regulatory requirements and maintaining certified quality systems are prerequisite factors for material specification in global supply chains. Duranex 3300 PBT and its production systems meet stringent international criteria, mitigating design risk and ensuring market access.

Regulatory & Quality Compliance

This grade is recognized for meeting critical health and safety standards, making it suitable for export and compliance-driven applications.

- Hazardous Substances: Fully compliant with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals). Halogen-free variants are also available.

- Specialty Use: FDA compliant grades are available for appropriate food contact applications.

- Safety Certification: Recognizes UL Yellow Card classification for fire and electrical safety (file number provided upon technical consultation).

Polyplastics maintains robust, globally recognized quality management frameworks: ISO 9001 (Quality), IATF 16949 (Automotive Quality), ISO 14001 (Environmental), and ISO 45001 (Occupational Health and Safety).

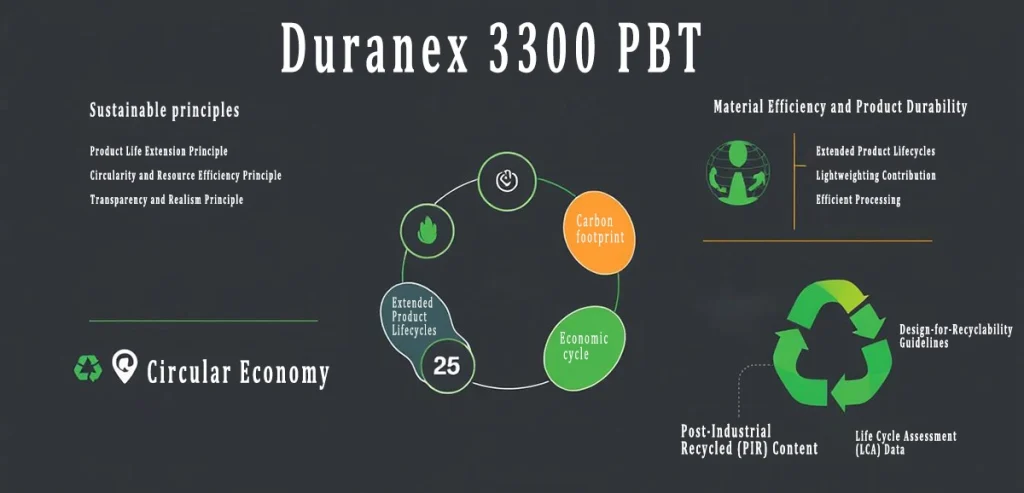

Sustainability Considerations

The Duranex 3300 PBT platform is engineered for material efficiency and longevity, but transparently managing its environmental footprint is essential.

Environmental Benefits

- Durability: The material’s inherent strength and stability extend product lifecycles, reducing replacement frequency.

- Efficiency: The lightweight nature of PBT compounds reduces mass and contributes to lower operational energy use (e.g., in automotive applications).

- Processing: Efficient processing methods often require less energy consumption than alternatives.

Circular Economy Considerations

- Options: Post-Industrial Recycled (PIR) content options are available for specific formulations, supporting responsible sourcing goals.

- Transparency: Life Cycle Assessment (LCA) data and specific design-for-recyclability guidelines are available to support detailed environmental evaluations by customers.

A key engineering reality is that the 30% glass fiber reinforcement complicates specialized industrial recycling processes. While the material is technically recyclable, current consumer recycling infrastructure is limited. Engineers must account for these end-of-life challenges when designing components. We offer technical consultation to optimize material selection and design for maximum sustainability benefits while upholding performance specifications.

Conclusion

Duranex 3300 PBT stands as a technical benchmark for its 30% glass fiber reinforced category, delivering a robust synthesis of mechanical integrity, thermal resilience, and inherent electrical insulation. Its versatility has established it as a reliable material solution for high-reliability components across the automotive, electrical/electronic, and industrial sectors, where performance must be sustained under demanding operational cycles.

Fully leveraging this material’s capabilities requires strict adherence to the defined processing parameters and strategic use of its diverse derivative grades. By managing the material’s specification across the entire Duranex family, engineers can precisely address specialized needs like hydrolysis resistance or low warpage without sacrificing the core PBT advantages.

The Duranex PBT portfolio will continue its evolution, driven by innovation focused on higher performance, enhanced sustainability options, and improved processing efficiency.

Ready to Specify Duranex 3300 PBT for Your Application?

Our technical specialists can provide detailed guidance on material selection, design optimization, and processing parameters for your specific requirements.