Polyphenylene Sulfide (PPS), a high-performance PPS polymer, maintains a position among engineering plastics with its balance of thermal stability, flame retardancy, and chemical resistance. This PPS material supports applications in automotive and electronic systems through mechanical properties and dimensional stability under environmental stress.

Bridging material data and production efficiency presents challenges for engineering teams. Grade selection involves understanding melt-processing stability and consistency across batches. This guide examines characteristics and processing variables that influence application outcomes, offering clarity for performance reliability and supply chain management.

Manufacturing and Chemistry

PPS synthesis occurs through polycondensation of sodium sulfide (Na₂S) and p-dichlorobenzene (p-DCB) in a polar solvent such as N-methylpyrrolidone (NMP) at temperatures near 250°C. The resulting structure features alternating aromatic rings and thioether linkages. Extraction of byproduct salts ensures dielectric properties and non-corrosive behavior in the PPS resin.

PPS macromolecular structures vary by polymerization and post-treatment:

Linear PPS

Achieved at high molecular weight without curing, providing tenacity, elongation, and impact resistance. Its purity suits fiber spinning and injection molding.

Cured PPS

Formed by thermal oxidation, increasing molecular weight and viscosity for stiffness and creep resistance, though with potential reductions in ductility.

Branched PPS

Incorporated with branching agents to adjust rheology, supporting melt strength and flow in extrusion and thin-wall molding.

Molecular weight distribution and compounding affect final performance. These structural variations influence fatigue life and production consistency.

Key Characteristics and Material Properties

This PPS polymer addresses needs between standard plastics and fluoropolymers, with a crystalline matrix that sustains mechanical and chemical integrity.

Thermal Endurance and Dimensional Integrity

PPS retains properties at elevated temperatures due to high crystallinity.

- Crystalline melting point (Tm): 280°C (536°F)

- Glass transition temperature (Tg): 85–97°C

- Heat Deflection Temperature (HDT): >260°C (reinforced grades)

- Continuous Service Temperature: Up to 220°C

- Moisture Absorption: <0.05%

- Coefficient of Thermal Expansion (CTE): Low, aiding tolerances in thermal cycling.

Chemical and Hydrolytic Stability

Thioether linkages resist organic solvents below 200°C. The PPS material withstands:

- Automotive fluids such as oils and fuels.

- Acids and bases (pH 2–12), including sulfuric and hydrochloric.

- Steam and disinfectants in sterilization.

Mechanical and Electrical Performance

Glass fiber or mineral fillers enhance modulus in PPS resin. Compare unfilled and reinforced:

| Property (at 23°C) | Unfilled Resin | 40% Glass-Reinforced |

| Density | 1.35 g/cm³ | 1.66 g/cm³ |

| Tensile Strength | 70–85 MPa | 185–200 MPa |

| Flexural Modulus | 3,400 MPa | 14,500 MPa |

| Notched Izod Impact | 20–30 J/m | 90–110 J/m |

| UL94 Flammability | V-0 (Inherent) | V-0 (Inherent) |

PPS functions as an insulator with dielectric strength of 18 kV/mm, stable across frequencies and humidity for interconnects and sensors.

Material Optimization: Additives and Fillers

Pure PPS resin provides a robust chemical and thermal foundation, yet its industrial utility is primarily realized through targeted compounding. By integrating specific reinforcements and functional fillers, the polymer’s baseline properties are calibrated to withstand high-stress structural loads or specialized electrical requirements.

Glass Fiber Reinforcement

Glass fiber (GF) remains the most prevalent reinforcement, elevating the material’s structural integrity and thermal resistance to an industrial-grade benchmark.

- 30% and 40% loadings balance flow and performance, with 40% often standard for structural parts.

- Elastomer modifications address brittleness in dynamic loads, preserving thermal stability.

Industry-leading glass-reinforced grades we supply include the DURAFIDE® series from Polyplastics and TORELINA™ from Toray, offering tensile strength from 140–190 MPa and flexural modulus up to 14 GPa.

Typical glass-reinforced grades show:

| Filler Level | Tensile Strength (MPa) | Flexural Modulus (GPa) | Key Features |

|---|---|---|---|

| 30% GF | 140–150 | 10–11 | Standard toughness, high flow options |

| 40% GF | 170–190 | 13–14 | High rigidity, balanced processability |

Mineral Fillers

To counteract the anisotropic shrinkage typical of fiber-reinforced polymers, mineral fillers and hybrid systems are employed.

- Glass beads or minerals ensure isotropic properties and low warpage.

- Hybrid systems combine rigidity with flow.

Carbon fiber adds conductivity, while PTFE improves tribology. In line with 2025 sustainability trends, we also supply emerging recycled and eco-friendly PPS grades, including mechanically recycled variants like DURAFIDE® rG-PPS with post-industrial content from Polyplastics.

Examples of reinforced and sustainable PPS compounds we supply:

| Performance Indicator | TORELINA A305MD1 (Toray) | DURAFIDE 6165A6 (Polyplastics) | DURAFIDE 6150T6 (Polyplastics) | TORELINA™ A490MA50 (Toray) |

|---|---|---|---|---|

| Filler/Reinforcement | 50% Glass Fiber + Mineral | 65% Glass Fiber + Mineral | 50% Glass Fiber + Mineral | ~50% Mineral |

| Density (g/cm³) | ~1.70–1.75 | ~1.84 | ~1.70 | 1.75–1.80 |

| Tensile Strength (MPa) | 140–160 | ~130 | ~140–160 | 100–120 |

| Flexural Modulus (GPa) | 14–15 | ~18.3 | ~12–14 | 12–14 |

| HDT (1.82 MPa, °C) | ~265 | >270 | ~265 | ~260 |

| Key Features | High flow, low warpage, excellent dimensional stability/strength | Ultra high rigidity, superior heat resistance, low mold shrinkage | Enhanced impact resistance, high toughness, good thermal shock performance | Low warpage, outstanding dimensional stability, isotropic shrinkage |

Precision Engineering Starts with the Right Specification

Identifying the optimal PPS grade requires balancing thermal stability with processing efficiency. Access our technical database for a side-by-side performance analysis of industry-leading PPS compounds—including DURAFIDE® and Torelina™—to ensure your next application meets its rigorous reliability targets.

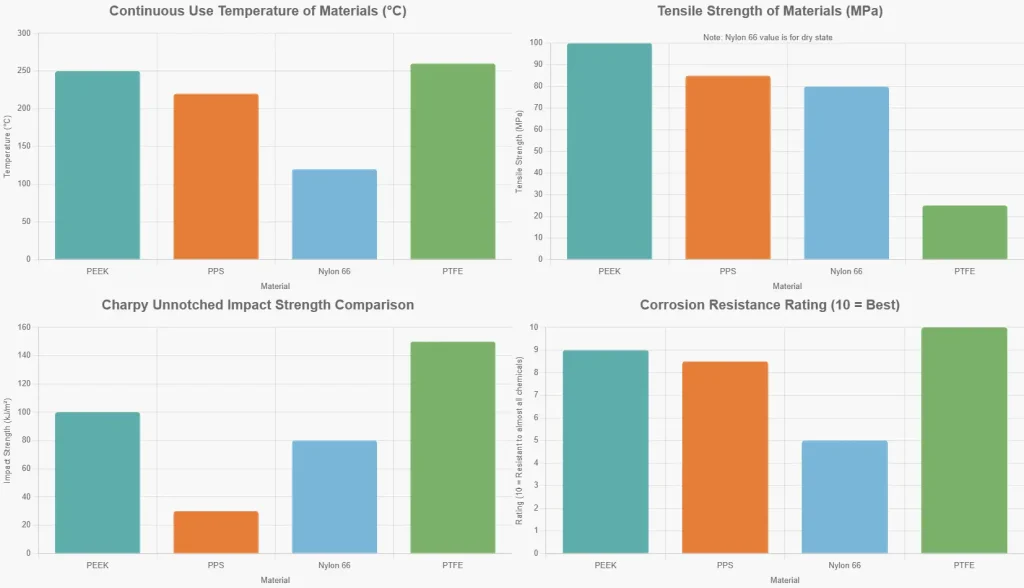

Comparative Performance Analysis

Identifying the optimal polymer requires a strategic evaluation of environmental stressors against economic feasibility. Polyphenylene Sulfide (PPS) occupies a critical middle ground, serving as a high-performance alternative when standard engineering plastics reach their thermal limits, and ultra-polymers like PEEK become cost-prohibitive.

PPS vs. PEEK

While PEEK serves ultra-high thermal thresholds, specifying PPS prevents over-engineering in environments where cost-efficiency is paramount.

PPS Advantages

- Lower cost (typically 30-50% less expensive)

- Superior chemical resistance to a broader range of substances

- Higher compressive strength (PPS: 134 MPa vs. PEEK: 102 MPa)

- Inherent flame retardancy without additives

PEEK Advantages

- Higher continuous service temperature (250°C vs. 220°C)

- Superior ductility and impact resistance

- Better wear resistance in unlubricated conditions

- Higher tensile strength (166 MPa vs. 103 MPa for unfilled grades)

In many industrial applications, PPS is selected not as a replacement for PEEK, but as a cost-effective alternative that meets performance requirements without over-engineering the solution.

PPS vs. Other High-Performance Polymers

PPS offers unique advantages and trade-offs compared to other engineering thermoplastics:

| Attribute | PPS | PEI | PPA | PTFE |

|---|---|---|---|---|

| Max Service Temp | 220°C | 170°C | 185°C | 260°C |

| Chemical Resilience | High | High | Moderate | High |

| Dimensional Stability | High | Excellent | Variable | Marginal |

| Melt Processability | Reliable | Reliable | High-Flow | Sintering |

Comprehensive Material Supply Beyond PPS

While PPS serves as a critical solution for high-heat environments, we understand that modern manufacturing requires a diverse array of polymer technologies. As a strategic material distributor, we offer a robust portfolio designed to meet both performance and sustainability targets across your entire product line.

Our core supply capabilities include:

- Sustainable Polymers: Advanced PLA and PHA resins for eco-friendly applications and carbon footprint reduction.

- Engineering Thermoplastics: High-quality PBT, PA (Nylon), and ABS for balanced mechanical performance and cost-efficiency.

- Specialty Grades: A wide selection of reinforced and modified compounds tailored for automotive, consumer electronics, and industrial packaging.

Whether you are looking for the thermal stability of PPS or the environmental benefits of biodegradable resins, our technical team provides the sourcing reliability and batch consistency your supply chain demands.

Processing Techniques

Successful PPS processing is dictated by its crystallization kinetics and high-melt viscosity. Achieving the polymer’s peak mechanical integrity and dimensional fidelity requires rigorous control over thermal history—from pre-molding preparation to post-molding stabilization.

Pre-Processing:

Effective desiccant drying is a non-negotiable pre-requisite, particularly for carbon-reinforced or mineral-filled compounds. Residual moisture can trigger hydrolytic degradation at melt temperatures, leading to splay or compromised mechanical properties.

- Desiccant drying condition: 150°C for 2–4 hours

- Effect: Reduces moisture content to below 0.02%, thus avoiding hydrolytic issues

Injection Molding

Injection molding remains the primary methodology for complex PPS architectures. The objective is to facilitate complete molecular orientation while managing the potential corrosive effects of sulfur-based outgassing.

Processing temperatures

- Melt temperature: 300–330°C

- Mold temperature: 140–160°C

Effects

- The specified mold temperature promotes full crystallinity

Tooling requirement

- Corrosion-resistant tool steels are adopted to handle potential outgassing

Extrusion and Post-Processing Stability

For profiles, fibers, and films, extrusion parameters prioritize shear management and cooling uniformity.

- Screw design parameter: L/D ratios of 24:1 to 30:1

- Effect: Maintains homogeneous melt without material degradation

Post-processing steps like annealing at 200–220°C for 1–4 hours enhance secondary crystallization and stress relief. Surface treatments improve adhesion for coatings or bonding.

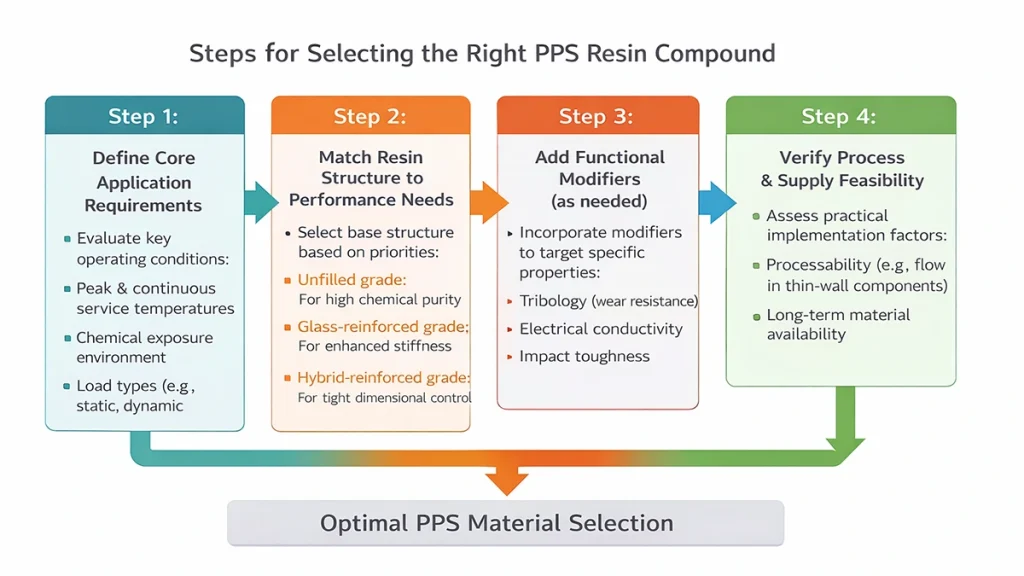

How to Select the Right PPS Grade

Selecting the optimal Polyphenylene Sulfide (PPS) grade is an exercise in balancing environmental stressors against manufacturing efficiency and total cost of ownership. Rather than a linear choice, it is a multi-dimensional validation process that aligns macromolecular performance with long-term application reliability.

Step 1: Define Core Application Requirements

Evaluate key operating conditions:

- Peak & continuous service temperatures

- Chemical exposure environment

- Load types (e.g., static, dynamic)

Step 2: Match Resin Structure to Performance Needs

Select base structure based on priorities:

- Unfilled grade: For high chemical purity

- Glass-reinforced grade: For enhanced stiffness

- Hybrid-reinforced grade: For tight dimensional control

Step 3:Add Functional Modifiers (as needed)

Incorporate modifiers to target specific properties:

- Tribology (wear resistance)

- Electrical conductivity

- Impact toughness

Step 4: Verify Process & Supply Feasibility

Assess practical implementation factors:

- Processability (e.g., flow in thin-wall components)

- Long-term material availability

Need Help Selecting the Right PPS Grade?

Our material experts can help you navigate the selection process and identify the optimal PPS formulation for your specific application requirements.

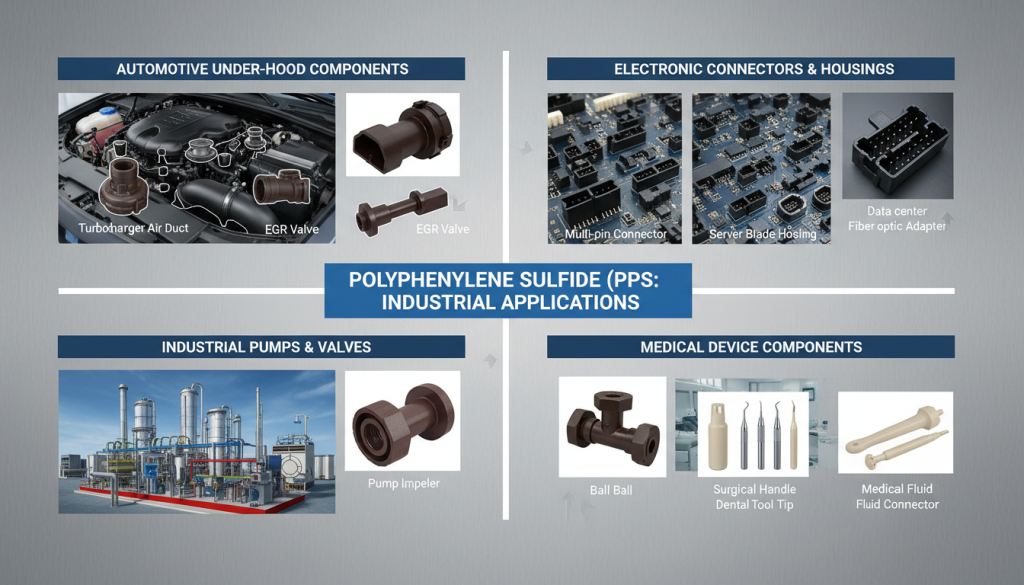

Key Applications

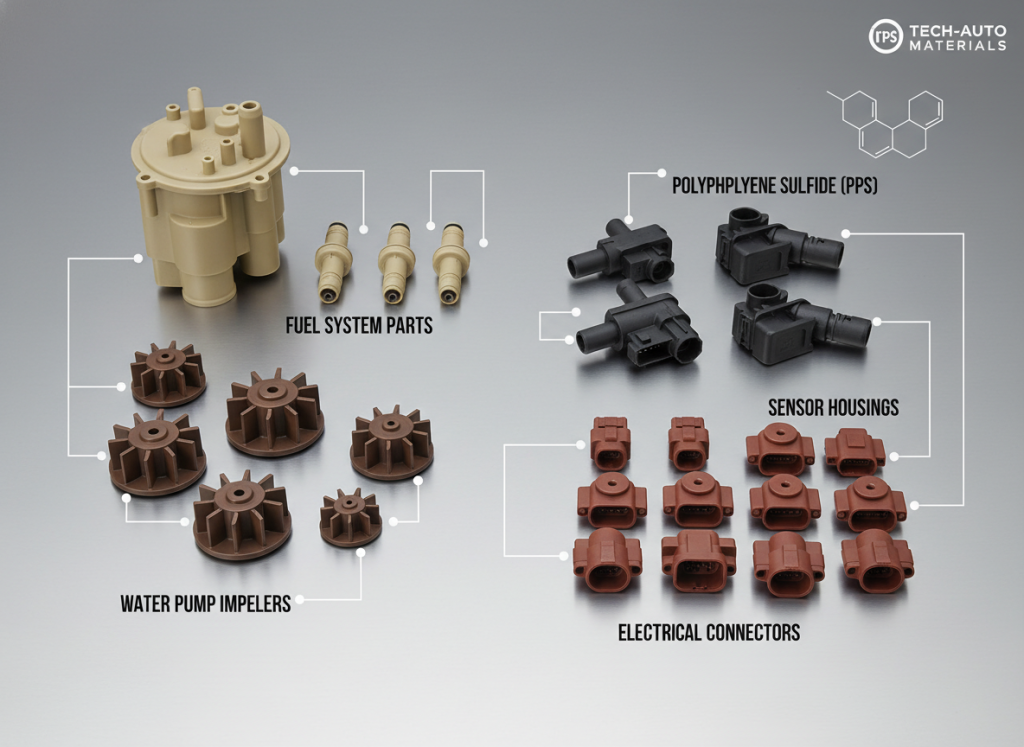

The technical profile of Polyphenylene Sulfide facilitates its deployment across sectors where component failure is not an option. By analyzing successful implementations, engineers can identify opportunities to replace traditional metals or lower-tier polymers with high-performance PPS compounds.

Automotive and E-Mobility Transition

Strategic implementation of PPS is concentrated in the thermal and fluid management systems of modern internal combustion and electric vehicles.

Thermal Management:

- Water pump impellers

- Thermostat housings

- Complex cooling circuits requiring long-term hydrolytic stability.

Power Electronics:

- Water pump impellers

- Thermostat housings

- Complex cooling circuits requiring long-term hydrolytic stability.

Precision Systems:

- Water pump impellers

- Thermostat housings

- Complex cooling circuits requiring long-term hydrolytic stability.

These applications often require PPS materials with proven long-term supply stability and consistent mechanical performance across production cycles.

Electrical, Electronic, and Telecommunications

The dimensional precision and inherent flame retardancy of PPS ensure reliability in high-density electronic assemblies.

- Interconnect Solutions: High-temperature connectors, sockets, and bobbins for surface-mount technology (SMT) processes.

- Optoelectronics: LED lighting frameworks and semiconductor fabrication hardware requiring chemical inertness.

- Infrastructure: Circuit board substrates and transformer components designed for sustained performance in high-humidity environments.

Industrial and Specialized Engineering

PPS serves as a cornerstone for equipment operating in aggressive chemical and high-pressure conditions.

Fluid Handling

Pump impellers, valve seats, and compressor seals exposed to corrosive media and synthetic lubricants.

Energy and Filtration

Heat exchanger components, oil and gas downhole tools, and advanced membrane filtration systems.

Technological Frontiers

Aerospace weight-reduction components, medical devices resilient to repeated sterilization, and high-performance 3D printing filaments for functional prototyping.

Successfully integrating PPS into these applications requires a localized understanding of grade availability and batch consistency to ensure that laboratory performance translates directly to the production floor.

Ready to Integrate PPS into Your Next Project?

Explore our detailed guide to compare different PPS grades and discover the best formulation for your specific needs.

Conclusion

Integration of Polyphenylene Sulfide (PPS) depends on precise specification aligned with processing capabilities. The combination of thermal endurance, chemical resistance, and dimensional fidelity in this PPS resin addresses evolving requirements in fields like e-mobility, electronics, and advanced filtration.

From synthesis and compounding to final processing, each step influences long-term behavior under stress. Engineers who account for molecular structure, reinforcement type, crystallization control, and batch consistency can bridge laboratory data with high-yield production outcomes. This understanding not only minimizes risks of degradation or warpage but also supports design optimization in increasingly demanding environments—such as electric vehicle thermal management systems or chemical processing equipment exposed to aggressive media.

Industries are pushing for lighter, more durable, and environmentally resilient components in 2025 and beyond. The versatility of PPS material—supported by reliable supply of established grades like DURAFIDE® (Polyplastics) and TORELINA™ (Toray)—positions it as a practical engineering solution. A thorough grasp of its properties and variables enables consistent performance, reduced failure rates, and innovation where conventional polymers fall short.