Growing sustainability expectations from consumers, regulators, and brand owners are driving a fundamental reassessment of ingredient choices within the cosmetics industry, particularly for rinse-off products such as exfoliating scrubs. Plastic microbeads, once favored for their uniformity and processing efficiency, have come under sustained scrutiny due to their environmental persistence and documented contribution to microplastic pollution. As regulatory restrictions tighten across multiple markets, manufacturers are increasingly compelled to move away from materials that introduce long-term ecological liabilities and compliance uncertainty.

Against this backdrop, biodegradable polymers such as Polylactic Acid (PLA) have emerged as a technically viable alternative. Derived from renewable plant-based resources, PLA offers controlled particle morphology, predictable mechanical behavior, and a favorable environmental profile compared to conventional petroleum-based abrasives. This combination enables formulators to meet evolving sustainability standards without compromising exfoliation efficacy or formulation stability, positioning cosmetic-grade PLA as a practical material solution for next-generation, environmentally responsible skincare products.

This article emphasizes technical parameters, supply chain benefits, and customization options of cosmetic-grade PLA pellets and powders tailored to exfoliant production.

What is PLA?

Polylactic Acid (PLA) is a biodegradable aliphatic polyester produced from renewable feedstocks such as corn starch or sugarcane through controlled fermentation and subsequent polymerization. From a materials science perspective, PLA bridges the gap between conventional synthetic polymers and naturally derived ingredients, offering both structural integrity during use and a defined degradation pathway after disposal under industrial composting conditions.

From plant to polymer: The sustainable production process of cosmetic-grade PLA

At the molecular level, PLA is composed of repeating lactic acid units forming linear polymer chains. This architecture allows cosmetic-grade PLA to be engineered into exfoliating particles with smooth surfaces, narrow particle size distributions, and consistent geometries. As a result, formulators can achieve predictable tactile performance while minimizing the risk of harsh abrasion, an important consideration for daily-use skincare products.

When compared with traditional polyethylene microbeads, PLA eliminates concerns related to environmental persistence and microplastic accumulation. By contrast, natural exfoliants such as crushed nut shells or fruit seed powders often suffer from irregular shapes, variable hardness, and batch-to-batch inconsistency. From a formulation standpoint, PLA offers a balanced alternative—combining controlled exfoliation performance, material uniformity, and a biodegradability profile aligned with modern cosmetic sustainability requirements.

Why Use PLA in Exfoliating Scrubs

The gentle exfoliating action of PLA-based scrubs makes them suitable for sensitive skin

Gentle Efficacy

One of the primary reasons cosmetic formulators turn to PLA lies in its ability to deliver effective mechanical exfoliation without excessive skin stress. Through controlled processing, cosmetic-grade PLA particles can be produced with smooth, rounded morphologies and narrow particle size distributions. As a result, dead skin cells are removed efficiently while reducing the likelihood of surface irritation commonly associated with irregular or overly abrasive exfoliating agents.

Biodegradability

From an environmental perspective, PLA offers a clear advantage over conventional plastic microbeads. Whereas petroleum-based polymers remain persistent in aquatic environments, PLA is designed to biodegrade into naturally occurring components under industrial composting conditions. This degradation pathway directly addresses growing environmental concerns surrounding microplastic accumulation and aligns with the sustainability expectations increasingly placed on rinse-off cosmetic products.

Biodegradation timeline: PLA vs. traditional plastic microbeads

Regulatory considerations

Regulatory considerations further reinforce the case for PLA. In response to global restrictions on plastic microbeads—implemented across regions including the European Union and the United States—PLA provides a compliant alternative that allows manufacturers to future-proof formulations without repeated reformulation cycles. Its biodegradability profile supports long-term regulatory alignment rather than short-term substitution.

Functional Versatility

In parallel, PLA’s formulation versatility contributes to its practical appeal. The material is compatible with both aqueous and oil-based systems and can be engineered for stable suspension across a wide range of viscosities. From a formulation standpoint, this flexibility enables consistent exfoliation performance while accommodating diverse product textures and application formats.

Experience the Difference

See how our cosmetic-grade PLA particles perform in your formulations.

Product Forms and Specifications

Cosmetic-grade PLA is supplied in multiple physical forms to accommodate different exfoliation profiles and formulation architectures. A clear understanding of these forms and their associated technical parameters enables formulators to align exfoliation performance with product positioning and skin-contact requirements.

Physical Forms

Depending on formulation needs, PLA exfoliating materials are commonly available in the following forms:

Spherical Particles

Precisely engineered beads with smooth, rounded surfaces, primarily used in facial cleansers and daily exfoliating products. Their uniform geometry supports controlled exfoliation intensity and a consistent sensory profile.

Irregular Granules

Particles with angular or textured morphologies designed to deliver more pronounced mechanical action. These are typically applied in body scrubs, foot treatments, or formulations targeting rough or thickened skin areas.

Fine Powders

Micronized PLA particles used where subtle exfoliation, visual effects, or rheology modification is required. Powder forms are often incorporated into hybrid cleansing or polishing systems.

Key Technical Parameters

From a technical standpoint, exfoliation performance is governed by particle size, hardness, and material density rather than shape alone. Typical specification ranges for cosmetic-grade PLA include:

| Parameter | Specification Range | Application Considerations |

|---|---|---|

| Particle Size (Fine) | 50–150 μm | Facial exfoliants, sensitive skin formulations |

| Particle Size (Medium) | 150–300 μm | General-purpose scrubs, combination skin |

| Particle Size (Coarse) | 300–500 μm | Body scrubs, foot care, intensive exfoliation |

| Color | Natural white to off-white | Compatible with pigments and color systems |

| Density | 1.24–1.26 g/cm³ | Influences suspension stability |

| Hardness (Shore D) | 70–90 | Determines exfoliation strength |

By adjusting particle size and hardness within these ranges, formulators can fine-tune exfoliation intensity without altering the base formulation.

Cosmetic-Grade PLA Options and Customization

In practice, cosmetic-grade PLA is offered in standardized grades optimized for facial, body, or multi-purpose exfoliating products. Beyond these standard options, customization remains a key advantage. Particle size distributions, surface treatments for improved compatibility with aqueous or oil-based systems, and tailored hardness profiles can be specified to achieve distinct sensory or functional outcomes. This level of control allows brands to develop differentiated exfoliating products while maintaining material consistency and regulatory alignment.

Technical Documentation

Access detailed specifications, safety data, and formulation guidelines for our cosmetic-grade PLA products.

Manufacturing and Processing Advantages

Formulating with PLA offers significant processing advantages

Formulation Compatibility

Cosmetic-grade PLA is well suited for integration into a broad range of cosmetic formulation systems. Its consistent dispersion behavior allows formulators to incorporate mechanical exfoliation without disrupting overall product stability or sensory characteristics.

PLA particles are compatible with:

- Water-based gel systems

- Oil-in-water and water-in-oil emulsions

- Anhydrous oil-based formulations

- Cleansing systems with varying surfactant concentrations

- Clay-based masks and treatment products

This flexibility supports exfoliating solutions across multiple product formats, ranging from lightweight daily cleansers to intensive treatment masks.

Processing Stability

PLA demonstrates reliable stability under standard cosmetic manufacturing conditions. The material maintains particle integrity within the temperature ranges typically used in hot-process formulations and remains stable across the pH conditions commonly applied in skincare products.

In addition, cosmetic-grade PLA particles show sufficient resistance to deformation during conventional mixing and homogenization. This ensures that exfoliation intensity remains consistent throughout processing, filling, and subsequent storage, reducing the risk of performance variation between production batches.

Modern manufacturing facility producing PLA-based exfoliating formulations

Compatibility with Bio-Based Ingredients

Cosmetic-grade PLA exhibits good compatibility with other biodegradable and bio-based materials, including Polyhydroxyalkanoates (PHA). This allows formulators to combine multiple sustainable components within a single formulation, with each material contributing distinct functional attributes.

Such compatibility supports the development of advanced exfoliating systems that align with sustainability objectives while maintaining predictable processing behavior and formulation robustness.

Supply Chain Advantages

Consumers increasingly seek sustainable exfoliation solutions

Derived from renewable agricultural resources, PLA contributes to reduced reliance on petroleum-based raw materials. Expanding global production capacity further supports consistent supply availability, even as demand for biodegradable cosmetic ingredients continues to grow.

The traceable, plant-based origin of cosmetic-grade PLA also facilitates documentation related to environmental impact and material sourcing, supporting regulatory compliance and substantiated sustainability claims.

Market Trends and Opportunities

Regulatory momentum continues to favor sustainable materials such as PLA. Following landmark bans on plastic microbeads in regions including the United States and the European Union, similar legislation has been adopted globally. Beyond explicit microbead restrictions, broader measures addressing plastic pollution and extended producer responsibility are further encouraging the incorporation of biodegradable alternatives like PLA in cosmetic formulations.

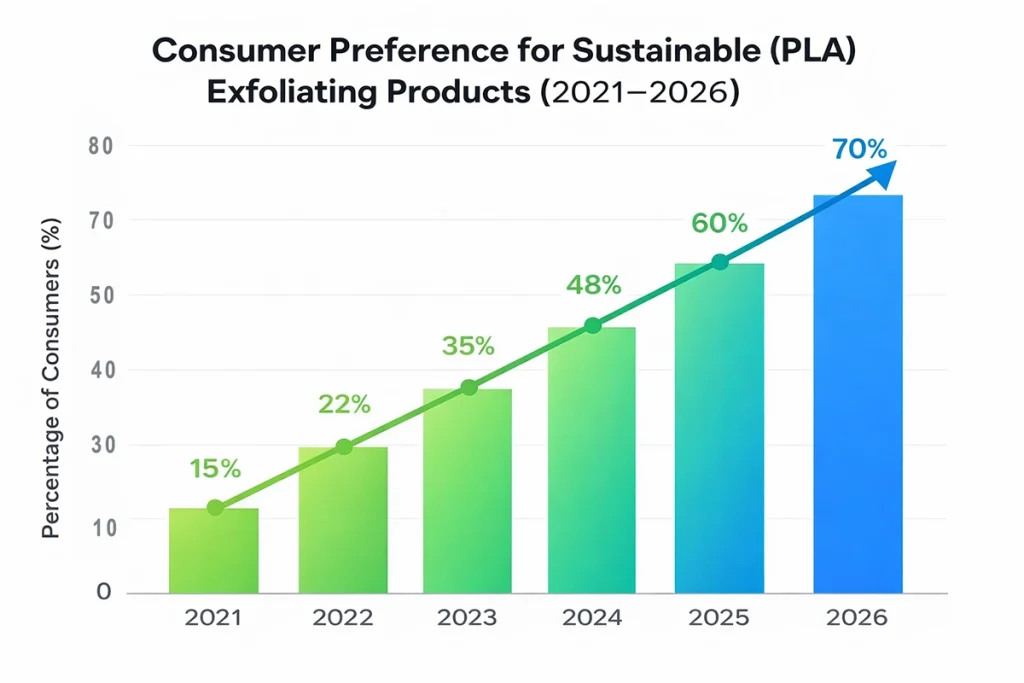

Consumer preference shifts reflect an increasing awareness of green beauty standards across mainstream markets. More consumers actively seek information on ingredient sourcing and environmental impact, with plant-based materials like PLA resonating strongly. This awareness creates an opportunity to position PLA-based exfoliants not only as compliant substitutes but also as premium, sustainability-driven functional ingredients.

Consumer Preference for Sustainable (PLA) Exfoliating Products

Market segmentation reveals expanding applications for cosmetic-grade PLA beyond facial exfoliants. Emerging categories include:

- Body care products targeting various skin areas with formulations ranging from gentle décolletage scrubs to intensive heel treatments

- Scalp care solutions that combine exfoliation with scalp health maintenance

- Lip care products utilizing ultra-fine PLA particles for delicate exfoliation

- Multifunctional formulations such as cleansers and masks that integrate exfoliation with additional skincare benefits

This diversity illustrates PLA’s adaptability and potential to address evolving consumer needs across personal care categories while supporting sustainable product innovation.

Our Cosmetic-Grade PLA Offerings

Sustainable PLA-Based Cosmetic Range and Biodegradable Beads

A specialized portfolio of cosmetic-grade PLA exfoliants has been developed to address the varied requirements of modern formulators. The product range includes finely tuned particle sizes and morphologies to match specific exfoliation needs and formulation types.

PLA Exfoliant Series

PLA Microspheres Fine

Uniform spherical particles sized between 50 and 150 microns, optimized for gentle facial exfoliation. These are suitable for daily-use cleansers and formulations targeting sensitive skin.

PLA Microspheres Medium

Particles ranging from 150 to 300 microns that provide balanced exfoliation. This grade offers versatility for both facial and body scrubs with moderate mechanical action.

PLA Granules Coarse

Irregular particles sized 300 to 500 microns designed for intensive exfoliation. These are particularly effective in body scrubs and treatments for rough or thickened skin areas.

Each grade is available with options for custom particle size distribution and surface characteristics, enabling formulators to tailor exfoliation intensity and sensory profiles according to product specifications.

Rigorous quality control measures ensure consistent performance across batches. Testing includes particle size distribution, morphology uniformity, microbial purity, heavy metal content, and residual monomer levels. This commitment to quality supports stable supply chains and meets the exacting standards of premium cosmetic formulations.

In addition, the portfolio aligns with global regulatory frameworks and sustainability goals. Certifications such as ISO 9001:2015 (Quality Management), ISO 22716:2007 (Cosmetic GMP), REACH registration, Non-GMO verification, and Vegan certification underscore the environmental responsibility and compliance embedded in our offerings.

Ready to Transform Your Exfoliating Formulations?

Contact our technical team to discuss your specific requirements and discover how our cosmetic-grade PLA can enhance your product line.

Conclusion

Cosmetic-grade PLA represents more than a regulatory-compliant substitute for plastic microbeads; it stands as a cornerstone for the future of sustainable exfoliation. By integrating environmental responsibility with high performance, PLA enables brands to develop products that align with evolving consumer expectations and corporate sustainability goals.

As the beauty industry advances toward increased environmental awareness, materials such as PLA will become integral to formulation strategies. Brands adopting these biodegradable solutions position themselves to navigate the challenges and seize the opportunities presented by a shifting marketplace.

Moreover, commitment to sustainable exfoliation drives ongoing innovation within the cosmetic-grade PLA portfolio. Collaboration with material partners fosters the development of the next generation of exfoliating products that deliver efficacy while minimizing environmental impact. Manufacturers embracing PLA contribute to a responsible beauty future that benefits consumers and the planet alike.