The 3D printing industry is at a critical inflection point. While bioplastics like PLA paved the way, the emergence of Polyhydroxyalkanoates (PHA) marks the arrival of a true green revolution. As makers and manufacturers seek alternatives that move beyond “less harmful” to “truly restorative,” PHA stands out as a game-changing material. Unlike conventional options—or even standard bioplastics that require industrial composting—PHA offers a rare combination of engineering-grade performance and certified marine and soil biodegradability.

This naturally derived biopolymer represents a fundamental shift toward a circular economy. It allows hobbyists, designers, and industrial manufacturers to achieve high-precision results without leaving a lasting footprint. By choosing PHA, you aren’t just selecting a filament; you are embracing a future where innovation and environmental responsibility are seamlessly integrated, ensuring that the products of today do not become the environmental burdens of tomorrow.

At Salesplastics, we supply filament-grade PHA raw materials engineered specifically for stable extrusion, consistent filament diameter, and reliable mechanical performance.

Our formulations are designed not just to look sustainable on paper, but to run consistently on industrial filament production lines.

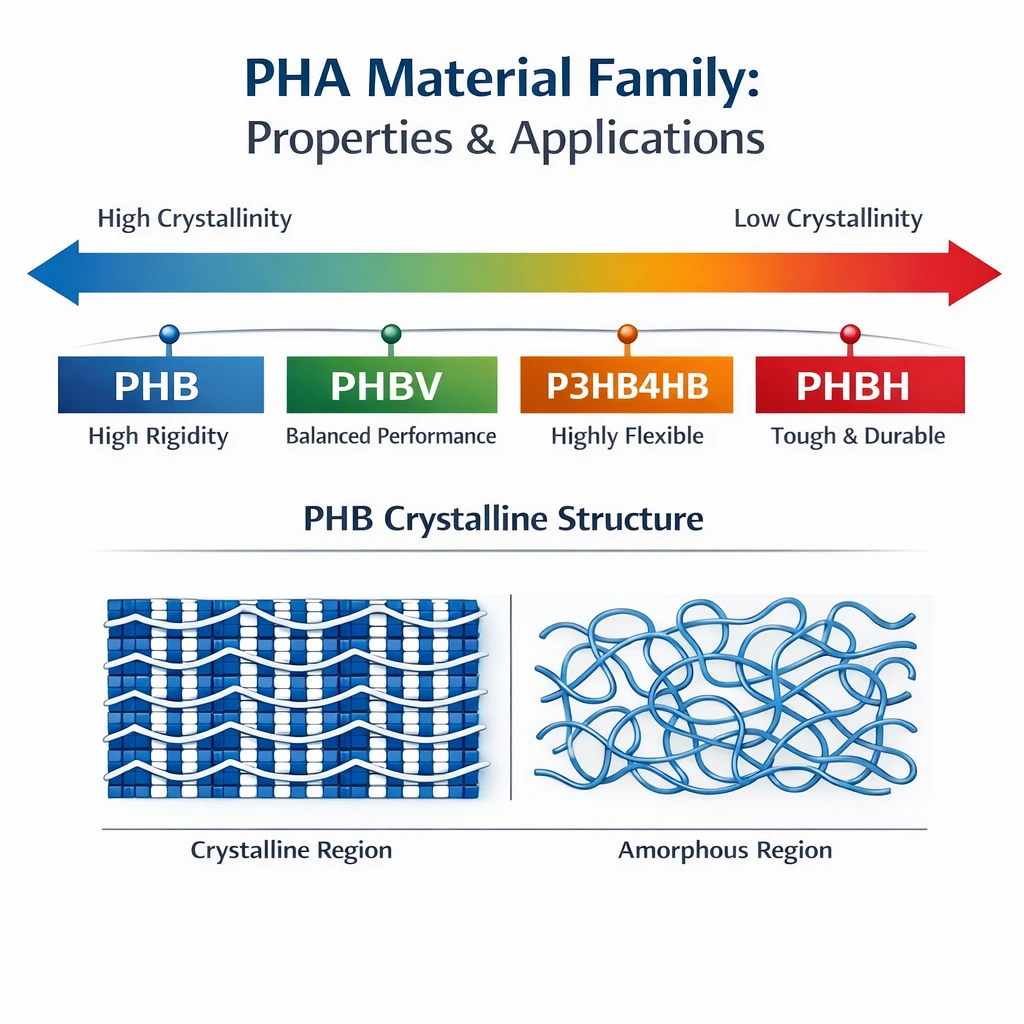

Major Types of PHA Raw Materials

PHA is not a single material but a versatile family of biopolymers. For filament manufacturers, selecting the correct grade is crucial for balancing “printability” with end-use durability.

PHB (Polyhydroxybutyrate): The High-Rigidity Base

Characterized by high crystallinity and stiffness comparable to traditional engineering plastics.While it offers excellent dimensional stability, pure PHB can be brittle and has a narrow processing window. For the 3D printing industry, PHB serves as an ideal high-modulus base for compounding, providing the structural backbone for sustainable composites.

PHBV (The Workhorse Standard)

By integrating hydroxyvalerate (HV), PHBV improves flexibility. It offers a more forgiving processing range, making it the preferred choice for general-purpose sustainable filaments.

P3HB4HB (The Elastic Specialist)

A game-changer for flexible applications. By adjusting the 4HB content, we provide resins that range from semi-rigid to highly elastic (TPE-like), perfect for gaskets and soft-touch prototypes without microplastic concerns.

PHBH (Next-Gen Performance)

Incorporating hexanoate (HH) monomers, PHBH represents the cutting edge. It features lower crystallinity, resulting in unmatched toughness and a wider processing window, allowing it to compete directly with PETG and ABS.

Unlike general-purpose PHA resins designed for injection molding or film extrusion, our filament-grade PHA materials are engineered with controlled molecular weight distribution and optimized melt viscosity.

Key engineering features include:

- Narrow MFI tolerance to ensure stable extrusion and consistent filament diameter

- Enhanced thermal stability to reduce residence-time degradation in heated nozzles

- Low ash content and impurity control to prevent nozzle clogging

- Tuned crystallization behavior to improve inter-layer diffusion during FDM printing

These parameters are validated on both single-screw and twin-screw filament extrusion lines, ensuring reliable scale-up from pilot runs to industrial production.

Explore PHA Material Science

Want to dive deeper into the chemistry and production methods behind PHA biopolymers? Download our comprehensive technical guide to understand how these materials are engineered for optimal 3D printing performance.

PHA filament properties: Why PHA is the Premium Choice

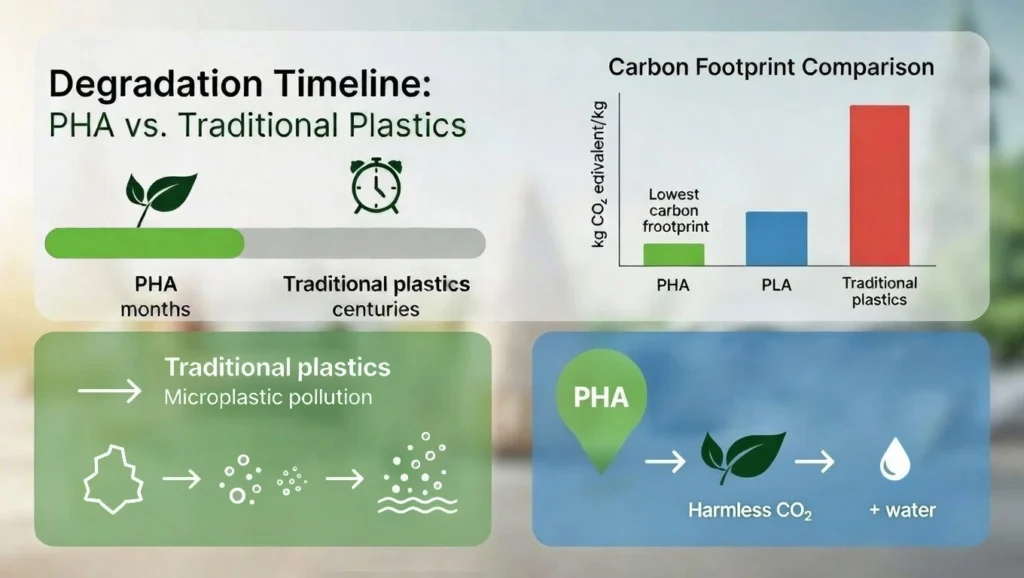

PHA vs. Traditional Plastics: Faster Degradation, Lower Carbon Footprint, Zero Microplastic Pollution

Environmental Circularity

PHA is the only 3D printing material that offers true 360-degree biodegradability.Unlike PLA, which requires industrial composting conditions, PHA can biodegrade in soil, freshwater, and marine environments without leaving persistent microplastics.

For a deeper look at how PHA breaks down in real ocean conditions and why this matters for plastic pollution, see our detailed analysis on Advantages of PHA’s Marine Biodegradation.

Superior Layer Fusion & Mechanical Strength

With a tensile strength of 30-40 MPa, PHA rivals ABS in durability. However, its real secret weapon is exceptional inter-layer adhesion. Due to its unique crystallization kinetics, PHA prints exhibit near-isotropic strength, meaning the “weak spots” typically found between layers in 3D prints are virtually eliminated.

Thermal Stability Warning

PHA is sensitive to Residence Time. As a technical partner, we advise ensuring that the material does not sit idle in a heated nozzle for extended periods to prevent thermal degradation and maintain optimal mechanical properties.

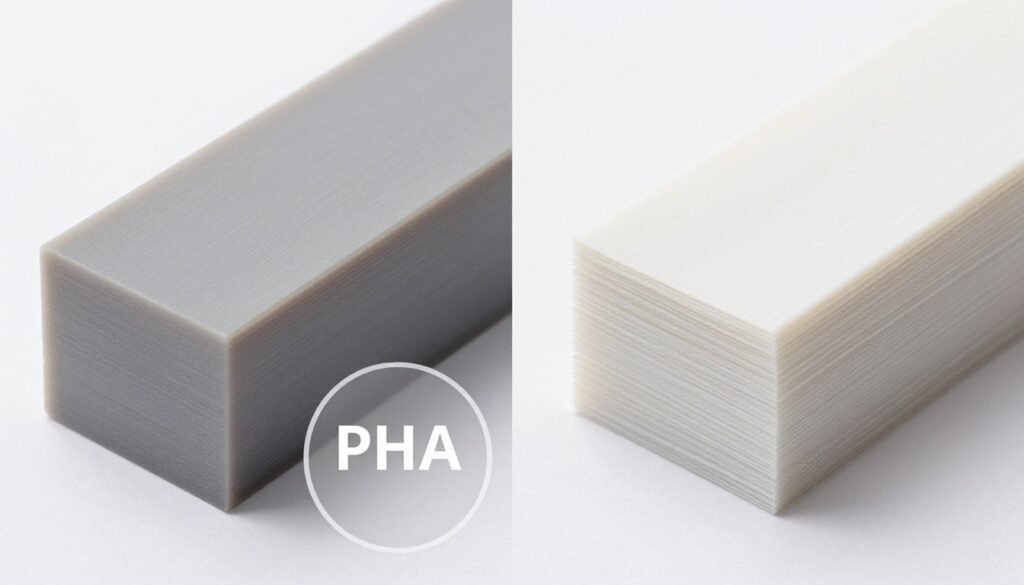

Bio-Aesthetic Excellence

PHA removes the “plastic-look” from 3D printing. It boasts a natural, matte, and slightly tactile finish. As a distributor, we offer grades that are highly compatible with organic fillers (like wood or coffee waste), allowing for a range of sensory experiences that traditional polymers cannot replicate.

| Property | PHA (Our Selected Grades) | PLA | ABS |

| Biodegradability | Universal (Soil/Marine/Home) | Industrial Only | Non-biodegradable |

| Regulatory Compliance | ISO 14855 / ASTM D6691 | ISO 14855 | N/A |

| Layer Adhesion | Superior (Near-Isotropic) | Good | Moderate (Warping) |

| Heat Resistance (HDT) | Up to 120°C (Post-Annealing) | ~55°C | ~95°C |

| Carbon Footprint | Low to Negative | Moderate | High |

Note on Heat Resistance:

While PHA prints at low temperatures, specific formulations (like our PHB-rich blends) can achieve an HDT of 120°C after a secondary crystallization/annealing process, far surpassing the limits of standard PLA.

Laboratory testing reveals PHA filament’s impressive mechanical properties

Advantages of PHA Filament in 3D Printing

Side-by-side comparison reveals PHA’s superior surface finish compared to conventional filaments

Advantages of PHA Filament

- Multi-Environment Degradation: The only filament that leaves zero microplastics in marine, soil, and compost settings.

- Industrial-Grade Performance: High heat deflection (up to 120°C) and superior Z-axis strength due to exceptional layer fusion.

- Printing Environment Friendly: Virtually odorless and non-toxic, making it ideal for schools and open-plan offices.

- Zero-Warp Reliability: Excellent dimensional stability for large-scale prints without the enclosure requirements of ABS.

- Aesthetic Versatility: A natural matte finish that masks layer lines, with high compatibility for bio-composite fillers (wood, hemp, etc.).

Challenges of PHA Filament

- Cost Efficiency: While the initial investment is higher than PLA, the “End-of-Life” value and reduced energy consumption (low-temp printing) offer a lower total environmental cost.

- Bed Adhesion: PHA performs best on unheated or low-temperature beds. We recommend specific bio-based adhesives to ensure perfect first-layer success.

- Moisture Management: Like all premium engineering materials, PHA is hygroscopic. We provide vacuum-sealed industrial packaging and storage guidelines to ensure consistent print quality.

- Material Selection: While pure PHA has a natural amber hue, our advanced compounding allows for an expanding palette of earth-toned and natural pigments that align with sustainable branding.

Applications of PHA Filament

The transition from traditional polymers to PHA is not merely a material swap; it is a strategic move toward a circular economy. By aligning its unique biodegradation profile with industrial-grade mechanical properties, PHA solves the “end-of-life” dilemma that has long plagued additive manufacturing.

Sustainable Prototyping

For R&D centers and design firms, PHA isn’t just a material; it’s an ESG statement. Its superior dimensional stability and matte finish reduce the need for post-processing. The true ROI: Eliminating the environmental liability of discarded iterations.

Educational Tools

Unlike ABS or even some PLA blends, our PHA releases zero toxic VOCs during extrusion. This makes it the gold standard for long-print-time anatomical models in surgical planning rooms and classroom settings where air quality and user safety are paramount.

Agricultural & Horticulture Applications

PHA is a game-changer for “place-and-forget” applications. We provide grades specifically for biodegradable clips, tree protectors, and pheromone traps. These components eliminate manual recovery costs and transform into organic matter after the growing season, integrating perfectly into carbon-neutral farming.

Packaging Prototypes

Packaging designers use PHA to prototype thin-walled containers that must mimic the barrier properties of petroleum plastics. This allows brands to test the “True End-of-Life” (Marine Degradability) of their concepts, ensuring they meet upcoming global plastic regulations.

Bio-Composite Art & Luxury Goods

The high compatibility of PHA with organic fillers (hemp, oyster shells, coffee waste) allows artists to create “Living Art.” These pieces offer a premium, non-plastic tactile experience that resonates with the luxury eco-conscious market.

Explore Industry-Specific Applications

Discover how PHA filament can address specific challenges in your industry. Our technical consultants can help identify opportunities to integrate sustainable 3D printing into your workflows.

Our PHA Raw Material Series

How to Choose the Right PHA Grade for Your Filament Line

- Replacing PLA with minimal process change → PHBV-rich blends

- Targeting PETG / ABS-like toughness → PHBH-based grades

- Fully compostable branding → Pure PHA series

- Flexible or soft-touch filaments → P3HB4HB series

- Industrial tooling or high stiffness → PHB-rich reinforced blends

At Salesplastics, our comprehensive range of PHA formulations offers more than just raw resin—we provide engineered solutions designed to optimize specific performance characteristics.

Pure PHA Series: The Gold Standard for Circularity

For clients pursuing the highest level of environmental certification and “zero-plastic” branding.

- Natural Grade: High-purity PHA in its original amber/matte state, ideal for naturalistic designs or further in-house compounding.

- Pigmented Pure PHA: Fully biodegradable color masterbatches (Black, White, Red, etc.) that maintain 100% soil and marine compostability without compromising performance.

Specialized Blends: Balancing Performance & Ease of Use

Designed to bridge the gap between traditional printing experiences and high-end biopolymers.

- Standard Performance Blends (e.g., PHA/PLA): Our “Workhorse” series. These blends significantly improve the toughness of PLA while ensuring an effortless printing experience on standard FDM hardware.

- Natural Bio-Composites: Innovative blends incorporating organic by-products like tea residue, coffee grounds, and fruit peels. These offer unique sensory textures and scent profiles, creating a distinct “circular story” for lifestyle brands.

Bespoke Formulation & Custom Services

We empower manufacturers to create proprietary filaments through our advanced customization lab:

- Performance Reinforcement: Custom integration of Glass Fiber (GF) for lightweight industrial tooling, significantly enhancing tensile strength and thermal resistance.

- Functional Additives: Specialized grades featuring Antimicrobial agents for healthcare prototypes or food-contact-ready formulations.

- Small-Batch R&D: Exclusive recipe development for niche applications, ensuring you have a unique competitive edge in the market with lower MOQ (Minimum Order Quantity) hurdles.

Conclusion

PHA filament represents the future of sustainable digital manufacturing

PHA filament represents a significant leap forward in sustainable 3D printing, offering a rare combination of environmental responsibility and high performance. As the additive manufacturing industry grows, the adoption of truly biodegradable materials like PHA will play a crucial role in minimizing the ecological footprint of digital fabrication.

What makes PHA particularly revolutionary is its ability to break down completely in various environments without leaving harmful microplastics. This end-of-life characteristic, combined with its bio-based origin and impressive mechanical properties, positions PHA as the ideal material for conscious creators who refuse to compromise.

The future of 3D printing is not just about what we can create, but about creating responsibly. At Salesplastics, we are more than just a supplier; we are a filament-grade PHA raw material partner, providing engineered formulations, stable supply, and technical support for scalable production. Whether you are looking for high-purity raw resins, specialized bio-blends, or custom-engineered formulations, we provide the expertise and reliable supply chain needed to bring your sustainable vision to life.

Ready to lead the green revolution?

Contact our technical team today to request a PHA Material Selection Guide or to discuss a custom formulation tailored to your specific production requirements.

Frequently Asked Questions

Is PHA better than PLA?

Better depends on your specific project goals and compliance requirements. While PLA is a cost-effective bio-based standard, PHA is the superior choice for “End-of-Life” responsibility. PHA’s primary advantage is its universal biodegradability—it degrades in home compost, soil, and marine environments, whereas PLA requires industrial composting.

Furthermore, our PHA formulations offer higher heat resistance (up to 120°C) and superior layer fusion, making it a higher-performance engineering material for functional parts that must also meet the highest sustainability standards.

Is PHA the same as PLA?

No. While both are bio-based, PLA is chemically polymerized from lactic acid. PHA is a naturally occurring polyester synthesized by bacteria. This makes PHA truly “nature’s polymer,” recognizable by microbes in almost any environment for complete breakdown.

What is PHA plastic?

PHA (Polyhydroxyalkanoates) is a family of bio-based polyesters produced through the natural fermentation of renewable carbon sources. Think of it as “nature’s energy storage”—bacteria create these polymers much like humans store fat.

As a raw material distributor, we harvest these polymers to create a 100% circular plastic alternative. PHA is remarkable because it offers the functional performance of petroleum-based plastics while being truly restorative; it returns to nature as water, CO₂, and biomass, leaving zero microplastic residue behind.

What printer settings work best for PHA filament?

For optimal results, settings should be calibrated based on the specific PHA grade (Pure vs. Blends):

- Extruder: 175–195°C (Pure PHA). Avoid overheating above 210°C to prevent degradation.

- Bed: Cold bed (0–30°C) with PVA adhesive is often best to prevent “elephant foot,” though low heat (45°C) can be used for large parts.

- Speed: 20–40 mm/s to allow for stable crystallization.

How should I store PHA filament?

PHA is mildly hygroscopic. We ship in vacuum-sealed high-barrier packaging. If exposed to humidity, dry at 45–50°C for 4–6 hours. Note: PHA will not degrade on the shelf; it requires the microbial activity of soil/compost to trigger the decomposition process.