Rigorous plastic mandates are no longer just a regulatory hurdle—they are a challenge to your bottom line. Manufacturers are trapped between high-cost pure biopolyesters and the demand for performance. Our Engineered Starch-Based Resins are the solution. By positioning modified starch as a high-performance backbone rather than a simple filler, we deliver up to 20% cost reduction while enhancing the processing stability of PLA and PBAT systems.

Starch innovations are no longer about “managing limitations” but about Unlocking Synergy. Through strategic molecular engineering, our starch-based concentrates act as the vital bridge in hybrid compositing. By integrating with PLA, PBAT, or natural fibers, starch becomes the functional driver that improves degradation kinetics and surface energy. This article details how our starch-centric materials are opening new commercial margins in packaging, agriculture, and high-end consumer goods.

Fundamentals of Starch-Based Composites

The evolution of Thermoplastic Starch (TPS) into a high-tier industrial resin is the foundation of our portfolio. We solve the “Compatibility Challenge” at the source. Utilizing advanced Interface Engineering and Reactive Extrusion, we create molecular bridges (MA-grafting) that fuse hydrophilic starch with hydrophobic polyesters. This ensures the resulting resin performs as a cohesive, high-strength material, preventing the phase separation issues often found in low-grade market alternatives.

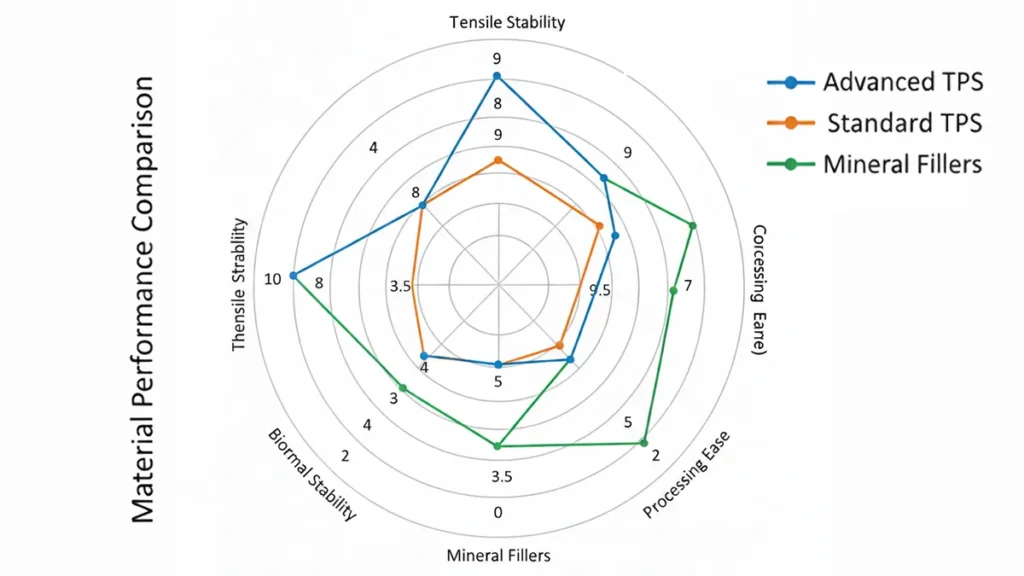

Comparative Performance Matrix of Starch-Based Architectures

Traditional starch limitations—such as moisture sensitivity and brittleness—are precisely what our Advanced Interface Engineering resolves. By disrupting crystalline granules through high-shear processing, we transform native starch into a stable industrial backbone. Our reactive extrusion process (MA-grafting) creates molecular bridges that eliminate phase separation. This ensures the composite performs as a cohesive, high-strength material, effectively replacing the instability of low-grade alternatives with a reliable, performance-ready resin.

Our Starch-Based Solutions vs. Traditional Challenges

- Fully Biodegradable: Meets global mandates without compromising shelf-life.

- Thermal Stability: Optimized formulations prevent retrogradation during storage.

- Processing Ease: “Drop-in” ready for conventional injection and extrusion lines.

- Cost Efficiency: Superior to mineral fillers in maintaining polymer integrity.

📖 Technical Background : To better understand the raw material origins and market evolution of these polymers, refer to our detailed analysis: Starch Based Biodegradable Plastics: Materials, Applications, and Commercial Reality.

Optimize Your Processing Workflow

Request our Technical Application Handbook for detailed insights into reactive extrusion parameters and interface optimization strategies.

Blending with PLA

Our Starch-PLA Series is engineered to eliminate the brittleness of pure PLA while significantly lowering your raw material spend. By utilizing epoxy-functionalized chain extenders, we’ve created a matrix where starch domains actually improve the “water-responsive” degradation required for eco-certified disposables.

💡 Related Resource: For a deeper look into the properties of pure polylactic acid, explore our comprehensive PLA Pellets: Sustainable Bioplastic Guide.

- Converter Advantage: Achieve high-clarity results for cutlery and containers at a fraction of the pure PLA cost.

- Supply Status: Bulk volumes of Grade-A injection molding resins are currently in stock for immediate trial.

Performance Evolution and Industrial Milestones

| Feature | Technological Breakthrough | Target Application |

| Barrier Properties | Tortuous path effect via starch nanocrystals | Oxygen-sensitive food packaging films |

| Toughness | Reactive toughening & interfacial slip | 3D printing filaments with reduced warping |

| Degradation | Micro-porous fragmentation during composting | Agricultural mulch & compostable coatings |

| Surface Finish | Phase morphology control | Premium consumer electronics & cutlery |

Blending with PBAT

For film blowing, our Starch-PBAT High-Load Series redefines the performance-to-cost ratio. While simple mineral fillers compromise film clarity and equipment lifespan, our modified starch maintains bubble stability that rivals virgin LDPE.

- Regulatory Edge: Unlike non-degradable additives, our high-load starch ensures your bags pass 100% compostability testing.

- Drop-in Ready: Designed for “Zero-Downtime” operation. We provide tailored MFI profiles to ensure our resins flow perfectly through your specific screw configuration, reducing waste during start-up.

Technical Benchmarking & Application Spectrum

| Performance Metric | Enhancement Mechanism | Commercial Application |

| Extreme Toughness | Dispersed TPS domains in PBAT matrix | Heavy-duty shopping & garbage bags |

| Thermal Stability | Reduced coefficient of linear expansion | Multi-season agricultural mulch films |

| Active Preservation | Controlled release of bio-antimicrobials | Smart food packaging (Meat/Produce) |

| Cost Optimization | High-filler loading without brittleness | Eco-friendly foam buffers & mailers |

Ready to replace conventional LDPE with a certified compostable solution?

Access our Processing & Troubleshooting Handbook to get precise extrusion parameters, anti-blocking settings, and heat-sealing specifications for our Starch-PBAT resins.

Reinforcement with Natural Fibers

To replace engineering-grade plastics, we provide Natural Fiber-Reinforced Starch Composites. By integrating upcycled bamboo or cellulose nanofibers, we create a structural “skeleton” within the starch matrix, boosting Heat Deflection Temperatures (HDT) for demanding environments.

- The Circular Narrative: These blends allow you to offer your clients a 100% bio-based, upcycled story, ideal for automotive interiors and structural pallets where sustainability is a brand requirement.

Performance Milestones and Industrial Applications

| Enhancement Metric | Technical Breakthrough | Target Application |

| Rigidity & Modulus | Efficient stress transfer via fiber-matrix bonding | Industrial pallets, structural crates |

| Thermal Stability | Elevated Heat Deflection Temperature (HDT) | Automotive interior panels, electronics |

| Biodegradability | Synergistic degradation of fiber and starch | Biodegradable flower pots, nursery trays |

| Surface Quality | Nano-cellulose smoothening effect | Premium reinforced food packaging layers |

Comparison and Future Trends

Selecting the right starch-based composites is a critical business decision that balances mechanical rigor with cost-efficiency. To simplify your material selection, we provide a structured matrix to help you navigate the diverse performance profiles and industrial advantages of modern bioplastics:

Performance & Application Matrix

| Material System | Mechanical Profile | Degradation Speed | Cost Advantage | Key Applications |

| Starch/PLA | High Rigidity | Moderate (Industrial) | Premium Efficiency | Cutlery, Rigid Packs, 3D Filaments |

| Starch/PBAT | High Ductility | Rapid (Home/Soil) | High | Shopping Bags, Mulch, Mailing Bags |

| Fiber/Starch | Structural Strength | Moderate | Maximum (Bio-filler) | Automotive, Pallets, Flower Pots |

Future Horizons (2025-2030): The Next Frontier

The next generation of sustainable bioplastics is moving beyond simple replacement toward high-performance functionalization. We are currently aligning our portfolio with the following global shifts:

100% Bio-based Evolution

Transitioning toward Bio-PBAT and ultra-high starch loading (up to 60%+) to meet stringent EU Plastic Bans and China’s Carbon Neutrality goals.

Advanced Functionalization

Integrating antimicrobial, antioxidant, and flame-retardant properties directly into the polymer matrix for high-value smart packaging.

Nano-Architecture

Utilizing Nanocomposite Reinforcement and multi-layer co-extrusion to achieve barriers and surface finishes that rival conventional engineering plastics.

Beyond Raw Materials: Dedicated Technical Support

While the industry navigates the fundamental pillars of Interfacial Compatibility and Thermal Stability, our resins are engineered to address these hurdles “at the source.” We believe that successful bioplastic production requires more than just high-quality resin; it requires a deep understanding of how these materials behave on the factory floor.

To ensure a seamless transition to our starch-based systems, we offer comprehensive technical guidance and processing parameter advice tailored to your specific equipment. By collaborating with us, you gain access to the expertise needed to optimize your yields and future-proof your product lines against evolving environmental mandates.

Ready to optimize your formulations with the latest starch-blending technologies?

Our experts can help you select the precise grade for your machinery. Contact us today for a Custom Formulation Feasibility Study or to request material samples.

Conclusion & Call-to-Action

Starch-based composites are the strategic pillar of the modern circular economy. Our portfolio offers the most versatile path to reducing your carbon footprint without sacrificing mechanical integrity or profit margins.

The future of high-performance bioplastics is centered on starch-based synergy. By merging renewable origins with engineering-grade performance, we provide a definitive answer to the global demand for circular solutions. Our team is ready to empower your production through customized formulation development, rigorous sample testing, and comprehensive on-site supply chain support designed to maximize your margins while ensuring regulatory compliance.

How we can support your transition today:

- Request a Sample Pack: Test our 2026 high-stability grades on your own machines.

- Custom Formulation: Need a specific MFI or HDT? Our engineers will tailor a starch blend to your specific application.

- Cost-Benefit Analysis: Contact us for a side-by-side comparison of our starch-based resins versus your current material costs.

Direct Contact for Project Inquiries:

Jerry | Project Manager (Starch-Based Division) 📧 Email: jerry@salesplastics.com ;📞 Phone/WhatsApp: +8618657312116