In material engineering, the decision to use acrylonitrile butadiene styrene (ABS) or polypropylene (PP) significantly impacts product performance, durability, and cost-effectiveness. These thermoplastics, each with distinct mechanical and chemical properties, are critical for applications ranging from automotive components to consumer electronics and medical devices. ABS offers superior impact resistance and toughness, making it ideal for structural components requiring durability under stress. In contrast, polypropylene excels in chemical stability and flexibility, suiting applications exposed to harsh environments or requiring lightweight designs.

This guide provides a detailed comparison of ABS and PP, focusing on their mechanical properties, processing characteristics, and practical applications. By understanding their strengths—such as ABS’s notched Izod impact strength of 200-400 J/m or PP’s resistance to pH 2-12 solutions—engineers and manufacturers can optimize material selection to enhance product reliability and market competitiveness. Additionally, factors like cost, ease of processing, and recyclability are explored to support informed decisions that balance performance and sustainability.

What is ABS Plastic?

Acrylonitrile butadiene styrene (ABS) is a robust thermoplastic polymer synthesized from acrylonitrile, butadiene, and styrene, delivering a unique combination of mechanical properties that make it a preferred material for demanding applications. The acrylonitrile component enhances chemical resistance and thermal stability, butadiene provides exceptional impact resistance, and styrene contributes to rigidity and processability. These attributes result in a material with a tensile strength of 35-50 MPa, a notched Izod impact strength of 200-400 J/m, and thermal stability up to 80-90°C, surpassing polypropylene in applications requiring toughness and precision.

ABS excels in versatility, supporting processes like injection molding, extrusion, and machining with ease, which optimizes manufacturing efficiency for components such as automotive instrument panels, electronic enclosures, and consumer product housings. Its density of approximately 1.04-1.06 g/cm³ ensures a balance of strength and lightweight design, while its Rockwell hardness (R 100-110) supports durability under mechanical stress. Compared to PP, ABS offers superior impact resistance and dimensional stability, though it may be less cost-effective for applications prioritizing chemical resistance or flexibility. This makes ABS ideal for engineers and manufacturers aiming to balance performance, durability, and processing efficiency in high-precision designs.

ABS Performance Data

| Property | ABS Performance |

|---|---|

| Tensile Strength | 35-50 MPa |

| Notched Izod Impact Strength | 200-400 J/m |

| Temperature Resistance | 80-90°C |

| Density | 1.04-1.06 g/cm³ |

| Hardness | Rockwell R 100-110 |

| Typical Applications | Automotive instrument panels, electronic enclosures, keyboard casings |

What is Polypropylene (PP) Plastic?

Polypropylene (PP) is a lightweight thermoplastic polymer formed from propylene monomers, characterized by a semi-crystalline structure that balances strength, flexibility, and chemical stability. Its linear hydrocarbon chains and organized molecular arrangement contribute to a low density of 0.90-0.91 g/cm³, a melting point of 160-170°C, and a tensile strength of 27.6-41.4 MPa, making it suitable for applications requiring durability and cost-efficiency. Compared to ABS, PP offers superior chemical resistance (e.g., to pH 2-12 solutions) but lower impact strength, typically 20-50 J/m depending on the formulation.

PP exists in two primary forms: homopolymers, which provide consistent strength and rigidity for applications like automotive battery cases, and copolymers, which offer enhanced flexibility and impact resistance for products like medical syringes and food packaging films. Its ease of processing through injection molding, blow molding, or extrusion, combined with its recyclability and lower cost relative to ABS, makes PP a preferred material for manufacturers prioritizing sustainability and affordability. These attributes ensure PP’s suitability for high-fatigue applications, such as reusable containers and textile fibers, where lightweight design and chemical resistance are critical.

Polypropylene Performance Data

| Property | Polypropylene Performance |

|---|---|

| Tensile Strength | 27.6-41.4 MPa |

| Notched Izod Impact Strength | 20-50 J/m (homopolymer: 20-30 J/m, copolymer: 30-50 J/m) |

| Melting Point | 160-170°C |

| Density | 0.90-0.91 g/cm³ |

| Hardness | Rockwell R 80-90 |

| Typical Applications | Food packaging films, medical syringes, automotive battery cases, textile fibers |

Structural Strength Comparison: ABS vs. Polypropylene

Acrylonitrile butadiene styrene (ABS) and polypropylene (PP) exhibit distinct mechanical properties that drive their suitability for specific applications. ABS offers a tensile strength of 35-50 MPa, surpassing PP’s 27.6-41.4 MPa, making it ideal for components requiring structural rigidity, such as automotive dashboards and electronic enclosures. Its notched Izod impact strength (200-400 J/m) significantly exceeds PP’s (20-50 J/m), ensuring superior toughness in high-impact environments like keyboard casings. Conversely, PP’s heat deflection temperature (HDT) of 100-140°C (at 0.45 MPa) outperforms ABS’s 95-110°C, supporting applications like hot-fill food containers that require thermal stability.

Beyond strength, PP’s lower density (0.90-0.91 g/cm³ vs. ABS’s 1.04-1.06 g/cm³) and excellent chemical resistance (e.g., to pH 2-12 solutions) make it preferred for lightweight, corrosion-resistant products like medical syringes and textile fibers. PP’s lower cost and recyclability further enhance its appeal for sustainable designs, while ABS’s higher hardness (Rockwell R 100-110 vs. PP’s R 80-90) suits precision-molded parts. By evaluating these properties—tensile strength, impact resistance, thermal stability, density, and cost—engineers can match ABS or PP to application needs, optimizing performance and manufacturing efficiency.

Performance Comparison: ABS vs. Polypropylene

| Property | ABS | Polypropylene |

|---|---|---|

| Tensile Strength | 35-50 MPa | 27.6-41.4 MPa |

| Notched Izod Impact Strength | 200-400 J/m | 20-50 J/m |

| Heat Deflection Temperature (0.45 MPa) | 95-110°C | 100-140°C |

| Density | 1.04-1.06 g/cm³ | 0.90-0.91 g/cm³ |

| Hardness | Rockwell R 100-110 | Rockwell R 80-90 |

| Typical Applications | Automotive dashboards, electronic enclosures, keyboard casings | Food-grade containers, medical syringes, textile fibers |

Processing Characteristics: ABS vs. Polypropylene

Acrylonitrile butadiene styrene (ABS) and polypropylene (PP) differ significantly in their processing characteristics, impacting manufacturing efficiency and product quality. Key differences include:

- Melt Temperature: ABS requires 220-250°C, higher than PP’s 190-230°C, affecting energy consumption.

- Injection Speed: PP’s higher melt flow index (MFI: 10-30 g/10min) supports faster injection than ABS (MFI: 5-15 g/10min), reducing cycle times.

- Shrinkage Rate: ABS’s low shrinkage (0.4-0.6%) ensures high precision, while PP’s higher shrinkage (1.0-2.5%) requires careful mold design.

- Cooling Time: PP cools faster (10-20 seconds) than ABS (15-30 seconds), enhancing throughput.

- Mold Pressure: PP needs lower pressure (70-100 MPa) compared to ABS (100-140 MPa), reducing equipment wear.

Impact on Manufacturing

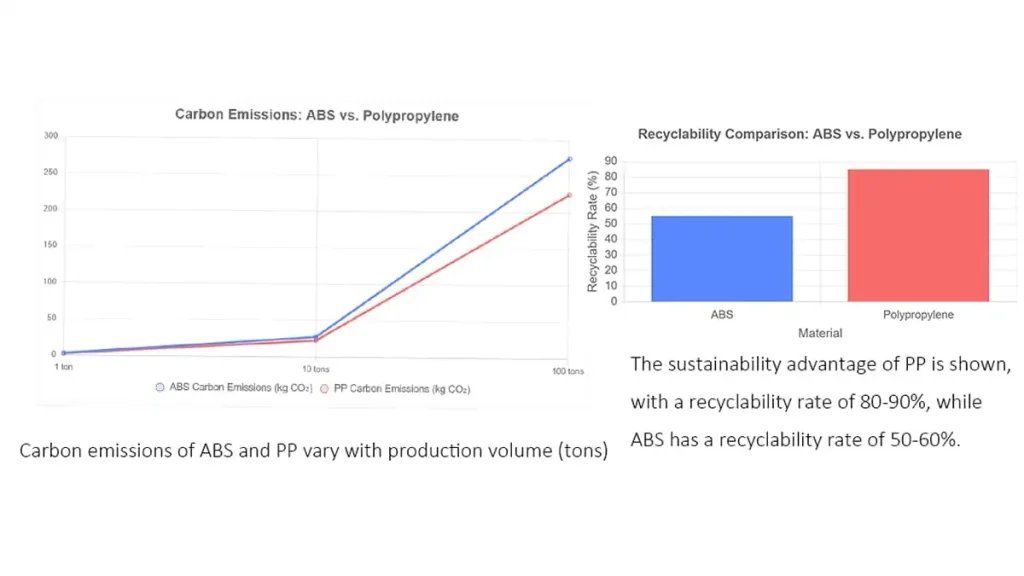

PP’s lower melt temperature and faster cooling reduce energy consumption by approximately 10-15% compared to ABS, making it cost-effective for high-volume production, such as Tupperware food containers. Its recyclability (80-90% recovery rate) further supports sustainable manufacturing. Conversely, ABS’s low shrinkage and superior surface finish make it ideal for precision components like Samsung electronic enclosures, though its higher processing temperature and complexity may increase mold costs and waste (recyclability ~50-60%). By matching these characteristics to production needs, manufacturers can optimize efficiency, cost, and sustainability.

Applications of ABS and Polypropylene

ABS Applications

Acrylonitrile butadiene styrene (ABS) is valued for its high impact resistance (200-400 J/m) and excellent surface finish, making it ideal for applications requiring durability and aesthetic appeal:

- Automotive Interior Components: Dashboard panels (e.g., Tesla Model 3) leverage ABS’s rigidity (tensile strength 35-50 MPa) and dimensional stability (shrinkage 0.4-0.6%) for precise, durable parts.

- Electronic Device Housings: Laptop casings (e.g., Apple MacBook) benefit from ABS’s toughness and smooth finish, ensuring protection and visual appeal.

- Consumer Electronics: Keyboard casings utilize ABS’s hardness (Rockwell R 100-110) for wear resistance in high-use devices.

- Musical Instrument Components: Guitar picks exploit ABS’s impact strength and moldability for consistent performance.

- 3D Printing Prototypes: ABS’s processability in additive manufacturing supports rapid prototyping with reliable mechanical properties.

PP Applications

Polypropylene (PP) excels in applications requiring lightweight design (density 0.90-0.91 g/cm³) and chemical resistance (e.g., to pH 2-12 solutions):

- Medical Device Manufacturing: Sterile syringes capitalize on PP’s chemical stability and recyclability (80-90%) for safe, cost-effective production.

- Food Packaging Solutions: Nestlé food containers rely on PP’s low density and thermal stability (HDT 100-140°C) for hot-fill applications.

- Automotive Fluid System Components: Battery casings use PP’s corrosion resistance and low cost ($1,200-1,500/ton) for durability in harsh environments.

- Laboratory Equipment: Test tubes benefit from PP’s chemical inertness, ensuring compatibility with diverse substances.

- Textile and Fabric Production: Carpet fibers leverage PP’s flexibility and fatigue resistance for long-lasting textiles.

Comparative Insights

ABS’s superior impact strength and surface finish make it preferred for precision components requiring durability and aesthetics, such as automotive and electronic applications. However, its higher cost ($1,500-1,800/ton) and lower recyclability (50-60%) may limit its use in cost-sensitive or sustainable designs. PP’s lightweight nature, chemical resistance, and lower processing costs (10-15% less energy than ABS) suit high-volume, corrosion-resistant products like packaging and medical devices. By matching material properties—ABS’s toughness (200-400 J/m) versus PP’s chemical stability and low density—to project needs, manufacturers can optimize performance, cost, and sustainability.

| Material | Key Applications | Driving Properties |

|---|---|---|

| ABS | Dashboard panels, laptop casings, keyboard casings, guitar picks, 3D printing prototypes | High impact strength (200-400 J/m), low shrinkage (0.4-0.6%), hardness (Rockwell R 100-110) |

| PP | Sterile syringes, food containers, battery casings, test tubes, carpet fibers | Low density (0.90-0.91 g/cm³), chemical resistance (pH 2-12), recyclability (80-90%) |

Sustainability and Environmental Impact

The environmental profiles of acrylonitrile butadiene styrene (ABS) and polypropylene (PP) significantly influence material choices in manufacturing. Key differences include:

- Production Energy: ABS requires 500-550 kWh/ton, emitting 2.5-3.0 kg CO₂/kg, while PP uses 450-475 kWh/ton, emitting 2.0-2.5 kg CO₂/kg (10-15% less).

- Recyclability: PP’s simpler structure enables 80-90% recyclability, supporting circular economy principles, whereas ABS’s complex composition limits recycling to 50-60%, often leading to landfill waste.

- Density and Emissions: PP’s lower density (0.90-0.91 g/cm³ vs. ABS’s 1.04-1.06 g/cm³) reduces transportation emissions, enhancing sustainability for applications like food packaging (e.g., Nestlé containers) and medical syringes.

- Cost: PP ($1,200-1,500/ton) is 10-20% cheaper than ABS ($1,500-1,800/ton), aligning with cost-effective, eco-conscious production.

PP’s lower energy consumption and high recyclability make it preferable for sustainable manufacturing, while ABS suits durable applications despite higher environmental impact. Innovations like bio-based PP and chemical recycling are reducing the environmental footprint of both materials, aligning with regulations like the EU’s Circular Economy Action Plan.

Optimizing Material Selection for Your Clients

Selecting the right thermoplastic—ABS or PP—drives performance, cost-efficiency, and sustainability in industries like automotive and packaging. Collaborate with our team to access high-quality ABS and PP pellets tailored to your needs, backed by our reliable supply chain. Follow these streamlined steps to make informed material decisions:

- Test Mechanical Properties: Perform tensile and impact tests to confirm ABS’s toughness (200-400 J/m) for durable parts or PP’s chemical stability for corrosive environments.

- Prototype Designs: Use 3D printing to validate ABS’s precision or PP’s flexibility, ensuring fit and function in real-world conditions.

- Simulate Performance: Run finite element analysis with tools like ANSYS to predict material behavior under stress or heat.

- Calculate Cost Efficiency: Weigh PP’s lower cost ($1,200-1,500/ton) against ABS’s durability ($1,500-1,800/ton) for budget optimization.

- Prioritize Sustainability: Choose PP for high recyclability (80-90%) or ABS for long-term durability (50-60% recyclability).

- Customize Solutions: Tailor ABS or PP with additives or colors to meet specific project requirements.

Our expertise ensures you select the optimal material for your application.

Material Selection Guide

| Factor | ABS | Polypropylene |

|---|---|---|

| Tensile Strength | 35-50 MPa | 27.6-41.4 MPa |

| Impact Strength | 200-400 J/m | 20-50 J/m |

| Heat Deflection Temp | 95-110°C (0.45 MPa) | 100-140°C (0.45 MPa) |

| Density | 1.04-1.06 g/cm³ | 0.90-0.91 g/cm³ |

| Recyclability | 50-60% | 80-90% |

| Cost | $1,500-1,800/ton | $1,200-1,500/ton |

| Applications | Electronic enclosures, automotive trim | Food containers, medical syringes |

Contact our specialists today for detailed material insights or tailored ABS and PP solutions to elevate your project’s success.

Conclusion

ABS delivers superior impact strength (200-400 J/m) and precision for durable applications like automotive dashboards and electronic enclosures. PP’s chemical resistance, low density (0.90-0.91 g/cm³), and high recyclability (80-90%) excel in cost-effective, sustainable products like food containers and medical syringes. Advances in bio-based plastics and recycling align both materials with global sustainability goals. Work with our dedicated team to source high-quality ABS and PP pellets tailored to your project’s needs. Reach out today via email at jerry@salesplastics.com or call +8618657312116 to request samples or discuss your specific requirements.

FAQs

A:Polypropylene (PP) has a tensile strength of 27.6-41.4 MPa, slightly lower than ABS’s 35-50 MPa, but its impact strength (20-50 J/m) is significantly less than ABS’s 200-400 J/m. ABS excels in toughness for high-impact applications like electronic enclosures, while PP’s flexibility suits less demanding uses like food packaging.

A:ABS offers higher tensile strength (35-50 MPa) and impact resistance (200-400 J/m) compared to high-density polyethylene (HDPE), which has a tensile strength of 20-30 MPa and impact strength of 50-100 J/m. ABS is ideal for durable components like automotive dashboards, while HDPE suits flexible, lightweight applications like bottles.

A:PP’s tensile strength (27.6-41.4 MPa) is comparable to or slightly higher than HDPE’s (20-30 MPa), but its impact strength (20-50 J/m) is lower than HDPE’s (50-100 J/m). PP’s superior chemical resistance (pH 2-12) makes it ideal for medical syringes, while HDPE is preferred for flexible containers.

A:ABS combines high impact strength (200-400 J/m), tensile strength (35-50 MPa), and hardness (Rockwell R 100-110) for durable applications like laptop casings. PP offers low density (0.90-0.91 g/cm³), chemical resistance (pH 2-12), and recyclability (80-90%) for cost-effective, sustainable products like food containers.

A:ABS’s toughness (200-400 J/m) and low shrinkage (0.4-0.6%) make it ideal for automotive dashboards and electronic enclosures, ensuring durability and precision. PP’s low cost ($1,200-1,500/ton) and thermal stability (HDT 100-140°C) suit packaging like food containers and automotive battery cases.