Rising concerns about plastic pollution have driven the search for alternatives such as polylactic acid (PLA), a polymer derived from renewable plant sources like corn starch. Promoted as an eco-friendly option, PLA has seen increased adoption in applications ranging from single-use packaging to additive manufacturing in 3D printing. Yet, does PLA degrade biologically under real-world conditions as often asserted? This in-depth guide dissects the scientific evidence on PLA’s biodegradation—requiring specific industrial composting environments rather than natural settings—assesses its full lifecycle environmental footprint, including greenhouse gas emissions during production, and evaluates it against other bioplastics for truly sustainable choices.

What is PLA? A Deep Dive into Its Composition and Origins

Polylactic Acid, or PLA, stands out as a leading bioplastic derived from renewable plant sources. Unlike conventional plastics made from fossil fuels, PLA is sourced from starches found in plants like corn, sugarcane, or cassava. This unique origin makes it a prime example of a sustainable and circular material.

The journey of PLA begins with the fermentation of these plant-based starches into lactic acid. This lactic acid is then converted into long polymer chains through a process called polymerization, which gives PLA its robust and versatile properties.

Initially synthesized by chemist Théophile-Jules Pelouze in the 19th century, PLA remained a niche material for decades. It was primarily valued for its biocompatibility and biodegradability, making it a key material in biomedical fields like surgical implants and sutures. Following a patent by DuPont in the mid-20th century and subsequent advancements in production, PLA has since expanded into a vast array of commercial applications, from food packaging and bottles to 3D printing filaments.

A key feature of PLA’s molecular structure is the presence of ester bonds. These bonds are susceptible to hydrolysis—a process where they can break down in the presence of water and specific environmental conditions. This characteristic is fundamental to understanding PLA’s potential for biodegradation, setting it apart from traditional plastics.

Benefits of PLA in Modern Applications

PLA has emerged as a leading material in the shift toward sustainable solutions, offering a compelling blend of performance and environmental responsibility. Its properties allow it to directly compete with conventional plastics across various sectors, making it more than just an eco-friendly alternative. Unlike many other bioplastics, PLA’s versatility, which includes its rigidity, clarity, and ease of processing, has enabled it to transition from niche applications to mainstream use.Versatile Applications Across Industries:

Packaging Industry

With its excellent clarity, stiffness, and printability, PLA is a popular choice for sustainable packaging. It serves as a durable and attractive alternative to traditional plastics for a variety of products, including disposable cups, cutlery, and containers. Its strong resistance to grease and oil makes it particularly useful in the food service industry.

3D Printing

PLA has become the definitive material for desktop 3D printing due to its user-friendly characteristics. It melts at a low temperature and produces minimal odor, making it safe and accessible for use in home or office environments. Its ease of printing and high rigidity make it ideal for creating prototypes, models, and decorative items with precise details.

Textile Industry

PLA fibers are processed into fabrics that offer a sustainable alternative to polyester and other synthetic textiles. These materials boast a silky luster and good drapability, along with functional properties like moisture-wicking and quick-drying. This makes them increasingly popular for clothing, sportswear, and home furnishings, aligning with the growing demand for eco-friendly fabrics.

Medical Applications

The medical field was an early adopter of PLA due to its unique biocompatibility. When used in the human body, PLA gradually breaks down into harmless lactic acid, eliminating the need for follow-up surgeries to remove devices. Its applications include resorbable sutures, orthopedic implants like screws and pins that provide temporary support, and innovative drug delivery systems.

Beyond its functional properties, a core benefit of PLA is its positive environmental impact. The production process requires significantly less fossil fuel and generates fewer greenhouse gas emissions than conventional plastic manufacturing. Studies have indicated that PLA production can emit up to three times less CO2 compared to the creation of traditional plastics, positioning it as a cornerstone of a more sustainable future.

Is PLA Truly Biodegradable and Compostable? Debunking Myths

The biodegradability of PLA is a topic often met with confusion. To understand its true nature, it’s crucial to first differentiate between a material being biodegradable and compostable. While both processes involve a material breaking down, compostability is a more specific and rigorous standard.

A compostable material must not only biodegrade but also completely break down into CO2, water, and biomass at a rate consistent with established standards like ASTM D6400 (North America) and EN 13432 (Europe), without leaving behind any toxic residue.

PLA is indeed biodegradable, but it’s a conditional process. Its degradation is a two-stage mechanism that is heavily dependent on specific environmental factors:

1.Hydrolysis: The process begins with water molecules attacking and breaking the long polymer chains of the PLA. This initial step reduces the material’s molecular weight, making it brittle and weak.

2.Microbial Action: Once the PLA has been broken down into smaller fragments by hydrolysis, microorganisms present in the environment can then metabolize these pieces. They convert the remaining material into biomass, CO2, and water.

| Environment | Temperature | Humidity | Approximate Degradation Time |

| Industrial Composting | 58°C+ (136°F+) | 70%+ | 30-90 days |

| Home Composting | 20-30°C (68-86°F) | Variable | Several years to decades |

| Landfill | Variable | Variable | 100+ years |

| Marine Environment | 4-25°C (39-77°F) | 100% | Decades to centuries |

The data above shows the essential takeaway: PLA requires the high temperatures and specific humidity of an industrial composting facility to biodegrade efficiently. In environments like a backyard compost bin, landfill, or the ocean, PLA’s decomposition rate is significantly slower, often comparable to conventional plastics. This reality underscores the importance of proper waste management infrastructure for PLA to fulfill its promise as a sustainable material.

Challenges and Environmental Impacts of PLA

While PLA presents a compelling environmental profile compared to petroleum-based plastics, a complete assessment requires a look at its inherent challenges and potential negative impacts. The path to a truly sustainable plastic is complex, and PLA is no exception. A comprehensive Life Cycle Assessment reveals that while PLA excels in certain areas, such as a lower carbon footprint during production, it also has drawbacks that must be critically examined. These challenges primarily fall into two categories: the upstream impacts related to its agricultural feedstock and the downstream issues concerning its end-of-life fate.

Environmental Benefits

- Derived from renewable resources rather than fossil fuels

- Lower carbon footprint during production (approximately 3x less CO2)

- Biodegradable under specific conditions

- Non-toxic during use and processing

- Reduced dependence on petroleum resources

Environmental Challenges

- Requires industrial composting facilities for proper biodegradation

- Agricultural impacts from feedstock production (land use, fertilizers)

- Potential competition with food production for land resources

- Energy-intensive production process

- Limited recycling infrastructure specific to PLA

The cultivation of crops like corn and sugarcane for feedstock requires significant land, water, and energy. This raises important questions about land use competition with food production, a critical issue as the global population grows. Furthermore, the use of fertilizers and pesticides in this process can contribute to greenhouse gas emissions, including nitrous oxide, a gas with a warming potential far greater than carbon dioxide.

Additionally, the limited availability of industrial composting facilities means that much PLA waste still ends up in landfills. This renders its biodegradability benefit moot, as it can persist for decades or longer in these conditions.

When improperly disposed of, PLA can also cause major contamination in conventional recycling streams. Even small amounts of PLA can compromise the quality of recycled PET (polyethylene terephthalate), a critical hurdle that must be addressed for PLA to be a truly sustainable solution.

PLA Production and Supply Chain: Key Considerations for Sourcing

For businesses aiming to adopt sustainable materials, a clear understanding of PLA’s production process and supply chain is essential for making informed sourcing decisions. This strategic approach begins with an understanding of the material’s global market dynamics and its projected growth, which are key to assessing long-term viability and supply chain stability.

Global Production Capacity

The global market for bioplastics, including PLA, is experiencing substantial growth. According to the Market Data Report 2023 from European Bioplastics, in cooperation with the nova-Institute, production capacity is projected to increase significantly from approximately 2.18 million tonnes in 2023 to around 7.43 million tonnes in 2028. This significant expansion is a direct result of rising global demand for sustainable alternatives to conventional plastics and a strong development in polymers like PLA. This trend indicates a robust and expanding market for businesses looking to integrate bioplastics into their supply chain.

Quality Considerations

When sourcing PLA, it is critical to evaluate specific material properties that directly impact performance and processing.

- Molecular weight: Higher molecular weight generally leads to superior mechanical properties and strength.

- D-isomer content: This factor influences the material’s crystallinity and heat resistance, which are crucial for specific applications.

- Additives: The presence of additives can enhance performance, but their impact on the material’s biodegradability should be carefully considered.

- Purity: High purity is vital for achieving optimal transparency and consistent processing behavior.

- Certification: Look for materials certified to relevant compostability standards

Certifications to Look For

To verify the environmental claims and quality of PLA materials, look for recognized third-party certifications. Key standards include:

ASTM D6400

U.S. standard for compostable plastics in industrial facilities

EN 13432

European standard for compostable packaging

ISO 17088

International standard for compostable plastics

Beyond certifications, it is advisable to vet suppliers based on their transparency regarding feedstock sourcing and production methods. Leading global manufacturers of PLA include NatureWorks, Total Corbion PLA, and Futerro.

Proper storage and handling are critical to maintaining PLA’s quality. The material is sensitive to moisture and heat, which can cause hydrolysis and degrade its properties. PLA pellets should be stored in dry conditions below 50°C (122°F) and must be thoroughly dried before processing to ensure optimal performance.

Can PLA Be Recycled? Exploring Alternatives

While industrial composting is often highlighted as PLA’s primary end-of-life solution, recycling presents another crucial pathway that warrants consideration. Understanding the recycling landscape is essential for a comprehensive view of PLA’s sustainability. However, this pathway is not without significant challenges in today’s waste management systems.

Current Recycling Landscape

Recycling PLA faces significant challenges within existing waste management infrastructure.

- Contamination Risk: PLA’s similar appearance to PET can lead to contamination of conventional recycling streams, compromising the quality of recycled materials.

- Limited Infrastructure: Most recycling facilities are not equipped with the specific sorting and processing technology required for PLA.

- Economic Barriers: The relatively low volume of PLA waste currently makes it economically challenging to establish dedicated collection and recycling systems.

Despite these hurdles, PLA is technically recyclable through both mechanical and chemical processes. Mechanical recycling involves shredding and melting the material to create new products, while chemical recycling breaks PLA down into its base monomers for repolymerization.

End-of-Life Hierarchy for PLA

For optimal environmental outcomes, the end-of-life management of PLA should follow a clear hierarchy. This framework prioritizes the most sustainable options and serves as a guide for both product design and disposal.

- Reduction: Minimize material use at the source wherever possible.

- Reuse: Design and utilize PLA products for multiple uses.

- Recycling: Direct clean PLA waste to dedicated recycling streams.

- Industrial Composting: Process products in certified facilities.

- Energy Recovery: Use incineration with energy capture as a last resort.

- Landfill: This is the least preferred option due to PLA’s slow degradation in a landfill environment.

Additionally, while some companies are developing additives to enhance PLA’s biodegradability, these must be carefully evaluated to ensure they do not contribute to microplastic pollution or compromise recycling streams. For a more in-depth look at PLA recycling, please see our dedicated article, “PLA Recycling.”

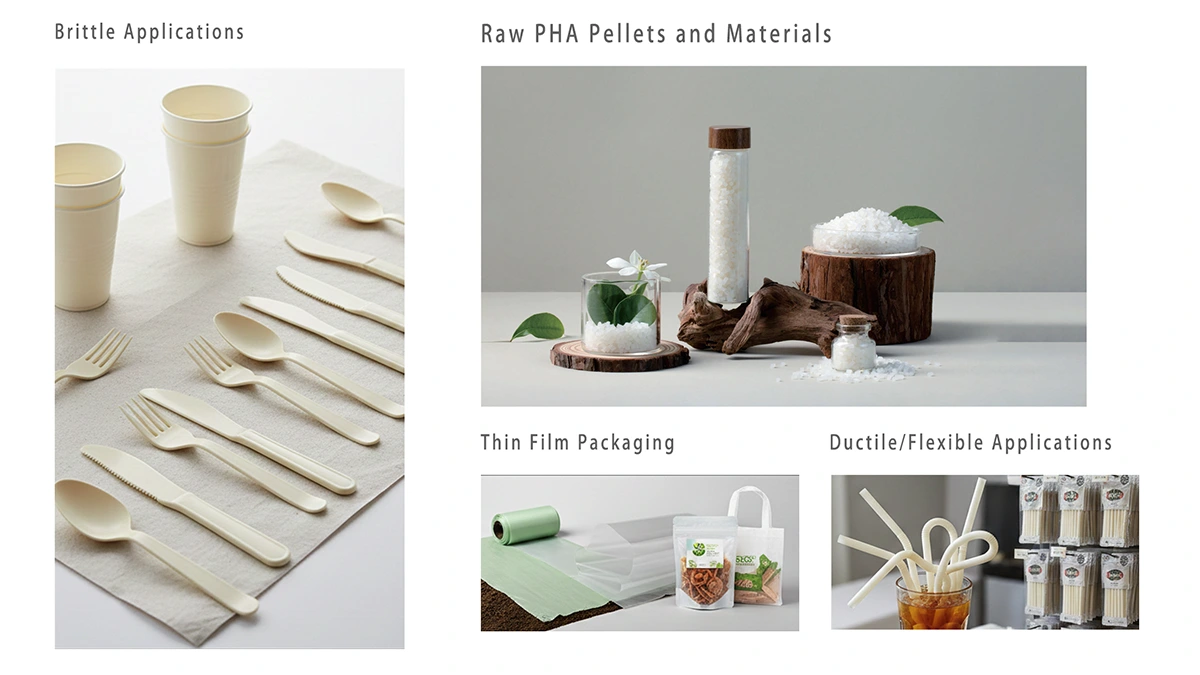

PLA vs. Other Bioplastics: A Comparative Analysis

While PLA is a prominent bioplastic, it is just one of several options available today. A comparative analysis with other alternatives provides a broader perspective, helping to inform the best material choice for specific applications. The following table provides a quick overview of how PLA stacks up against other common bioplastics.

| Property | PLA | PHA | Starch-based | Cellulose-based |

| Source | Corn, sugarcane | Microbial fermentation | Corn, potato, wheat | Wood, cotton |

| Biodegradability | Industrial composting | Marine, soil, home compost | Home compostable | Variable |

| Mechanical Properties | Rigid, brittle | Flexible to rigid | Moderate, moisture sensitive | Strong, rigid |

| Heat Resistance | Low (55-60°C) | Medium (80-120°C) | Low | Medium to high |

| Cost | Moderate | High | Low to moderate | Moderate to high |

Polyhydroxyalkanoates (PHA) offer a key advantage in their superior biodegradability, capable of breaking down in a wider range of natural environments, including marine and soil settings. However, this comes at a higher production cost and with more variable properties depending on the specific polymer.

Starch-based bioplastics, often used for films and packaging, can be more readily compostable in home settings. The trade-off is often inferior mechanical properties and greater sensitivity to moisture compared to PLA.

Cellulose-based materials, derived from wood pulp or cotton, offer excellent strength and rigidity, making them suitable for structural applications. Their biodegradability, however, varies widely and depends heavily on chemical modifications and additives used during production.

This comparison highlights that each bioplastic presents a unique set of trade-offs between performance, cost, and environmental benefits, guiding material decisions based on the end-use requirements of a product.

Reducing Environmental Impact: Practical Tips for Sustainable Use

Maximizing the environmental benefits of PLA requires conscious decisions from both businesses and consumers. These practical guidelines can help ensure PLA is used and disposed of in a way that aligns with its sustainable promise. The responsibility for sustainable use lies at every stage of the product’s life, from design to disposal. The following sections provide actionable steps for each group to contribute to a more sustainable PLA lifecycle.

For Businesses

Design Considerations

- Design for End-of-Life: Design products with their final destination in mind, whether that’s industrial composting or dedicated recycling streams.

- Minimize Material Use: Employ efficient design practices to reduce the overall amount of material needed for a product.

- Clear Labeling: Label products with clear, unambiguous instructions on how to properly dispose of them to prevent contamination.

Supply Chain Management

- Verify Certifications: Prioritize sourcing PLA from suppliers who provide third-party certifications (e.g., ASTM D6400) to validate environmental claims.

- Seek Transparency: Partner with suppliers that are transparent about their feedstock sourcing and agricultural practices to ensure a truly sustainable supply chain.

- Local Sourcing: Consider regional sourcing to reduce transportation emissions and support local economies.

For Consumers

- Check Local Capabilities: Before buying PLA products, verify that your local waste management or composting facilities can process them.

- Look for Labels: Always check for certification labels on products to confirm their compostability claims.

- Reuse First: Prioritize durability and reusability. A reusable product, even if not compostable, often has a lower overall impact than a single-use alternative.

It is crucial to remember that PLA should never be mixed with conventional plastic recycling unless specifically instructed. Contamination can compromise entire batches of recycled materials, undermining the very recycling systems we rely on.

Conclusion: Navigating PLA Responsibly in a Sustainable Future

PLA represents a significant step in the evolution of sustainable plastics, offering a clear path to reduced reliance on fossil fuels and a viable alternative to conventional materials. However, its environmental benefits are not a given; they are highly dependent on responsible production practices and proper end-of-life management.

The biodegradability of PLA is a powerful advantage, but it is one that requires careful management. Its potential is fully realized only within industrial composting facilities, which remain limited in many regions. This reality underscores a core principle of sustainability: there is no single perfect solution. The most responsible approach is to consider a material’s complete lifecycle impact, from the sourcing of raw materials to its ultimate disposal.

By understanding both the distinct advantages and the inherent challenges of PLA, businesses and consumers can move beyond marketing claims to make truly informed decisions. This informed approach is what will ultimately drive the development of better waste management infrastructure and foster a more genuinely sustainable future for materials like PLA.

For expert guidance on sourcing the right PLA pellets for your specific needs, or to learn more about our product offerings, contact our team today. We are here to help you navigate the complexities of sustainable plastics and find the ideal solution for your applications.

Email: jerry@salesplastics.com

Phone: +8618657312116

Frequently Asked Questions

Is PLA truly biodegradable?

Yes, PLA is biodegradable, but this is a conditional process. It requires the high temperatures, specific humidity, and microbial activity found in an industrial composting facility to break down efficiently. In these controlled environments, PLA can biodegrade into water, CO2, and biomass within 30 to 90 days. However, in natural settings like a home compost pile, landfill, or the ocean, it biodegrades extremely slowly and can persist for decades or centuries, much like conventional plastics.

How is PLA different from PETG? Is PETG biodegradable?

PLA and PETG are both popular plastic materials, but they have key differences. PLA is a bioplastic made from renewable resources like corn starch and is biodegradable under industrial composting conditions. PETG (Polyethylene Terephthalate Glycol), on the other hand, is a petroleum-based plastic. PETG is not biodegradable or compostable, and its end-of-life is typically incineration or recycling, where possible. For a more detailed comparison of these two materials, please refer to our dedicated article, ‘PETG vs PLA‘.

What is PLA made of?

PLA is a type of plastic, specifically a bioplastic. It is made from fermented plant starches, most commonly from corn, sugarcane, or cassava roots. The starch is converted into lactic acid, which is then polymerized to form the long chains that make up PLA. This plant-based origin is what makes it a bioplastic.

Is PLA recyclable?

PLA is technically recyclable, but it faces significant challenges within the current recycling infrastructure. Most municipal recycling facilities are not equipped to process PLA, and its similar appearance to PET can lead to contamination of PET recycling streams, compromising the quality of the recycled material. Therefore, while recycling is a potential end-of-life pathway, it is currently not a widespread or reliable option. For a more detailed look at this topic, please see our dedicated article, ‘PLA Recycling‘.

Is PLA food-safe?

Yes, PLA is widely regarded as food-safe. It is used for many food-related applications, including packaging, disposable cutlery, and food containers. Its use in the medical field for implants and sutures also attests to its biocompatibility and non-toxic nature. For more comprehensive information, you can refer to our article on this subject, ‘PLA and Food Safety‘.

Does PLA biodegrade in a landfill or in the human body?