This article examines the long-term trajectory of biodegradable materials as replacements for conventional plastics. We highlight key alternatives, home compostability progress, policy forces, and a realistic hierarchy for tackling plastic pollution.

The Contenders

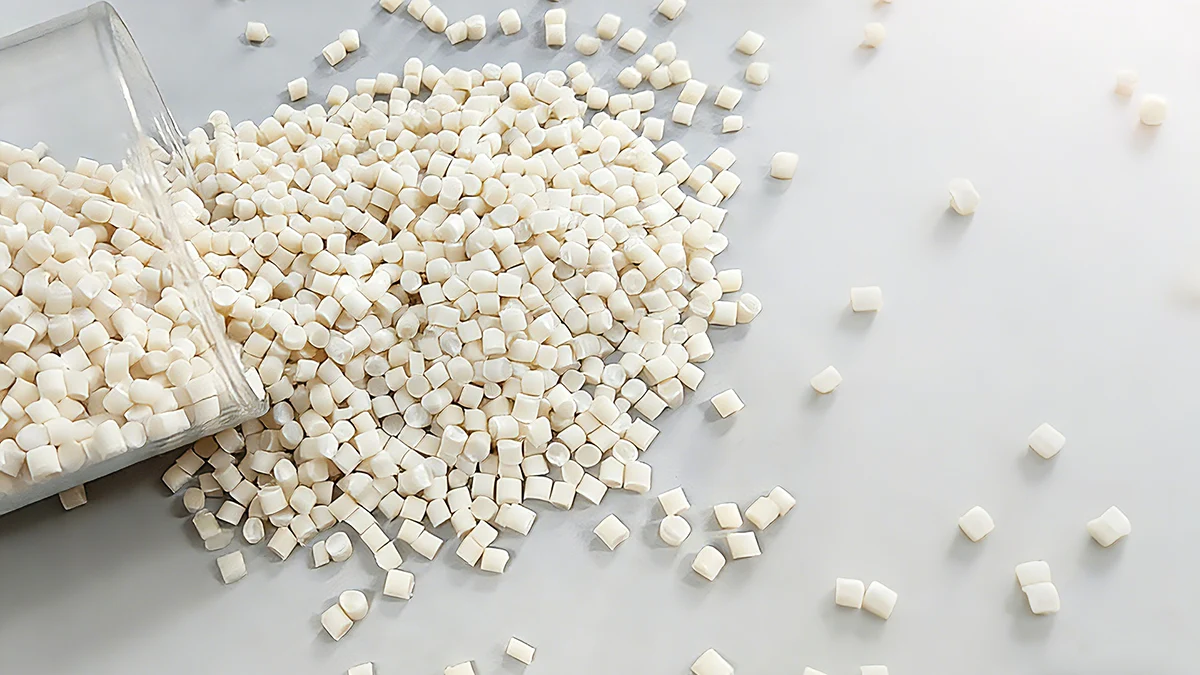

PLA vs PHA, PBAT, PBS: Which Holds the Strongest Future?

PLA

The mainstream choice for rigid packaging and 3D printing. Leads in clarity and cost-efficiency.

PHA

The fastest-rising contender. True biodegradability in marine and soil environments.

PBAT

Excels in flexibility. Frequently blended with PLA for bags and agricultural films.

PBS

Steady niche with good heat resistance. Ideal for high-temp packaging.

Projected Timeline

PLA + PBAT blends lead due to cost-performance balance and production scale.

PHA surges fastest, likely forming a dual-leadership pattern with PLA in premium segments.

For a detailed introduction to PLA, its production, environmental behavior, performance comparison with traditional plastics, limitations, best use cases, greenwashing risks, and FAQs (e.g., “Is PLA actually better than plastic?” or “Does PLA turn into microplastics?”), see our comprehensive guide: PLA vs Traditional Plastic: Why Choose Biodegradable Materials?

Progress Toward Home-Compostable Materials

Most biodegradable plastics today (PLA, PBAT, PBS) require industrial composting facilities (high temp/humidity). True home compostability remains technically challenging as household compost lacks the intense thermophilic phase.

- Recent Advances: Enhanced PHA variants, enzyme-boosted composites, and starch blends.

- 2030 Projection: Home-compostable options <10–15% market share.

- Regulation: Stricter laws and consumer awareness will accelerate R&D.

"Industrial composting infrastructure will remain essential for large-volume applications."

Policy & Market Drivers (2025–2030)

Global bioplastics capacity to double from 2.3M (2025) to 4.7M tonnes (2030).

Packaging accounts for the largest portion of the projected market growth.

The primary engine of growth, driven by carbon goals and massive capacity build-out.

A Practical Hierarchy

Biodegradable materials are valuable but not a complete fix. We advocate for a widely accepted priority order:

Reduce First

Cut plastic use through lightweighting, reusables, and smarter design.

Reuse & Recycle Next

Maximize closed-loop systems for conventional plastics and bio-based non-degradables.

Biodegradable / Compostable Last

Apply only where recycling is impractical (e.g., contaminated food packaging).

Related Posts

Biodegradation Performance and Environmental Impact of PHA Bioplastics

Polyhydroxyalkanoates (PHA) are biodegradable polymers produced by microorganisms, offering a revolutionary solution for a plastic-free future. “Research highlights PHA’s ability to break down in diverse environments. This section examines evidence

Starch Based Biodegradable Plastics: Materials, Applications, and Commercial Reality

As global plastic regulations tighten, starch-based biodegradable plastics have transitioned from a promising alternative to a comprehensive commercial solution. By leveraging the natural polymer structure of starch, these materials offer

Material ComparisonStarch-Based Plastics vs PLA vs PBAT vs PHA

Understanding the differences between biodegradable materials is critical for selecting the right solution. Below is a realistic comparison from a materials and application perspective. For a deeper exploration of starch-based

POM GB-25: From Properties to Supply – Comprehensive Technical Guide

Polyoxymethylene with 25% Glass Bead reinforcement (POM GB-25) represents a critical niche in engineering thermoplastics. By bridging the gap between the ductility of standard Acetal and the rigidity of glass