Nylon 6 and Nylon 66, two cornerstone polyamides, are integral to engineering applications, from automotive components to high-performance textiles, due to their exceptional tensile strength, thermal stability, and processability. These semi-crystalline thermoplastics, characterized by amide linkages (-CONH-), combine rigid crystalline regions for durability with amorphous areas for flexibility, making them ideal for demanding environments. Despite their shared backbone, differences in molecular structure—stemming from Nylon 6’s caprolactam base and Nylon 66’s hexamethylene diamine and adipic acid composition—result in distinct mechanical, thermal, and processing properties. This article provides a detailed comparison of their performance, production processes, and cost implications, equipping engineers and manufacturers with insights to optimize material specification for specific applications, including considerations of sustainability and market trends.

Chemical Structure and Production Processes

Figure 1: Chemical structures of Nylon 6 (left) and Nylon 66 (right)

Nylon 6 and Nylon 66, cornerstone polyamides, exhibit distinct chemical compositions and production methods that dictate their mechanical performance, scalability, and cost-effectiveness. Nylon 6’s single-monomer structure, derived from caprolactam, enables a streamlined production process, while Nylon 66’s dual-monomer synthesis, involving hexamethylenediamine and adipic acid, yields higher crystallinity and strength. These differences influence critical properties like tensile strength, thermal stability, and environmental impact, guiding engineers and manufacturers in optimizing material specification for applications ranging from automotive components to high-performance textiles.

Nylon 6: Derived from caprolactam (C6H11NO), a single monomer with six carbon atoms, it is polymerized through a streamlined ring-opening process at lower temperatures. This enables cost-effective, high-volume production with widely available raw materials.

Nylon 66: Synthesized from hexamethylenediamine and adipic acid, each contributing six carbon atoms—hence the designation “66”. Condensation polymerization forms amide bonds, releasing water as a byproduct. This energy-intensive process requires precise control to ensure high-purity monomers, yielding a more symmetrical molecular structure with enhanced crystallinity.

While Nylon 6’s simpler production facilitates scalability, it may exhibit slight batch variability. Conversely, Nylon 66’s rigorous process ensures uniformity, critical for high-precision components in aerospace and automotive applications. Additionally, Nylon 6 benefits from lower raw material costs due to its single-monomer reliance, whereas Nylon 66’s dual-monomer process may increase waste management demands due to water byproducts, impacting sustainability considerations.

Key Material Properties Comparison

| Property | Nylon 6 | Nylon 66 |

| Melting Point | 215-220°C | 250-265°C |

| Density | 1.13 g/cm³ | 1.14 g/cm³ |

| Moisture Absorption | Higher (3.5% equilibrium) | Lower (2.5% equilibrium) |

| Heat Deflection Temperature | Lower | Higher |

| Crystallinity | Less crystalline | More crystalline |

| Abrasion Resistance | Withstands ~40,000 cycles | Withstands ~60,000 cycles (50% higher) |

| Heat Age Strength at 180°C | ~25 MPa (after 1000 hours, ASTM D638, dry state) | ~40 MPa (after 1000 hours, ASTM D638, dry state) |

Figure 2: Comparative analysis of key physical properties

Thermal Properties

The higher melting point of Nylon 66 (250-265°C vs. 215-220°C for Nylon 6) translates to superior performance in high-temperature environments. This becomes particularly evident when examining heat age strength: at 180°C, Nylon 66 maintains 11.5 kg of strength compared to Nylon 6’s dramatic drop to just 2.6 kg. This significant difference makes Nylon 66 the preferred choice for applications involving sustained high-temperature exposure.

Moisture Absorption and Dimensional Stability

Both nylons absorb moisture due to their amide groups forming hydrogen bonds with water molecules. However, Nylon 6 exhibits higher water absorption (3.5% at equilibrium compared to 2.5% for Nylon 66). This characteristic affects dimensional stability, with moisture absorption causing volume expansion and reductions in modulus, tensile strength, and hardness. Applications requiring precise dimensional tolerances in humid environments may benefit from Nylon 66’s lower moisture sensitivity.

Mechanical Performance Comparison

Nylon 6 and Nylon 66 both offer tensile strengths of 70–90 MPa, with Nylon 66 providing higher stiffness and abrasion resistance—about 50% better than Nylon 6. Nylon 6 excels in impact resistance, flex fatigue, and elastic recovery, while Nylon 66 shows superior creep resistance and rigidity. Nylon 6 also has lower mold shrinkage, aiding dimensional accuracy. Chemical resistance differs: Nylon 6 resists hydrocarbons better, Nylon 66 resists acids more effectively.

Nylon 6 Strengths

- Superior impact resistance, especially at low temperatures

- Better flex fatigue resistance

- Higher elastic recovery

- Lower mold shrinkage (dimensional accuracy)

- Excellent resistance to hydrocarbons

Nylon 66 Strengths

- Higher tensile strength and modulus

- Superior wear and abrasion resistance (33% better)

- Better creep resistance under sustained loads

- Higher stiffness and rigidity

- Superior acid resistance

The mechanical performance differences stem directly from their molecular structures. Nylon 66’s higher crystallinity creates a more rigid material with excellent load-bearing capacity but somewhat reduced impact resistance. Nylon 6’s more flexible molecular arrangement provides better impact absorption and elastic recovery, making it ideal for applications requiring these properties.

Processing Requirements and Considerations

Differences in molecular structure between Nylon 6 and Nylon 66 dictate distinct processing requirements, influencing production efficiency, part precision, and cost in manufacturing. Nylon 6’s lower viscosity facilitates simpler molding and extrusion, reducing energy use, while Nylon 66’s higher crystallinity demands precise control for superior dimensional stability. These characteristics guide optimization of processing parameters for applications like automotive components, technical fibers, and precision tubing, balancing quality and economic considerations.

Injection Molding Parameters

| Processing Parameter | Nylon 6 | Nylon 66 |

| Barrel Temperature | 230-260°C | 270-290°C |

| Mold Temperature | 70-80°C | 80-90°C |

| Injection Pressure | 80-120 MPa | 100-140 MPa |

| Mold Shrinkage | 1.0-1.5% | 1.5-2.0% |

| Drying Requirements | 80°C for 4-6 hours | 80°C for 6-8 hours |

Nylon 6’s lower melting point translates to lower processing temperatures, reduced energy consumption, and less thermal stress on equipment. Its lower mold shrinkage (1.0-1.5% compared to Nylon 66’s 1.5-2.0%) provides better dimensional accuracy for molded parts, reducing the need for complex mold compensation calculations.

Conversely, Nylon 66 requires higher processing temperatures and pressures, which can increase production costs but may be necessary for applications demanding its superior thermal and mechanical properties. Both materials require thorough drying before processing to prevent hydrolysis and surface defects, with Nylon 66 typically needing longer drying times due to its higher processing temperature.

Extrusion

Nylon 6 extrudes consistently at lower temperatures (240-260°C), reducing thermal degradation and energy use, ideal for films and fibers. Nylon 66 requires precise temperature control (270-290°C) to prevent voids, but its higher melt strength supports complex profiles like tubing or structural components.

Flowability Considerations

Nylon 6’s higher melt flow index enables smoother molding and extrusion, ideal for thin-walled housings and high-throughput production. Nylon 66’s higher viscosity requires higher-pressure equipment but ensures dimensional stability for precision parts.

Real-World Applications and Case Studies

Figure 3: Industrial applications across sectors

Automotive Industry Case Study

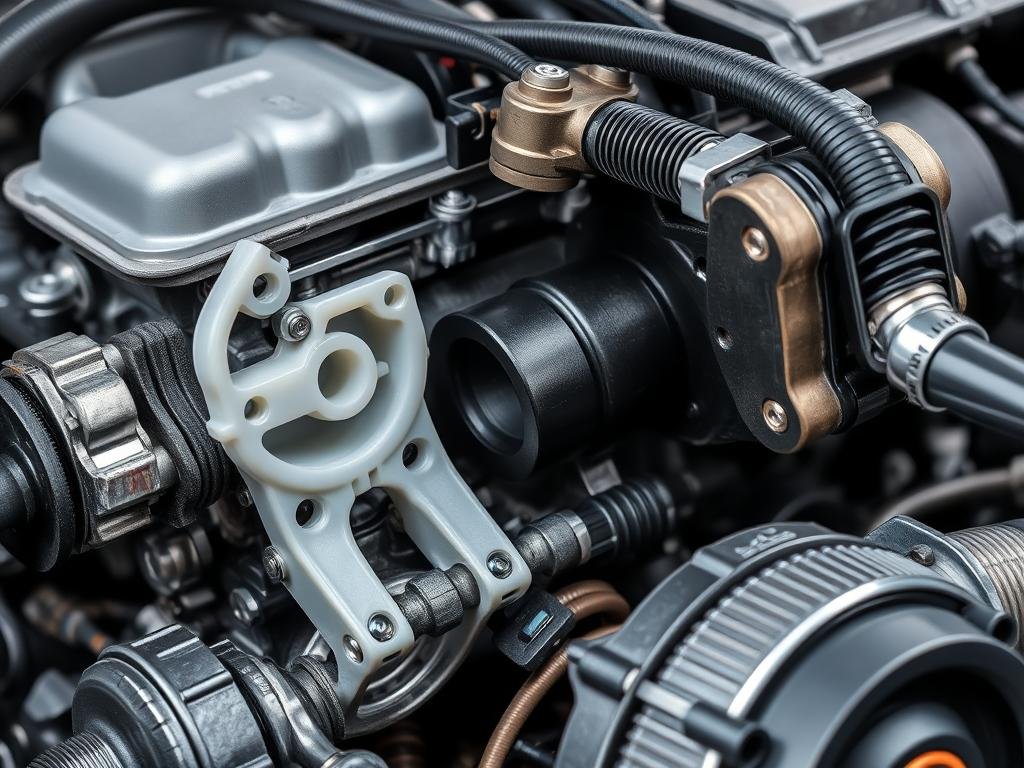

In automotive applications, material selection between Nylon 6 and Nylon 66 directly impacts component performance and longevity. Engine covers and under-hood components typically utilize Nylon 66 due to its superior heat resistance and ability to maintain structural integrity at elevated temperatures. A major European automaker switched from Nylon 6 to Nylon 66 for their engine cooling system components after field tests revealed that Nylon 6 parts experienced premature degradation when exposed to sustained temperatures above 180°C. The Nylon 66 components demonstrated 40% longer service life despite the 15% higher material cost.

Figure 4: Nylon 66 automotive components near high-temperature zones

Textile Industry Case Study

In the textile sector, Nylon 6 dominates applications requiring lustrous appearance and elastic recovery. A sportswear manufacturer developed a high-performance athletic fabric using Nylon 6 fibers that demonstrated 22% better elastic recovery after repeated stretching compared to Nylon 66 alternatives. The material’s superior flexibility and moisture management properties made it ideal for compression garments and activewear, while its ability to accept vibrant dyes created visually appealing products with better color retention through multiple wash cycles.

Figure 5: Nylon 6 textile applications demonstrating elasticity and color properties

Environmental Impact and Sustainability Considerations

Figure 6: Environmental impact comparison across lifecycle stages

The production and lifecycle of Nylon 6 and Nylon 66 pose significant environmental challenges due to their reliance on petroleum-based monomers, driving emissions and energy demands. Nylon 6’s simpler synthesis emits higher volatile organic compounds (VOCs), while Nylon 66’s condensation process generates wastewater, increasing its environmental footprint. Sustainable practices, including bio-based alternatives and advanced recycling, mitigate these impacts, aligning with regulatory demands like the EU’s circular economy framework. These considerations guide manufacturers in optimizing material choices for reduced environmental impact in applications like automotive components and technical textiles.

- Production Emissions: Nylon 6’s production (15-25 MJ/kg) releases more VOCs due to its single-monomer process, while Nylon 66’s energy-intensive synthesis (20-30 MJ/kg) produces wastewater, contributing to a higher global warming potential.

- Recycling and Sustainability: Nylon 6’s chemical recycling achieves up to 90% caprolactam recovery, enabling closed-loop systems. Nylon 66 is less recyclable but benefits from mechanical recycling. Both can leverage bio-based monomers (e.g., from castor oil), though mechanical recycling may reduce mechanical properties and chemical recycling remains costly.

Sustainable practices enhance material viability, supporting compliance with environmental regulations and meeting demand for eco-friendly solutions in automotive and textile industries.

Nylon 6 Sustainability Profile

- Better chemical recyclability (closed-loop potential)

- Lower processing temperatures (reduced energy consumption)

- Higher molecular mobility (easier to blend with recycled content)

- Lower carbon footprint during manufacturing

Nylon 66 Sustainability Profile

- Longer service life in demanding applications

- Higher durability (fewer replacements needed)

- Better retention of properties when mechanically recycled

- Emerging bio-based production pathways

Material Selection Decision Framework

Performance, environmental conditions, processing, and cost must be balanced when comparing Nylon 6 and Nylon 66. Nylon 6 performs better below 150 °C, offering superior impact resistance and moisture tolerance, while Nylon 66 provides higher strength, rigidity, and thermal stability up to 180 °C, along with enhanced acid resistance. This framework supports matching material properties to specific engineering requirements.

Figure 7: Decision framework for material selection

When selecting between Nylon 6 and Nylon 66, engineers should consider these key decision factors:

| Selection Factor | Choose Nylon 6 When | Choose Nylon 66 When |

| Operating Temperature | Below 150°C continuous | Up to 180°C continuous |

| Mechanical Stress | Impact resistance is critical | Tensile strength and rigidity are priorities |

| Environmental Exposure | Hydrocarbon contact is expected | Acid exposure is anticipated |

| Processing Complexity | Complex geometries with thin walls | Simpler geometries with thicker sections |

| Dimensional Precision | Tight tolerances are required | Tolerances can accommodate higher shrinkage |

| Aesthetic Requirements | Lustrous finish and vibrant coloring needed | Functional appearance is sufficient |

| Budget Constraints | Lower material and processing costs preferred | Performance justifies higher material cost |

If you need high-quality Nylon 6 or Nylon 66 pellets with consistent specifications and reliable supply, we source directly from trusted manufacturers. You can contact us to discuss your material requirements, request technical datasheets, or explore cost-effective supply solutions tailored to your production.

Conclusion: Making the Optimal Selection

Nylon 6 and Nylon 66 offer distinct advantages driven by their molecular structures, enabling tailored solutions for diverse engineering applications. Nylon 6’s flexibility and cost-effective processing make it preferred for lightweight components like textiles and automotive interiors, while Nylon 66’s superior strength and heat resistance suit high-performance parts in aerospace and industrial settings.

By evaluating performance, processing, cost, and sustainability factors, such as Nylon 6’s recyclability, manufacturers can optimize material choice to meet application demands and align with trends like the EU’s circular economy framework. Standardized testing and consultations with material suppliers at contact jerry@salesplastics.com or call +8618657312116 provide technical datasheets to ensure informed decisions for automotive, aerospace, and textile applications, balancing performance, cost, and environmental goals.

fAQs

Q:What is the melting point difference between Nylon 6 and Nylon 66?

A:Nylon 6 has a melting point of approximately 215–220°C, while Nylon 66 melts between 250–265°C. The higher melting point of Nylon 66 provides improved thermal stability for applications involving sustained elevated temperatures.

Q:How do the properties of Nylon 6 compare to Nylon 66?

A:Nylon 6 generally offers better impact resistance, higher elasticity, and lower mold shrinkage, but absorbs more moisture (~3.5%) which can affect dimensional stability. Nylon 66 exhibits higher tensile strength, greater stiffness, superior abrasion resistance, and better heat aging performance, with lower moisture absorption (~2.5%).

Q:What are the structural differences between Nylon 6 and Nylon 66?

A:Nylon 6 is a polyamide made from a single monomer, caprolactam, forming repeating units with six carbon atoms. Nylon 66 is a condensation polymer of hexamethylene diamine and adipic acid, with two six-carbon segments per repeat unit. This molecular difference leads to Nylon 66 being more crystalline and thermally stable.

Q:What are the typical applications of Nylon 6 and Nylon 66?

A:Nylon 6 is used in textile fibers, injection-molded parts requiring impact toughness, and components exposed to hydrocarbons. Nylon 66 is favored in automotive under-hood parts, industrial gears, bearings, and applications demanding higher mechanical strength and heat resistance.

Q:What are the disadvantages of Nylon 66?

A:Nylon 66 can be more brittle at low temperatures, has slightly higher mold shrinkage compared to Nylon 6, and though it absorbs less moisture, it still undergoes dimensional changes in humid environments, which may require compensation in design.

Q:How do Nylon 6, Nylon 66, and Nylon 12 differ in properties and uses?

A:Nylon 12 features the lowest moisture absorption and superior chemical resistance among the three, ideal for fuel lines and flexible tubing. Nylon 6 and 66 offer higher strength and thermal resistance but higher moisture uptake, influencing their selection in harsher chemical or humid conditions.