PA6 GF30 consists of polyamide 6 reinforced with 30 wt% short glass fibers. This composite significantly improves stiffness and strength compared to unreinforced PA6, while retaining processability via injection molding. The following analysis examines key mechanical properties and their microstructural origins.

Strength and Stiffness Gains

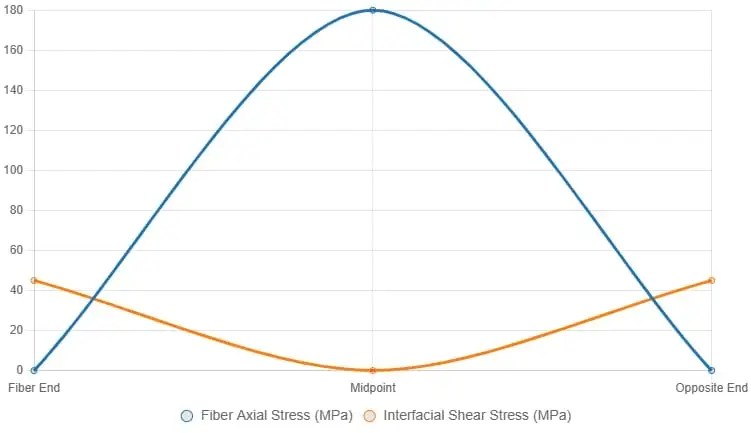

Tensile strength increases from 80 MPa (pure PA6, dry, ISO 527) to 180 MPa in PA6 GF30 under identical conditions—a 125% enhancement. Load transfers from the matrix to fibers through interfacial shear, following the shear lag model .

Observe how axial stress builds gradually toward the fiber center, enabled by silane-mediated bonding. Uniform fiber dispersion (variation coefficient <5%) ensures consistent stress transfer.

Flexural modulus reflects a similar trend. The flexural modulus (stiffness under bending) of PA6 GF30 reaches 9.5 GPa—three times that of pure PA6 (3.2 GPa, ISO 178). Values up to 9.8 GPa are achievable with controlled fiber alignment during molding.

Toughness and Fracture Mechanisms

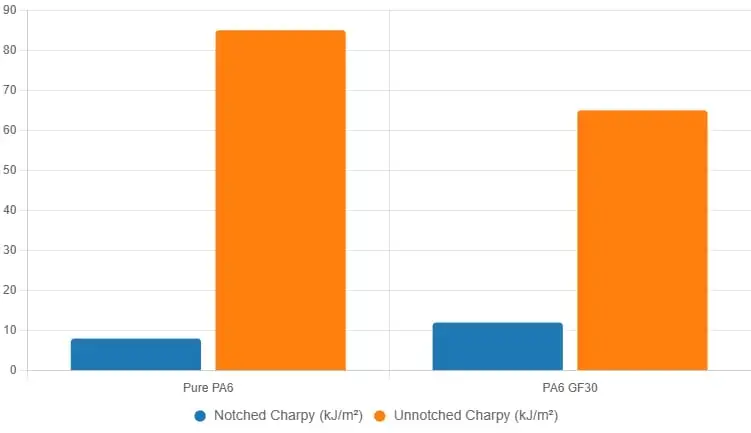

Impact behavior requires nuance. Notched Charpy impact strength rises from 8 kJ/m² (pure PA6) to 12 kJ/m² in PA6 GF30, due to crack bridging by fibers. Unnotched values decrease from 85 to 65 kJ/m², indicating reduced ductility .

Two main energy absorption mechanisms observed under a scanning electron microscope were demonstrated:

- Fiber pull-out: Fibers debond and slide, dissipating energy via interfacial friction.

- Matrix shear yielding: Localized plastic deformation forms shear bands, further blunting crack tips.

Fatigue resistance improves markedly. PA6 GF30 sustains 10⁶ cycles at 90 MPa (50% of tensile strength), compared to 50 MPa for unreinforced PA6. Microcracks initiate at fiber ends but propagate slowly due to bridging.

Performance in Service Conditions

Environmental stability matters: under 50% RH, tensile strength drops ~20% due to plasticization. Dry-as-molded (DAM) conditions yield optimal performance.

These mechanisms—stress transfer, crack bridging, and energy dissipation—enable structural components such as automotive brackets (25% lighter than metal), power tool housings, and load-bearing inserts. Retain fiber length above 0.3 mm post-molding to preserve properties.

For a deeper understanding of PA6 GF30, read:PA6 GF30: Properties, Applications, and Market Trends.

PA6 GF30 demonstrates how targeted reinforcement transforms a general-purpose polymer into an engineering-grade material. Technical datasheets and microstructure reports are available upon request.