Microbial synthesis allows for precise control over the monomeric constituents of the PHA backbone, directly dictating the resulting polymer’s macroscopic behavior. The fundamental repeating unit, defined by the side-chain substituent (R) and the carbon chain length, determines the packing efficiency of the polymer crystals. In homopolymers like Poly(3-hydroxybutyrate) (PHB), the methyl side group facilitates high stereoregularity, leading to a crystallinity exceeding 60%. While this confers excellent tensile strength, the restricted chain mobility often results in a brittle failure mode under low strain.

Material Properties of PHA

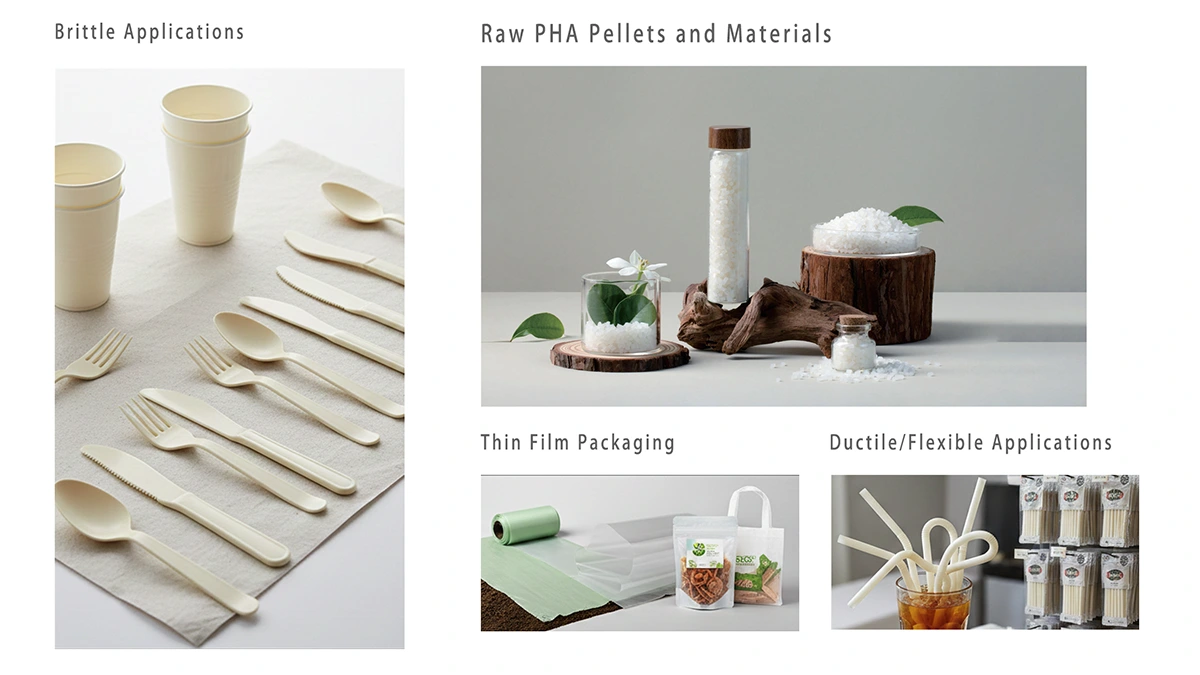

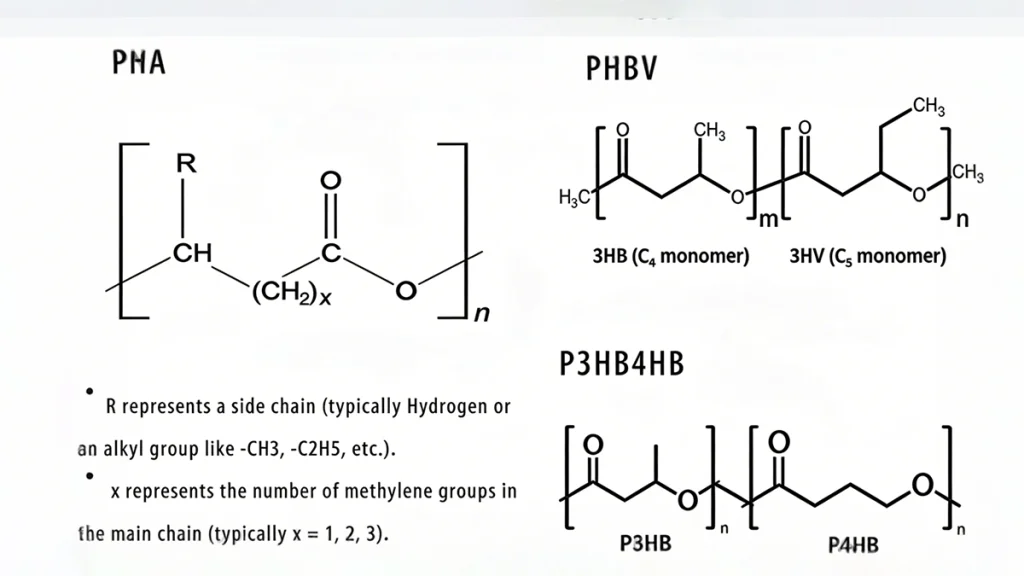

Chemical Structures of PHA, PHBV, and P3HB4HB

Polyhydroxyalkanoates (PHAs) are microbial-synthesized biopolyesters that serve as fully biodegradable alternatives to conventional plastics. Their molecular architecture enables a wide range of mechanical behaviors, from highly crystalline and brittle homopolymers to ductile, elastomeric copolymers engineered for demanding applications.For readers seeking a broader understanding of PHA biosynthesis, material classifications, degradation pathways, and sustainability positioning, a detailed overview is available in our A Comprehensive Guide to Polyhydroxyalkanoates (PHA).

The core repeating unit is defined by side-chain length (R-group) and carbon chain. In homopolymers like poly(3-hydroxybutyrate) (PHB), high stereoregularity yields crystallinity >60%, delivering excellent tensile strength but limited ductility (<8% elongation).

Strategic copolymerization overcomes this limitation:

- PHBV (Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)): Incorporation of 3-hydroxyvalerate (HV) units disrupts crystal packing, reducing melting point and increasing flexibility.

- P3HB4HB (Poly(3-hydroxybutyrate-co-4-hydroxybutyrate)): Longer methylene segments lower Tg dramatically, producing tough, elastomeric behavior.

Key Physical Properties Affecting Ductility and Brittleness

The following table delineates the relationship between molecular structure and the transition from brittle to ductile behavior:

| Material Grade | Tg (°C) | Tm (°C) | Crystallinity (%) | Elongation at Break (%) | Mechanical Character |

| Pure PHB | 2 to 5 | 175 to 180 | 60–75 | < 8% | Brittle / Rigid |

| PHBV (12% HV) | -2 to 1 | 145 to 160 | 40–50 | 15–25% | Semi-Ductile |

| P3HB4HB (15% 4HB) | -15 to -5 | 130 to 150 | 30–40 | 200–500% | Tough / Flexible |

| P4HB Homopolymer | -50 to -45 | 55 to 60 | 30–35 | > 1000% | Elastomeric |

Our Main Grades for Markets

We offer a comprehensive PHA portfolio that includes industrial-grade materials as standard, while also providing research-grade and medical-grade PHA upon request. The table below highlights our core industrial grades, which cover a wide spectrum of ductility requirements and ensure compliance with major global standards. Research-grade and medical-grade variants (with higher purity, USP Class VI compliance, and specialized certifications) are available for R&D, biomedical, and pharmaceutical applications.

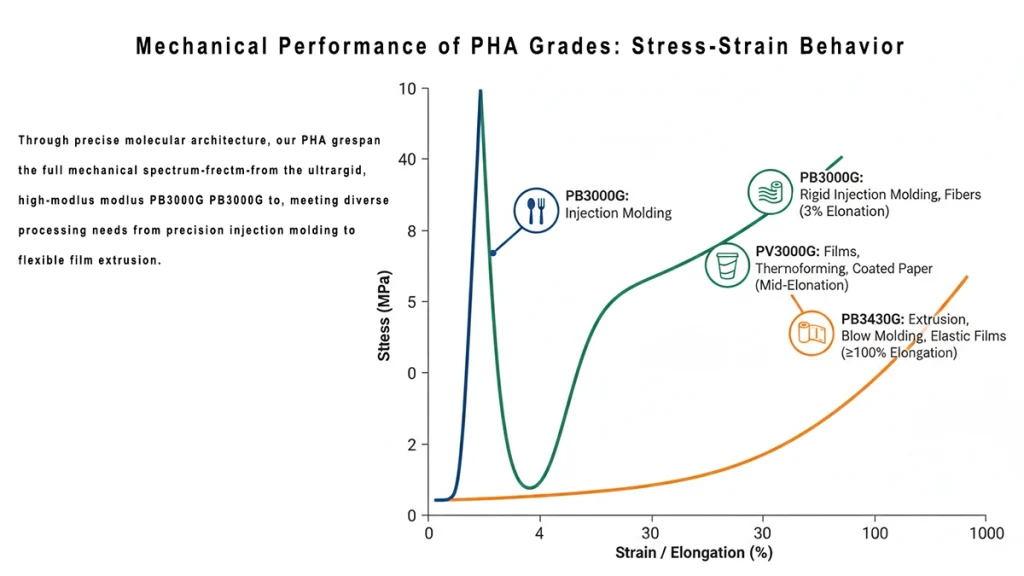

Stress-Strain Curve Comparison for PB3000G, PV3000G, and PB3430G

| Grade | Type/Composition | MFI (g/10min) | Elongation at Break | Typical Applications | Key Certifications |

|---|---|---|---|---|---|

| PV3000G | PHBV copolymer | 8–15 | – | Films, thermoforming, coated paper, blending modification | EN 13432, OK Biodegradable Marine, OK Biobased, FDA food contact, REACH, Halal |

| PB3000G | PHB homopolymer | 10–20 | 3% | Rigid injection molding, fibers, 3D printing | EN 13432, OK Compost Home/Industrial, Bio-based, REACH |

| PB3430G | PHA copolymer (medium-chain) | 12–18 | 100% | Extrusion, blow molding, elastic films, blending | OK Biodegradable Marine, Compostability, Food contact, Halal |

Our industrial-grade PHA raw materials (PV3000G, PB3000G, PB3430G) are versatile for injection molding, film casting, extrusion, coating, fibers, thermoforming, and blending with PLA, PBS, or PBAT to improve heat resistance, oxygen/moisture barrier properties, low-carbon performance, and controlled degradation rates.

We also offer customized 3D printing solutions:

- Pure PHA (natural color)

- Pure PHA / blends

- Compounded PHA blends

Specialized solutions include:

- Coating grades PB1001LA and PB1002LA – optimized for food packaging paper, paper cups, and barrier coatings with excellent adhesion and food-contact compliance.

- Injection molding PB2001IM – ideal for cutlery, cosmetic packaging, and children’s toys; certified for marine/soil degradability, home/industrial compostability, and highest bio-based content.

- Straw solutions PB1001ST – offers outstanding heat resistance (up to 110°C), high toughness, multiple size/format options, food-contact safety, OK Biobased certification, and rapid marine degradation (nearly 90% decomposition in 42 days per independent testing).

All grades carry a combination of biodegradability, compostability (home/industrial), bio-based, food contact compliance, REACH, and Halal certifications as required for specific markets.

Need a custom grade or blending recommendation to meet specific regulatory or performance requirements?

Contact our material scientists to develop a custom copolymer ratio or blending solution designed to meet your specific mechanical, performance, and regulatory requirements.

Overcoming PHA Brittleness Challenges

While PHB homopolymers are inherently brittle, modern copolymerization and formulation strategies reliably deliver ductile, tough materials suitable for demanding applications.

Primary Control Levers

Copolymer composition

Higher HV or 4HB content reduces crystallinity and Tg, increasing free volume and chain mobility.

Molecular weight:

Mw >350,000 g/mol ensures sufficient entanglements for toughness.

Processing optimization

Controlled thermal history prevents degradation and excessive crystallinity.

Practical Solutions for Common Issues

Processing methods and their effect on PHA crystallinity and mechanical properties

Narrow processing window

PHA melts close to degradation onset. Recommended parameters: pre-dry at 80°C for 4 hours; barrel temperatures 165–175°C; minimize residence time. Our technical team provides detailed processing guidelines.

Secondary crystallization (aging)

Slow post-processing crystallization can reduce elongation by up to 50%. Proven nucleating packages (available pre-compounded) suppress this effect by >50%.

Toughening formulations

Flexible packaging

70% PLA + 20% our PHBV-012 + bio-plasticizer → elongation >150%, full EN 13432 compliance.

Marine-degradable films

50% PBAT + 30% PBS + 20% our marine-certified PHA → meets TÜV OK Biodegradable Marine.

High-impact parts

80% PLA + 15–20% medium-chain-length PHA → impact strength increased 3× while maintaining compostability.

Optimize Your PHA Formulation

Request a consultation with our material scientists to develop a custom PHA formulation with the optimal balance of ductility and strength for your specific application requirements.

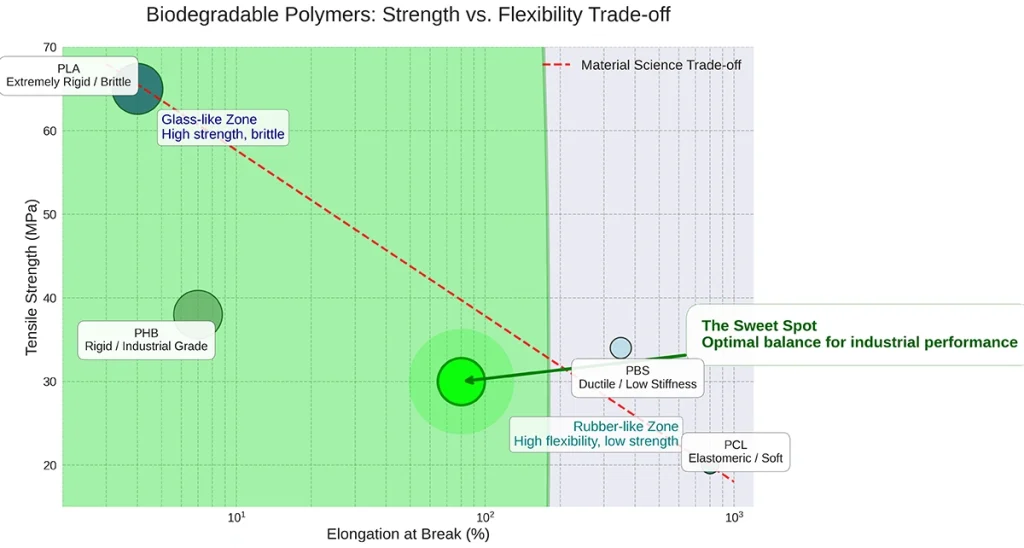

Comparing PHA with Other Bioplastics

Material Property Comparison of Key Biodegradable Polymers

Evaluating the thermomechanical positioning of PHAs relative to other biodegradable polyesters is essential for optimizing material substitution strategies. While PHAs exhibit a broad spectrum of mechanical behaviors, their unique combination of marine degradability and tunable crystallinity distinguishes them from fossil-based and starch-derived alternatives.

| Property | PHB (Rigid) | PHBV (Flexible) | PLA | PBS | PCL |

| Tensile Strength (MPa) | 35–40 | 20–35 | 55–70 | 30–38 | 15–25 |

| Young’s Modulus (GPa) | 3.0–3.5 | 1.0–2.0 | 3.2–3.7 | 0.5–0.7 | 0.3–0.5 |

| Elongation at Break (%) | 5–8 | 20–100+ | 2–6 | 200–500 | >700 |

| Impact Strength (kJ/m²) | 1–2 | 5–15 | 2–4 | 8–12 | Non-breaking |

| Marine Degradability | Excellent | Excellent | Negligible | Moderate | Limited |

Key Comparative Insights

PHAs bridge the performance gap between the high rigidity of PLA and the extreme elasticity of PCL.

PHA Advantages

- Excellent biodegradability in various environments (soil, marine, compost)

- Tunable mechanical properties through copolymerization

- Better thermal resistance than PCL

- Biocompatibility for medical applications

- Produced from renewable resources

PHA Limitations

- Higher brittleness than PBS and PCL

- Narrower processing window than PLA

- Secondary crystallization causing embrittlement over time

- Higher production cost than most bioplastics

- Lower tensile strength than PLA

Custom Blending: Engineering Your Specific Solution

There is no “one-size-fits-all” formula in bioplastics. The optimal blend depends on your specific equipment, target cost, and end-use environment. We don’t just provide resin; we provide the formulation expertise to turn these raw materials into high-performance products.

- Toughening PLA: For packaging plants dealing with brittle PLA films, we recommend incorporating 10–25% PB3430G.

- The Result: It creates a “core-shell” morphology that triggers shear yielding, shifting the material from brittle to ductile failure.

- Strengthening PBAT: For agricultural film makers, PHA provides the mechanical “spine” that PBAT lacks.

- The Result: Enhanced puncture resistance and stiffness, ensuring automated mulching machines don’t tear the film during installation.

Applications of PHA in Industries Requiring Ductility

Industrial applications of PHA materials where ductility plays a crucial role

Engineering the ductility-brittleness balance allows PHAs to meet the rigorous mechanical specifications of diverse sectors. By leveraging specific copolymer ratios and advanced formulation engineering, manufacturers can transition from rigid structures to highly resilient materials tailored for dynamic environments.

Packaging Industry

The packaging sector utilizes the tunable crystallinity of PHA to achieve both structural protection and end-of-life circularity.

- High-Performance Flexible Films: PHBV grades with optimized 3-hydroxyvalerate (3HV) fractions, often synergized with bio-based plasticizers, provide the necessary tear strength and puncture resistance for food-grade flexible packaging.

- Barrier Coatings: PHA-based aqueous dispersions or extrusion coatings on fibrous substrates offer a robust moisture barrier while maintaining the flexibility required to endure folding and mechanical stress without delamination.

- Composite Containers: Blending PHA with aliphatic-aromatic polyesters (e.g., PBAT) enhances the fracture toughness of thermoformed trays, ensuring structural integrity during refrigerated transport.

Medical Applications

PHA materials in medical applications requiring specific mechanical properties

The inherent biocompatibility and non-toxic metabolic byproducts of PHAs are complemented by their highly customizable elasticity.

- Absorbable Surgical Devices: The exceptional elongation of P4HB (exceeding 1000%) facilitates the production of high-tensile, flexible monofilament sutures that conform to physiological movements.

- Regenerative Scaffolds: P3HB4HB copolymers are engineered to match the Young’s modulus of specific soft tissues, providing a bio-resorbable framework that supports cellular infiltration while maintaining mechanical compliance.

Agricultural Films

In precision agriculture, the mechanical durability of PHA is synchronized with its environmental degradation profile.

- Functional Mulch Films: Sophisticated PHA/PBS blends provide the elongation required for automated laying machinery, ensuring the film resists wind-tearing while offering predictable soil-incorporation timelines.

- Encapsulation Technologies: PHA coatings for controlled-release fertilizers (CRF) utilize ductile matrices to prevent premature coating rupture, ensuring a steady nutrient release calibrated to crop growth cycles.

Consumer Products

Consumer product design increasingly integrates PHA to replace traditional polyolefins in applications requiring impact resilience.

- Durable Goods and Tools: Toughened PHA composites, enriched with natural fibers or mineral fillers, are utilized in injection-molded components where a balance of tactile “soft-touch” and impact strength is paramount.

- Biodegradable Consumer Electronics: Specialized PHA alloys offer the flame retardancy and drop-test resilience necessary for sustainable electronic housings and accessories.

Explore Application-Specific PHA Grades

Request samples of our application-optimized PHA grades with enhanced ductility for packaging, medical, agricultural, or consumer product applications.

Conclusion

The mechanical evolution of Polyhydroxyalkanoates represents a significant milestone in transitioning from traditional polyolefins to functional biopolyesters. While the inherent crystallinity of homopolymers like PHB necessitates a rigorous approach to brittleness management, the structural diversity within the PHA family provides a sophisticated toolkit for mechanical customization.

Achieving the requisite ductility for demanding applications is a multifaceted endeavor, requiring the strategic integration of monomeric ratios—such as 3-hydroxyvalerate (3HV) or 4-hydroxybutyrate (4HB)—with precision processing and multi-phase blending. These interventions do more than just improve elongation; they optimize the material’s energy absorption capacity and fracture toughness, enabling PHA to perform reliably under dynamic stress.

Advancements in mitigating secondary crystallization and expanding the thermal processing window are rapidly de-risking the commercial adoption of PHA. The synergy between high-strength PLA/PHA alloys and high-flexibility PHA/PBAT blends ensures that sustainability no longer requires a compromise in structural integrity. By prioritizing a deep understanding of crystallization kinetics and interfacial adhesion, engineers can unlock the full potential of these renewable materials.

The future of sustainable material science lies in this data-driven approach to formulation. Leveraging the tailorable nature of PHA allows for the development of applications that are not only high-performing but also fully circular across diverse biological environments. Continuing to innovate at the intersection of polymer physics and industrial scalability will solidify PHA’s position as a cornerstone of the global bioeconomy.

Have More Questions About PHA Materials?

Our technical experts are available to answer your specific questions about PHA material properties, processing, and applications.

Frequently Asked Questions

What are the properties of PHA materials?

Polyhydroxyalkanoates are semi-crystalline, thermoplastic polyesters synthesized through microbial fermentation. Their performance profile is highly dependent on the side-chain length (R group), resulting in a crystallinity range of 30% to 75%. From a mechanical perspective, PHAs bridge the gap between high-modulus polymers and elastomers, exhibiting tensile strengths from 15 to 45 MPa and elongation at break from 5% (homopolymers) to over 1000% (copolymers like P4HB). Thermally, they possess melting points (Tm) between 60°C and 180°C. One of their most significant technical advantages is their superior oxygen barrier performance compared to LDPE and PP, coupled with high moisture resistance and excellent biocompatibility.

How long does PHA take to degrade?

Degradation kinetics of PHA are primarily driven by surface-active enzymatic hydrolysis, rather than simple chemical hydrolysis. The duration required for complete mineralization varies by environment and geometry:

- Industrial Composting (EN 13432): Complete disintegration typically occurs within 90 to 180 days under controlled thermophilic conditions (58°C).

- Marine and Aquatic Environments: PHAs are among the few polymers that biodegrade in cold seawater, generally requiring 6 to 18 months depending on surface-to-volume ratios.

- Soil Environments: Mineralization occurs within 6 to 24 months, influenced by microbial population density and moisture levels.

- Anaerobic Digestion: Rapid degradation can be achieved within 30 to 60 days in specialized biogas facilities. Molecular weight, crystallinity, and the presence of nucleating agents are the primary internal factors that regulate these degradation rates.

What polymers are brittle?

Brittleness is defined by a material’s inability to dissipate energy through plastic deformation, typically characterized by an elongation at break below 10%. Common brittle polymers include:

- Poly(3-hydroxybutyrate) (PHB): The homopolymer form of PHA, which is rigid and prone to secondary crystallization.

- Polylactic Acid (PLA): High modulus but low fracture toughness, necessitating impact modification for durable use.

- Polystyrene (PS) & PMMA: Amorphous polymers with limited chain entanglement, leading to high clarity but poor impact resistance.

- Unplasticized PVC (uPVC): Rigid with high intermolecular forces that restrict chain slippage. Compared to these materials, PHA copolymers (such as PHBV or PHBH) offer a unique advantage: they can be engineered to transition from a brittle state to a ductile or even elastomeric state by simply adjusting the monomeric ratio during the fermentation process, effectively eliminating the need for external plasticizers that may migrate over time.