Environmental pressures from plastic pollution have increased interest in biodegradable alternatives to petroleum-based materials such as Polyethylene (PE), Polypropylene (PP), and PET. Key bio-based options include PHA, PLA, and starch-based plastics, each offering distinct properties compared to conventional plastics and other biodegradable polymers like PBAT or PBS.

Renewable

Plant & Bacteria Sourced

Compostable

Natural Degradation

Bio-Based vs. Traditional Plastics

| Category | Traditional (PE/PP/PET) | PHA / PLA / Starch |

|---|---|---|

| Raw Material | Crude Oil & Natural Gas | Corn, Sugarcane, Bacterial Fermentation |

| Environmental Impact | High carbon footprint; persists for centuries | Reduced reliance on fossil fuels; lower CO2 emissions |

| Biodegradability | Minimal / Non-existent | Environmentally degradable (Specific conditions) |

| Performance | High stability & low cost | Variable (Higher cost, specialized properties) |

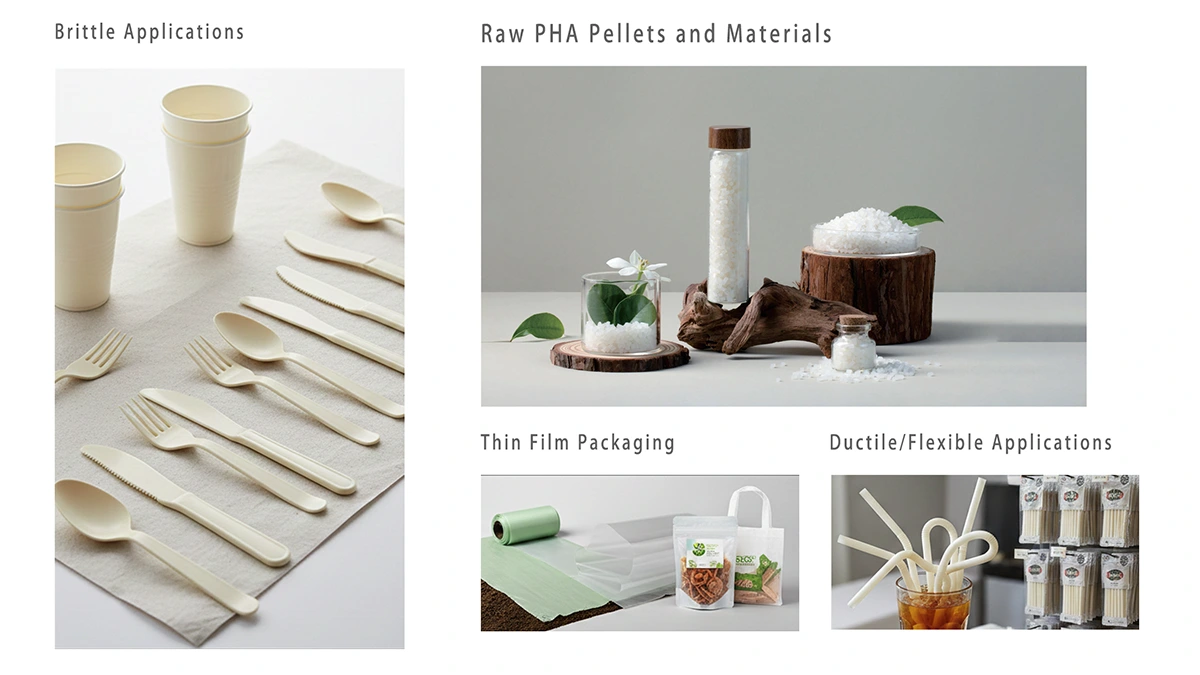

PHA

Broad biodegradability in soil, marine, and home composting. Ideal for marine packaging and agricultural mulch.

- High cost (4-10x)

- Bacterial fermentation

PLA

Transparent and rigid. Best for cutlery, cups, and 3D printing. Requires industrial composting (heat/moisture).

- Brittle at high temp

- Scalable production

Starch-Based

Cost-effective for flexible films and shopping bags. Often blended with other polymers for strength.

- Moisture sensitive

- Highly affordable

Relation to Other Polymers

Life Cycle & Market Trends

Global bioplastics capacity is set to reach 4.69 million tonnes by 2030, with a CAGR of 15-20%.

Data source: European Bioplastics (2025 data).

Dive Deeper into Sustainable Material Science

Access our comprehensive guide for detailed side-by-side tables and technical data sheets.

Regulatory Support & Certifications

EU PPWR (2025)

Requires all packaging to be recyclable by 2030, favoring bio-based and compostable formats.

EN 13432 / ASTM D6400

Gold standards for verifying industrial compostability for PLA and PBAT polymers.

Asian Growth

China's strict plastic restrictions drive large-scale adoption of starch-blends and PHA.

OK Biodegradable MARINE

Specific certification confirming PHA's ability to safely degrade in ocean environments.

In Summary

While PHA offers the best environmental adaptability, PLA provides the scalability needed for rigid packaging, and starch-based materials deliver cost-effective solutions for the flexible film market.