The global transition toward sustainability demands materials that effectively mitigate the environmental impact of petrochemical polymers. Polylactic Acid (PLA) and its stereoisomer, Poly-L-Lactic Acid (PLLA), stand at the forefront of this shift, gaining substantial commercial traction due to their renewable origins and versatile end-of-life characteristics. This analytical guide dissects the fundamental molecular and stereochemical distinctions separating PLA from PLLA. We provide a rigorous examination of their specific thermal properties, mechanical profiles, and processing envelopes, offering the technical clarity necessary for strategic material specification in high-demand industrial sectors.

Core Concepts: Understanding PLA and PLLA

The fundamental structures of Polylactic Acid (PLA) and Poly-L-Lactic Acid (PLLA) dictate their respective properties and ultimate commercial utility. A clear grasp of their stereochemical relationship is necessary for precise material selection.

What is PLA (Polylactic Acid)?

Polylactic acid (PLA) functions as a versatile, thermoplastic polyester derived from renewable feedstocks, typically fermented plant starches (e.g., corn, sugarcane). The polymerization process converts the resulting lactic acid into the base polymer. Architecturally, generic PLA is classified as a family of materials, typically featuring varying compositions of L- and D-lactic acid isomers. This mixed composition defines the base material’s initial processability, biocompatibility, and foundation crystallinity levels.

Molecular structure of polylactic acid (PLA)

What is PLLA (Poly-L-Lactic Acid)?

PLLA represents the homopolymer of L-lactic acid. It consists exclusively of L-isomer molecules linked in a highly regular, stereo-pure chain. This structural uniformity allows PLLA to achieve a high degree of crystallinity (up to 50%), which in turn confers superior mechanical strength, enhanced thermal resistance, and a significantly slower degradation rate compared to its mixed-isomer counterparts. PLLA’s ordered structure makes it the benchmark for applications demanding high-performance engineering specifications.

The molecular structure of PLLA shows the L-isomer.

What is PDLA / PDLLA? (Brief explanation)

Material specification within the polylactide family requires recognizing two critical related structures:

- PDLA (Poly-D-Lactic Acid): This is the stereo-pure homopolymer of D-lactic acid, acting as the mirror image of PLLA.

- PDLLA (Poly-D,L-Lactic Acid): This is an amorphous copolymer composed of a random, non-uniform distribution of both D and L isomers. It exhibits dramatically different thermal and mechanical behavior from the crystalline pure forms.

These variants are crucial for advanced applications, particularly in forming stereocomplex PLA (sc-PLA)—a blend of PLLA and PDLA that exhibits a dramatically elevated melting point (over 200℃), further increasing the material’s performance ceiling.

Key Molecular Difference

The performance chasm between PLA and PLLA originates in their stereochemical composition:

Generic PLA

Features an inconsistent ratio of L- and D-lactic acid isomers, hindering the alignment necessary for high-level crystallization.

PLLA

Consists of 100% L-lactic acid isomers, creating the stereochemical purity required to maximize chain folding and crystalline domain formation.

This molecular difference directly governs the glass transition temperature, melting point, and mechanical robustness of the final product.

Properties Comparison: PLA vs PLLA

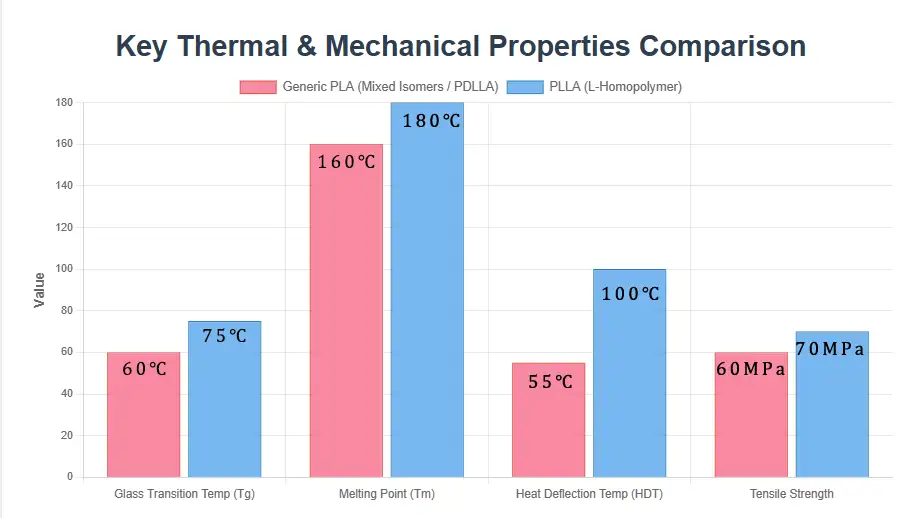

Precise material specification hinges on a granular understanding of the performance attributes dictated by the stereochemical differences between PLA and PLLA. The following table details the critical properties that distinguish the two polymers in commercial use.

| Property | Generic PLA (Mixed Isomers) | PLLA (L-Homopolymer) |

| Crystallinity | Semi-crystalline (0-35%) | Highly Crystalline (up to 50%) |

| Tensile Strength | 45-60 MPa | 55-70 MPa |

| Elongation at Break | 5-15% (Brittle) | 5-10% (Semi-rigid), ≈ 100% (Annealed/Stretched) |

| Glass Transition Temp. (Tg) | 55-60°C | 60-75°C |

| Melting Point (Tm) | 150-160°C (Varies by D-isomer content) | 175-180°C |

| Heat Deflection Temp. (HDT) | Low (Often below 55°C) | Higher (Can exceed 100°C with annealing) |

| Hydrolytic Stability | Moderate | High (Slower degradation) |

| Optical Clarity | Good to High | Excellent (High transparency) |

Comparative analysis of key mechanical properties between PLA and PLLA

Mechanical Performance

PLLA exhibits a notable advantage in intrinsic mechanical robustness, achieving higher tensile strength and, crucially, superior performance when subjected to post-processing. Its highly ordered crystalline lattice allows PLLA materials to be annealed or oriented (stretched), dramatically enhancing toughness and ductility. This structural capability is why PLLA is specified for high-stress, load-bearing components.

Thermal Behavior and Processing

The significantly higher melting point (Tm) of PLLA (175-180℃)—a direct result of its stereochemical purity—provides greater thermal stability than generic PLA. This feature directly translates to a higher potential Heat Deflection Temperature (HDT) in the final part, a key metric for applications exposed to elevated temperatures or requiring high-heat sterilization processes.

Degradation and Stability

PLLA’s uniform crystalline structure limits water penetration and restricts chain mobility, resulting in superior hydrolytic stability and a slower in vivo/environmental degradation rate compared to the more amorphous, mixed-isomer PLA. This extended stability profile is critical for material selection in long-term biomedical implants and durability-focused engineering parts.

Need Detailed Technical Specifications?

Access our comprehensive technical data sheets for PLA and PLLA to make an informed material selection for your project.

Processing Performance Head-to-Head

The stereochemical purity inherent in PLLA necessitates distinct processing methodologies compared to generic PLA, directly influencing throughput, energy consumption, and final component integrity. Optimized material handling and thermal profiles are non-negotiable for maximizing yield.

Injection Molding

PLA

- Processes at a lower temperature range (170-180°C).

- Exhibits lower melt viscosity, promoting fast flow into complex molds.

- Allows for shorter cooling phases and quicker cycle times.

PLLA

- Requires elevated processing temperatures (190-210°C).

- Needs a significantly longer cooling phase due to high crystallization kinetics.

- A high mold temperature is mandatory for achieving superior surface finish and detail reproduction.

Extrusion

PLA

- Utilizes lower extrusion temperatures.

- Features moderate melt strength and reduced shear sensitivity for easy processing.

- Requires pre-drying but is less sensitive to moisture than PLLA.

PLLA

- Mandates higher extrusion temperatures.

- Exhibits higher melt strength, favoring thermoforming and blow molding.

- Requires stringent pre-drying due to high moisture sensitivity at processing temperatures.

- Offers better dimensional stability in extruded products.

3D Printing Compatibility

PLA

- Prints reliably within a standard range (180-220°C).

- Minimal shrinkage and warping, often eliminating the need for a heated print bed.

- Favored for high-speed printing and broad prototyping.

PLLA

- Requires a higher printing temperature range (190-230°C).

- Often necessitates a heated bed for reliable layer adhesion on large components.

- Offers superior interlaminar strength and better heat deflection performance in finished parts.

Post-Processing Considerations

- PLLA exhibits an excellent response to annealing treatments, which significantly boosts its thermal and mechanical properties.

- PLA is generally easier to machine, sand, and finish due to its lower hardness.

- PLLA maintains superior dimensional stability during secondary operations.

- PLLA’s higher melting point allows it to reliably withstand high-heat sterilization methods (e.g., autoclaving).

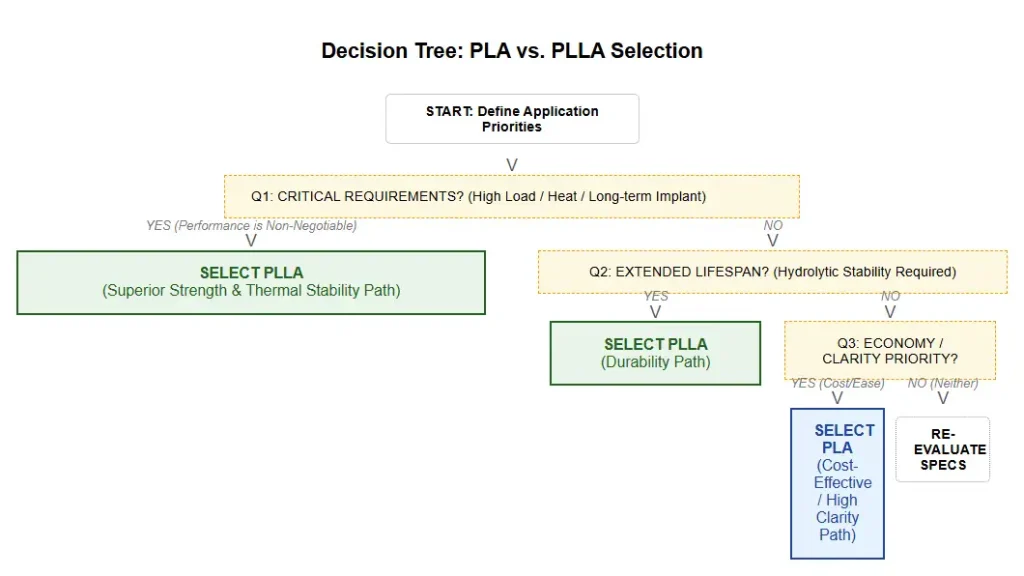

Quick Selection Decision Tree

The final determination between PLA and PLLA involves balancing specific performance trade-offs against cost-effectiveness. The polymer selection is driven by the application’s most critical non-negotiable requirements.

Decision flowchart for selecting the optimal bioplastic based on application requirements

Primary Selection Factors

| Prioritize PLA when the focus is on: | Prioritize PLLA when the focus is on: |

| Cost-sensitive mass production | Superior mechanical strength and load-bearing capacity |

| Standard process window and faster throughput | Higher thermal stability and heat deflection temperature (HDT) |

| Faster degradation profile (short-term use) | Extended hydrolytic stability and product lifespan |

| Simplicity in FFF (3D printing) and reduced equipment needs | High-performance engineering parts and advanced medical devices |

| High optical clarity requirements | Biocompatibility requirements for long-term clinical implants |

Not Sure Which Material Is Right For Your Application?

Our material specialists can analyze your specific requirements and recommend the optimal bioplastic solution.

Major Application Battlegrounds: PLA vs PLLA

The selection between PLA and PLLA is ultimately determined by matching the material’s intrinsic properties—specifically cost, mechanical rigor, and degradation profile—to the demands of the operating environment.

Medical Devices and Implants

Medical devices and implants manufactured from PLA and PLLA bioplastics

PLA Applications

- Short-term resorption devices (3-6 months)

- Drug elution systems

- Temporary sutures and wound management

- Soft tissue engineering matrices

PLLA Applications

- Long-term load-bearing implants (1-3 years)

- Orthopedic bone fixation screws and plates

- Cardiovascular stents and scaffolds

- Hard tissue (e.g., bone) engineering matrices

PLLA is the established standard for applications demanding extended hydrolytic stability, predictable bioresorption, and high mechanical integrity, such as specialized fixation devices. PLA is reserved for temporary, low-stress applications where rapid in vivo degradation is a design requirement.

Packaging Solutions

Sustainable packaging solutions utilizing PLA and PLLA bioplastics

PLA Applications

- General-purpose food containers and serviceware

- Flexible films for fresh produce (short shelf-life)

- Single-use beverage cups and disposable cutlery

PLLA Applications

- High-temperature resistant food trays

- High-barrier rigid packaging for extended shelf stability

- Premium, stiff blister packaging requiring puncture resistance

PLA offers the optimal balance of cost-effectiveness and clarity for high-volume, short-term packaging markets. PLLA is specified when the application requires enhanced barrier performance, superior rigidity, or thermal tolerance that justifies the material premium.

3D Printing Applications

3D printed objects showcasing the capabilities of PLA and PLLA filaments

PLA Applications

- Prototyping and iterative design

- Educational models and consumer goods

- Low-stress components and decorative items

PLLA Applications

- Functional engineering components

- High-temperature tooling and fixtures

- Precision medical models and devices

PLA remains the baseline material, valued for its wide processing window and minimal warping. PLLA is increasingly utilized in industrial and engineering environments where post-annealing potential and superior heat deflection are critical performance requirements.

Other Industry Applications

| Industry | PLA Applications | PLLA Applications |

| Textile | Standard spun fibers, disposable nonwovens | High-performance filtration textiles, surgical mesh |

| Agriculture | Biodegradable mulch films, disposable plant pots | Controlled-release encapsulation systems, durable field components |

| Automotive | Interior non-structural trims, temporary protection films | Heat-stabilized under-hood components, durable fasteners |

| Electronics | Device casings and protective transit packaging | Precision, heat-resistant components (e.g., connector housings) |

Need Application-Specific Guidance?

Our industry experts can provide tailored recommendations based on your specific application requirements and performance goals.

Sustainability & End-of-Life Performance

Assessing the ecological impact of PLA and PLLA requires a Life Cycle Assessment (LCA) perspective, comparing feedstock sourcing, processing energy requirements, and end-of-life options.

Complete lifecycle comparison of PLA and PLLA bioplastics from production to end-of-life

Raw Material Sourcing

PLA

- Derived from renewable, first-generation feedstocks (e.g., corn starch, sugarcane).

- Benefits from a demonstrably lower carbon intensity profile compared to petrochemical polymers.

- Production consumes less energy due to simpler polymerization and purification steps.

PLLA

- Utilizes the same renewable feedstock base as PLA.

- Incurs higher production energy costs due to the mandatory stereochemical control required for polymer purity.

- This specialized synthesis pathway contributes to the material’s premium price point.

Biodegradation Timeline

The material’s crystalline structure dictates the rate of hydrolytic breakdown and the overall degradation timeline. PLLA’s high crystallinity inherently resists hydrolysis more effectively than generic, semi-crystalline PLA.

| Environment | PLA (Semi-Crystalline) | PLLA (Highly Crystalline) |

| Industrial Composting (58°C) | 3-6 months (Full breakdown) | 6-12 months (Slower kinetics) |

| Home Composting (25-35°C) | 1-2 years | 2-3 years |

| Soil Burial (Typical) | 2-3 years | 3-5 years |

| Marine Environment | 3-5 years | 5+ years |

| Landfill (Anaerobic) | Decades | Decades (Minimal breakdown) |

Recycling Potential

Both materials exhibit robust recyclability options, crucial for achieving closed-loop material flow:

- Mechanical Recycling: Polymers must be segregated from PET streams to prevent contamination. PLLA requires stricter process control to preserve its high-value properties.

- Chemical Recycling: Chemical depolymerization back to high-purity lactic acid is a highly effective method for both, maintaining feedstock value and enabling true circularity.

Microplastics Concerns

Physical weathering can cause fragmentation in both PLA and PLLA. Critically, the resulting microplastics retain their fundamental ultimate biodegradability, unlike conventional polymers. The key distinction is time: PLLA’s superior stability means its fragments will persist for a demonstrably longer period in natural environments than the more rapidly degrading PLA. This persistence requires careful consideration for applications with potential environmental release.

Conclusion & Procurement Recommendations

The distinction between PLA and PLLA is rooted fundamentally in their stereochemical purity, which dictates the resulting thermal resistance, mechanical performance, and hydrolytic stability. Material specification is ultimately an engineering trade-off tailored to the application’s most critical requirements.

- PLA remains the economically superior choice for high-volume manufacturing and applications requiring an aggressive degradation timeline and standard thermal tolerance.

- PLLA is the definitive selection for projects demanding structural integrity, dimensional stability, and longevity, such as long-term biomedical implants and high-heat engineering components.

Cost Considerations

PLLA typically commands a premium over generic PLA, a cost justified by the specialized production needed for its high crystalline structure. This material premium purchases a guaranteed increase in melting point and enhanced performance ceiling, making it an investment in product reliability and extended service life.

Future Outlook

Research continues to advance the capabilities of both materials, notably through the development of stereocomplex PLA which further boosts heat deflection and mechanical properties. As processing efficiencies improve and material science evolves, both PLA and PLLA are poised to capture an increasing share of markets currently reliant on conventional polymers.

For precise material matching, ensuring the correct stereoisomer ratio and appropriate compounding for your specific processing equipment is essential. Contact our technical sales team for consultation on selecting the optimal polylactide grade for your project.

Ready to Implement PLA or PLLA in Your Projects?

Request material samples and technical support to evaluate which bioplastic is best suited for your specific application.

Frequently Asked Questions

What is the primary manufacturing difference between PLA and PLLA?

The key difference lies in stereochemical control during production. PLLA is a stereo-pure homopolymer, consisting exclusively of L-lactic acid isomers. This purity requires stringent purification and controlled ring-opening polymerization to eliminate D-isomers. Standard PLA, conversely, contains varying (and less controlled) ratios of L- and D-isomers. This difference in manufacturing complexity directly contributes to PLLA’s higher material cost.

How does PLLA's crystallinity benefit engineering applications?

PLLA’s high, ordered crystalline structure is essential for its superior mechanical and thermal performance:

- Thermal Resistance: The higher melting point (Tm) and potential Heat Deflection Temperature (HDT) allow PLLA components to withstand sterilization and higher operating temperatures.

- Mechanical Strength: High crystallinity provides improved tensile strength and dimensional stability, making PLLA suitable for load-bearing or high-precision parts.

- Hydrolytic Stability: The denser crystalline lattice slows water penetration, extending the product’s lifespan in demanding or long-term applications.

What are the common PLA uses across industries?

PLA’s versatility, ease of processing, and cost-effectiveness make it suitable for high-volume applications where renewable sourcing and adequate performance are valued:

- Packaging: Food serviceware, disposable films, beverage cups, and blister packaging.

- Additive Manufacturing: Filament for rapid prototyping and general consumer products.

- Consumer Goods: Disposable cutlery, toys, and low-stress housings.

- Agricultural: Biodegradable mulch films and plant pots.

Are there concerns about PLA microplastics?

While both PLA and PLLA can fragment into microparticles via physical weathering, they present a lower long-term environmental risk than conventional petrochemical plastics. Unlike the latter, PLA microplastics retain ultimate biodegradability and will fully break down into carbon dioxide and water under the appropriate industrial composting conditions. The primary concern remains ensuring adequate waste stream management, as PLA fragments may persist for years in cold or passive environments.

In which medical applications are PLLA and PLA typically used?

The choice is defined by the required degradation timeline and mechanical load:

- PLA: Specified for short-term applications (e.g., temporary sutures, drug delivery carriers) where rapid bioresorption (3-6 months) is beneficial.

- PLLA: Designated for long-term, structural applications (e.g., orthopedic fixation devices, specialized implants) requiring predictable stability and high mechanical integrity for 1-3 years or more.

Is PLLA used only for fillers, and why is it expensive?

No, PLLA is a versatile polymer used for high-performance engineering components and long-term medical devices. Its expense is due to the mandatory upstream purification required to achieve stereo-pure L-lactide, ensuring the precise crystalline structure that delivers its enhanced properties (strength, heat resistance, long degradation time).