Polycarbonate (PC) Injection Molding Produces Precision Components Essential for Advanced Technology, from Medical Devices to Electronics, Across Asia, Europe, and the Americas. This Process Transforms High-Quality Plastic Pellets into Durable, Intricate Parts, Integrating Material Science, Engineering, and Innovative Design. As a Distributor of High-Quality Plastic Pellets Sourced Directly from Manufacturers, We Understand the Critical Role of Premium Materials in Achieving Superior Injection-Molded Parts. Our Direct Factory Sourcing Ensures Consistent Quality, Competitive Pricing, and Reliable Supply, Helping You Avoid Costly Downtime and Material Inconsistencies.

This Guide Explores the Fundamentals of PC Injection Molding, Detailing Its Processes, Applications, and Technological Advancements. Created for Engineers and Professionals, It Offers Practical Insights into Material Properties, Process Optimization, and Industry Trends. Learn How PC Molding Shapes Not Only Components but Also the Future of Precision Manufacturing. By Focusing on Our Pellets’ Advantages—Such as High Purity and Batch Traceability—We Help Address Common Challenges Like Material Variability and Rising Costs.

What is Polycarbonate?

Polycarbonate Is an Engineering-Grade Thermoplastic Recognized for Its Balance of Strength, Transparency, and Thermal Resistance. Its Molecular Structure, Built from Repeating Bisphenol-A and Carbonate Groups, Provides High Dimensional Stability and Toughness Under Mechanical or Thermal Stress.

Key performance characteristics include:

- High Impact Strength: PC Resists Fracture and Absorbs Energy During Impacts, Making It Fit for Safety Shields, Structural Covers, and Automotive Housings. For Example, It Can Withstand Forces Equivalent to Those in High-Speed Collisions Without Shattering.

- Thermal Resistance: It Retains Structural Integrity from –40°C to 130°C, Supporting Applications Where Heat Deflection Matters, Such as Engine Components Exposed to Elevated Temperatures.

- Optical Transparency: With Light Transmission Up to 89%, It Suits Applications Needing Visual Clarity, Like Optical Lenses, Protective Panels, and Display Windows.

- Dimensional Precision: Low Shrinkage During Molding Allows Tight Tolerances, Vital for Intricate Parts in Electronics and Medical Assemblies.

- Processability and Recyclability: As a Thermoplastic, It Enables Efficient Molding and Reprocessing, Aligning with Circular Manufacturing Goals.

PC’s Combination of Mechanical and Optical Properties, Along with Reliable Behavior During Molding, Positions It as a Material for Producing Durable, High-Performance Parts in Industries Requiring Precision, Clarity, and Thermal Endurance.

To Make This More Relatable, Consider a Scenario Where an Engineer Faces Inconsistent Transparency in Lenses—Our Directly Sourced Pellets Minimize Impurities, Reducing Rejection Rates and Saving on Rework Expenses.

Raw Polycarbonate (PC) Resin Granules

Our PC Resin Granules Come Directly from Trusted Manufacturers, Offering Uniform Size and Purity for Smooth Processing. These Granules Form the Foundation for High-Quality Molding, Where Even Minor Variations in Pellet Quality Can Lead to Costly Issues Like Uneven Flow or Defects.

View Polycarbonate Data Sheets →

Polycarbonate(PC) Injection Molding Process

Injection molding of PC Demands Precise Control Over Thermal, Mechanical, and Timing Parameters to Form Complex, High-Tolerance Components. The Process Is Sensitive to Moisture, Temperature Changes, and Shear Rate (the Speed at Which Material Flows Under Force), Requiring Calibrated Equipment to Preserve Properties and Achieve Accuracy.

The process includes several critical stages:

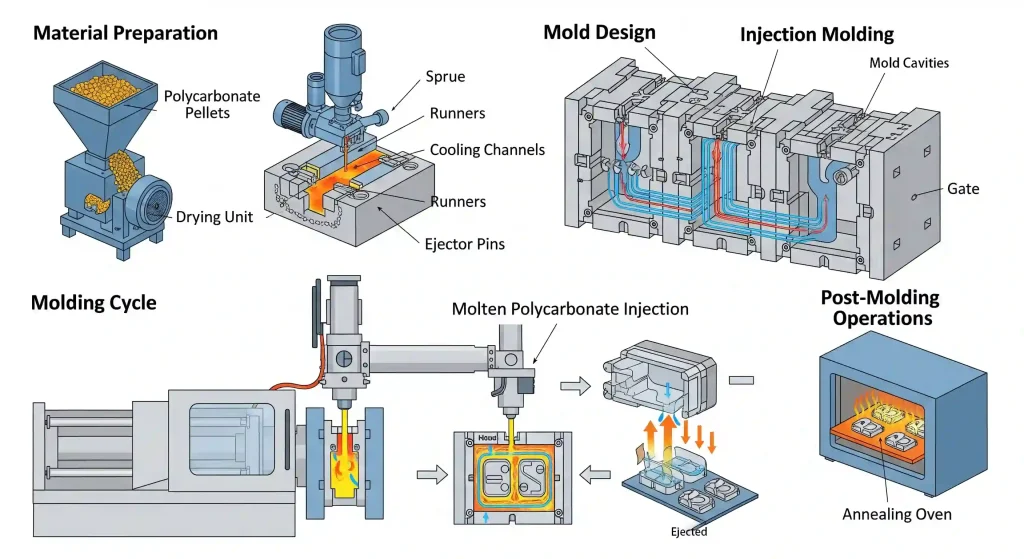

Material Preparation:

PC Pellets Need Thorough Drying at 110–120°C for 3–4 Hours to Reduce Moisture Below 0.02%. Without This Step, Hydrolysis (a Reaction Where Water Breaks Down the Material) Can Occur During Melting, Leading to Lower Molecular Weight and Surface Defects Like Splay (Silver Streaks) or Bubbles. Our Pellets Arrive with Low Initial Moisture Due to Factory-Sealed Packaging, Simplifying Your Preparation and Cutting Energy Costs for Drying.

Mold Design:

Effective Mold Design Maintains Uniform Flow and Prevents Stress Concentrations. Use CAD Tools for Balanced Runner Systems (Channels Guiding Molten Material), Proper Gate Locations (Entry Points into the Mold), and Efficient Cooling Channels to Reduce Warpage (Distortion from Uneven Cooling) and Sink Marks (Depressions from Insufficient Material). Venting (Air Escape Paths) Avoids Gas Entrapment During Filling. With Our Technical Support, We Guide You on Matching Pellet Grades to Mold Designs, Ensuring Fewer Iterations and Lower Tooling Expenses.

Molding Cycle:

Process the Material at Melt Temperatures of 280–320°C, Based on Grade and Application. Injection Pressure Ranges from 100–150 MPa. Adjust Screw Speed, Back Pressure, and Shot Size to Prevent Shear Degradation (Material Breakdown from Excessive Force). Maintain Mold Temperatures at 80–120°C for Surface Replication and Stress Control. Our High-Flow Pellet Options Allow Lower Pressures, Extending Machine Life and Reducing Energy Bills.

Post-Molding Operations:

After Ejection, Annealing (Controlled Heating to Relieve Stress) May Follow, Along with Trimming Gates or Flash (Excess Material), and Finishing Like Polishing or Coating. Cool Parts Gradually to Avoid Warping or Cracking. Our Pellets’ Consistency Minimizes Post-Processing Needs, Helping You Control Overall Production Costs.

Precise Control Across All Stages—From Conditioning to Tool Design and Thermal Regulation—Ensures Stable Processing and High-Quality PC Components for Electronics Housings, Optical Parts, or Structural Assemblies.

Advantages and Challenges

Polycarbonate (PC) injection molding produces durable, precise parts critical for industries like electronics, automotive, and medical devices, meeting strict performance standards. Its ability to create complex shapes with consistent quality makes it a go-to choice for manufacturers aiming to innovate without sacrificing reliability. By using high-quality PC pellets, companies can reduce defects like warping or bubbles, cutting production costs by up to 15% in real-world cases.

| ✅ Advantages | ⚠️ Challenges |

|---|---|

| High Impact ResistanceWithstands force without fracturing; ideal for protective equipment and structural components. | Scratch SusceptibilitySurfaces are prone to abrasion, reducing aesthetics and functionality. |

| Optical ClarityProvides excellent transparency for lenses, display panels, and lighting covers. | Moisture AbsorptionAbsorbs up to 0.15% moisture; inadequate drying may cause bubbles and defects. |

| Thermal StabilityMaintains integrity across -40°C to 120°C, suitable for demanding environments. | Chemical SensitivityVulnerable to degradation from certain solvents, limiting durability. |

| Design FlexibilityAllows intricate geometries, enabling innovative product designs. | Thermal ManagementRequires precise processing temperatures (280–320°C) to prevent material degradation. |

| Processing EfficiencySupports rapid cycles, improving cost-effectiveness in manufacturing. |

Optimization Strategies:

- Quality Control: Implement rigorous inspections to monitor moisture levels and surface integrity, ensuring defect-free parts.

- Material Preparation: Dry pellets at 110-120°C for 3-4 hours to eliminate moisture-related defects like splay or bubbles.

- Mold Design Enhancements: Apply scratch-resistant coatings and chemical-resistant gate designs to improve part durability and appearance.

- Environmental Control: Maintain stable processing conditions to prevent thermal or chemical degradation during molding.

By addressing these challenges with targeted strategies, manufacturers can maximize polycarbonate’s advantages, producing high-quality components efficiently. Our direct-sourced pellets, backed by Certificates of Analysis (CoA), tackle issues like material variability and moisture absorption, helping you save on production costs. For example, one client in electronics reduced defect-related losses by thousands annually by switching to our consistent, high-flow pellets.

Common Issues and Solutions

Defects in polycarbonate (PC) injection molding can disrupt part quality and production efficiency, especially in high-stakes industries like electronics, automotive, and medical devices. Addressing these through systematic troubleshooting and robust quality control ensures reliable components that meet strict standards.

Common Defects and Solutions:

- Warping: Uneven cooling causes distortion. Optimize cooling channel design to maintain uniform rates (2-5°C/s) and adjust mold temperature (80-100°C) to minimize stress.

- Sink Marks: Insufficient cooling or thick sections lead to surface depressions. Increase holding pressure (100-150 MPa) and ensure adequate cooling time to promote uniform solidification.

- Bubbling: Trapped air or moisture forms voids. Enhance venting with additional exhaust ports and dry pellets at 110-120°C for 3-4 hours to eliminate moisture.

- Burn Marks: Excessive melt temperature or poor venting causes scorching. Lower melt temperature (280-300°C) and improve ventilation to prevent material degradation.

Proactive Strategies:

- Real-Time Monitoring: Use sensors to track temperature and pressure during molding, catching issues like warping or splay early. Our technical team offers free process audits to optimize your setup with our pellets.

- Material Consistency Checks: Test pellet batches for uniformity before molding to avoid flow marks or bubbling. Our Certificates of Analysis (CoA) guarantee consistent quality, reducing variability-related defects.

- Regular Mold Maintenance: Clean and inspect molds to prevent residue buildup that causes burn marks or splay. Our support includes mold design recommendations to pair with our pellets for optimal results.

- Data-Driven Optimization: Use production data to fine-tune parameters like injection pressure and cooling time, ensuring defect-free parts. Our pellets’ predictable performance simplifies this process, saving setup time.

Continuous monitoring, regular mold maintenance, and precise parameter adjustments eliminate defects, ensuring high-quality components. Our direct-sourced pellets reduce common issues like splay and flow marks, helping manufacturers achieve consistent results. For example, one automotive client cut scrap rates by 10% using our high-flow pellets, saving significant costs.

Applications and Industries

Polycarbonate’s (PC) exceptional strength, optical clarity, and thermal stability make it a key material for injection-molded components across demanding industries. Its ability to create durable, precise parts supports innovative designs, delivering high-performance solutions for critical applications. From lightweight automotive lenses to sterile medical enclosures, PC’s properties reduce production costs and enhance product reliability, especially when paired with our high-purity pellets sourced directly from trusted manufacturers. Our pellets ensure consistent quality, helping you avoid costly defects and meet tight deadlines.

Key applications include:

- Aerospace: The high-strength properties of polycarbonate are leveraged for creating durable cabin windows and instrument panels that must withstand extreme temperatures and impacts.

- Automotive: Used to produce lightweight, impact-resistant headlamp lenses and panoramic windows. It enhances vehicle safety and improves fuel efficiency by offering a weight reduction of up to 50% compared to glass.

- Electronics: Its excellent thermal stability and durability enable the production of robust smartphone housings, laptop casings, and durable optical discs, ensuring reliability under stress and heat (up to 120°C).

- Healthcare: The material’s chemical resistance, transparency, and biocompatibility make it ideal for medical device enclosures, surgical tools, and sterile packaging, where clarity and safety are essential.

- Construction: In architectural applications, polycarbonate glazing provides superior light transmission (up to 90%) and insulation, contributing to improved energy efficiency.

| Application Area | Key Property Focus | Suggested Granule Type |

| Aerospace | Dimensional & Heat Stability | Heat-Stabilized PC Compounds |

| Automotive | Impact & UV Resistance | High-impact / UV-stabilized PC |

| Electronics | Flame Retardancy & Precision | UL94 V-0 PC / PC-ABS alloys |

| Healthcare | Clarity & Sterilization | ISO 10993 Medical-Grade PC |

| Construction | Transparency & Weatherability | UV-Stabilized or Light-Diffusing PC |

Our inventory includes these granule types, sourced directly from manufacturers to match your specific needs, ensuring fast delivery and competitive pricing to address supply chain challenges. New: For instance, a medical device manufacturer switched to our ISO 10993-compliant pellets, reducing material costs by 12% while meeting strict regulatory standards. Facing tight budgets or complex designs? Contact us for tailored pellet solutions and free technical support to optimize your production.

Sustainability and Recycling

Polycarbonate’s durability and versatility make it a critical material for high-performance components, but its sustainability hinges on effective recycling practices. Advanced recycling techniques minimize waste, conserve resources, and reduce the ecological footprint of polycarbonate production, aligning with modern environmental goals.

Recycling processes face challenges:

- Mechanical Recycling: Breaks Down Waste into Granules for Reprocessing. It Consumes ~30% Less Energy Than Virgin Production but Suits Less Demanding Applications Due to Property Degradation.

- Chemical Recycling: Decomposes PC into Monomers for Repolymerization, Yielding High-Purity Materials for Stringent Applications. It’s Cost-Intensive and Needs Contamination-Free Inputs.

- Challenges: Mixed Materials and Contaminants Complicate Separation; Moisture Risks Quality Loss.

Optimizing sustainability involves adopting closed-loop systems, enhancing material sorting technologies, and exploring bio-based polycarbonate alternatives. These strategies, combined with rigorous waste management, ensure recycling maximizes resource efficiency and supports long-term environmental stewardship in manufacturing.

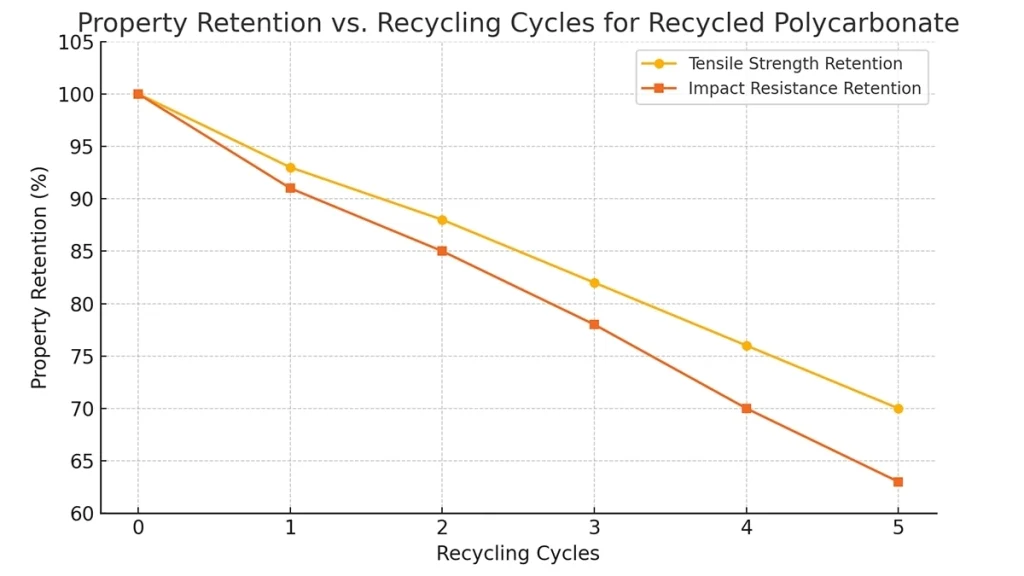

Performance Retention in Recycled PC

Recycled polycarbonate retains approximately 70–90% of its original mechanical properties, depending on the number of reprocessing cycles and the effectiveness of drying and contamination removal. For optical or load-bearing applications, blending virgin resin (10–30%) with PCR material is a common strategy to ensure stability and compliance.

Mechanical Property Degradation of Recycled PC with Recycling Cycles

Several global manufacturers now offer post-consumer recycled (PCR) polycarbonate that meets stringent quality and regulatory standards. Notable suppliers include:

- Covestro – “Makrolon® RE” series (mass-balanced, ISCC PLUS certified)

- SABIC – “LNP™ ELCRIN™” PCR-PC blends

- LG Chem / LOTTE Chemical – Asia-based suppliers offering high-clarity PCR-PC for electronics and lighting applications

These products are increasingly used in consumer electronics, automotive interiors, and lighting enclosures to help manufacturers meet sustainability targets.

Role of Plastic Pellet Distributors

In polycarbonate injection molding, specialized polymer distributors are more than intermediaries; they are strategic partners. They bridge the gap between large-scale primary resin producers and the dynamic needs of injection molders, directly impacting production efficiency, cost management, and final product quality.

Core Value Functions:

- Access to Premier Materials: Diverse Portfolio Ensures Material Fit for Applications, with Our Direct Sourcing Guaranteeing Purity and Affordability.

- Supply Chain Management & Risk Mitigation: Local Stock and Just-in-Time Delivery Prevent Disruptions, Reducing Inventory Costs—Vital for Volatile Markets.

- Dedicated Technical Expertise: Support for Material Matching, Optimization, and Defect Troubleshooting Extends Beyond Sales, Including Free Audits to Cut Your Expenses.

- Guaranteed Quality & Compliance: Quality Controls and Lot Traceability with Certificates of Analysis (CoA) Ensure Compliance and Consistency.

Ready to Source Premium PC Pellets? Contact us for Tailored Solutions and Expert Support. Our Approach Solves Pain Points Like Unreliable Suppliers by Providing Transparent Pricing and Custom Blends.

Market Trends and Future Outlook

The polycarbonate molding sector is experiencing a significant shift, driven by sustainability goals, digital transformation, and material innovation. Understanding these developments is essential for manufacturers and material suppliers aiming to maintain a competitive edge.

- Green Manufacturing Initiatives Regulations and Demands Drive Use of Recycled PC, Energy-Efficient Machines, and Cleaner Systems, Boosting Credibility and Savings.

- Smart Production Technologies IoT and Automation Enable Real-Time Monitoring, Maintenance, and Quality, with AI Reducing Waste and Downtime.

- High-Performance PC Materials Formulations Improve Heat Resistance, Durability, and Flame Retardancy Without Halogens, Expanding Roles in Medical Devices and Lighting.

- Process and Tooling Advancements Variothermal Control, Hot Runners, and Simulations Enhance Precision, Cut Defects, and Shorten Cycles.

Together, these trends point to a maturing industry with strong potential for growth. Companies that align their operations with evolving material standards, invest in digital infrastructure, and embrace responsible sourcing practices will be better positioned to capture future opportunities in the polycarbonate molding market.

Conclusion

This Guide Covers PC Injection Molding—from Characteristics and Processes to Performance Considerations. Understanding Polymer-Molding Compatibility Is Key for Parts Meeting Durability, Aesthetics, and Reliability Standards.

Examining Benefits, Limitations, and Challenges Underscores Compatibility’s Importance. It Highlights Solutions for Consistency and Efficiency.

Sustainability Emerges as Crucial, with Recycled Materials and Efficient Systems Reducing Impact and Costs.

Simplifying Concepts and Offering Insights Equips Professionals to Align Practices with Demands. Optimizing Cycles, Reducing Defects, or Enhancing Performance Drives Innovation and Competitiveness.

For Questions or High-Quality PC Resins, Get in Touch. We Provide Custom Pellet Recommendations to Solve Your Specific Pain Points, Like Material Selection for Cost Savings.

📧 Email: jerry@salesplastics.com

📞 Phone: +8618657312116

FAQs

A:Polycarbonate Undergoes Injection Molding. This Thermoplastic Processes into Parts Due to Strength, Transparency, and Heat Resistance.

A: Barrel Temperature Ranges from 260°C to 320°C (500°F to 608°F), Based on Grade and Requirements. Mold Temperatures Set Between 70°C and 120°C (158°F to 248°F).

A: Dry Resin at 120°C (248°F) for 3-4 Hours to Remove Moisture, Use Barrel Temperatures of 260°C to 320°C, Mold Temperatures of 70°C to 120°C, and Pressures of 10,000 to 20,000 psi. Maintain Moderate Screw Speeds and Venting to Avoid Defects. Our Pellets Simplify This with Pre-Tested Compatibility.

A: Standard Hydraulic or Electric Machines with Temperature and Pressure Control. Use Screws with Low Compression Ratio (1.5:1 to 2:1) to Prevent Degradation.

A: Flat, Extruded Panels from PC Resin, Known for Impact Resistance, Transparency, and Lightweight. Used in Glazing, Roofing, and Covers—Separate from Injection Molding but Sharing Material Benefits.

A: Grades Include General-Purpose (e.g., Lexan 141R), High-Flow (e.g., Lexan 121R), and Flame-Retardant (e.g., Lexan 940). Match to Requirements for Strength, Clarity, or Heat. We Stock These for Quick Delivery.

A: Issues Include Moisture Defects Like Splay, Stress Cracking from Cooling, Yellowing from Overheating, and Sink Marks from Packing. Proper Drying and Control Mitigate These. Our Expertise and Pellets Help Prevent Them, Reducing Your Troubleshooting Time.