Polycarbonate(PC) sheets and granules are high-performance materials prized for their exceptional strength, clarity, and versatility in industries like construction, automotive, and electronics. Renowned for their impact resistance—up to 250 times stronger than glass—and excellent light transmission (up to 90%), these materials enable innovative designs and durable solutions. This guide provides a detailed overview of their properties, benefits, and applications, while debunking common misconceptions. By the end, you’ll understand why polycarbonate is a preferred choice for engineers and manufacturers seeking reliable, adaptable materials for demanding projects.

Introduction to Polycarbonate(PC) Sheets and Granules

Polycarbonate materials have revolutionized modern engineering and design due to their exceptional strength, clarity, and versatility. Polycarbonate sheets, often selected as a superior alternative to glass, offer high impact resistance, optical clarity, and durability, making them a preferred choice across industries such as construction, automotive, and signage. Derived from polycarbonate granules, these sheets are formed through precise manufacturing processes like extrusion or injection molding, enabling customization for diverse applications.

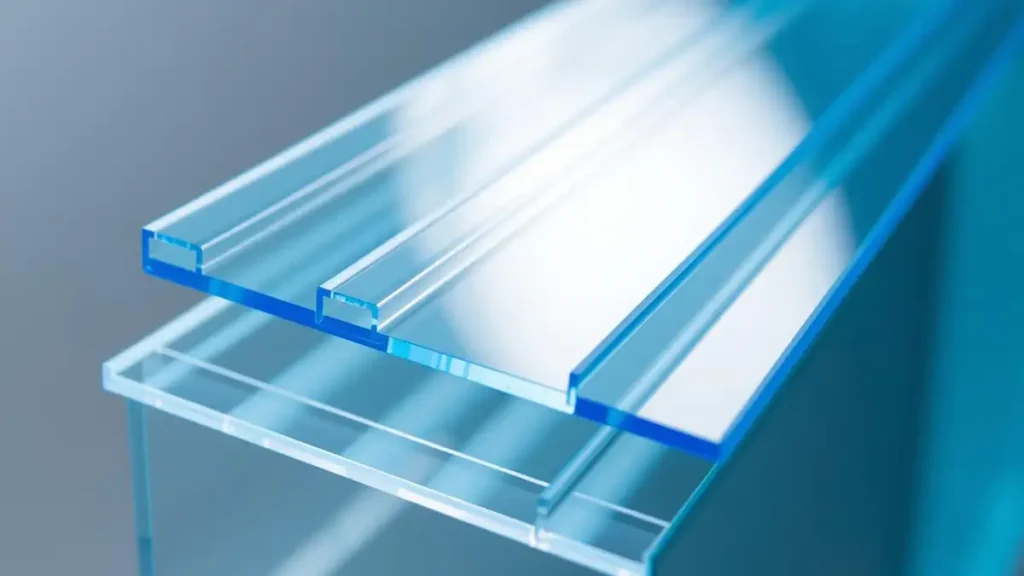

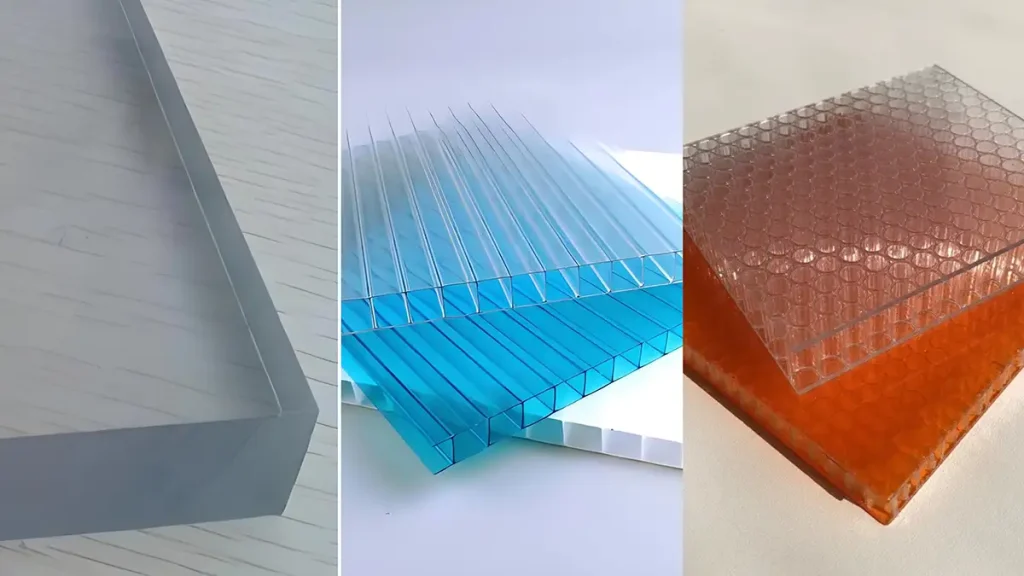

Polycarbonate(PC) sheets are prized for their ability to combine transparency with resilience. With an impact strength up to 250 times greater than glass and 30 times that of acrylic, they are ideal for demanding applications such as safety glazing, greenhouse panels, and roofing systems. Available in three primary forms—solid, multi-wall, and corrugated—each type serves distinct purposes. Solid sheets provide excellent thermal insulation and optical clarity, making them suitable for windows and protective covers. Multi-wall sheets, with their hollow structure, offer a balance of strength and lightweight properties, ideal for energy-efficient building facades. Corrugated sheets, designed for roofing, facilitate water runoff and withstand harsh weather conditions.

Advancements in polycarbonate technology are driving sustainable manufacturing practices, including the use of recycled materials and energy-efficient production methods. Industry trends indicate growing demand for PC sheets and granules in eco-conscious construction, particularly for energy-efficient buildings and lightweight automotive components. Compliance with standards such as ISO 9001 and ASTM D3935 ensures consistent quality and performance, enabling businesses to select the right polycarbonate products for their specific needs.

Properties and Benefits of PC Sheets

PC sheets are increasingly favored across industries for their exceptional properties. They offer remarkable impact resistance, with a strength up to 250 times greater than glass and 30 times greater than acrylic, making them virtually unbreakable. Additionally, they feature built-in UV resistance, ensuring long-term clarity and durability without yellowing or degrading under sunlight exposure.

Key Properties

- Impact Resistance: Up to 200 times stronger than glass and 30 times stronger than acrylic, polycarbonate sheets are virtually unbreakable, even under extreme force.

- Transparency: Offers up to 89% light transmission for clear sheets, comparable to glass while maintaining durability, ideal for applications requiring high clarity.

- Lightweight: Weighs approximately 50% less than glass of equivalent thickness, simplifying handling and installation.

Granule-Driven Performance

High-quality polycarbonate granules enhance the sheets’ performance:

- Durability: UV-resistant granules ensure sheets maintain clarity and strength for 10-20 years under normal conditions, resisting yellowing or degradation.

- Versatility: Consistent molecular structure allows easy fabrication, thermoforming, and cutting for diverse applications, such as curved roofing and safety glazing.

- Thermal Efficiency: Excellent insulation (U-value of 1.6–3.5 W/m²·K for single-layer sheets, depending on thickness) reduces energy costs by stabilizing indoor temperatures.

Benefits

The use of premium granules amplifies the benefits of PC sheets:

- Cost-Effectiveness: Long-lasting clarity and strength reduce maintenance and replacement costs compared to glass or acrylic.

- Safety and Savings: Lightweight design lowers transportation and installation expenses, while impact resistance enhances safety.

- Sustainability: Energy-saving insulation reduces environmental impact by lowering heating and cooling demands.

Polycarbonate sheets, crafted from premium granules, offer exceptional strength, clarity, and lightweight properties, making them ideal for specialized applications. They provide shatterproof durability for high-traffic environments, such as retail walkways and bus terminal canopies, ensuring long-term safety. In greenhouses and agricultural facilities, their transparency optimizes sunlight for enhanced crop yields, while superior insulation minimizes energy expenses. For industrial and automotive uses, like warehouse roofing and vehicle windshields, their robust construction and ease of shaping deliver reliable performance and lower installation costs, ensuring cost-effective, durable solutions across construction, agriculture, and automotive sectors.

Applications of Polycarbonate(PC) Sheets

Polycarbonate(PC) sheets, extruded from high-purity polycarbonate granules, offer exceptional durability, optical clarity, and lightweight properties. These attributes stem from the granules’uniform molecular structure, enabling precise performance in demanding applications. Below are key uses across industries, supported by verified data.

Construction and Architectural Glazing

Polycarbonate(PC) sheets are widely used for glazing in homes and commercial buildings. They insulate better than glass, reducing heat loss, and allow up to 90% light transmission for energy-efficient natural lighting. Lighter than glass by half, they simplify installation for skylights, curtain walls, and large windows. Consistent granules ensure sheets have clear visuals and robust strength for architectural needs.

Agricultural Greenhouses

In agriculture, polycarbonate(PC) sheets are essential for greenhouses. They diffuse sunlight evenly, supporting healthy plant growth, and are far tougher than glass, resisting harsh weather like hail. Multiwall sheets, formed from carefully processed granules, enhance insulation and durability, making them ideal for year-round farming in challenging climates.

Safety and Protective Barriers

Polycarbonate(PC) sheets serve as protective barriers in schools, sports facilities, and public spaces. They withstand strong impacts while maintaining clear visibility for safety and surveillance. High-purity granules produce flawless, reliable sheets, ensuring performance in high-traffic environments.

Automotive and Optical Components

In the automotive sector, polycarbonate(PC) sheets create lightweight, shatter-resistant headlight lenses and vehicle windows that meet strict safety standards. For optics, they form durable, clear eyewear lenses, often with scratch-resistant coatings. Optical-grade granules ensure high transparency and toughness, critical for these precision applications.

Polycarbonate vs Other Materials

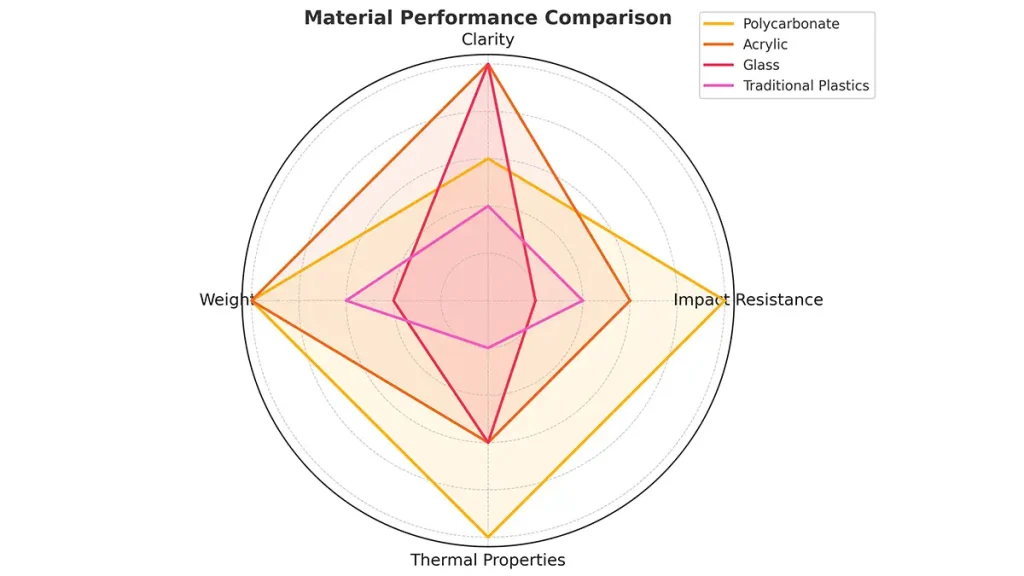

When evaluating transparent thermoplastics, polycarbonate (PC) is frequently compared with acrylic (PMMA), glass, and traditional plastics. A structured analysis of impact resistance, optical clarity, weight, and thermal performance is essential for material selection in engineering, construction, and safety-related applications.

1. Impact Resistance

- Polycarbonate: 250× stronger than glass, 30× stronger than acrylic.

- Acrylic: Better than glass, but brittle under repeated stress.

- Glass: Fragile, prone to shattering.

- Traditional Plastics: Vary widely; generally poor in load-bearing or safety use.

2. Clarity

- Acrylic: Highest light transmission (~92%), excellent optical quality.

- Polycarbonate: Slightly lower (~88%) but better long-term clarity and UV resistance.

- Glass: Clear but fragile and heavy.

- Traditional Plastics: Inconsistent clarity and poor UV performance.

3. Weight

- PC & Acrylic: ~50% lighter than glass, easier to install and ship.

- Glass: Heavy, needs more structural support.

- Plastics: Weight varies, often lightweight but may lack rigidity.

4. Thermal Resistance

- Polycarbonate: Operates from –40°C to 120°C, stable under load.

- Acrylic: Up to ~80°C, may deform with heat.

- Glass: Good thermal tolerance, but brittle.

- Traditional Plastics: Poor thermal performance.

| Material | Impact Resistance | Clarity | Weight | Thermal Range |

|---|---|---|---|---|

| Polycarbonate | ★★★★★ | ★★★★☆ | ★★★★★ | –40°C to 120°C (Excellent) |

| Acrylic (PMMA) | ★★★☆☆ | ★★★★★ | ★★★★★ | ~80°C (Good) |

| Glass | ★☆☆☆☆ | ★★★★★ | ★★☆☆☆ | Moderate |

| Traditional Plastics | ★★☆☆☆ | ★★☆☆☆ | ★★★☆☆ | Poor |

Polycarbonate offers a balanced performance profile: high strength, reasonable clarity, light weight, and superior thermal stability. Compared to alternatives, it is the most versatile solution for safety, structural, and optical applications. A clear understanding of these differences ensures optimal material selection based on specific end-use requirements.

Types of PC Sheets

PC sheets are available in three primary structural forms—solid, twin-wall, and multi-wall—each engineered for specific applications based on their mechanical and thermal properties. Selecting the appropriate type requires a clear understanding of their structural differences, performance characteristics, and optimal use cases. These sheets are manufactured using advanced extrusion processes, ensuring consistent quality and durability across applications. Their versatility makes them a preferred choice in industries ranging from construction to protective glazing.

1. Solid Sheets

These are single-layer, transparent sheets with high impact resistance—much stronger than glass. They offer good optical clarity and are commonly used in safety glazing, partitions, and protective barriers.

2. Twin-Wall Sheets

Twin-wall sheets have two layers with a hollow center, offering better thermal insulation and lower weight. They are mainly used in greenhouses, roofing, and skylights, where light diffusion and energy savings are important.

3. Multi-Wall Sheets

With three or more layers, multi-wall sheets provide improved insulation and sound reduction. They are suitable for industrial roofs and large-span structures, where energy efficiency matters.

Installation Note

Solid sheets are easy to cut and install. Twin-wall and multi-wall sheets require more care during cutting and sealing to avoid moisture penetration.

Choose solid sheets for strength and transparency, twin-wall for lightweight insulation, and multi-wall for enhanced energy efficiency. Your choice should align with the specific functional and structural needs of the application.

Custom Polycarbonate Granules

Custom polycarbonate granules play a critical role in the production of high-performance polycarbonate components. These granules are engineered to meet precise mechanical, optical, and thermal requirements—such as enhanced impact strength, flame retardancy, UV resistance, or improved flow characteristics—based on the specific end-use application.

Two primary processing methods—extrusion and injection molding—are used to shape these granules into finished products:

| Manufacturing Process | Key Advantages | Typical Applications |

|---|---|---|

| Extrusion | Consistent wall thickness, smooth surface finish | Flat sheets, corrugated panels, pipes, tubing |

| Injection Molding | High dimensional accuracy, complex geometries | Automotive housings, electrical enclosures, lenses |

Key Customization Options

- Performance:UV resistance for outdoor use, flame retardancy (e.g., UL 94 V-0), and high impact strength.

- Color Matching:Custom shades, gloss levels, or transparency based on application needs.

- Functional Additives:Options include glass fibers for stiffness, anti-scratch or anti-static agents, and blends with other polymers (e.g., ABS, PETG).

These tailored formulations help manufacturers meet application-specific demands and comply with standards like RoHS, REACH, or FDA.

In summary, custom PC granules offer versatile, targeted solutions across construction, automotive, electronics, and consumer goods—where both performance and compliance matter.

Processing and Applications of Polycarbonate Granules

Polycarbonate granules are primarily processed through extrusion, injection molding, and blow molding, selected based on the desired product geometry, mechanical properties, and production volume. Each method offers distinct advantages: extrusion enables continuous profiles with consistent thickness, injection molding delivers complex, high-precision parts, and blow molding produces hollow components with excellent impact resistance.

- Extrusion is used to produce sheets, films, and tubes. Extruded polycarbonate sheets are widely used in construction, safety glazing, and protective panels, while films are applied in optical layers, labels, and electronic displays due to their clarity and dimensional stability.

- Injection molding forms complex, rigid parts by injecting molten granules into precision molds. Typical applications include automotive interior components, electronic housings, and lighting parts, where heat resistance and mechanical strength are essential.

- Blow molding is less common but suitable for producing hollow containers and protective enclosures, especially where impact resistance and transparency are required.

These processing methods enable the production of high-performance polycarbonate products used in sectors such as automotive, electronics, construction, and optics, meeting stringent technical and safety standards.

Common Misconceptions

Despite their widespread use in construction, automotive, and protective applications, polycarbonate(PC) sheets are often misunderstood. These misconceptions can cause hesitation or lead to undervaluing their performance benefits. It’s important to address these myths with factual information to make informed material choices.

- Lack of Strength or Durability

These materials are exceptionally impact-resistant, approximately 200–250 times stronger than glass of equivalent thickness, making them among the most robust transparent thermoplastics. This durability supports their use in security glazing, protective shields, and high-impact environments. - Poor UV Resistance

While untreated polycarbonate may yellow or become brittle under prolonged UV exposure, most commercial products feature UV-resistant coatings or co-extruded layers. These enhancements ensure outdoor stability, typically maintaining clarity and strength for 10–15 years under standard conditions. - High Maintenance Requirements

Maintaining these materials is straightforward, requiring only mild soap and water for cleaning to preserve clarity and performance. Their shatter-resistant nature also minimizes the need for frequent replacements, reducing long-term maintenance costs.

Frequently Asked Questions

A:PC sheets scratch more easily than glass or acrylic, which can reduce their clarity. Without UV stabilizers or coatings, they may yellow and degrade when exposed to sunlight over time. Recycling polycarbonate is more complex than some other plastics, making disposal and sustainability more challenging.

A:The durability of PC sheets depends on the quality of the granules. Granules with UV stabilizers, impact modifiers, and heat stabilizers improve strength, weather resistance, and lifespan. High molecular weight and purity in granules also contribute to better mechanical performance and fewer defects.

A:Yes, polycarbonate granules can be mechanically recycled by grinding scrap sheets and blending with virgin material. Maintaining purity during recycling is essential to preserve optical clarity and mechanical properties. Proper recycling reduces raw material use and environmental impact but requires strict quality control.

A:PC sheets are fire-resistant but not fireproof. They ignite at temperatures above approximately 580°C (1076°F) and generally self-extinguish once the heat source is removed. Flame retardant additives are commonly used to meet fire safety standards such as UL 94 V-2 or higher.

A:PC sheets are stronger and more impact-resistant than plexiglass, making them less likely to crack or break. Plexiglass (acrylic) offers better scratch resistance and optical clarity but is more brittle. The choice depends on whether impact strength (polycarbonate) or surface hardness and clarity (plexiglass) are the priority. For detailed comparisons, “Polycarbonate vs Plexiglass” guides can provide in-depth information on mechanical properties and applications.

Conclusion

Polycarbonate(PC) sheets and granules stand out as high-performance materials offering exceptional strength, clarity, and versatility across a wide range of industries including construction, automotive, agriculture, and electronics. Their superior impact resistance, excellent light transmission, and customizable forms make them an ideal choice for demanding applications where durability and safety are paramount. Advances in granule technology and sustainable manufacturing further enhance their value by improving UV resistance, thermal insulation, and recyclability. Understanding the distinctions between polycarbonate and alternatives like plexiglass helps engineers and manufacturers select the most suitable materials to meet specific project requirements. For more detailed guidance or to discuss your polycarbonate needs, please contact us at jerry@salesplastics.com or call +8618657312116. Our team is ready to support your next project with expert advice and high-quality materials.