Lightweight, durable, and moisture-resistant—polyethylene (PE) foam is quickly becoming a go-to solution across industries ranging from construction and packaging to automotive and electronics. In countries like Malaysia, Singapore, Laos, Vietnam, and Bangladesh, demand for PE foam continues to grow due to its performance and cost-effectiveness.

This article breaks down what makes PE foam so adaptable: how it’s made, why closed-cell structures offer superior insulation and shock absorption, and where it’s being used to reduce waste, lower shipping damage, and improve energy efficiency in buildings. Whether you’re sourcing materials or designing better products, understanding PE foam’s capabilities can lead to smarter, more sustainable choices.

What is Polyethylene(PE) Foam?

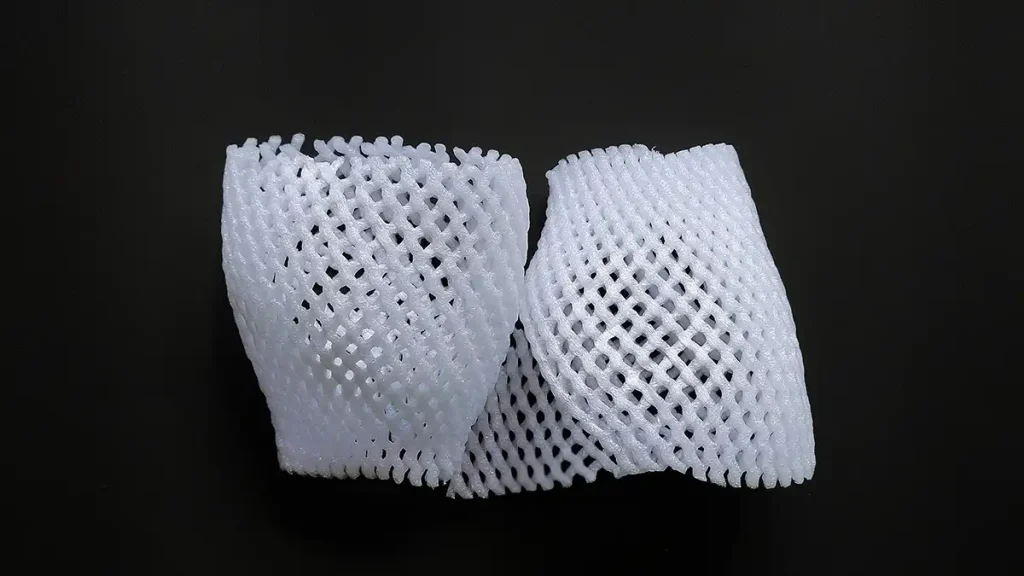

Polyethylene (PE) foam is a closed-cell material crafted from polyethylene resin. Renowned for being lightweight, flexible, and chemically inert, it’s used in a wide range of applications from protective packaging to thermal insulation and automotive components.

The closed-cell structure means each microscopic cell is sealed and separate, making the foam resistant to water and air. This gives it excellent moisture resistance, shock absorption, and thermal insulation, qualities that are especially valuable in humid climates. Its ability to maintain cushioning and structural integrity under pressure makes it a reliable material for vibration dampening, floor underlay, and shipping protection.

Manufacturers and engineers favor the material not only for its performance but also for its versatility; it can be easily cut, molded, laminated, or layered to suit specific needs. Understanding its composition helps professionals choose the right density, thickness, and type to meet project requirements, whether it’s lightweight padding for electronics or firm support in construction panels.

| Characteristic | Description |

| Structure | Composed of small interconnected polymer cells |

| Water Resistance | Effectively resists water absorption |

| Cushioning Properties | Maintains cushioning under pressure |

| Durability | Offers long-lasting performance |

Characteristics of Polyethylene(PE) Foam

Polyethylene(PE) foam offers a combination of mechanical strength, chemical resistance, and thermal performance that makes it suitable for demanding environments. Here are its key characteristics:

- Durability: PE foam resists wear and tear, retaining its shape and cushioning properties even after repeated compression or impact.

- Chemical Resistance: It withstands exposure to common acids, bases, and solvents without degrading, making it suitable for industrial and packaging uses.

- Thermal Insulation: Thanks to its closed-cell structure, PE foam provides effective thermal insulation, helping to retain heat or block external temperatures in both hot and cold environments.

- Sound Absorption: It reduces noise transmission, making it useful in automotive cabins, HVAC systems, and building interiors.

- UV Resistance: Certain grades of PE foam are treated to resist UV radiation, improving performance in outdoor applications such as construction and marine use.

These features allow PE foam to protect sensitive equipment, reduce energy loss, and improve comfort across a variety of sectors. By selecting the right foam grade, businesses can match material performance to specific functional and environmental needs.

How It’s Made

The production of polyethylene (PE) foam involves a precise, multi-step process that transforms raw polyethylene resins into a lightweight, resilient material with controlled density and performance characteristics. Here’s how it’s typically made:

- Raw Material Selection

The process begins by selecting the appropriate polyethylene resin—typically low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE)—based on the required mechanical and thermal properties of the final foam product. - Additive Blending

Various additives are mixed into the resin, such as foaming agents (e.g., butane or CO₂), cross-linking agents to enhance strength, and stabilizers. These directly influence the foam’s density, flexibility, and durability. - Foam Extrusion or Molding

The resin mixture is melted and processed through extrusion dies or molds, depending on the product type (e.g., rolls, sheets, or custom forms). During extrusion, gas expansion forms the closed-cell structure that defines PE foam. This step ensures uniform cell size and material thickness. - Cooling, Curing & Cutting

The foam is cooled and stabilized to retain its structure, then cut or laminated into the desired size or shape. Precise cutting ensures dimensional accuracy for downstream uses in packaging, insulation, or automotive components.

The entire process requires tight quality control to ensure consistency in density, compression strength, and thermal performance. Manufacturers may also apply surface treatments or laminate other materials (such as aluminum foil or film) depending on the end-use requirements.

Types of PE Foam

PE foam is primarily categorized into two types: closed-cell and open-cell.

- Closed-cell foam features tightly sealed cells that make the material rigid, moisture-resistant, and thermally stable. It maintains its shape under pressure and doesn’t absorb water or air, making it ideal for protective packaging, thermal insulation, and vibration dampening.

- Open-cell foam has interconnected cells, resulting in a softer, more flexible structure. It’s more breathable and compressible but less resistant to moisture and structural stress, often used in sports padding.

Because cell architecture drives a foam’s density, resilience, and environmental resistance, selecting closed- or open-cell PE directly shapes how—and where—the material performs best. The following section explores those application choices in detail.

Applications of PE Foam

The distinct properties of closed-cell and open cell polyethylene foam allow it to serve a wide range of industries. From protective packaging to thermal insulation and vibration dampening, each application relies on selecting the right foam structure for the job.

Common Application Areas:

| Application | Industry | Foam Type | Key Benefits |

|---|---|---|---|

| Protective Packaging | Logistics | Closed-cell | Lightweight, moisture-resistant, impact-absorbing |

| Thermal Insulation | Construction | Closed-cell | Temperature regulation, water resistance, energy efficiency |

| Vibration Dampening | Automotive | Closed-cell | Noise reduction, shock absorption, long-term durability |

| Sports Padding | Recreation | Open-cell or soft closed-cell | Comfort, flexibility, repeated impact absorption |

In packaging, closed-cell PE foam is widely used by companies like packaging solution provider for its ability to cushion delicate items while resisting moisture and compression. In construction, its thermal insulation properties help improve building energy performance. Automotive manufacturers rely on its structural resilience to reduce vibration and noise, while open-cell variants are sometimes used in comfort-driven applications like sports gear and padding.

PE Foam vs Polyurethane Foam: Which is Right for You?

Polyethylene (PE) foam and polyurethane (PU) foam are two of the most commonly compared options when selecting foam materials—each with distinct physical characteristics and performance trade-offs.

PE foam is a closed-cell structure, known for its rigidity, water resistance, and long-term durability. It maintains its shape under pressure, resists moisture and chemicals, and is ideal for structural or protective applications like packaging, insulation, or vibration dampening. Its low water absorption and resistance to deformation make it suitable for outdoor or high-impact environments.

Polyurethane foam, by contrast, is usually open-cell and significantly softer and more flexible. It conforms easily to irregular surfaces, providing superior comfort and cushioning. This makes it a popular choice in furniture, bedding, and acoustic panels, where breathability and softness are valued over moisture resistance.

From a cost and lifecycle perspective, PE foam is generally more economical over time. While PU foam may offer a better tactile experience, it degrades faster—especially in humid or exposed environments—due to its porous structure. PE foam, though firmer, often lasts longer and maintains performance with less material fatigue.

In short, pe foam is preferred for durability, water resistance, and structural applications, while polyurethane foam is chosen for comfort, flexibility, and indoor use. Understanding the functional demands of each project is key to choosing the right material.

Environmental Impact and Sustainability

Unlike many flexible foams, polyethylene is a thermoplastic, meaning it can be re-melted and reprocessed without losing core performance. This allows offcuts, production scrap, and post-consumer waste to be collected and recycled into new foam products or other polyethylene-based materials.

Recycling infrastructure for PE foam is also expanding. Specialized facilities now use technologies such as densification and pelletizing to compact and repurpose used foam efficiently, significantly reducing landfill waste and lowering carbon impact.

In addition, manufacturers are developing bio-based and oxodegradable versions of PE foam, made from renewable feedstocks or designed to break down more easily under specific conditions. These innovations help businesses align with international sustainability goals, including extended producer responsibility (EPR) and carbon neutrality targets.

For companies, adopting recyclable or bio-based PE foam not only reduces environmental harm but also meets growing consumer expectations around sustainability—offering both regulatory compliance and brand value enhancement.

Safety and Practical Considerations

To ensure the safe use of this foam, proper storage and handling are essential. It should be stored in a cool, dry environment, away from direct sunlight and excessive heat. Managing static electricity is also crucial during processing and handling, as static buildup can pose fire risks.

Fire safety is another important factor, as the foam’s fire retardancy varies. Selecting materials with the appropriate fire rating is essential depending on the application. By considering these practical aspects—storage, static control, fire safety, and chemical compatibility—you can optimize the foam’s performance and safety.

Our Premium PE Pellets for Foam Production

High-quality polyethylene pellets are the cornerstone of superior foam products. Sales Plastics supply a comprehensive range of authentic PE resins from trusted global manufacturers such as SABIC, ExxonMobil, Borouge, LyondellBasell, Borealis, Marlex, QAPCO, and DOW.

For foam manufacturing, our key offerings focus on:

- Low-Density Polyethylene (LDPE): including SABIC LDPE, Borealis LDPE, Marlex LDPE, and ExxonMobil LDPE—valued for its excellent processability, flexibility, and foamability, making it ideal for closed-cell foam production.

- Linear Low-Density Polyethylene (LLDPE): featuring SABIC LLDPE, ExxonMobil LLDPE, Marlex LLDPE, QAPCO Lotrene LLDPE, and DOW LLDPE—providing enhanced strength, toughness, and durability when blended with LDPE for improved foam properties.

- Modified High-Density Polyethylene (HDPE): such as SABIC Multimodal HDPE and Borouge HDPE—used selectively in specialized foam applications requiring higher stiffness and chemical resistance, often in structural or composite foam products.

By leveraging these carefully selected PE resins, foam producers can optimize their formulations for consistent cell structure, mechanical strength, thermal insulation, and long-term stability. Our role as a distributor ensures access to genuine, high-quality pellets that support efficient processing and superior end-product performance.

FAQs

Q:A: Yes, most polyethylene(pe) foam is closed-cell, which blocks water and air—ideal for insulation, flotation, and moisture-proof packaging.

Q:Yes, most PE foam is closed-cell, which blocks water and air—ideal for insulation, flotation, and moisture-proof packaging.

Q:It’s made by extrusion or molding, where heated pellets are expanded into foam sheets or blocks using a blowing agent.

Q:Medium to high-molecular-weight pellets with good melt strength are best, ensuring durability and consistent foam quality.

Q:Yes, clean closed-cell PE foam can be recycled into products like floor underlayment, composite materials, or new foam sheets.

Q:It resists water, insulates heat, absorbs impact, and is lightweight—suitable for packaging, construction, and marine uses.

Q:PE foam is firmer and water-resistant, while polyurethane foam is softer and better for cushioning or comfort.

Conclusion

PE foam, powered by salesplastics premium PE pellets, delivers unmatched performance for packaging, insulation, and automotive applications. Its recyclability, safety, and cost-effectiveness make it a top choice. Partner with us for high-quality pellets and technical support to elevate your foam production.

If you have questions about PE pellets, get in touch.You can email us at jerry@salesplastics.com or call +8618657312116. We’re here to help.