The ongoing pursuit of enhanced engineering materials presents designers and engineers with significant challenges in balancing demands for performance, durability, and environmental responsibility. Traditional materials, such as nylon, often face limitations in areas like chemical resistance or hydrolytic stability, pushing the search toward advanced polymers. Polyketone (POK) is emerging as a strong candidate, offering a unique combination of high mechanical strength, excellent barrier properties, and a more favorable sustainable profile due to its carbon monoxide-derived backbone. This article provides a comprehensive, parameter-by-parameter analysis of Polyketone versus Nylon (Polyamide), detailing key performance advantages and material properties to help inform critical material specification decisions for demanding applications.

Fundamentals of Polyketone

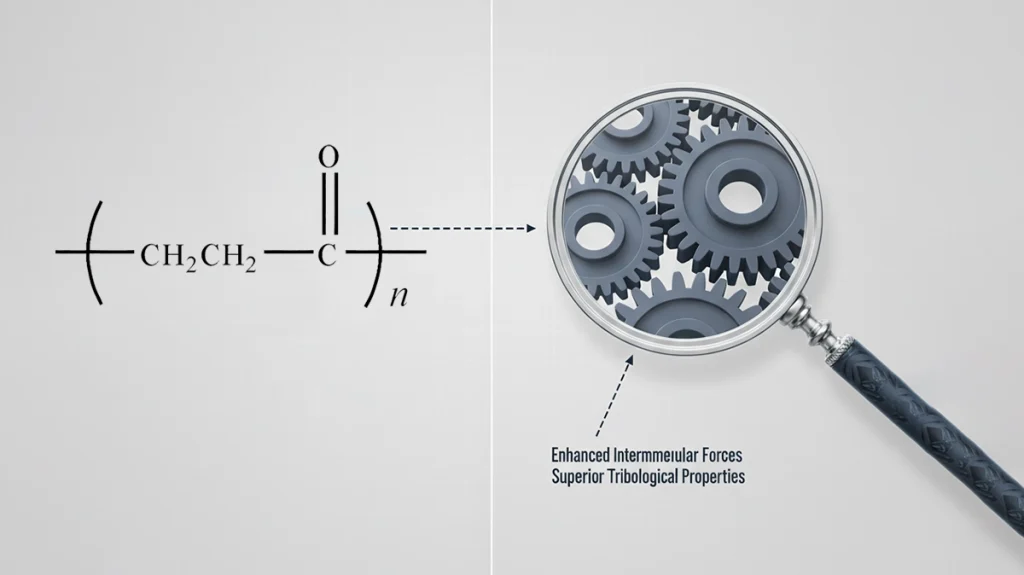

Polyketone, specifically aliphatic polyketone, is a semi-crystalline engineering thermoplastic distinguished by a backbone featuring alternating ethylene and ketone carbonyl (C=O) groups. This is a fundamental chemical distinction from the amide groups found in nylons. Commercial POK grades are typically terpolymers, incorporating a low percentage of propylene (~ 5-15%) to optimize both melt processability and mechanical performance. The high polarity of the ketone groups facilitates strong intermolecular bonding, which results in POK’s signature balanced property profile.

This chemical foundation yields several key performance characteristics that are highly advantageous in demanding technical applications:

- Mechanical Balance: POK offers high tensile strength and stiffness combined with exceptional ductility and impact resistance, providing a resilient material solution.

- Superior Tribology: It exhibits excellent wear, friction, and abrasion resistance, making it highly effective for moving parts like gears and bushings.

- Hydrolytic Stability and Chemical Resistance: Unlike Polyamides, POK has minimal moisture absorption (typically <0.5% at equilibrium), ensuring superior dimensional stability. It also demonstrates strong resistance to a broad range of chemicals, hydrocarbons, and fuels.

- Processing Efficiency: POK typically offers faster molding cycles than competitive materials due to its high crystallinity and rapid solidification rate, and generally does not require pre-drying for moisture control.

These properties position POK as a high-performance alternative, particularly where materials like Nylon (PA) or Acetal (POM) face challenges due to moisture sensitivity, chemical exposure, or inadequate impact-wear balance. The following sections will explore how these specific advantages translate to component longevity and reliability in industries such as automotive and industrial fluid handling.

Polyketone vs Nylon: Head-to-Head Comparison

When specifying materials for critical engineering components, a direct comparison across key performance metrics is essential. While both Polyketone (POK) and Nylon (Polyamide, PA) are classified as high-performance engineering plastics, their distinct chemical structures lead to significant differentiation in application suitability, particularly under dynamic or hydrolytic conditions.

| Property | Polyketone (POK, Unfilled) | Polyamide (PA 6/6, Dry-as-molded) | Note |

| Tensile Strength (MPa) | 65-75 | 80-85 | PA shows higher peak strength (DAM) |

| Impact (kJ/㎡) | No Break (Izod, notched) | 4.5-5.5 | POK offers superior ductility |

| Moisture Absorption (%) | <0.5 (Equilibrium, 23℃/50%RH) | 2.5-3.5 (Equilibrium, 23℃/50%RH) | POK maintains stability under humidity |

| Dimensional Stability | Excellent | Fair (Moisture Dependent) | POK is more stable |

| Melting Point (℃) | 220-225 (Homopolymer/Terpolymer dependent) | 255-265 | PA offers a higher limit |

| Chemical/Fuel Resistance | Excellent (Alkalines, Hydrocarbons) | Good (Weakened by Acids) | POK is generally broader |

| Wear Volume (mm³/Nm) | 0.2-1.0 (Low friction grades) | 1.5-3.0 | POK provides lower wear |

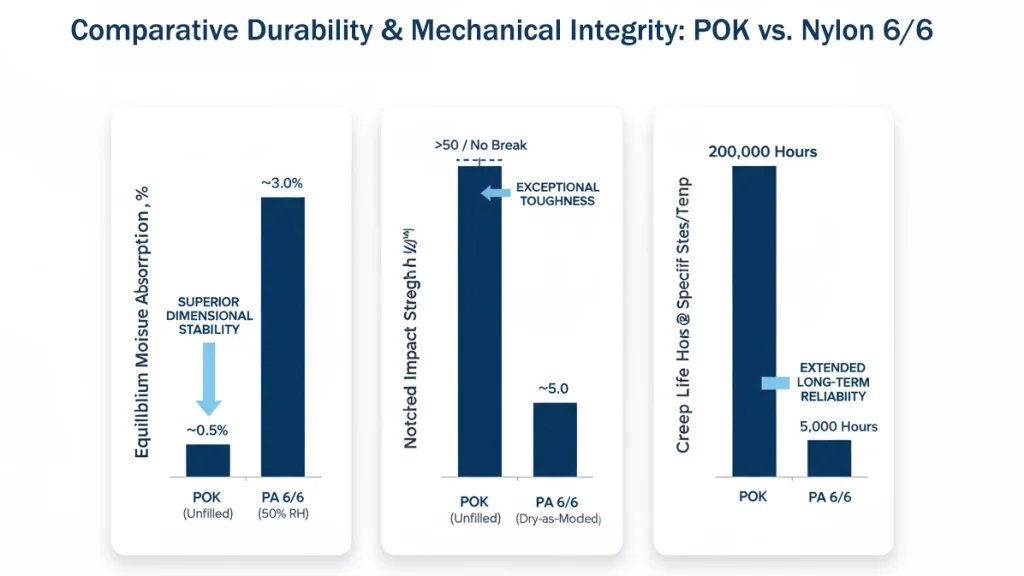

The primary advantage for POK lies in ductility and long-term dimensional stability. While PA 6/6 shows a higher maximum tensile strength in the dry-as-molded state, POK demonstrates superior ductility, often with elongation at break values exceeding 150%. This, combined with exceptional impact resistance, makes POK suitable for components subject to high dynamic loading and shock.

POK’s low moisture absorption is a critical performance advantage. Unlike PA 6/6, which can absorb 3-4 times the moisture of POK at equilibrium, POK components maintain stable dimensions and consistent mechanical properties, making it a high-reliability material for precision parts in wet or fluctuating humidity environments.

Processing & Mold Compatibility

Transitioning a component from Polyamide (PA) to Polyketone (POK) often improves operational efficiency while requiring only minor tooling adjustments. POK’s inherent material characteristics provide notable advantages in the injection molding process, primarily impacting throughput and pre-treatment steps.

Injection Molding Parameter Comparison

| Processing Parameter | Polyketone (POK) | Polyamide (PA 6/6) | Advantage/Note |

| Pre-drying | Not Required | Required (80℃ for 4-6 hours) | POK simplifies pre-treatment, saving time and energy. |

| Melt Temperature (℃) | 220-240 | 270-290 | POK melts at a lower temperature, reducing energy consumption. |

| Mold Temperature (℃) | 40-80 | 80-95 | Lower mold temperatures possible for POK. |

| Cycle Time | Shorter (Typically 15-30% faster) | Standard | POK’s rapid crystallization enables faster de-molding. |

The key process benefit of POK is the elimination of the pre-drying step, a mandatory requirement for Polyamides due to their high moisture absorption. Additionally, POK’s high and rapid crystallization rate allows for shorter cooling periods and faster cycle times, typically 15% to 30% faster than comparable PA grades, improving overall factory throughput.

Tooling Compatibility and Shrinkage

A significant cost advantage of specifying POK is its high compatibility with molds originally designed for Nylon. While PA exhibits anisotropic shrinkage (different rates along the flow and transverse directions), POK demonstrates a nearly isotropic shrinkage profile. This characteristic is particularly valuable for precision parts, such as gears and bearings, as it minimizes non-uniform deformation, leading to reduced part-to-part variation and improved dimensional accuracy.

Successful mold conversion necessitates minor adjustments focused on:

- Shrinkage Compensation: Accounting for POK’s generally uniform, slightly lower shrinkage rate compared to PA.

- Gate and Runner Design: Optimizing for POK’s typically lower melt viscosity to ensure proper mold filling.

- Cooling System: Utilizing efficient cooling to maximize the benefit of POK’s rapid solidification.

By managing these parameters, processors can transition from PA to POK using existing capital equipment, facilitating a cost-effective material change with improved productivity. This flexibility highlights POK’s viability not just as a performance upgrade, but as a manufacturing efficiency enabler.

The Sustainability Edge: Lower Carbon Footprint and Environmental Benefits

As industries accelerate the integration of sustainability goals, Polyketone (POK) presents a distinct environmental advantage over traditional Polyamides (PA), impacting the material lifecycle from raw material extraction through to end-of-life management.

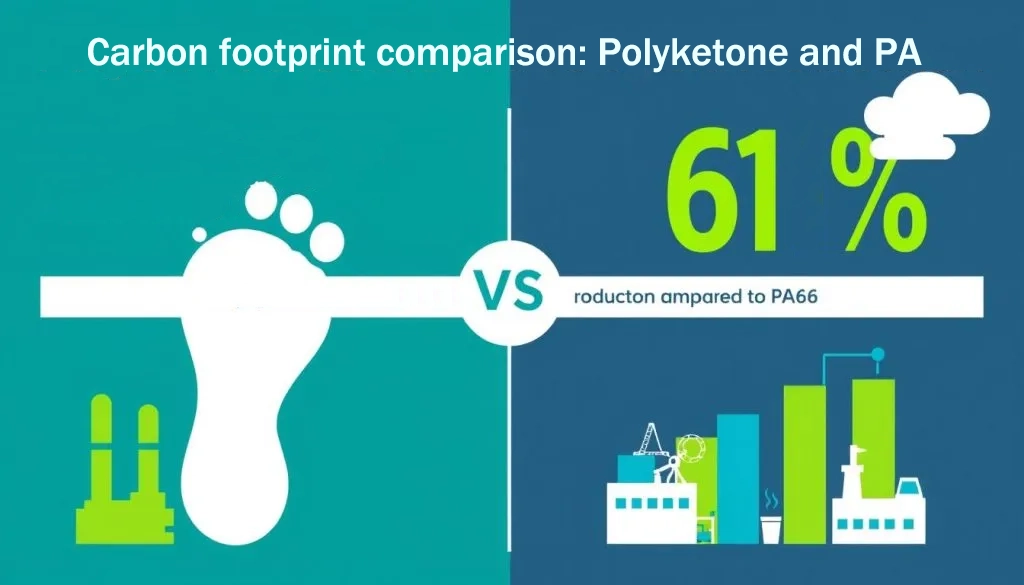

Reduced Life Cycle Energy and Emissions

POK’s production process is inherently more energy efficient than that of Polyamides:

- Lower Production Energy:

- POK polymerization operates at lower temperatures and pressures.

- Energy consumption is approximately 65 MJ/kg, compared to the ~ 120 MJ/kg often required for PA 6/6 manufacturing.

- Reduced CO₂ Emissions:

- This lower energy requirement translates directly to reduced greenhouse gas emissions.

- POK production typically yields ~ 3.2 kg CO₂ eq/kg, compared to the ~ 5.5 kg CO₂ eq/kg associated with Nylon.

Durability and the Circular Economy

POK enhances resource efficiency and supports circularity through its component longevity and material characteristics:

- Extended Service Life:Due to superior tribological properties (wear resistance) and exceptional dimensional stability, POK components typically achieve a service life that is 1.5 to 2 times longer than equivalent Nylon parts in demanding applications.

- High Recyclability: Unlike Polyamides, which are susceptible to property degradation from moisture (hydrolysis) during reprocessing, POK maintains its mechanical properties with minimal loss through multiple molding cycles.

- Resource Efficiency: The high retention of performance upon reprocessing makes POK a valuable material within circular economy initiatives focused on material recovery and reuse.

Enhance Your Sustainability Profile

Discover how transitioning to polyketone can help meet your sustainability goals while improving performance.

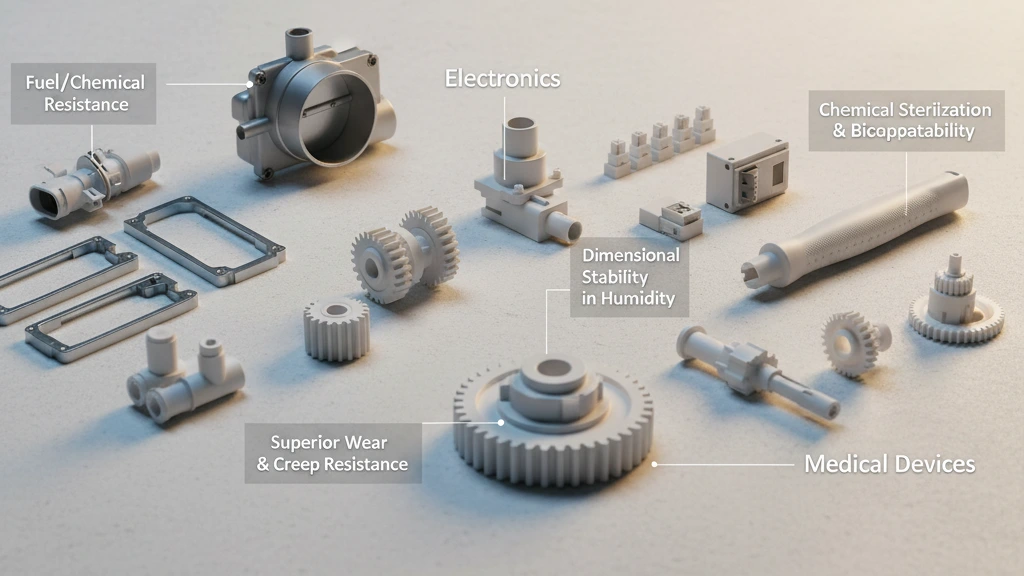

Key Applications by Industry

Automotive

- Specified for critical under-hood and fluid system components

- leveraging excellent resistance to aggressive biofuels, gasoline, and additives.

- Used for gears, bushings, and structural parts requiring high impact resistance and dimensional stability under thermal cycling.

Industrial

- Utilized for long-life, high-wear components such as high-performance gears and bearings in unlubricated or chemically exposed environments.

- Excellent hydrolysis resistance makes it ideal for pump and valve components in fluid handling systems.

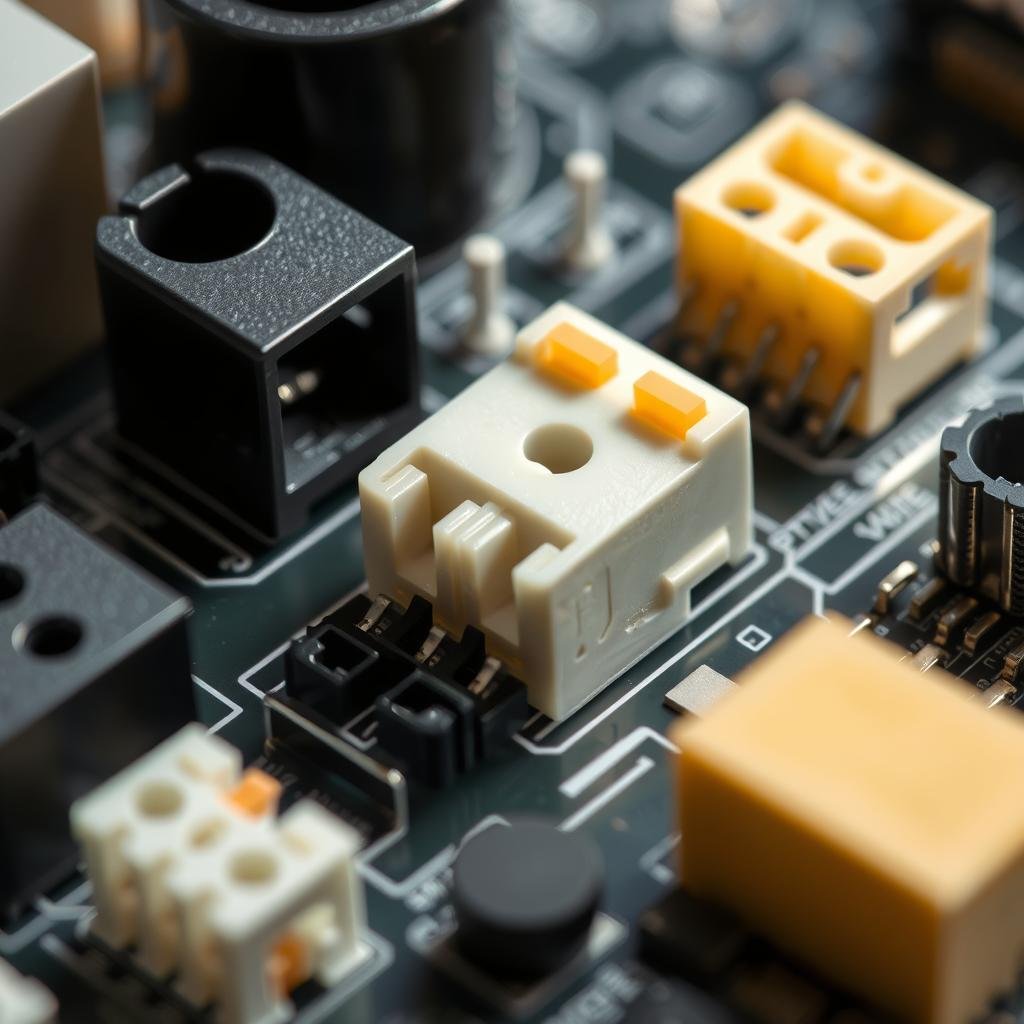

Electrical and Electronics

- Selected for connectors and housings that require dimensional integrity in fluctuating humidity, mitigating risks associated with PA’s moisture absorption.

Medical Devices

- Applied in diagnostic equipment components

- These components must be able to withstand frequent contact with corrosive cleaning agents and chemicals

- They need to be accurate and disinfection compatible.

In each of these sectors, POK is specified not just as a replacement, but as a technical upgrade for components requiring long-term reliability where the performance envelope of Nylon (PA) is frequently exceeded due to moisture sensitivity, chemical interaction, or long-term creep.

Explore Material Options for Your Application

Our team of material specialists can help you determine if polyketone is the right choice for your specific application requirements. Request a consultation or material sample for testing.

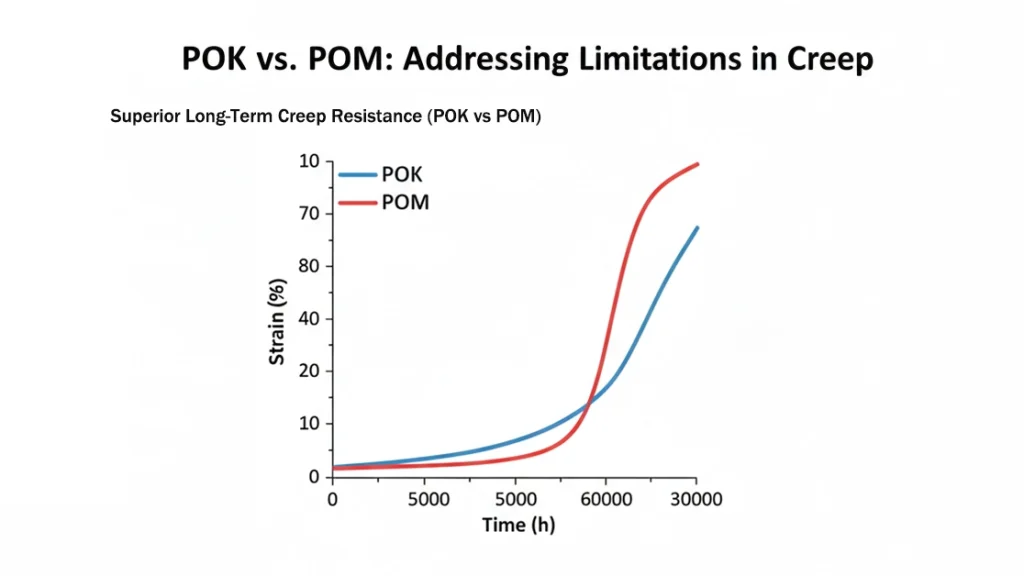

Polyketone vs. Related Materials: POK vs POM Comparison

While Polyamide (PA) is the primary comparative material, understanding how Polyketone (POK) compares against other common engineering polymers, such as Polyoxymethylene (POM, or Acetal), provides necessary context. Both POK and POM are recognized for their excellent dimensional stability and low friction/wear characteristics; however, POK presents distinct advantages in critical performance areas.

| Property | Polyketone (POK) | Polyoxymethylene (POM) | Key Differentiator |

| Chemical Structure | Ketone groups in backbone | Carbon-oxygen backbone (-CH₂O-) | Affects chemical stability |

| Impact Resistance | High (Highly Ductile) | Moderate (More brittle) | POK is more resistant to shock loads |

| Wear/Friction | Excellent | Excellent | Both offer strong tribological performance |

| Chemical Resistance | Excellent (Broad range) | Good (Weak with strong acids/bases) | POK offers better resistance to hydrolysis and pH extremes |

| Creep Resistance | Superior (Typically > 200,000 hrs) | Good (Typically ~ 50,000 hrs) | POK handles sustained load much longer |

| Processing | No pre-drying required | Careful thermal management required | POK offers easier processing |

POK’s key differentiation from POM centers on its superior ductility, impact strength, and long-term creep resistance. While POM exhibits high dimensional stability, its lower ductility makes it susceptible to sudden fracture or earlier creep rupture failure under sustained stress loads compared to POK. For applications requiring the simultaneous need for low friction/wear and high resistance to impact or long-term static loading, POK is the more robust material choice. By addressing the limitations of both PA (moisture sensitivity) and POM (impact/creep), POK is positioned for the most demanding mechanical and fluid system applications.

Ready to Explore Polyketone for Your Application?

Connect with our material specialists to determine if polyketone is the right solution for your specific requirements.

Conclusion: Transition to Polyketone with Confidence

Polyketone (POK) represents a distinct advancement in engineering polymers, offering a technically sound alternative to traditional Polyamides (PA) and Polyoxymethylenes (POM) across diverse applications. Its unique chemical architecture delivers a highly balanced performance profile that addresses common limitations found in these established materials.

Summary of POK Advantages

The material benefits of specifying Polyketone include:

- Dimensional Stability: Superior consistency due to minimal moisture absorption.

- Durability: Excellent chemical, fuel, and hydrolysis resistance, leading to longer component life in aggressive environments.

- Mechanical Integrity: Superior ductility, impact strength, and creep resistance for long-term reliability under dynamic or sustained static loads.

- Environmental Profile: Reduced CO₂ footprint and high recyclability potential compared to PA.

Material Specification Considerations

While POK offers significant improvements, engineers must note its comparative positioning against PA:

- Tensile Strength: PA typically exhibits a higher peak tensile strength in the dry-as-molded state.

- Thermal Limit: POK has a lower melting point than PA 6/6, limiting its suitability in the highest temperature environments.

- Tooling: Transitioning to POK requires adjustments to processing parameters (melt/mold temperatures) and may necessitate minor mold modifications to leverage its isotropic shrinkage profile.

Engineers should conduct material evaluation and testing during the transition to ensure optimal component performance, confirming POK’s viability as an upgraded material solution.

Frequently Asked Questions

What is polyketone resin used for?

POK is specified across multiple demanding sectors where its balanced property set outperforms conventional materials:

- Automotive: Utilized in fuel system components, under-hood parts, clips, and EV battery housings, leveraging its superior chemical resistance to fuels and high thermal stability.

- Industrial: Applied in high-wear environments for pump components, seals, conveyor elements (especially food-handling), and bearings, benefiting from its wear resistance and chemical durability.

- Electronics: Suitable for connectors and housings where dimensional stability across fluctuating humidity and good electrical properties are critical.

- Mechanical Components: Chosen for precision gears and seals requiring excellent wear resistance and long-term mechanical reliability.

- Medical & Healthcare: Selected for precision components in diagnostic equipment, drug delivery systems, and surgical tools due to biocompatibility (where applicable) and resistance to aggressive sterilization and cleaning agents.

How does polyketone compare to nylon in chemical resistance to fuels, solvents, and acids?

POK demonstrates a significantly broader and superior chemical resistance profile compared to Polyamide (PA) across aggressive substances:

- Acids and Bases: POK exhibits exceptional stability against both weak and strong acids (e.g., 30% sulfuric acid) and bases (e.g., ammonium hydroxide/sodium hypochlorite), environments where Nylon grades typically experience rapid degradation or dissolution.

- Fuels and Hydrocarbons: POK’s structure provides excellent resistance to aliphatic and aromatic hydrocarbons, making it the preferred material for fuel system components where PA can be prone to swelling or property loss.

- Alcohols and Glycols: POK maintains superior property retention when exposed to substances like ethanol and ethylene glycol (antifreeze), even at elevated temperatures (~120℃) over extended periods (~ 1,000 hours).

Which is better for high-wear applications: polyketone or nylon?

POK generally outperforms Nylon in high-wear applications due to inherent material advantages:

- Tribological Performance: POK offers superior baseline friction, abrasion, and wear resistance, often exceeding both unmodified Nylon and Acetal (POM) under dynamic loading.

- Environmental Consistency: Unlike Nylon, whose wear properties can degrade significantly with increasing moisture content, POK’s wear and dimensional stability remain consistent across variable humidity levels.

- Chemical Synergy: In chemically aggressive environments, POK maintains its mechanical and surface integrity better than Nylon, which can experience compounding degradation from chemical exposure and wear.

Is polyketone more sustainable than nylon?

Yes, POK provides distinct sustainability advantages over conventional Polyamides like PA 6/6:

- Lower CO₂ Footprint: Life cycle analyses (LCA) indicate POK production results in a significantly lower CO₂ emission footprint compared to PA 6/6.

- Energy Efficiency: The POK manufacturing process requires less energy than conventional Nylon production.

- Extended Durability: POK’s superior resistance to degradation and wear extends component lifecycles, reducing replacement frequency and the associated environmental impact of continuous new material consumption.

Can polyketone replace nylon in existing molds?

In most instances, POK can replace Nylon in existing tooling with minimal modifications and process adjustments:

- Shrinkage: POK’s shrinkage rates (~ 1.5% to 2.0%) are generally comparable to Nylon, but its isotropic shrinkage profile (uniformity) requires different compensation than Nylon’s anisotropic behavior.

- Processing: POK processes at lower temperatures than PA 6/6 and requires no pre-drying, simplifying pre-treatment and potentially reducing cycle times by ~ 15%-30%.

- Tooling Adjustments: Fine-tuning of gate design and cooling channels is recommended during an initial processing trial to optimize part quality and fully leverage POK’s rapid crystallization.

What are the main differences between POK and POM?

The key differentiators between POK and POM are structural and mechanical:

- Chemical Structure: POK has a ketone-group-containing carbon backbone; POM has repeating -CH₂O- units with oxygen in the backbone.

- Mechanical Performance: POM typically offers higher stiffness, while POK provides superior impact resistance and ductility (elongation at break >150%).

- Creep Resistance: POK demonstrates superior long-term creep performance (~ 4 times better than POM under identical conditions), making it more reliable for sustained load-bearing applications.

- Chemical Resistance: POK exhibits a broader resistance to pH extremes (acids and bases) compared to POM.