Polyoxymethylene (POM) M25, with a melt flow rate of approximately 25 g/10 min, is valued for its high crystallinity, low friction, and excellent wear resistance under moderate loads. Neat POM M25 offers good dimensional stability, chemical resistance, and fatigue performance, which explains its established role in precision gears, clips, and conveyor parts.

In more demanding conditions, however, its limitations become apparent: modulus below 3 GPa, heat deflection temperature around 100–110 °C under 1.8 MPa, notched Izod impact strength of only 5–7 kJ/m², and no inherent antistatic or conductive properties. These constraints have traditionally kept M25 in general engineering rather than high-performance sectors.

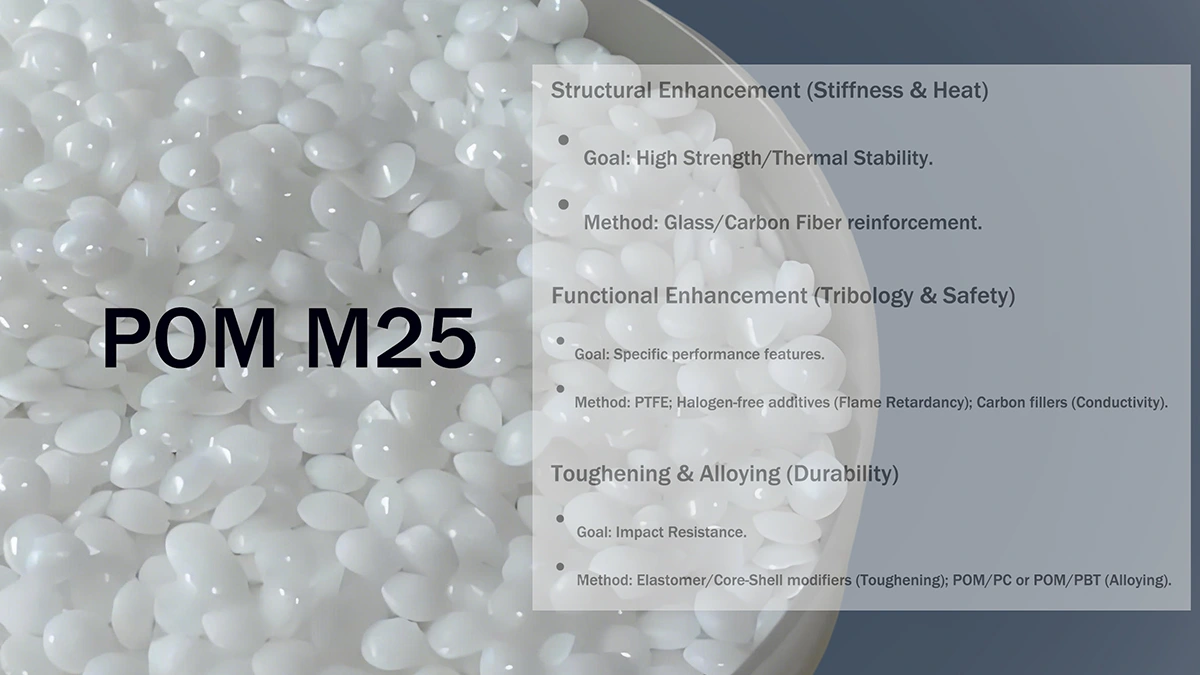

Strategic modification addresses these gaps systematically. Through reinforcement, functional additives, and toughening, POM M25 can now meet requirements in automotive powertrain components, electronic housings, drone structures, and medical devices. For readers who first need to understand the baseline performance and processing characteristics of neat and standard high-flow abrasion-resistant POM M25, we have prepared a detailed technical & buyer guide here: POM M25 High Flow Abrasion-Resistant POM – Technical & Buyer Guide The modifications discussed below build directly on these foundational grades.

Structural Reinforcement

Glass Fiber Reinforcement

Incorporating 10–40 wt% glass fiber raises tensile modulus to 9–14 GPa, tensile strength to 120–170 MPa, and HDT (1.8 MPa) above 165 °C. Fiber orientation during injection molding can cause warpage, but optimized silane-based coupling agents, low-shear screw geometry, and controlled annealing reduce distortion to acceptable levels for most structural parts.

Carbon Fiber Reinforcement

Carbon-fiber grades achieve specific stiffness comparable to aluminum while providing volume resistivity as low as 10–100 Ω·cm. The combination of light weight and EMI shielding makes them suitable for 5G equipment housings and lightweight motion-control components.

Mineral Reinforcement

Talc, mica, or wollastonite at 15–30 wt% improves isotropic stiffness and significantly lowers warpage compared to glass fiber. These grades balance cost and dimensional stability in flat panels and large enclosures.

Functional Enhancement

Low-Friction and Wear-Resistant Grades

Addition of PTFE, silicone oil, MoS₂, or UHMW-PE reduces the dynamic coefficient of friction to 0.08–0.12 and wear factors by up to 95 % under dry conditions. Such compounds extend service life in plain bearings, gears, and linear guides.

Flame-Retardant Grades

Phosphorus- and nitrogen-based halogen-free systems enable UL94 V-0 rating down to 0.75 mm thickness with limited compromise in flow or toughness. These materials appear in connectors, switchgear, and public-transportation interiors.

Permanent Antistatic and Conductive Grades

Carbon black, carbon nanotubes, or stainless-steel fibers yield stable surface resistivity between 10³ and 10⁹ Ω/sq. Volume-conductive versions reach below 10² Ω·cm, supporting ESD protection and ATEX-compliant fuel-system components.

Impact Modification and Alloying

Elastomer-Toughened POM

Blending with TPU, POE, or core-shell acrylate modifiers increases notched Izod impact strength from ~6 kJ/m² to 40–70 kJ/m² (or no-break at higher loadings) while preserving most of the base stiffness and wear resistance.

Polymer Alloys

POM/PC and POM/PBT alloys, stabilized by compatibilizers, combine low-friction surfaces with improved heat and hydrolysis resistance. They perform well in automotive exterior trim and power-tool housings exposed to moisture and temperature cycles.

Conclusion

Ongoing development focuses on multifunctional compounds that integrate several properties—e.g., glass- or carbon-fiber reinforcement plus permanent conductivity plus low-friction additives—in a single grade. These materials respond to the need for lighter, safer, and more reliable components in electric vehicles, robotics, and telecommunications.