Polyoxymethylene (POM), a semi-crystalline engineering thermoplastic, maintains a significant position in functional component design due to its inherent high modulus, low coefficient of friction, and excellent fatigue resistance. Among its grades, M270 is an advanced copolymer formulation optimized specifically to meet the demands of high-volume production and stringent tolerance requirements. This article provides an in-depth technical analysis of M270's processing behavior, structural mechanics, and tribological characteristics, underscoring its engineering value.

High Flowability: Enabling Efficient Molding of Precision Components

The most distinctive feature of M270 is its superior ability to extend the processing window, primarily attributed to its high flowability. The material boasts a high Melt Volume-flow Rate (MVR) of 23 cm³/10 min (measured at 190℃/2.16 kg), indicating that its melt exhibits exceptional shear thinning characteristics.

Melt Volume-flow Rate (MVR) Comparison

MVR tested at 190℃/2.16 kg) M270’s high flow enables superior shear thinning.

This low melt viscosity provides critical advantages in high-precision injection molding:

- Geometric Complexity and High Aspect Ratios: The high flow ensures the melt can easily fill tool cavities featuring micro-features or long flow paths, effectively mitigating the thin-wall effect and avoiding weld line defects common with conventional POM grades under high packing pressure. (For a detailed analysis on how M270 breaks the limits of thin-wall injection molding, see our full technical article: M270-44(POM): Breaking the Limits of Injection Molding for Thin Walls and Complex Structures).

- Multi-Cavity Efficiency: It ensures excellent filling consistency across multi-cavity tools, thereby improving yield rates and reducing injection cycle times.

Structural Mechanics: Long-Term Reliability of Critical Properties

M270 provides a high level of reliability in its mechanical properties. The combination of its elastic modulus (approximately 2800 MPa) and yield strength (approximately 67 MPa) allows it to withstand high contact stresses without undergoing plastic deformation, offering robust rigidity.

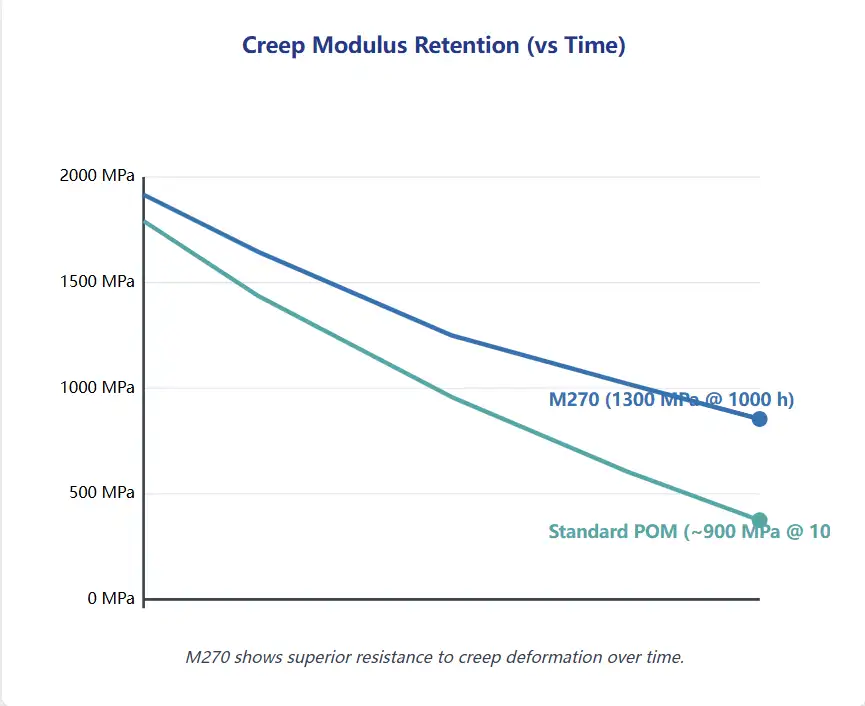

Creep Modulus Retention (vs Time)

M270 shows superior resistance to creep deformation over time.

For structural components subjected to continuous load, creep resistance is the core metric of long-term stability. M270 exhibits excellent resistance to creep, evidenced by its creep modulus remaining at approximately 1300 MPa after 1000 hours of sustained loading.

This data strongly confirms M270's capacity to maintain geometric integrity under sustained stress conditions, which is crucial for high-precision bearing housings and fasteners.

Regarding environmental stability, M270’s low water absorption of 0.75% is highly significant. This characteristic ensures that the material's molecular structure is less prone to hydrolysis or plasticization in hot and humid environments, thereby guaranteeing the long-term thermal/hygroscopic retention of its mechanical properties and dimensional stability.

Tribological Characteristics: Enhancing Motion System Durability

As an engineering plastic, M270's inherent tribological properties make it an ideal candidate for sliding and rotational applications. The optimized material structure results in a consistently low coefficient of friction and an excellent wear rate, minimizing both energy loss and heat generation during contact motion.

Typical Tribological Applications

Precision Gears

Sliding Bearings

Cam Mechanisms

M270 provides extended wear life in dynamic systems.

M270 is specifically suited for manufacturing critical motion control elements, including Precision Gears, Sliding Bearings, and Cam Mechanisms. In these applications, M270's optimized tribological profile significantly enhances the equipment's overall durability and operational efficiency by extending wear life and reducing system maintenance frequency.

The M270 Advantage

M270 represents a cutting-edge POM copolymer, successfully integrating superior manufacturability (high flow), exceptional reliability (creep resistance), and high-performance functionality (low friction). By offering these synergistic advantages, M270 provides design engineers with a cost-effective and highly reliable solution for material down-gauging and system efficiency enhancement. It stands as a robust contender for demanding precision engineering applications.