Polyoxymethylene (POM), commonly referred to as acetal or polyacetal, is a high-performance engineering thermoplastic renowned for its superior mechanical properties, including high tensile strength, low friction coefficient, and excellent dimensional stability. These attributes make POM a preferred material for precision components in demanding industrial environments. Its high crystallinity ensures robust fatigue resistance and creep resistance, while its chemical stability enables reliable performance in contact with fuels, solvents, and lubricants. This guide introduces POM’s unique characteristics, offering engineers and manufacturers a comprehensive resource for leveraging its capabilities in high-precision applications.

POM stands out among engineering plastics due to its combination of rigidity, toughness, and self-lubricating properties, often surpassing alternatives like nylon or polycarbonate in applications requiring low wear and high accuracy. Key industries, including automotive, electronics, and medical device manufacturing, rely on POM for components such as gears, bearings, fasteners, and fluid-handling systems. Its ease of processing through injection molding and machining further enhances its appeal for producing complex, tight-tolerance parts. This article explores POM’s properties, processing techniques, application-specific advantages, and environmental considerations, providing technical insights to optimize material selection and manufacturing efficiency.

The following sections detail POM’s mechanical and thermal properties, compare its performance with other thermoplastics, and discuss best practices for processing and sustainability. By addressing both practical and technical aspects, this guide equips professionals with the knowledge to apply POM effectively in their projects, ensuring performance, durability, and cost-effectiveness in industrial applications.

Overview of POM Material

Polyoxymethylene (POM), commonly known as acetal or polyacetal, is a semi-crystalline thermoplastic renowned for its high strength, rigidity, and low friction. Its molecular structure, characterized by repeating (-CH₂O-)n units, imparts exceptional toughness and the ability to withstand mechanical stress, making it a cornerstone material in precision engineering applications. Available in homopolymer and copolymer forms, POM combines dimensional stability, wear resistance, and ease of processing, enabling its use in demanding industrial environments such as automotive and machinery manufacturing.

- Homopolymer vs. Copolymer:

- Homopolymer POM: Delivers superior mechanical strength (tensile strength up to 90 MPa) and stiffness, ideal for high-load components. However, it is more prone to thermal degradation and hydrolysis, requiring careful processing.

- Copolymer POM: Offers enhanced resistance to hydrolysis, chemicals, and thermal degradation, with a slightly lower tensile strength (60–70 MPa). It is better suited for applications involving moisture or chemical exposure.

- Key Properties:

- High Tensile Strength: 60–90 MPa, comparable to some metals, ensuring durability in structural components.

- Low Coefficient of Friction: 0.2–0.3, providing self-lubricating properties that reduce wear in moving parts.

- Creep Resistance: Maintains shape under prolonged stress, critical for long-term performance in gears and bearings.

- Chemical Resistance: Withstands oils, fuels, and most solvents, ensuring reliability in harsh environments.

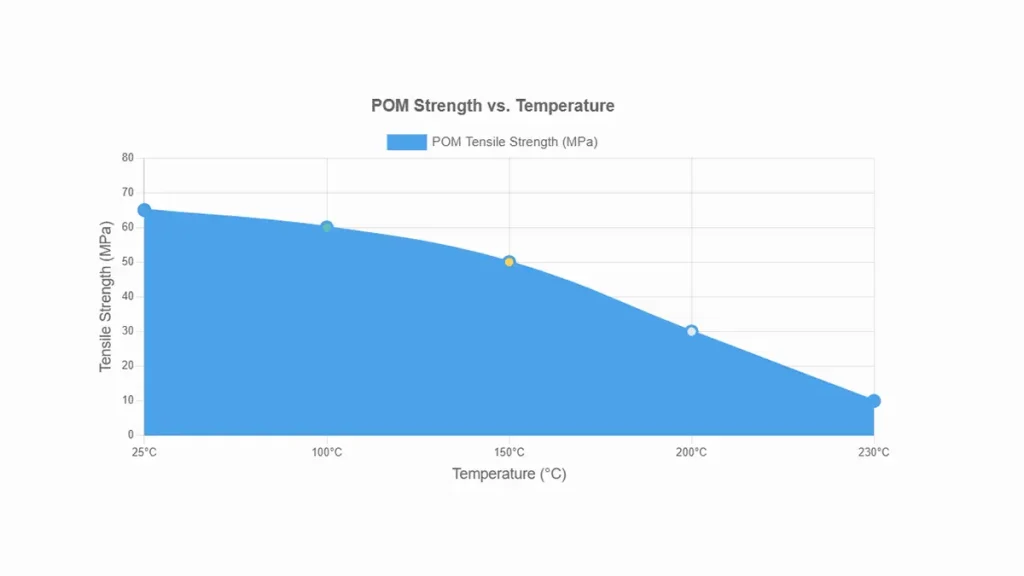

- Temperature Range: Operates effectively from -40°C to 120°C (copolymer) or 140°C (homopolymer).

- Density: 1.41–1.43 g/cm³, offering a lightweight yet robust alternative to metals.

- Electrical Insulation: High dielectric strength (20–30 kV/mm), suitable for electrical components.

POM’s combination of low friction, high strength, and dimensional stability makes it a go-to material for components requiring tight tolerances and long-term reliability. Its ease of machining and injection molding further enhances its appeal for manufacturers seeking efficient production processes. In the following sections, we explore how these properties translate into practical applications across industries.

Looking for high-quality POM granules for your industrial applications? Contact us for customized solutions and competitive pricing.

Advantages of Polyoxymethylene (POM) in Industrial Applications

Polyoxymethylene (POM) excels in precision engineering due to its robust mechanical, chemical, and functional properties, making it a preferred material for industries like automotive, electronics, and medical device manufacturing. Building on its established performance characteristics, this section highlights how POM’s attributes translate into practical benefits, enabling engineers to design reliable, high-performance components. The following subsections detail POM’s advantages, with comparisons to alternative materials and considerations for specific applications.

Mechanical Performance

POM’s mechanical properties support the design of durable, lightweight components:

- High Strength and Stiffness: Enables gears, fasteners, and structural parts in automotive systems (e.g., transmission components), reducing weight compared to metals while maintaining robustness.

- Low Friction and Wear Resistance: Self-lubricating properties minimize maintenance in moving parts like bearings and conveyor rollers, ideal for industrial machinery and consumer electronics.

- Fatigue and Creep Resistance: Ensures reliability in dynamic components like springs and clips, withstanding repetitive stress in applications such as appliance mechanisms.

Chemical and Environmental Stability

POM performs reliably in challenging environments:

- Chemical Resistance: Resists oils, greases, and organic solvents, ensuring durability in fuel systems and hydraulic components. Note: Limited resistance to strong acids and alkalis requires careful application design.

- Low Moisture Absorption: With water uptake below 0.2% (per ASTM D570), POM maintains performance in humid conditions, outperforming nylon in outdoor or marine applications.

- Dimensional Stability: Maintains tight tolerances in precision parts like valve bodies and electronic connectors, even under temperature fluctuations.

Additional Functional Benefits

POM offers unique attributes for specialized applications:

- Electrical Insulation: A dielectric strength of ~20 kV/mm (per ASTM D149) makes POM suitable for electrical housings and insulators in electronic devices.

- Surface Finish: Provides a smooth, aesthetically pleasing finish for visible components like appliance handles, enhancing both functionality and appearance.

- Processing Compatibility: Supports high-precision injection molding and machining, enabling cost-effective production of complex geometries.

Comparative Advantages

The table below compares POM with other engineering plastics, highlighting its competitive edge:

| Property | POM | Nylon 6/6 | Polycarbonate (PC) |

|---|---|---|---|

| Moisture Absorption | <0.2% (ASTM D570) | 1.0-2.0% (ASTM D570) | 0.15-0.35% (ASTM D570) |

| Friction Coefficient | 0.2-0.3 (self-lubricating) | 0.3-0.4 (requires lubrication) | 0.3-0.5 (requires lubrication) |

| Chemical Resistance | Strong (oils, solvents) | Moderate (oils, solvents) | Moderate (limited to solvents) |

| UV Resistance | Limited (requires additives) | Moderate | Good (UV-stabilized grades) |

This comparison underscores POM’s superior low moisture absorption and self-lubricating properties, making it ideal for precision and low-maintenance applications. However, its limited UV resistance may require protective coatings for outdoor use.

Applications of Polyoxymethylene (POM)

Polyoxymethylene (POM) is applied in industries requiring precision and durability, leveraging its low friction, low moisture absorption, and chemical resistance outlined previously. This section highlights POM’s key applications in automotive, medical, and electronics sectors, with concise case studies demonstrating its performance. These applications showcase POM’s versatility, supported by its compatibility with precision manufacturing.

Automotive Applications

- Gears and Fuel Systems: High strength and chemical resistance ensure reliable fuel pumps and transmission parts.

- Seatbelt Mechanisms: Low friction enables smooth operation under varying conditions.

Medical Device Applications

- Insulin Pens: Copolymer POM’s biocompatibility (ISO 10993) supports safe, reusable drug delivery systems.

- Surgical Tools: Sterilizability and precision ensure reliable performance.

Electronics Applications

- Connectors: Electrical insulation (~20 kV/mm, ASTM D149) suits circuit assemblies.

- Insulating Housings: Low moisture absorption ensures stability in humid environments.

Case Studies

- Automotive Fuel Pumps: POM’s resistance to gasoline ensures durable fuel system components, maintaining performance over time.

- Medical Insulin Pens: Copolymer POM’s precision molding and biocompatibility meet FDA standards for reliable drug delivery.

Application Summary

POM excels in precision applications but requires UV stabilizers for outdoor use. The table below summarizes its suitability:

| Industry | Key Applications | POM Advantage |

|---|---|---|

| Automotive | Gears, fuel systems | Chemical resistance, low friction |

| Medical | Insulin pens, surgical tools | Biocompatibility, sterilizability |

| Electronics | Connectors, housings | Electrical insulation, stability |

POM’s applications benefit from its processing efficiency, explored in subsequent sections on manufacturing and sustainability.

Limitations and Challenges of Polyoxymethylene (POM)

While polyoxymethylene (POM) offers robust mechanical and chemical properties for applications like automotive gears and medical devices, as discussed previously, engineers must evaluate its limitations to ensure optimal performance. This section examines POM’s thermal, environmental, and material challenges, providing mitigation strategies to address these constraints. By understanding these limitations, manufacturers can design components that maximize POM’s benefits while minimizing risks in demanding environments.

Thermal and Environmental Limitations

POM’s thermal and environmental performance restricts its use in specific conditions:

- Limited Heat Resistance: POM supports continuous use up to 100-150°C (depending on grade), but degrades above 230°C, limiting its application in high-temperature environments like engine compartments.

- UV Sensitivity: Prolonged UV exposure causes surface chalking and reduced strength, affecting outdoor components like automotive exterior parts.

Chemical and Material Challenges

POM’s chemical and mechanical properties present additional considerations:

- Hydrolysis in Hot Water: Copolymer POM resists hydrolysis better than homopolymer, but prolonged exposure to hot water (>80°C) or steam can degrade performance, impacting medical sterilization processes.

- Flammability: Rated UL94 HB, POM is flammable and requires flame-retardant additives for applications like electrical housings.

- Notch Sensitivity: Susceptible to cracking under sharp impacts, POM requires careful design to avoid stress concentrations in components like fasteners.

Mitigation and Design Considerations

To address these limitations, engineers can adopt targeted strategies:

- UV Stabilizers: Apply UV-resistant coatings or additives for outdoor applications, such as automotive trim.

- Copolymer Selection: Specify copolymer POM for moisture-exposed or chemically aggressive environments, like medical devices.

- Design Optimization: Minimize sharp edges and stress concentrations to enhance impact resistance in precision parts.

- Processing Controls: Maintain processing temperatures below 230°C and ensure ventilation to manage potential formaldehyde release.

Summary of Limitations

The table below outlines POM’s limitations and their impact on applications:

| Limitation | Impact on Applications | Mitigation Strategy |

|---|---|---|

| Heat Resistance | Unsuitable for >150°C environments | Use alternative materials (e.g., PEEK) |

| UV Sensitivity | Reduced strength in outdoor use | Apply UV stabilizers or coatings |

| Hydrolysis | Degradation in hot water/steam | Select copolymer POM |

| Flammability | Risk in electrical applications | Add flame-retardant additives |

| Notch Sensitivity | Cracking in high-impact parts | Optimize design to reduce stress |

These considerations ensure POM is applied effectively, particularly in precision manufacturing. Subsequent sections explore processing techniques and environmental impacts to guide sustainable use.

Modifying POM with Additives

Tailoring POM through carefully selected additives enables the material to meet demanding industrial requirements across structural, frictional, and environmental conditions. The use of reinforcing and functional modifiers dramatically alters the polymer’s performance profile during both processing and end-use.

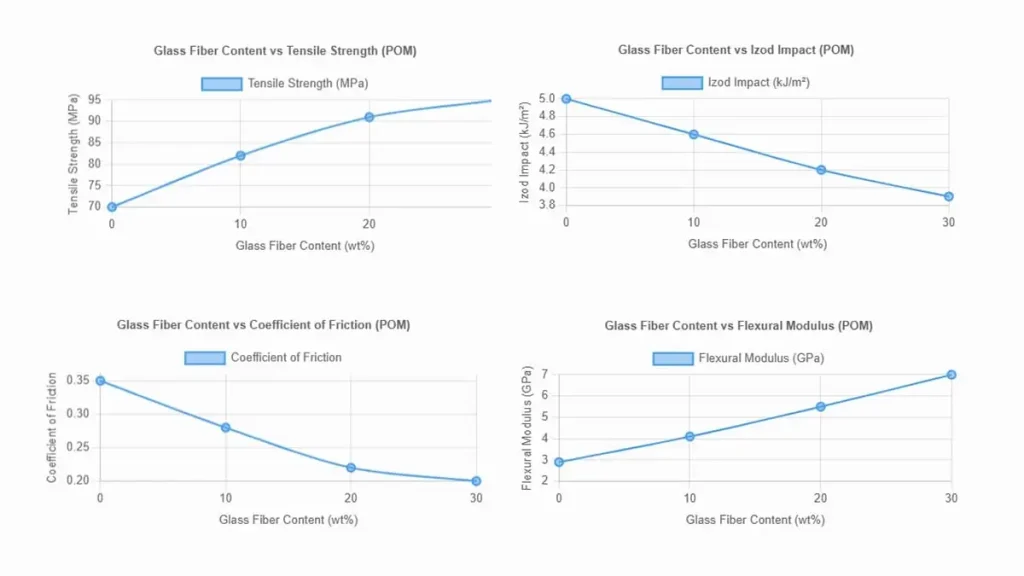

- Glass Fiber Reinforcement

Incorporating 10–30 wt% glass fiber significantly increases the tensile strength (up to ~95 MPa) and flexural modulus of POM, greatly improving load-bearing capability and dimensional rigidity. This modification supports long-term structural use in high-precision gears, automotive housings, and pump components where metal replacement is desired. - PTFE & Silicone Lubricants

PTFE or silicone micro-powders are dispersed within the polymer matrix to reduce the coefficient of friction to as low as 0.15, delivering superior wear resistance under dry-running conditions. These internally lubricated grades perform reliably in sliding bushings, conveyor bearings, and complex cam mechanisms without the need for external lubrication. - UV Stabilizers

UV-absorbers and hindered amine light stabilizers (HALS) minimize photo-oxidative chain scission, extending the service life of POM exposed to sunlight and outdoor environments. Such formulations are often adopted in irrigation systems, agricultural machinery fittings, and exterior electronic components. - Flame-Retardant Systems

Incorporating halogen-free phosphorous or nitrogen-based fire-retardant systems helps POM meet UL 94 V-0/V-2 ratings without compromising mechanical integrity. These POM-FR compounds are frequently specified in terminal blocks, relay holders, and precision switch parts within electrical and electronic assemblies. - Impact Modifiers

Thermoplastic elastomer (TPE) or rubber-based modifiers are blended with POM at 5–15 wt% to improve notched Izod impact strength by 30–50%, allowing the material to withstand sudden loads or drop tests. These toughened grades are commonly employed in industrial tool housings, locks, and complex snap-fit designs. - Heat Stabilizers & Processing Aids

Antioxidants, processing lubricants, and thermal stabilizers help preserve molecular weight during molding, reducing melt degradation at temperatures above 180 °C. Stable processing characteristics ensure excellent surface quality and dimensional consistency, supporting precision mass-production.

Example: A 20 wt% glass fiber-reinforced POM compound exhibits approximately a 30% increase in tensile strength compared with unfilled POM, providing a viable alternative for heavy-duty load-bearing gears in compact mechanical assemblies.

Processing Techniques for Polyoxymethylene (POM)

Polyoxymethylene (POM) requires precise processing to leverage its high strength and low friction, as outlined in prior sections, for applications like automotive gears and medical insulin pens. This section details key processing methods—injection molding, extrusion, and machining—addressing challenges like formaldehyde emissions from overheating, as noted in limitations. These techniques ensure precision and durability, supporting efficient manufacturing while mitigating risks.

Processing Methods

- Injection Molding: Operates at 190–210°C barrel and 80–100°C mold temperatures (ASTM D4703), enabling high-precision parts like medical device components with short cycle times.

- Extrusion: Processes POM into sheets or rods at 180–200°C, requiring strict temperature control to prevent degradation in conveyor components.

- Machining: POM’s low friction (0.2-0.3, ASTM D1894) supports CNC machining for complex geometries, using sharp tools and coolant to avoid overheating.

Best Practices and Considerations

- Moisture Control: Dry granules to <0.2% moisture (ASTM D570) to prevent voids in molded parts.

- Emission Management: Use corrosion-resistant equipment and ventilation (OSHA PEL 0.75 ppm) to handle formaldehyde release above 230°C.

- Temperature Stability: Maintain consistent melt temperatures to avoid warping, critical for precision applications like electronic connectors.

Processing Summary

The table below outlines POM processing parameters and challenges:

| Method | Key Parameters | Challenges |

|---|---|---|

| Injection Molding | 190–210°C barrel, 80–100°C mold | Formaldehyde emissions, moisture |

| Extrusion | 180–200°C | Degradation risk, cooling control |

| Machining | Sharp tools, coolant | Overheating, tool wear |

These techniques optimize POM’s performance in precision manufacturing. Subsequent sections explore environmental impacts, including waste management and emissions control.

Safety and Storage Guidelines for Polyoxymethylene (POM)

Polyoxymethylene (POM) granules require controlled storage and handling to maintain their low moisture absorption and mechanical properties, supporting applications like medical insulin pens and automotive gears, as discussed previously. This section outlines guidelines for storage, safety, and waste management, addressing challenges like formaldehyde emissions from processing (noted in limitations). Proper practices ensure material integrity and compliance with safety standards, facilitating efficient use in precision manufacturing.

Storage Guidelines

- Controlled Environment: Store POM at <30°C and <60% relative humidity (ASTM D570) to maintain moisture content below 0.2%, critical for medical-grade components.

- Sealed Containers: Use airtight packaging to prevent moisture absorption, ensuring performance in high-precision applications like electronic connectors.

- UV Protection: Avoid prolonged sunlight exposure to prevent surface degradation, as noted in UV sensitivity limitations.

Safety and Waste Management

- Ventilation: Ensure adequate ventilation (OSHA PEL 0.75 ppm) during processing to manage formaldehyde emissions, as highlighted in processing challenges.

- Protective Equipment: Wear gloves and masks (NIOSH-approved) when handling molten POM to ensure operator safety.

- Waste Disposal: Comply with REACH/EPA standards for POM waste, segregating for mechanical recycling to minimize environmental impact.

Storage and Safety Summary

The table below summarizes key guidelines for POM handling:

| Aspect | Key Requirements | Purpose |

|---|---|---|

| Storage Conditions | <30°C, <60% RH, sealed containers | Prevent moisture and UV degradation |

| Safety Measures | Ventilation (OSHA PEL 0.75 ppm), PPE | Manage formaldehyde, ensure operator safety |

| Waste Management | REACH/EPA-compliant recycling | Minimize environmental impact |

Comparison with Alternative Engineering Plastics

Polyoxymethylene (POM) provides distinct advantages in applications like automotive gears and medical insulin pens, as discussed previously, but its performance must be evaluated against alternatives like nylon 6/6, polycarbonate (PC), and PEEK. This section compares their mechanical, chemical, and thermal properties, addressing limitations such as POM’s heat sensitivity. These insights guide material selection for precision components in demanding environments.

Performance Comparison

The table below compares POM with nylon 6/6, polycarbonate, and PEEK across key properties:

| Material | Strength (MPa) | Friction Coefficient | Moisture Absorption (%) | Chemical Resistance | Cont. Use Temp (°C) |

|---|---|---|---|---|---|

| POM | 60–90 | 0.2–0.3 | <0.2 | Good (oils, fuels) | 100–140 |

| Nylon 6/6 | 70–100 | 0.3–0.4 | 1.0–2.0 | Moderate | 150–180 |

| Polycarbonate | 55–75 | 0.3–0.5 | 0.15–0.35 | Poor (solvents) | 120–130 |

| PEEK | 90–100 | 0.3–0.4 | <0.5 | Excellent | 250–300 |

Application and Selection Considerations

POM outperforms nylon in low-friction applications like conveyor rollers due to its 0.2–0.3 friction coefficient (ASTM D1894) and low moisture absorption (<0.2%, ASTM D570), unlike nylon’s 1–2%, which affects dimensional stability in humid environments. Compared to polycarbonate, POM’s superior chemical resistance (ASTM D543) suits automotive fuel systems, though polycarbonate provides better impact resistance for safety housings. PEEK outperforms POM in high-temperature applications like aerospace components (250–300°C), but its higher cost limits its use compared to POM’s cost-effective profile for high-volume production, enhanced by its ease of processing (noted in processing techniques). Material selection should balance performance, cost, and sustainability, explored in subsequent sections.

Performance Visualization

The chart below compares tensile strength across materials:

Environmental Impact and Recycling of Polyoxymethylene (POM)

Polyoxymethylene (POM) production and disposal present environmental challenges, building on prior discussions of processing emissions and waste management. This section examines POM’s environmental footprint, focusing on production, recycling, and sustainability. By addressing formaldehyde emissions noted in limitations and processing, manufacturers can align with environmental standards to support applications like automotive and medical components.

Production and Recycling

POM’s production involves formaldehyde, a volatile organic compound, requiring strict emission controls to comply with EPA and REACH standards. Mechanical recycling through regrinding and remolding achieves up to 80% recovery rates, suitable for non-critical parts like automotive brackets. However, repeated recycling may reduce mechanical strength by 10-20%, necessitating quality control. Energy consumption in POM production is lower than for high-performance polymers like PEEK, offering a more sustainable option for high-volume manufacturing.

Sustainability and Recommended Practices

Copolymer POM resists biodegradation, posing disposal challenges, unlike more degradable alternatives like PLA. Research into bio-based POM is under development to improve sustainability. Recommended practices include:

- Closed-Loop Systems: Implement recycling loops to minimize waste, supporting applications like conveyor components.

- Certified Recycling: Partner with ISO 14001-certified facilities to handle POM scrap, reducing environmental impact.

- Emission Control: Maintain ventilation (OSHA PEL 0.75 ppm) during processing to manage formaldehyde, as noted in processing guidelines.

Environmental Summary

The table below outlines POM’s environmental considerations and solutions:

| Aspect | Key Considerations | Solutions |

|---|---|---|

| Production | Formaldehyde emissions (EPA/REACH) | Strict emission controls |

| Recycling | 80% recovery, strength loss (10-20%) | Mechanical recycling, quality control |

| Sustainability | Resistant to biodegradation | Explore bio-based POM, certified recycling |

Frequently Asked Questions

Polyoxymethylene (POM) is optimized for precision applications, building on its mechanical properties, processing requirements, and environmental considerations discussed in prior sections. These FAQs address its suitability for gears and bearings, comparisons with other plastics, storage needs, and performance in challenging environments, guiding engineers in leveraging POM effectively.

A:Polyoxymethylene (POM) is optimized for gears and bearings due to its low friction coefficient (0.2-0.3, ASTM D1894) and high strength (60-90 MPa, ASTM D638), ensuring durability in automotive seat adjusters and conveyor systems. Its self-lubricating properties, enhanced by additives like PTFE (noted in additives section), reduce maintenance, while its dimensional stability maintains precision under load, outperforming nylon’s higher moisture absorption (1-2%, ASTM D570).

A:POM demonstrates superior low friction (0.2-0.3, ASTM D1894) and chemical resistance (ASTM D543) compared to nylon 6/6 and polycarbonate, making it ideal for fuel systems, as discussed in material comparisons. Its dimensional stability surpasses nylon’s (1-2% moisture absorption). However, PEEK offers better performance above 250°C, and nylon excels in high-impact applications, requiring careful application matching.

A:POM granules require storage in sealed containers at <30°C and <60% relative humidity (ASTM D570) to maintain moisture content below 0.2%, critical for medical components, as outlined in storage guidelines. During processing, ensure ventilation (OSHA PEL 0.75 ppm) to manage formaldehyde emissions and use corrosion-resistant equipment to preserve material quality, as noted in processing techniques.

A:POM maintains stability up to 100-140°C (ASTM D3418) but degrades above 230°C, limiting its use in high-temperature environments, as highlighted in limitations. Copolymer POM resists hydrolysis in acidic conditions better than homopolymer (ISO 16770), suitable for mild acidic exposure. For prolonged acid or high-temperature applications, PEEK or PTFE are recommended alternatives, per material comparisons.

A: POM stands for polyoxymethylene, also known commercially as acetal or polyacetal. It is classified as a high-performance engineering thermoplastic used for precision applications requiring excellent dimensional accuracy and low friction.

A: POM is polymerized from formaldehyde monomers, resulting in a linear chain of repeating –CH₂O– units. Depending on the formulation, the polymer can be produced as a homopolymer (POM-H) or as a copolymer (POM-C) where small amounts of comonomer (such as ethylene oxide) are introduced to improve thermal and hydrolytic stability.

A: Many unfilled POM grades are approved by regulatory agencies such as the FDA (USA) and EU 10/2011 for direct contact with food and drinking water because of their low extractables, smooth surface, and high chemical resistance. However, only POM resins explicitly labeled as food-contact compliant should be used in food equipment parts such as dispensing valves, pumps, or coffee machine components.

A: POM is a semi-crystalline engineering plastic with high tensile strength, fatigue resistance, and outstanding wear properties. It delivers metal-like stiffness and precision, making it ideal for gears, bearings, fuel system parts, and structural components in automotive, electronics, and consumer appliance sectors.

Conclusion: Leveraging POM for Precision Engineering

Polyoxymethylene (POM) demonstrates superior performance in precision applications, such as automotive gears and medical insulin pens, due to its high strength (60-90 MPa, ASTM D638) and low friction coefficient (0.2-0.3, ASTM D1894). As discussed in prior sections, its dimensional stability and chemical resistance make it ideal for fuel systems and conveyor components. However, limitations like heat sensitivity (100-140°C continuous use, ASTM D3418) and UV degradation require mitigation through additives like glass fibers and UV stabilizers, as well as precise processing (injection molding at 190-210°C). Proper storage (<0.2% moisture, ASTM D570) ensures material integrity, while mechanical recycling (up to 80% recovery) supports sustainability.

Future Trends and Recommendations

POM’s cost-effective profile, compared to alternatives like PEEK (noted in material comparisons), positions it for high-volume production. Ongoing research into bio-based POM, as highlighted in environmental considerations, aims to enhance sustainability, aligning with circular economy trends. Engineers can optimize designs by integrating closed-loop recycling and emission controls (OSHA PEL 0.75 ppm for formaldehyde). By balancing POM’s mechanical advantages with environmental strategies, manufacturers can drive innovative, sustainable solutions for automotive, industrial, and medical applications.

Partner with us for reliable POM granules to power your next project. Email us at jerry@salesplastics.com , or call +8618657312116 to request samples, get specifications, or place bulk orders.