As global plastic regulations tighten, starch-based biodegradable plastics have transitioned from a promising alternative to a comprehensive commercial solution. By leveraging the natural polymer structure of starch, these materials offer a unique balance of environmental integrity and cost-effectiveness. But how can businesses effectively integrate these materials into existing production lines? This guide explores the advanced science and market-ready applications of starch-based plastics, providing a roadmap for manufacturers to lead the sustainable transition.

What Are Starch-Based Biodegradable Plastics?

Starch-based plastics are high-performance materials derived from renewable sources like corn, potato, and cassava. By harnessing the natural polymers—amylose and amylopectin—these bioplastics offer a sustainable yet robust alternative to petroleum-based resins.

Currently commanding 50% of the global bioplastics market, starch-based materials are the most commercially proven solution available today. For manufacturers, the real value lies in their versatility. We provide specialized formulations tailored for distinct industrial needs:

- High-Performance Blends (Starch + PLA/PBAT): Engineered for film blowing and packaging, offering excellent tensile strength and flexibility.

- Thermoplastic Starch (TPS): A cost-effective base for rigid applications.

- Functional Composites: Enhanced with nanoparticles for superior moisture barriers and thermal resistance, matching the performance of conventional PP or PE.

This adaptability ensures that our materials can be integrated into your existing production lines with minimal equipment adjustment, bridging the gap between ecological responsibility and manufacturing efficiency.

How Thermoplastic Starch (TPS) Works

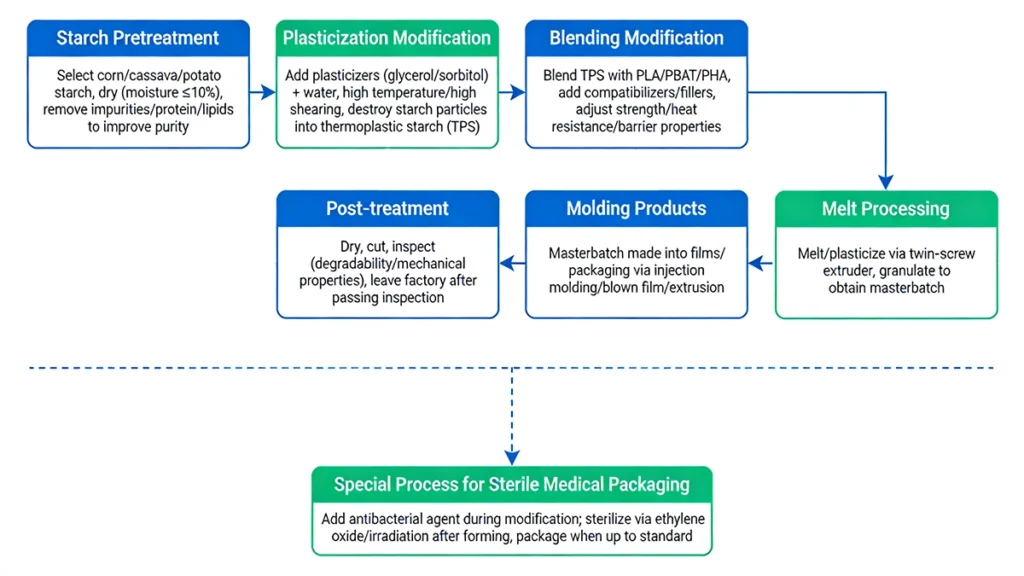

Thermoplastic Starch (TPS) is the engine behind sustainable plastic substitution. At [Your Company Name], we don’t just supply raw starch; we provide engineered TPS resins that have undergone advanced molecular transformation.

Precision Processing for Superior Quality

Our conversion process goes beyond simple gelatinization. We utilize high-efficiency Plasticization techniques, where bio-based polyols are precision-injected to decouple starch chains. This results in a resin that offers:

- Wide Processing Window: Compatible with standard injection and extrusion machinery.

- Thermal Stability: Minimized yellowing or degradation during high-temperature cycles.

Optimized Amylose/Amylopectin Ratios

We carefully select starch sources to balance the Linear Amylose (for structural integrity and film clarity) with Branched Amylopectin (for superior melt flow). This ensures our material doesn’t just “act” like plastic—it performs like it.

Overcoming Industrial Hurdles: While pure starch is naturally hydro-sensitive, our Modified TPS Blends are engineered to be moisture-resistant and mechanically robust. By integrating biodegradable polyesters and nano-reinforcements at the molecular level, we deliver a material that rivals conventional PE and PP in durability while remaining 100% compostable.

Applications of Starch-Based Plastics

The versatility of our starch-based resins allows manufacturers to enter diverse markets with confidence. We provide specialized grades optimized for the most demanding commercial sectors:

High-Volume Packaging (The Compliance Leader)

As global plastic bans tighten, our film-grade starch blends offer a seamless transition for shopping bags, food trays, and mailing wraps. These materials deliver the necessary barrier properties and tensile strength while meeting strict EN 13432/ASTM D6400 composting standards.

Sustainable Agriculture (The Efficiency Booster)

Our Starch-based Mulch Film Resin is a game-changer for large-scale farming. Unlike traditional PE films, these can be plowed directly into the soil after harvest, eliminating costly labor for removal and disposal while improving soil health.

Eco-Conscious Consumer Goods

For the food service and retail industries, our injection-molding grades are ideal for Compostable Cutlery, plates, and personal care packaging. They offer a premium “bio-feel” that helps brands command a sustainability premium.

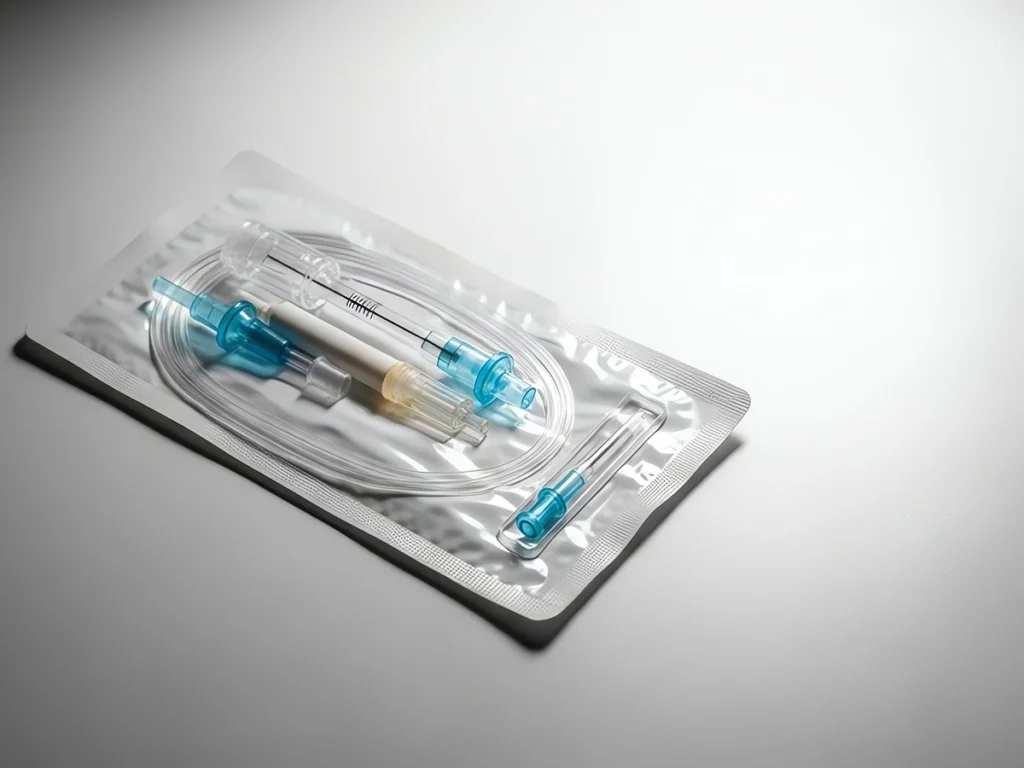

Technical & Medical Niches

Beyond everyday use, the inherent biocompatibility of starch enables specialized applications in drug delivery and sterile medical packaging, showcasing the advanced purity and quality of our raw materials.

Explore Implementation Strategies for Your Industry

Discover how to effectively integrate starch based plastics into your specific applications with our comprehensive implementation guide.

Environmental Benefits — and the Reality

Starch-based plastics offer a powerful tool for decarbonization, but their true environmental value is realized through correct material selection and end-of-life planning.

The Sustainable Advantage

- Carbon Sequestration: Our starch resins utilize rapid-growth crops that capture CO₂ during growth, often resulting in a 30% to 50% lower carbon footprint than fossil-based PE or PP.

- Certified Compostability: We ensure our raw materials meet international standards like EN 13432 and ASTM D6400, providing your products with the “Green Passport” needed for global markets.

The Reality Check

Advantages

- Renewable resource utilization

- Potential for complete biodegradation

- Reduced fossil fuel consumption

- Compatible with existing waste management

- Lower toxicity in production and use

Challenges

- Higher eutrophication potential from fertilizer use

- Land use competition with food production

- Requires specific conditions to biodegrade properly

- Energy-intensive processing in some cases

- Potential contamination of recycling streams

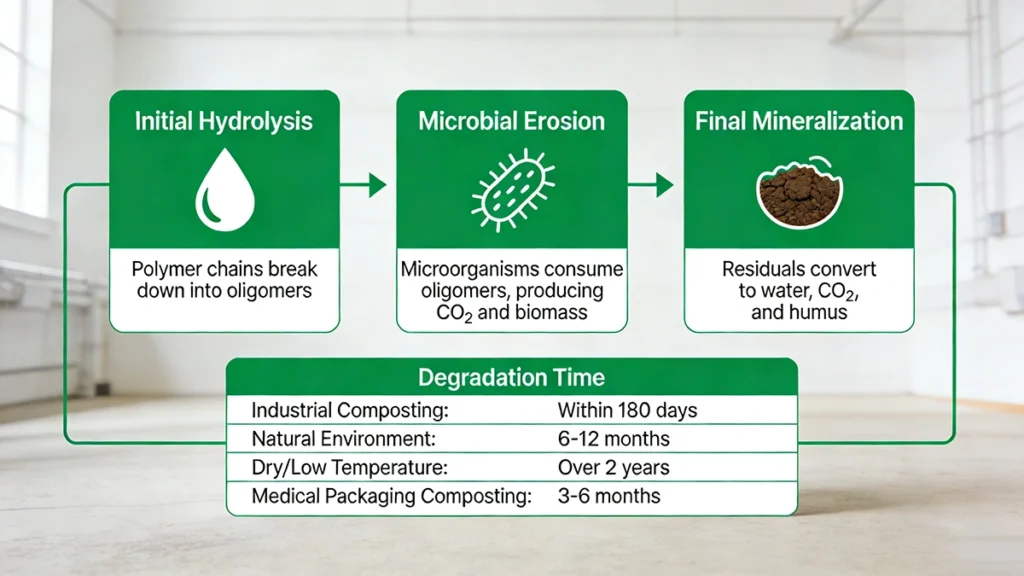

End-of-Life Realities

Choosing the right grade is crucial for your target market’s infrastructure:

| Target Environment | Recommended Resin Grade | Biodegradation Reality |

| Industrial Facilities | Standard Starch Blends | 100% breakdown within 180 days in controlled settings. |

| Home Composting | Home-Compostable Series | Degrades at ambient temperatures; ideal for garden-waste systems. |

| Soil/Agriculture | Soil-Degradable Grade | Designed to disappear post-harvest, leaving no microplastic residue. |

The environmental impact of starch-based biodegradable plastics ultimately depends on the entire lifecycle—from agricultural practices used to grow the starch source to the actual end-of-life management. While they offer significant potential benefits over conventional plastics, realizing these benefits requires appropriate infrastructure and consumer education about proper disposal.

Advantages and Limitations

Choosing starch-based resins is a strategic decision that balances environmental leadership with functional requirements. While pure starch has inherent limits, our Advanced Starch Blends are engineered to bridge the performance gap.

Performance: Engineered for Your Needs

We don’t just sell “starch”; we provide task-specific formulations. By blending starch with high-performance biopolymers (like PBAT or PLA), we achieve mechanical properties that meet industrial standards:

- Tensile Strength: Optimized to 30-50 MPa, perfect for heavy-duty shopping bags and mulch films.

- Moisture Barrier: Our proprietary hydrophobic treatments significantly extend the shelf life of food packaging.

The Cost Evolution

While the upfront resin cost may be higher than traditional PE, the Total Value of Ownership is shifting:

Regulatory Shield

Avoid increasing “Plastic Taxes” and non-compliance fines.

Brand Premium

Consumers are proven to pay a 10-15% premium for products in sustainable packaging.

Processing Efficiency

Our resins are designed for “Drop-in” compatibility, meaning no major capital investment is needed for your existing machinery.

Strategic Summary

| Factor | Our Starch-Based Solutions | Commercial Benefit |

| Processing | Standard extrusion/injection temp | Low energy consumption, no new equipment |

| Compliance | Certified Compostable (EN 13432) | Access to restricted “Green Zone” markets |

| Supply Chain | Renewable & Scalable | Stable pricing, independent of oil volatility |

Manufacturing Excellence: Seamless Transition to Starch-Based Resins

Transitioning to sustainable materials shouldn’t be a hurdle. we provide Optimized Resin Grades specifically engineered to run on your existing machinery with minimal adjustment, ensuring a smooth path from conventional plastics to eco-friendly production.

Process Compatibility: "Drop-In" Performance

Our starch-based formulations are designed for versatility across standard manufacturing platforms:

- Film Blowing: Our High-Melt-Strength Starch Blends provide the stability needed for high-speed production of bags and wraps.

- Injection Molding: We offer Fast-Cycle Grades that minimize cooling time, keeping your production efficiency competitive with PP or PS.

- Extrusion & Thermoforming: Superior melt-flow control ensures consistent wall thickness and reduced scrap rates.

Precision Technical Support

We eliminate the guesswork in processing. Every batch comes with a Technical Processing Datasheet (TDS) and access to our engineers to help you optimize:

- Temperature Profiles: Our resins are stabilized for processing up to 180°C, providing a wider, more forgiving “processing window.”

- Moisture Management: We provide clear pre-drying protocols to ensure zero-defect manufacturing.

Economic Efficiency

While raw material unit prices differ, we help you optimize the Total Cost per Piece. By utilizing high-flow formulations and providing on-site optimization, we help manufacturers reduce waste and energy consumption, making the sustainable choice a financially viable one.

Conclusion

Starch-based biodegradable plastics have evolved from a promising concept into a proven commercial reality. As global regulations and consumer preferences shift decisively toward sustainability, these materials offer the most viable pathway for brands to future-proof their products.

While the transition involves technical nuances, you don’t have to navigate them alone.we bridge the gap between material science and industrial application. We don’t just supply high-quality starch resins; we provide the technical expertise to ensure they perform flawlessly on your production lines.

Take the Next Step Toward Sustainability: Don’t let processing concerns or material limitations hold your business back. Whether you are looking to optimize an existing product or launch a new eco-friendly line, our team is ready to support you with:

- Tailored Material Selection: Matching the right resin grade to your specific needs.

- On-Site Technical Support: Optimizing your machinery for seamless integration.

- Compliance Assurance: Providing all necessary certifications (EN 13432, ASTM D6400).

Need Expert Guidance on Starch-Based Bioplastics?

Our materials specialists can help you evaluate whether starch based plastics are right for your specific application needs.

Frequently Asked Questions

Are starch-based plastics biodegradable?

Yes, our starch-based resins are fully biodegradable and certified. While rate depends on environment, our materials are engineered to meet strict international standards like EN 13432. We offer specific grades for Industrial Composting (3-6 months) and Home Composting, ensuring that your products can return to nature without leaving microplastics. We provide all necessary certification support to help your brand pass environmental audits.

What are the disadvantages of starch-based bioplastics?

Historically, starch faced limits in moisture and heat resistance. However, as a specialist distributor, we provide modified starch alloys (blended with PBAT/PLA) that effectively bridge these gaps. We’ve optimized our resins to offer enhanced tensile strength and hydrophobic properties, making them a viable, cost-effective alternative to conventional plastics in packaging and catering.

How long does cornstarch bioplastic last?

In standard storage, our cornstarch-based products have a stable shelf life of 12-24 months, comparable to traditional plastics. The “biodegradation clock” only starts once the material hits a microbial-active environment (like soil or compost). We can tailor the formulation to match your specific product’s lifespan, ensuring durability during use and rapid breakdown after disposal.

How to make biodegradable plastics from starch?

While the basic chemistry involves gelatinization and plasticization, commercial-grade production requires precise molecular grafting. We provide pre-compounded, ready-to-use pellets that eliminate the complexity of raw starch processing. Our resins are designed for “drop-in” compatibility with your existing extrusion or injection molding lines, backed by our technical processing guides.

What is the problem with bioplastics?

The industry faces challenges like infrastructure gaps and cost premiums. However, the “problem” is often a misalignment of material and application. We help you navigate this by selecting the right grade to avoid performance failures. Furthermore, as plastic taxes rise, our starch-based solutions offer a strategic hedge against regulatory risks, providing a long-term economic advantage.

Is there a truly biodegradable plastic?

Yes. A “truly” biodegradable plastic is defined by its ability to vanish completely without toxic residue. Our Starch and PHA-based resins are true biopolymers. We help you select materials based on Third-Party Certifications (BPI, TUV Austria), ensuring your environmental claims are scientifically backed and legally compliant in global markets.

Why are starch-based polymers biodegradable?

It’s all about the natural glucose backbone. Microorganisms recognize starch as a primary energy source, using enzymes to break down glycosidic bonds. By choosing our starch-based resins, you are utilizing a circular material that leverages 100% renewable resources, resonating with today’s eco-conscious consumers.