For many fused deposition modeling (FDM) applications, the choice of filament is the single most critical decision. Polylactic Acid (PLA) and its enhanced variant, PLA+, are core polymers in the industry, but their similar names can obscure crucial differences in performance. This guide provides a definitive comparison.

Whether you’re a prototyping enthusiast, a production manager, or a materials buyer, the distinction between these two filaments can mean the difference between a successful print and costly material waste. This guide breaks down their unique compositions, mechanical properties, and ideal use cases to help you select the right material and achieve consistent, high-quality results.

What is PLA? Definition, Composition, and Key Features

Polylactic Acid (PLA) is a biodegradable thermoplastic polymer derived from renewable resources like corn starch, sugarcane, or tapioca. Its production involves fermenting these plant-based starches into lactic acid, which is then polymerized to form the filament. This eco-friendly composition and a low environmental footprint have made PLA a go-to choice for a wide range of users, from hobbyists to industrial manufacturers.

✅Key Features and Benefits

- Ease of Use: It prints reliably at low temperatures, which minimizes warping and makes it accessible for even novice users.

- High-Resolution Prints: The material also excels at producing high-resolution prints with clean, sharp details and a smooth, often glossy finish.

⚠️Limitations

- Rigidity and Brittleness: PLA is known for its rigidity and brittleness, offering low impact resistance.

- Low Heat Tolerance: Its low glass transition temperature, typically around 60°C, also means that printed parts can deform when exposed to heat.

Ultimately, PLA’s balance of printability, detail, and biodegradability makes it the industry standard for general-purpose prototyping, educational models, and aesthetic applications where durability and heat resistance are not primary requirements.

What is PLA+? Definition, Composition, and Key Features

PLA+ is an upgraded version of standard PLA, a designation that signifies a formulation enhanced with proprietary additives. While it maintains PLA’s base composition, these additions—such as impact modifiers, plasticizers, or copolymers—are engineered to significantly improve its mechanical properties. This customization by manufacturers allows PLA+ to address the inherent weaknesses of standard PLA without compromising its core benefits.

✅Benefits & Improvements

- Superior Durability: PLA+ offers superior tensile strength, flexibility, and enhanced impact resistance, making prints less prone to shattering.

- Stronger Parts: It provides better layer adhesion, which produces more robust and durable parts with stronger bonds between layers.

- Higher Heat Resistance: It withstands temperatures up to 70-80°C before softening, a notable improvement over standard PLA.

- Premium Aesthetics: Many PLA+ formulations feature a desirable matte finish, providing a premium look.

⚠️ Trade-offs & Considerations

- Higher Cost: PLA+ typically comes at a slightly higher cost than standard PLA.

- Varied Formulations: Due to varied formulations, it can have a steeper learning curve for print calibration.

Ultimately, PLA+ bridges the gap between basic filaments and more advanced materials, making it an excellent choice for functional prototypes and end-use parts that require greater reliability than standard PLA can provide.

PLA vs PLA+: Head-to-Head Comparisons

The final filament decision for any project is a strategic balance between material properties and budget. The perfect material is not about a simple choice, but about aligning the polymer’s capabilities with your application’s specific demands for functionality, durability, and aesthetics. This table offers a direct comparison of key properties, providing the data needed to make a confident, informed decision for your prints.

| Property | PLA | PLA+ |

| Tensile Strength | Moderate (around 50-60 MPa) | Higher (60-70 MPa or more) |

| Flexibility | Low; brittle under stress | Improved; more ductile |

| Impact Resistance | Poor; shatters easily | Better; absorbs impacts |

| Heat Resistance | Low (softens at ~60°C) | Slightly better (~70-80°C) |

| Print Temperature | 180-220°C | 190-230°C |

| Bed Temperature | 0-60°C (often none needed) | 0-60°C |

| Ease of Printing | Excellent; beginner-friendly | Good; may need minor tweaks |

| Surface Finish | Glossy and shiny | Matte and smoother |

| Cost | Lower ($15-25/kg) | Higher ($20-35/kg) |

| Biodegradability | High | Similar, but additives may vary |

These values represent general benchmarks. Actual performance can vary depending on the manufacturer’s specific formulation and your printer’s settings.

As the data shows, PLA+ consistently surpasses standard PLA in mechanical properties, offering greater tensile strength, flexibility, and impact resistance. This makes it the superior choice for functional prototypes, durable parts, or any application where the final object needs to withstand stress. Conversely, standard PLA remains the top contender for cost-sensitive projects, visual models, and applications that prioritize ease of printing over structural integrity. The final selection should align directly with your project’s specific needs and budget.

Printing Parameters: Optimizing PLA and PLA+ for Best Results

Fine-tuning your printer settings is critical for achieving professional-grade results with any filament. While manufacturer defaults provide a good starting point, adjusting key parameters based on your specific setup is essential. Here is a guide to optimizing your prints for both PLA and PLA+.

Nozzle & Bed Temperatures

- The nozzle temperature is the most critical setting. For PLA, aim for 190-210°C. For PLA+, use a slightly higher range of 200-220°C due to its additives.

- A heated bed at 40-60°C is recommended for both materials to prevent warping and improve adhesion.

Print Speed & Cooling

- A good starting print speed is 40-60 mm/s. For PLA+, we recommend staying at the lower end of this range to ensure strong layer bonding.

- Use full fan cooling after the first layer for PLA. For PLA+, reduce cooling to 50-75% to promote stronger bonds between layers.

Note on Material Consistency

Beyond printer settings, material quality is paramount. Our factory-sourced PLA granules undergo rigorous quality control, ensuring consistent diameter, purity, and thermal properties. This consistency means you can rely on our filaments to perform predictably with these recommended settings, minimizing trial-and-error.

Applications: When to Use PLA vs PLA+

The ideal filament for your project is determined by its specific requirements—from mechanical demands and aesthetic goals to environmental considerations. This section provides a practical guide for enthusiasts and manufacturers to align material properties with their intended application, ensuring optimal results.

🟢 PLA: The Standard for Accessibility & Detail

Standard PLA is the preferred choice for projects that prioritize cost-effectiveness and ease of use. It is ideal for:

- Aesthetic & Educational Projects: Its ease of printing, affordability, and vivid colors make it the go-to for visual models, art pieces, and educational tools where visual precision and a forgiving workflow are top priorities.

- Prototyping & High-Volume Prints: Its low cost makes it perfect for rapid prototyping and large-scale manufacturing runs of non-functional parts, such as architectural mockups or figurines.

- Eco-Conscious Initiatives: Derived from renewable resources, PLA is a perfect fit for projects prioritizing biodegradability under industrial composting conditions.

When to Avoid PLA: PLA is not suited for functional parts that require high impact resistance or for use in high-temperature environments (e.g., inside a car on a hot day), as it becomes soft at temperatures above 60°C.

🔵 PLA+: Enhanced Durability & Professional Finish

Enhanced PLA+ is engineered for applications where strength and reliability are paramount. It is the superior material for:

- Functional & Durable Parts: Its improved tensile strength and impact resistance make it the superior choice for items that will endure moderate stress, such as mechanical components or custom tools.

- Consumer Products & Product Testing: Its enhanced layer adhesion and premium matte finish lend themselves to professional-looking prototypes and small-batch consumer goods, ensuring parts hold up during testing and use.

- Outdoor & Semi-Durable Applications: With its slightly higher heat tolerance (up to 70-80°C), PLA+ is a viable option for items exposed to mild outdoor conditions, such as garden stakes or camping gear.

When to Avoid PLA+: While more robust, PLA+ is not a replacement for materials like ASA for prolonged outdoor use due to its limited UV resistance. It is also not suited for high-heat applications or for projects where cost is the primary factor for non-functional models.

Ultimately, the right filament is a direct reflection of your project’s needs. If your print requires the ability to flex, withstand impacts, or handle light stress, then PLA+ is the clear choice. For all other applications where cost and simplicity are the main drivers, standard PLA is an unbeatable value.

Ready to bring your vision to life with PLA or PLA+?

Contact us for high-quality granules that ensure vibrant, reliable prints.

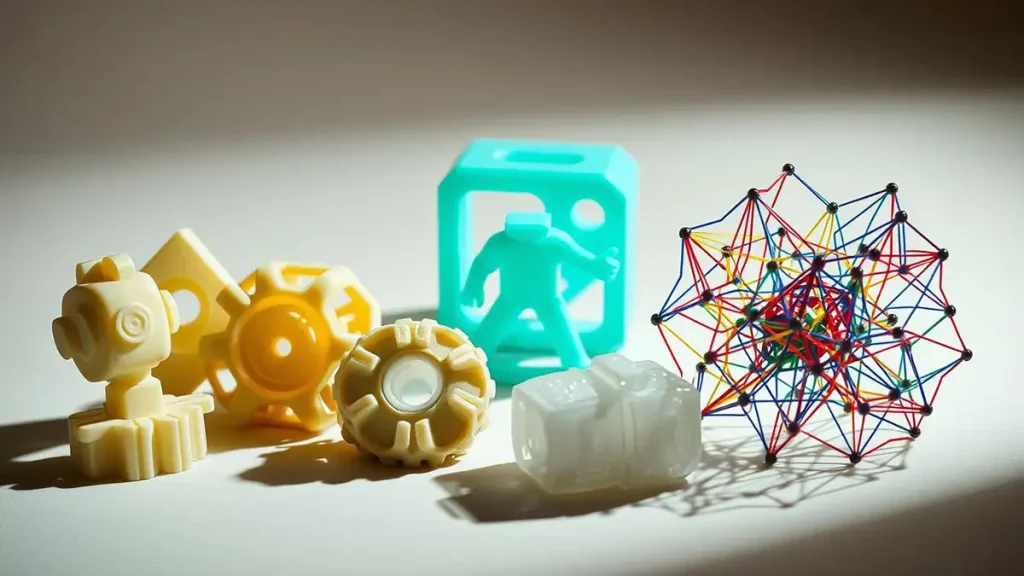

Alternatives to PLA and PLA+

While PLA and PLA+ are the go-to materials for most entry-level 3D printing, a range of specialized filaments offers distinct advantages for more demanding applications. These advanced materials are engineered to overcome PLA’s inherent limitations, providing enhanced durability, heat resistance, and specialized properties like flexibility or chemical tolerance. When PLA’s core properties are insufficient, exploring these alternatives can unlock new possibilities for your projects.

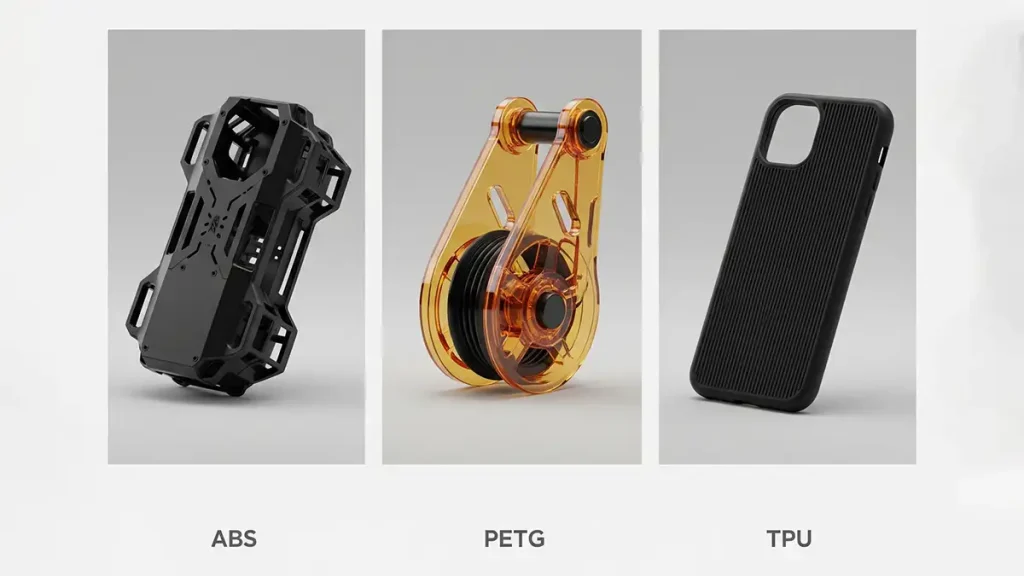

- PETG: Combines PLA’s ease with ABS-like durability; excellent for food-safe items or parts needing chemical resistance. Heat tolerance up to 80°C.

- ABS (Acrylonitrile Butadiene Styrene): Tough and heat-resistant (up to 100°C), ideal for automotive or enclosures, but warps easily and requires an enclosure.

- ASA: Similar to ABS but UV-resistant, great for outdoor applications.

- Nylon: Highly flexible and strong for gears or wearables, but absorbs moisture and needs drying.

- TPU : Rubber-like flexibility for phone cases or seals, though slower to print.

| Material | Heat Resistance | Strength | Flexibility | UV Resistance | Print Difficulty |

|---|---|---|---|---|---|

| PETG | ~80°C | High | Moderate | Moderate | Easy |

| ABS | ~100°C | High | Moderate | Low | Hard (enclosure needed) |

| ASA | ~100°C | High | Moderate | Excellent | Hard (enclosure needed) |

| Nylon | ~120°C | Very High | High | Low | Medium (moisture sensitive) |

| TPU | ~70°C | Moderate | Very High | Low | Hard (slow speeds, direct drive) |

The limitations of PLA and PLA+ don’t have to constrain your projects. By understanding the unique properties of these specialized filaments, you can select the right material to meet the specific demands of any application, ensuring durability, functionality, and a professional finish.

Conclusion

The key to exceptional 3D printing lies in strategic material selection. By understanding the distinct properties of PLA and PLA+—from durability and cost to their ideal applications—you are empowered to make informed decisions that elevate your projects from good to truly exceptional.

Our commitment is to provide a transparent source for high-quality plastic granules, the foundational material for premium 3D printing filaments. We ensure the utmost consistency and purity in every batch, empowering filament manufacturers to produce a product that minimizes defects and maximizes results for you, the end-user. This focus on quality at the source is what allows you to print with confidence.

Ready to take your prints to the next level? Explore our range of materials today and experience the difference that source quality makes.

📩Email: jerry@salesplastics.com

☎Phone: +8618657312116

FAQs

A:Not necessarily. PLA+ is an enhanced version of PLA, offering superior mechanical properties like greater tensile strength, flexibility, and impact resistance. This makes it a better choice for functional parts that need to withstand stress. However, standard PLA remains the top material for applications where cost and simplicity are the main drivers, excelling in aesthetics and detail. The “better” filament depends entirely on your project’s specific needs.

A:You can print PLA+ and PLA together, as their chemical compositions are very similar and they generally adhere well to each other. However, we don’t recommend this practice for functional or critical parts. The final object’s performance will be a mix of both materials, making the mechanical properties unpredictable. For the best results and consistency, it’s always better to print with a single filament type.

A:PLA+ is an excellent material for applications that require more durability than standard PLA. It’s ideal for functional prototypes and end-use parts like phone cases, tool handles, and enclosures. The filament’s enhanced durability also makes it a great option for more rugged items such as toys and accessories that might be handled roughly. Additionally, many PLA+ formulations offer a matte finish that’s perfect for professional-looking models and prototypes.

A:Yes. The “plus” in PLA+ is a designation for a proprietary blend of additives, and these vary by manufacturer. Some specialized PLA+ formulations are engineered for specific properties, such as enhanced heat resistance, improved flow characteristics for high-speed printing, or even increased impact strength for rugged parts.

A:The core PLA material is derived from renewable resources and is biodegradable under specific industrial composting conditions. The additives in PLA+ are generally non-toxic and used in small quantities. However, their presence can affect the final product’s degradation rate. While still a more sustainable option than petroleum-based plastics like ABS, a PLA+ part may take longer to compost than a pure PLA part.

A:Common 3D printing issues are often the same for both materials. For example, warping is a frequent problem where the corners of your print lift from the build plate. This can be addressed by using a heated bed (40-60°C) and an adhesive like a glue stick. If you notice stringing, where fine threads of plastic are left between parts of your print, you can adjust your retraction settings by increasing the retraction distance or speed. If your layers are not bonding well, resulting in a weak or brittle part, increase your nozzle temperature in 5°C increments. For PLA+, you can also reduce fan cooling to promote stronger layer bonding.

A:PLA is the easier material to print with, excelling in fine detail and aesthetics. It also has the advantage of being more environmentally friendly. PETG, however, is significantly more durable and tough, with better temperature and chemical resistance. This makes PETG the better choice for functional parts that need to withstand heat and wear, while PLA is the go-to for visual models and educational projects.Please see PETG vs PLA: Key Differences, Pros and Cons, and Best Use Cases.

A:ABS is the stronger, more durable material with a much higher heat resistance (~100°C), making it a staple for high-stress, end-use parts. However, ABS is much more difficult to print with than PLA. It requires a heated enclosure to prevent severe warping and releases a strong odor. PLA is the ideal material for beginners and general-purpose printing due to its ease of use and lack of warping.Please see PLA vs ABS.