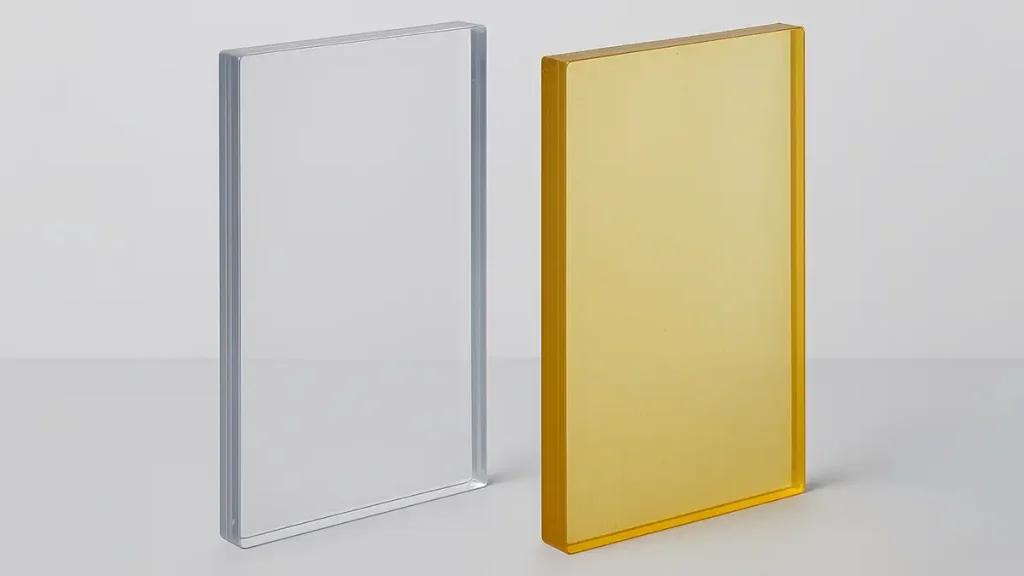

Have you noticed your high-quality sunglasses, safety shields, or building panels developing an unwanted yellow tint over time? This discoloration can be perplexing, especially for polycarbonate sheets, which are prized for their exceptional clarity, strength, and UV-resistant properties. This guide explores the science behind polycarbonate yellowing, pinpointing specific causes and offering targeted prevention and restoration methods. We’ll examine the role of UV exposure, oxidation, and environmental factors, while highlighting advanced UV protection strategies to maintain the clarity and durability of polycarbonate materials. Designed for technical professionals, engineers, and industries worldwide, this resource provides practical insights to combat yellowing and ensure long-lasting performance of polycarbonate products.

Introduction

Polycarbonate is renowned for its exceptional strength and optical clarity, making it a preferred material for applications ranging from eyewear and automotive components to protective covers and lighting fixtures. However, a common concern is whether polycarbonate yellows over time, as this discoloration can impair both its aesthetic appeal and functional performance.

Questions often arise, such as: Does polycarbonate yellow despite UV protection, and how does UV exposure affect its long-term optical properties? This section introduces the nature of polycarbonate, the role of UV light in degradation, and the critical importance of UV protection. Yellowing, driven by environmental and chemical factors, can compromise durability and clarity, reducing the lifespan of polycarbonate products. The following sections will delve into the specific causes of yellowing, including UV-induced degradation and oxidation, while outlining effective strategies for prevention and restoration to maintain polycarbonate’s pristine appearance and performance.

What Causes Polycarbonate Yellowing?

Polycarbonate yellowing results from a combination of environmental and chemical factors, with ultraviolet (UV) light exposure being the primary driver. This section examines the specific causes of yellowing, including UV-induced photodegradation, heat-accelerated oxidation, chemical interactions, and natural aging, providing a clear understanding of their impact on polycarbonate’s clarity and durability.

UV Exposure and Photodegradation

Polycarbonate’s molecular structure is susceptible to UV light, which triggers photodegradation by breaking down its polymer chains. This process alters the material’s optical properties, causing a yellow tint and, over time, increased brittleness. Although polycarbonate has some inherent UV resistance, prolonged or intense exposure overwhelms these defenses, initiating surface-level yellowing that progresses deeper without intervention. Factors like sunlight intensity and duration exacerbate this degradation.

Heat and Oxidation

Elevated temperatures accelerate polycarbonate yellowing by promoting oxidation, a chemical reaction that degrades the material’s molecular structure. Heat causes the polymer chains to react with oxygen, leading to discoloration and reduced mechanical strength. In high-temperature environments, such as those with prolonged sun exposure or industrial settings, this process is significantly faster, compounding the effects of UV exposure and hastening material deterioration.

Chemical Exposure

Exposure to harsh chemicals, such as aggressive cleaning agents or environmental pollutants, can compromise polycarbonate’s protective surface layers. These chemicals may strip away UV-resistant coatings or additives, increasing the material’s vulnerability to UV light and accelerating yellowing. For example, alkaline cleaners or solvents can erode the surface, reducing its ability to block UV radiation and leading to faster discoloration.

Natural Aging

Like all polymers, polycarbonate undergoes natural aging, which gradually affects its appearance and structural integrity. Even with minimal UV or chemical exposure, long-term molecular changes can cause slight yellowing over time. This intrinsic process is influenced by the material’s formulation and environmental conditions, though it occurs more slowly than UV- or heat-induced degradation.

| Cause of Yellowing | Primary Contributing Factor | Preventative Measures |

|---|---|---|

| UV Exposure | Photodegradation | Apply UV-resistant coatings or stabilizers |

| Heat and Oxidation | High temperatures | Maintain stable, moderate temperatures |

| Chemical Exposure | Harsh chemicals | Use mild, polycarbonate-compatible cleaners |

| Natural Aging | Time | Optimize material formulations with anti-aging additives |

How Fast Does Polycarbonate Yellow?

Polycarbonate yellowing is a critical concern across industries and consumer applications, as it impacts both aesthetics and functionality. The rate of yellowing depends on the material’s composition, environmental exposure, and protective treatments. This section examines the key factors influencing yellowing speed, including UV exposure, temperature, pollutants, and material type, to provide clarity on polycarbonate’s longevity and performance.

UV Exposure and Material Response

UV light is the primary driver of polycarbonate yellowing. Untreated polycarbonate is highly permeable to UV rays, leading to photodegradation that causes discoloration. Standard polycarbonate sheets may yellow within 2–4 months under intense UV exposure, such as continuous sunlight, and within 1–2 years under moderate exposure. In contrast, UV-stabilized polycarbonate, treated with protective coatings or additives, can resist yellowing for 12–18 months under intense conditions and up to 4–5 years in moderate settings. Glass-filled polycarbonate, reinforced with glass fibers, offers improved UV resistance, typically yellowing after 6–12 months in intense conditions or 3–4 years in moderate ones, due to enhanced structural stability.

Additional Environmental Factors

High temperatures accelerate yellowing by intensifying oxidation, which degrades polycarbonate’s molecular structure. For instance, prolonged exposure to heat above 60°C can significantly hasten discoloration, especially when combined with UV exposure. Environmental pollutants, such as industrial chemicals or airborne contaminants, further exacerbate yellowing by eroding protective layers or reacting with the material’s surface, reducing its UV resistance.

Impact of Polycarbonate Type

The type of polycarbonate significantly influences its yellowing rate. Standard polycarbonate lacks inherent UV-blocking properties, making it prone to rapid degradation. UV-stabilized variants incorporate absorbers or stabilizers that extend clarity, while glass-filled polycarbonate benefits from added durability, though it is not immune to yellowing. Selecting the appropriate type based on environmental conditions is crucial for optimizing longevity.

| Polycarbonate Type | Rapid UV Exposure | Moderate UV Exposure |

|---|---|---|

| Standard Polycarbonate | 2–4 Months | 1–2 Years |

| UV-Stabilized Polycarbonate | 12–18 Months | 4–5 Years |

| Glass-Filled Polycarbonate | 6–12 Months | 3–4 Years |

Key Considerations

Understanding the interplay of UV exposure, temperature, pollutants, and material composition is essential for predicting and managing polycarbonate yellowing. By selecting UV-stabilized or glass-filled polycarbonate and controlling environmental factors, users can significantly extend the material’s clarity and structural integrity. The following sections will explore prevention and restoration strategies to maintain polycarbonate’s performance over time.

The Role of UV Protection

Polycarbonate has inherent resistance to ultraviolet (UV) radiation, but prolonged exposure still leads to surface degradation, yellowing, and loss of optical clarity. Over time, UV photons break down the polymer chains in the material, resulting in discoloration and reduced mechanical performance.

To counteract this, UV protection strategies are widely used in polycarbonate manufacturing. These include the incorporation of UV stabilizers during resin formulation or the application of co-extruded UV-blocking surface layers. UV stabilizers—such as benzotriazoles or hindered amine light stabilizers (HALS)—either absorb or dissipate UV energy before it can damage the polymer structure.

Proper UV protection significantly extends the service life of polycarbonate, particularly in applications with continuous sun exposure. Benefits include:

- Reduced yellowing and surface embrittlement over time

- Retention of light transmission and optical clarity

- Improved material durability and mechanical integrity

- Lower replacement and maintenance frequency

The following table compares standard polycarbonate sheets with UV-protected variants:

| Polycarbonate Type | UV Resistance | Typical Lifespan | Common Applications |

|---|---|---|---|

| Standard Polycarbonate Sheet | Low | 5–10 years | Enclosures, lighting covers (indoor) |

| UV-Protected Polycarbonate Sheet | High | 10–20 years | Skylights, protective glazing, panels |

Incorporating UV protection is essential for maintaining the long-term performance of polycarbonate in exposed environments. Without it, yellowing and structural deterioration become significantly more pronounced, especially in clear or transparent applications.

How to Prevent and Mitigate Yellowing in Polycarbonate

Polycarbonate is susceptible to yellowing over time, particularly when exposed to ultraviolet (UV) radiation. While certain grades are manufactured with built-in UV resistance, not all polycarbonate products offer the same level of protection. Understanding how to enhance and preserve UV stability is essential to maintaining the material’s clarity and mechanical properties.

Several strategies can be used to prevent or slow yellowing:

1. Select UV-Resistant Grades

Use polycarbonate resins or sheets that incorporate UV stabilizers or co-extruded UV-protective layers. These formulations are specifically designed to block or absorb UV radiation, reducing photodegradation of the polymer chains.

2. Apply Protective Coatings or Films

Secondary coatings—such as hardcoats or UV-absorbing overlays—can provide an additional barrier against UV radiation. These treatments are especially beneficial for extended outdoor use, as they enhance surface durability and weathering resistance.

3. Implement Proper Maintenance

Routine cleaning with mild, non-abrasive detergents helps remove contaminants like dust, organic deposits, or residues that can accelerate degradation. Avoid the use of ammonia-based or solvent-based cleaners, which may compromise the UV-protective surface.

The following table summarizes different mitigation strategies and their relative effectiveness:

| Strategy | Description | Effectiveness |

|---|---|---|

| UV-Resistant Polycarbonate | Built-in UV stabilizers or co-extruded UV-blocking layer | High |

| Protective Overlays | Applied films or coatings with additional UV inhibitors | High |

| Routine Cleaning | Removal of harmful surface contaminants | Moderate |

Periodic inspection of polycarbonate components is also recommended. Signs of early yellowing or surface wear may indicate the need for recoating or replacement, especially in high-UV environments. Long-term performance depends not only on initial material selection but also on consistent surface care and protective measures.

Cleaning and Restoring Yellowed Polycarbonate

Managing polycarbonate yellowing involves both preventive maintenance and corrective treatment. While UV protection can reduce degradation over time, effective cleaning and surface restoration are necessary to extend the material’s usable life and maintain visual clarity.

1. Use Proper Cleaning Methods

Regular cleaning helps remove dirt, dust, and environmental contaminants that can accelerate surface breakdown. Use mild soap with warm water or cleaners specifically formulated for polycarbonate. Avoid solvents, alcohol-based products, or ammonia-containing solutions, which can damage protective coatings and exacerbate yellowing.

2. Restore with Polishing and Coatings

For surfaces that have already begun to yellow, mechanical polishing with fine abrasives (e.g., plastic-safe polishing compounds) may reduce discoloration and restore clarity. After polishing, applying a UV-protective coating can help prevent future degradation. These coatings often contain UV absorbers or stabilizers to shield the material from further exposure.

Note: Restoration methods should be applied carefully. Excessive polishing or inappropriate products can scratch or thin the sheet, compromising its mechanical strength and clarity.

3. Best Practices: Do’s and Don’ts

| Do | Don’t |

|---|---|

| Clean polycarbonate regularly using non-abrasive cleaners | Don’t use harsh chemicals like acetone, ammonia, or strong solvents |

| Apply UV-protective coatings as part of long-term maintenance | Don’t scrub with abrasive pads or tools that can scratch the surface |

| Monitor for early signs of discoloration and act promptly | Don’t ignore yellowing, as it worsens and becomes harder to reverse |

In severe cases, where yellowing is deep or widespread, restoration may be ineffective or impractical. If mechanical properties or transparency are significantly compromised, replacement of the affected parts may be the most cost-effective option.

Proactive care, combined with timely surface treatments, can significantly slow the effects of aging and UV exposure on polycarbonate materials, preserving both appearance and performance.

Key Considerations

For distributors and users of polycarbonate pellets, managing material integrity before and during processing is essential to minimizing yellowing in final applications. Although UV-resistant additives can be included in formulations, improper handling or storage of raw pellets may compromise their long-term performance.

Proper Storage of Pellets

Store polycarbonate pellets in sealed, UV-shielded containers away from direct sunlight. Even though the material is processed later, prolonged exposure of pellets to light, moisture, or heat can begin to degrade the polymer chains or destabilize added UV inhibitors.

- Maintain storage temperature below 40°C (104°F)

- Keep in low-humidity environments (ideally <50% RH)

- Use opaque or UV-resistant packaging when applicable

Handling and Transport

Minimize pellet exposure during handling or transfer. Use closed conveying systems or covered containers to reduce exposure to ambient light. Avoid contamination with dust, moisture, or other polymers, which can affect melt flow and optical properties in the final product.

Support for Compounders and Processors

- Provide clear documentation on whether UV stabilizers are included in the pellet formulation

- Where UV resistance is required, advise customers on the suitability of different grades (e.g., base resin vs. pre-compounded UV-stabilized grades)

- Educate customers on the impact of regrind ratios and processing temperatures on long-term clarity and yellowing behavior

Quality Control and Traceability

Maintain traceability through batch records and delivery logs. Ensure that material certifications (such as presence of UV additives, melt flow index, moisture content) are shared with customers as needed for quality assurance.

Communication of Limitations

Where warranties or performance guarantees are provided by the resin manufacturer, communicate clearly what is covered—especially regarding UV-related discoloration. This helps customers set realistic expectations based on their application environment and processing conditions.

By maintaining proper controls over pellet storage and advising end-users on processing best practices, yellowing risks can be significantly reduced. This ensures that the final products retain their clarity and mechanical integrity over time, especially in outdoor or UV-exposed applications.

Conclusion

Polycarbonate is a versatile and durable engineering plastic, but it is not immune to degradation. Yellowing can occur due to prolonged exposure to ultraviolet (UV) radiation, elevated temperatures, oxidation, and certain chemicals. Even natural aging contributes to discoloration over time.

Preventing yellowing requires a proactive approach. Incorporating UV stabilizers during compounding, applying protective coatings, and ensuring proper handling and storage all play key roles in maintaining the material’s optical and mechanical properties.

In summary:

- Yes, polycarbonate can yellow—but it can be mitigated.

- Proper formulation, processing, and care are critical to long-term clarity and performance.

For compounders, processors, and manufacturers, understanding these causes and preventive strategies enables better material selection and longer-lasting end products.

For more technical guidance or to explore UV-stabilized polycarbonate solutions, please contact us at:

📧 jerry@salesplastics.com

📞 +8618657312116

FAQs

A:Polycarbonate is generally more resistant to impact and heat than acrylic, but it is also more prone to yellowing under prolonged UV exposure. Acrylic, on the other hand, tends to maintain its clarity longer in outdoor applications, though it is more brittle. For long-term UV stability, UV-coated acrylic may outperform untreated polycarbonate.

A:Yes. Polycarbonate can discolor with time, especially under UV radiation, heat, and oxidative stress. The material may shift from clear to a yellowish hue, depending on exposure levels and whether protective additives or coatings are used.

A:Yes. Transparent polycarbonate phone cases, especially those without UV inhibitors, can turn yellow over several months due to exposure to sunlight, body oils, and heat. This is a common issue with clear protective accessories made from this material.

A:Yellowing can begin within 6–12 months under continuous outdoor UV exposure if the polycarbonate lacks UV stabilizers. Indoors or in low-UV environments, this process may take years. The exact timeline depends on the grade of polycarbonate and the presence of protective additives or coatings.

A:Yellowing caused by UV degradation is largely irreversible because it results from structural changes in the polymer chains. While surface-level yellowing due to dirt or contaminants can be cleaned with mild polishing agents or hydrogen peroxide-based cleaners, permanent yellowing cannot be restored through cleaning alone. Replacement or recoating is typically required.

A:Fluoropolymers (like PTFE) and UV-stabilized acrylics show excellent resistance to yellowing. Additionally, polycarbonate grades that include UV inhibitors or are co-extruded with UV-resistant layers are significantly less prone to discoloration. Choosing the right formulation is key for long-term clarity.

A:UV-resistant polycarbonate sheets are co-extruded or coated with layers containing UV-absorbing additives. These prevent ultraviolet rays from penetrating the base material, greatly reducing yellowing, embrittlement, and optical degradation. Such sheets are ideal for outdoor glazing, roofing, and protective barriers.

A:Yes. Thermoplastic polyurethane (TPU), especially transparent grades, tends to yellow due to UV light and oxidative exposure. This is a known limitation of TPU used in clear phone cases or wearable devices. Manufacturers often add stabilizers, but these only slow down the process.