The persistent demand for enhanced product durability, higher operational efficiency, and improved sustainability creates complex challenges for engineers and product designers. The critical difficulty often lies in identifying materials that satisfy rigorous technical specifications without compromising the overall cost-efficiency of the final product. Polyketone (POK) has emerged as a significant advancement in engineering polymer technology, strategically addressing this divide. It offers a distinctive and balanced performance profile characterized by high mechanical strength, excellent chemical resistance, and notable processing versatility. As application requirements intensify, POK presents a robust alternative, effectively bridging the performance gap between standard engineering plastics and the high cost of specialty polymers.

What is Polyketone (POK)?

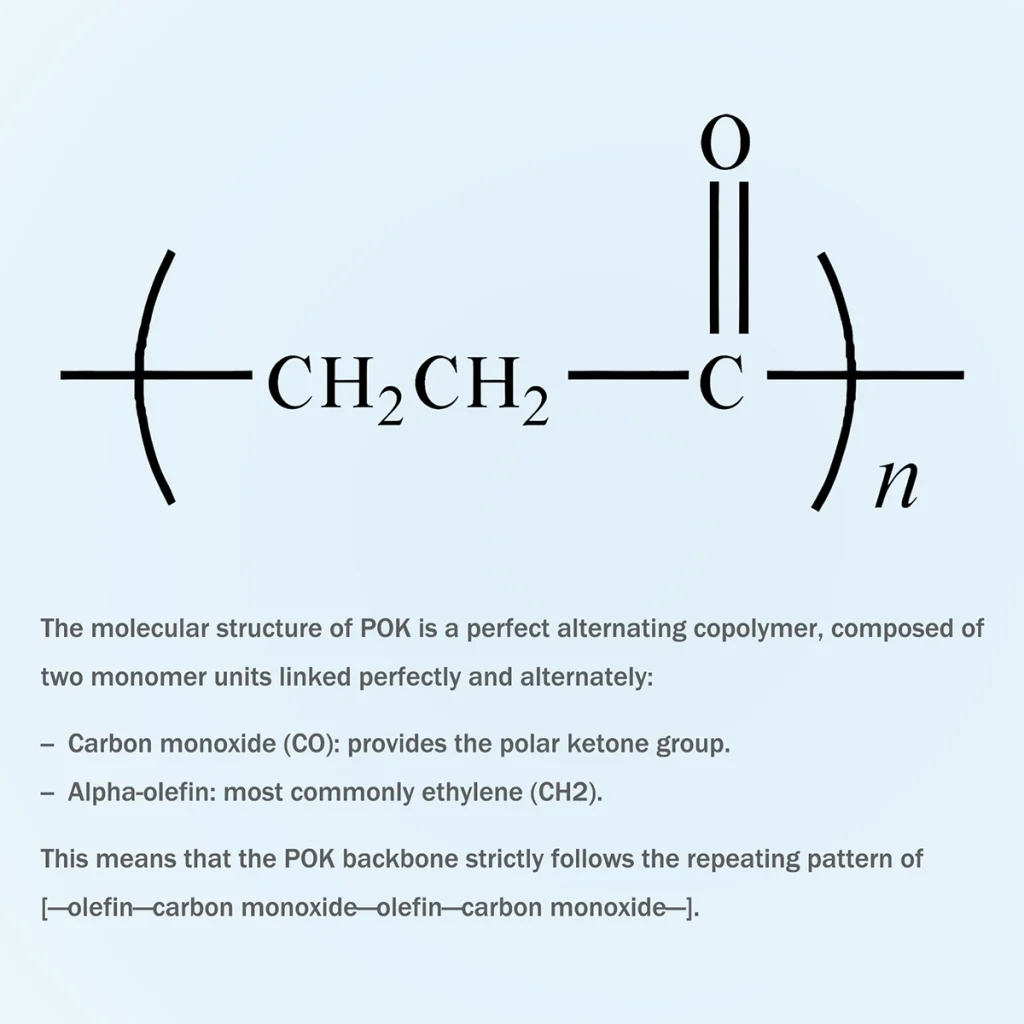

Polyketone (POK) is an aliphatic engineering thermoplastic distinguished by its molecular structure: a perfectly alternating copolymer of carbon monoxide and alpha-olefin units (most commonly, ethylene). This highly linear backbone, which embeds polar ketone groups (C=O) at regular intervals, is the foundation for its robust property set. Having been commercialized on a large scale by Hyosung Chemical, POK represents a significant advancement in materials science, offering a novel combination of characteristics.

The key to POK’s performance lies in its chemical structure. The high density of polar ketone groups creates strong intermolecular forces (dipole-dipole interactions) between the polymer chains. This powerful attraction facilitates a highly ordered and compact crystalline arrangement, resulting in a material with:

- A high melting point (Tm) of approximately 220°C.

- High mechanical robustness, including superior impact strength (toughness) and excellent wear and abrasion resistance.

- Robust chemical stability, showing notable resistance to hydrolysis, solvents, automotive fluids, and salts.

It is this specific, regular molecular configuration—not found in traditional polyamides or polyacetals—that provides POK with its compelling balance of properties while maintaining the consistent processing characteristics expected of a modern engineering thermoplastic.

Deep Dive into POK Technology

Request a copy of our comprehensive technical data sheet to validate POK’s property set and explore the molecular foundation of its balanced performance profile.

Performance-Driven Advantages of Polyketone

Polyketone (POK) is engineered to solve complex material challenges by delivering a distinct and balanced set of properties. Understanding these key advantages allows product designers to strategically leverage POK’s capabilities across demanding industrial sectors.

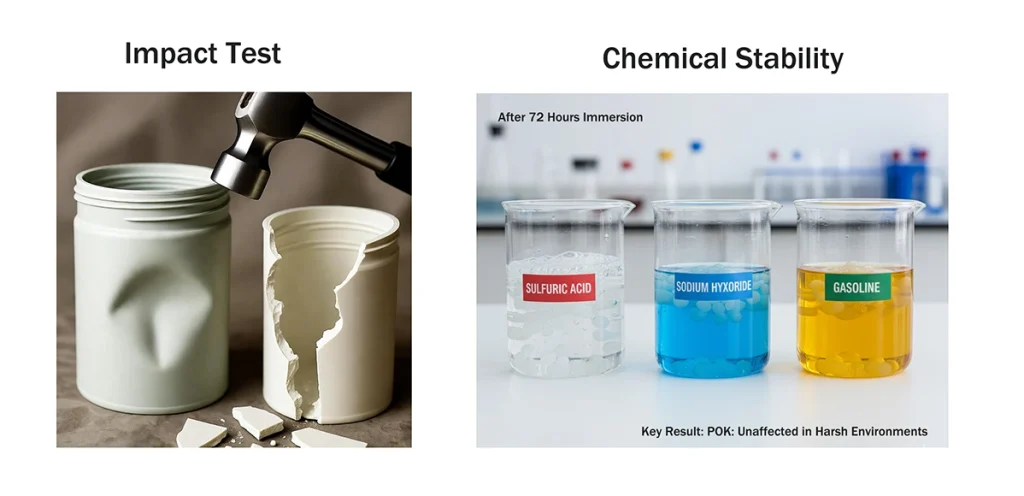

Exceptional Impact Strength and Toughness

POK offers impact resistance superior to many conventional engineering polymers. Its high yield strain, exceeding 20%, enables excellent energy absorption, ensuring components maintain structural integrity under sudden mechanical stress.

Superior Chemical and Hydrolysis Resistance

POK exhibits robust stability when exposed to hydrocarbons, automotive fluids, fuels, oils, and general cleaning agents. Crucially, its inherent resistance to hydrolysis makes it a reliable choice for fluid handling systems and applications exposed to continuous moisture or chemical solutions.

Excellent Gas Barrier Properties

POK provides superior barrier performance against common gases, including oxygen (O₂) and carbon dioxide (CO₂). This makes it highly valuable for multi-layer films and precision packaging where preserving product freshness and extending shelf life are paramount.

Outstanding Wear and Abrasion Resistance

The material demonstrates remarkable longevity in dynamic applications. This resistance to wear, often exceeding that of polyacetals (POM) and Polyamides (PA), significantly extends the service life of moving parts, translating directly into reduced maintenance and replacement costs.

Minimal Moisture Absorption

Unlike standard polyamides (nylons), POK absorbs minimal moisture(typically <0.5%). This fundamental characteristic ensures consistent dimensional stability and maintains mechanical properties across varying humid environments, thereby simplifying processing by eliminating the need for pre-drying.

Environmental Safety

POK is free from harmful substances such as bisphenol A (BPA), phthalates, and heavy metals. This composition secures certifications for sensitive applications, including food contact, aligning with modern sustainability and health initiatives.

| Property | Performance Level | Engineering Benefit |

| Impact & Toughness | Superior | High durability under mechanical stress and shock. |

| Wear Resistance | Outstanding | Extended service life for frictional and moving components. |

| Chemical Resistance | Robust | Reliability in harsh fluid and solvent environments. |

| Moisture Absorption | Very Low | Predictable dimensional stability and processing ease. |

| Gas Barrier | Excellent | Enhanced preservation in packaging and containment. |

Polyketone vs. Traditional Engineering Polymers

When evaluating material alternatives for critical components, a detailed comparison with established engineering polymers is essential. The following analysis highlights where Polyketone (POK) provides distinct performance advantages and offers a compelling replacement strategy for material substitution.

POK vs. Polyoxymethylene (POM/Acetal)

POK presents a stronger profile for demanding environments:

- Superior chemical resistance, especially to strong acids and bases.

- Enhanced impact performance across both room and low temperatures.

- Cleaner processing, being free from formaldehyde emissions.

- Comparable dimensional stability and processing characteristics, facilitating direct substitution.

POK vs. Polyamide (PA / Nylon)

POK fundamentally addresses the dimensional stability challenges associated with PA:

- Significantly lower moisture absorption, ensuring exceptional dimensional and mechanical consistency (avoiding the “plasticizing” effect of water).

- Eliminates the necessity for extensive pre-drying before processing, saving time and energy.

- Wider chemical compatibility, offering superior resistance to various acids and specific solvents.

- Comparable mechanical strength and fatigue resistance to many unreinforced PA grades.

POK vs. Polybutylene Terephthalate (PBT)

POK is advantageous in applications demanding high durability and dynamic performance:

- Higher impact strength, particularly at low temperatures.

- Better chemical resistance to hydrocarbons.

- Improved abrasion resistance for moving parts.

- Maintains electrical properties comparable to PBT.

“Polyketone represents a significant advancement in engineering polymers, offering a balanced performance profile that addresses many of the limitations found in traditional materials while maintaining competitive processing characteristics.”

– Materials Engineering Journal

Need Help Selecting the Right Material?

Our team can help you evaluate whether Polyketone is the optimal choice for your specific application requirements.

Excellence in Healthcare: Core Applications

Polyketone (POK) truly excels in the medical field, where its unique combination of biocompatibility, chemical resistance, and mechanical durability addresses demanding requirements for both external and implantable devices. POK’s advantages are rooted in its non-toxic, carbon-based backbone and extensive international certifications.

Key Features Driving Medical Adoption

POK is rapidly gaining preference over traditional materials due to its superior cost-to-performance ratio:

- Durability and Wear: Offers high abrasion resistance (up to 14 times better than POM), essential for long-term contact and dynamic medical devices like pumps and surgical tools.

- Cost-Effectiveness: Provides similar high toughness and heat resistance (melting point 220℃ to 255℃) at a significantly lower cost compared to ultra-high performance polymers like PEEK.

- Biocompatibility: Compliant with stringent standards, including USP Class VI and ISO 10993, confirming its safety for internal and external human contact.

- Processing Efficiency: A low and consistent shrinkage rate simplifies mold design and allows for robust snap-fit assembly in external instruments.

Core Applications in a Regulated Market

The application growth is robust, benefiting from POK’s stability against rigorous clinical environments:

| Application Category | POK Advantage Leveraged | Market Trends and Cases |

| Implants & Surgical Tools | Sterilization Resistance (Gamma/Steam), High Mechanical Strength (Impact Resistance>100). | Growing trend of using POK-based biodegradable implants (e.g., bone fixation frames) to potentially eliminate secondary removal surgeries. |

| Diagnostic & Infusion Systems | Chemical Resistance (disinfectants/bodily fluids), Low Leakage. | Adoption in disposable syringes and infusion bottles is increasing, driven by POK’s superior chemical stability compared to standard plastics. |

| External Instruments | Abrasion/Oil Resistance, Processability (low and consistent shrinkage rate). | Used in medical pump valves, complex catheters, and sterilization trays, benefiting from simplified manufacturing via robust snap-fit designs. |

| Emerging Technology | Gas Barrier Properties, Sustainability (recyclable, bio-based potential). | New applications include battery components for implantable pacemakers and high-barrier film packaging, with bio-based variants expected for absorbable implants by 2030. |

In a market traditionally reliant on high-cost specialty polymers, POK provides a strategic material solution that meets both performance requirements and the growing demand for cost-efficient, sustainable medical device manufacturing.

Explore POK for Your Industry

Discover how Polyketone can solve specific challenges in your industry with our application-specific technical resources.

Why Choose Sales Plastics for Polyketone Solutions?

The technical superiority of Polyketone is clear. To realize the full potential of this advanced material, engineers require a partnership that extends beyond the transaction. Sales Plastics focuses on providing the precise expertise and logistical framework necessary to seamlessly integrate POK into your most demanding applications.

Sales Plastics distributes a comprehensive range of POK grades to meet the rigorous demands of modern manufacturing. Our portfolio ensures engineers can readily capitalize on POK’s superior properties across various applications.

We offer several key product grades:

- Unreinforced Grades: Ideal for applications requiring exceptional toughness, low friction, and chemical resistance.

- Glass Fiber Reinforced Grades: Offering enhanced mechanical strength, stiffness, and dimensional stability for structural components.

- Specialty Grades: Including high-flow types(e.g., POK M330F) for complex, thin-walled parts, and grades formulated for specific regulatory compliance (e.g., food contact).

Applied Technical Guidance

Our team provides targeted support on material selection, mold flow analysis, and processing parameters based on extensive experience with POK across diverse industries.

Rigorous Sourcing

We source POK materials that strictly adhere to international standards, including ISO 9001 and specific industry certifications (e.g., FDA compliance where applicable).

Inventory Stability

We maintain strategic inventory levels and strong, direct supplier relationships to guarantee the consistent availability of Polyketone materials, minimizing disruption in today’s complex supply environment.

Custom Formulation Development

Beyond standard grades, we collaborate to develop specialized POK formulations, optimizing properties like impact resistance, lubricity, or flame retardancy for your unique operating conditions.

Batch Consistency

Every delivery is backed by a robust quality control process, ensuring the predictable mechanical and thermal performance required for reliable mass production.

Sustainability Alignment

Our focus includes supporting material solutions that contribute to your sustainability goals—offering POK grades known for their longer service life, reduced maintenance requirements, and compatibility with end-of-life recycling programs.

Partner with Sales Plastics for Your POK Needs

Experience the difference that expert support and quality materials can make in your next project.

Frequently Asked Questions (FAQs)

Get answers to common questions about Polyketone (POK) properties, applications, and processing considerations.

What kind of material is POK?

POK is an aliphatic engineering thermoplastic characterized by its highly ordered molecular structure: a perfectly alternating copolymer of carbon monoxide and an alpha-olefin (typically ethylene). This unique backbone, featuring regular ketone groups (C=O), provides its balanced profile of high mechanical strength, excellent chemical stability, and toughness.

What is the specific gravity of polyketone?

The typical specific gravity (density) of neat (unfilled) Polyketone is approximately 1.25 g/cm³ (ranging from 1.24 to 1.30 g/cm³ for various grades). This density is comparable to many high-performance engineering plastics.

What are the uses of polyketone?

POK is utilized in demanding applications across multiple sectors. Key areas include:

- Automotive: Fuel system components, fluid connectors, and EV battery parts due to chemical resistance.

- Industrial Equipment: Bearings, gears, and bushings, leveraging its outstanding abrasion resistance.

- Healthcare: Surgical tools, diagnostic devices, and fluid systems, capitalizing on its biocompatibility and chemical stability.

What is the glass transition temperature of polyketone?

The glass transition temperature (Tg) of neat Polyketone is typically in the range of 15 ℃ to 35℃. This low Tg contributes significantly to the material’s high impact strength and toughness at room temperature, while the material remains dimensionally stable up to its higher melting point (Tm ≈ 220℃).

How does POK compare to nylon in humid environments?

POK offers a distinct advantage over nylon in humid environments due to its significantly lower moisture absorption. Unlike PA, which exhibits high hygroscopy leading to dimensional change and reduced mechanical strength, POK absorbs less than 0.5% moisture. This ensures POK components maintain consistent mechanical properties and dimensional stability regardless of environmental humidity.

Can POK be injection molded like POM?

Yes. POK is fully compatible with standard thermoplastic processing methods, including injection molding and extrusion. POK exhibits processing characteristics similar to POM/Acetal, allowing for seamless integration into existing manufacturing lines. A major processing benefit is that POK does not require the extensive pre-drying typical of PA, nor does it release formaldehyde emissions like POM.

Ready to Explore Polyketone for Your Application?

Contact our technical team today to discuss how POK can solve your material challenges and improve your product performance.