As the global regulatory landscape shifts—driven by the EU’s Single-Use Plastics (SUP) Directive and stringent national plastic bans—manufacturers are under unprecedented pressure to pivot toward sustainable alternatives. However, the transition is fraught with operational challenges: inconsistent processing stability, ambiguous degradation environments, and the constant struggle of cost-performance optimization.

Navigating the ‘Big Three’—PHA, PLA, and Starch-based plastics—requires more than just an environmental conscience; it demands technical precision. This comprehensive guide deconstructs these biopolymers to help you mitigate risk, ensure compliance, and identify the exact material that aligns with both your production requirements and your bottom line.

Profiles of the "Big Three" Biopolymers

Not all “biodegradable” materials are created equal. For manufacturers, the choice between biopolymers involves a complex trade-off between environmental degradation limits, processing compatibility, and long-term cost-efficiency. To help you navigate this, we categorize the “Big Three” based on their strategic fit in the modern circular economy:

PLA (Polylactic Acid): The Industrial Benchmark

Derived from the fermentation of corn or cassava starch, PLA is currently the most commercially mature and widely adopted bioplastic.

- Best For: Rigid packaging, high-transparency films, and 3D printing.

- Key Advantage: Offers the highest mechanical strength and clarity, mimicking traditional PET. It is the “safe bet” for large-scale industrial production.

- Constraint: Biodegrades only under industrial composting conditions (typically ≥58°C, high humidity); poor performance in home compost, soil, or marine environments.

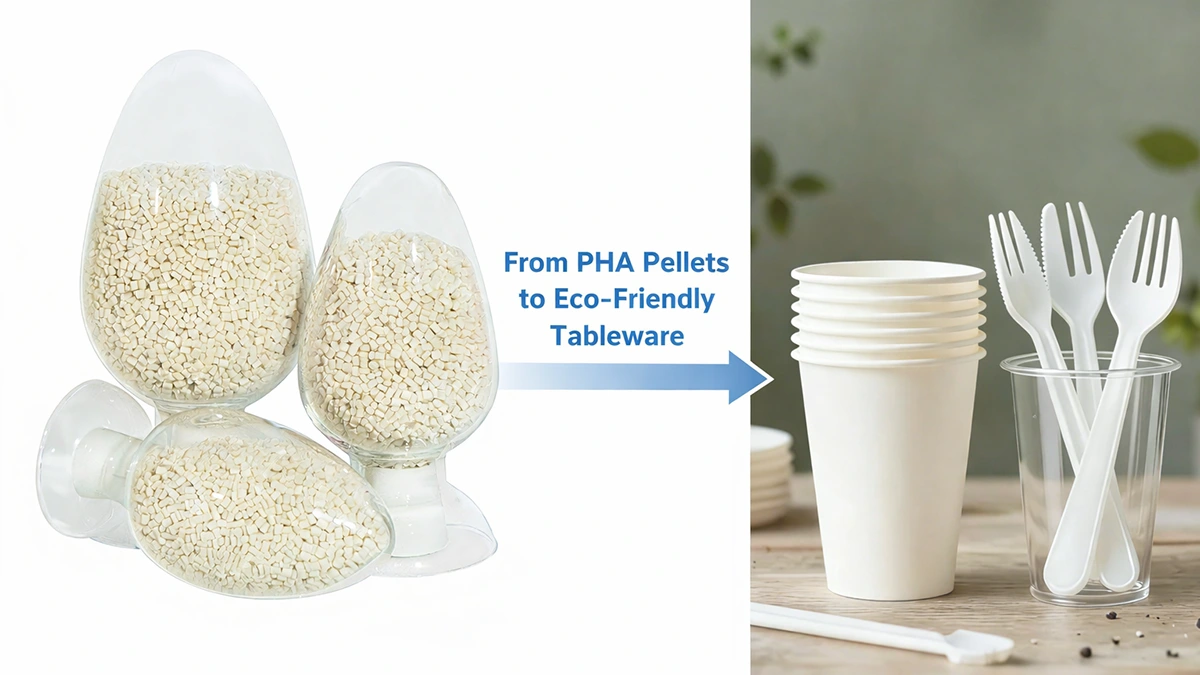

PHA (Polyhydroxyalkanoates): The Most Environmentally Versatile

Often referred to as “microbial fat,” PHA is synthesized naturally by bacteria under unbalanced growth conditions. It is the only material in this group that is truly “born from nature.”

- Best For: Marine-safe packaging, agricultural mulching, and medical-grade implants.

- Key Advantage: Exceptional environmental adaptability; it is fully biodegradable in soil, home compost, and even marine environments.

- Constraint: Higher production costs due to the complex fermentation process, positioning it as a premium choice for high-end sustainable branding.

Starch-Based Plastics: The Synthetic 'Gold

By physically blending natural starch with biodegradable polyesters (such as PBAT or PLA), these materials offer a pragmatic balance between sustainability and economics.

- Best For: Express mailing bags, single-use cutlery, and flexible film packaging.

- Key Advantage: The most cost-effective route to reducing carbon footprints. The blending process allows for adjustable flexibility and toughness.

- Constraint: Higher sensitivity to moisture; requires careful storage and specific processing adjustments to maintain structural integrity.

Unsure which of these technologies aligns with your specific product roadmap? Explore our detailed guide to master the basics of bioplastic chemistry and applications.

Read More: What Are Bioplastics? A Guide to PLA, PHA, and Starch-Based Types

Not sure which biopolymer fits your production line?

Get a free material compatibility assessment from our technical experts.

Technical Face-off: Key Performance Indicators

The following data provides a benchmark for material selection based on mechanical requirements and end-of-life goals.

| Property | PLA (Polylactic Acid) | PHA (Polyhydroxyalkanoates) | Starch-based Blends |

| Primary Source | Corn starch, Sugarcane | Bacterial fermentation | Potato, Tapioca, Corn |

| Biodegradability | Industrial Compost (≥58°C) | Marine, Soil, Home Compost | Home/Industrial (blend dependent) |

| Mechanical Strength | High (Rigid, Tensile: 50-70 MPa) | Medium to High (Versatile) | Low to Medium (Tough but soft) |

| Heat Resistance | Low (55–60°C) / CPLA: Up to 90°C | Medium to High (80–120°C) | Very Low (≤ 50°C) |

| Moisture Barrier | Moderate | Excellent | Poor |

| Regulatory Fit | FDA Food Contact, EN 13432 | Marine Safe, ASTM D6691 | High Bio-content certification |

| Relative Cost | Medium (most scaled) | High (2–4× PLA) | Lowest |

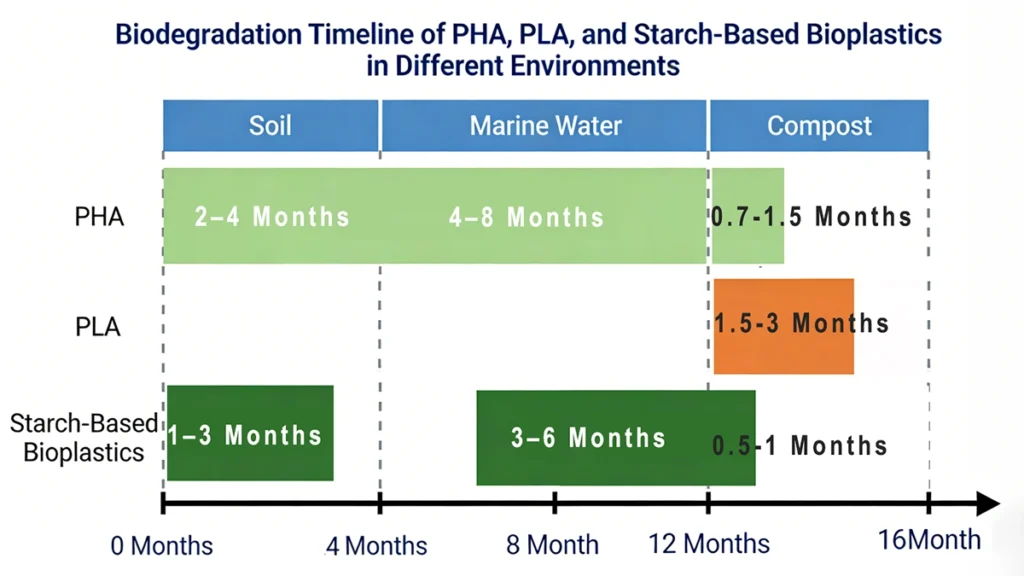

Biodegradation timelines vary significantly between materials and environments

Processing Guide: Which Resin Fits Your Existing Machinery?

Integrating sustainable resins into existing production lines requires precise thermal management and moisture control.

Extrusion

- PLA: Best for transparency and stiffness. Ideal for cold-chain packaging.

- Requirement: Pre-drying <250ppm.

- PHA: Best for high-heat straw production. Superior “Home Compostable” profile.

- Starch: Primarily used for foamed loose-fill or low-precision industrial profiles.

Injection Molding

- PLA: The industry standard for rigid packaging.

- Key Logic: High melt flow allows for fast cycle times comparable to PS/PP. Crucial: Resin must be dried to ≤ 250 ppm to prevent hydrolytic degradation.

- PHA : Excellent for high-durability parts.

- Key Logic: Requires precise mold temperature control to manage crystallization rates and prevent warping.

- Starch : Best for low-precision items.

- Key Logic: High viscosity often necessitates blending with PBAT or other carriers to achieve adequate mold filling.

Blown Film

- PLA : Challenging due to low melt strength. Usually requires “Impact Modifiers” or blending for film stability.

- PHA : Naturally suited for flexible packaging. Offers superior puncture resistance and marine degradability for the shipping industry.

- Starch: The “Economy Choice” for carrier bags.

- Key Logic: Must be blended (e.g., Starch+PBAT) to provide the necessary elasticity and tensile strength for thin-gauge applications.

Processing Tip: Material suppliers can often provide custom compounds optimized for your specific processing equipment. This significantly reduces setup time and material waste during transition.

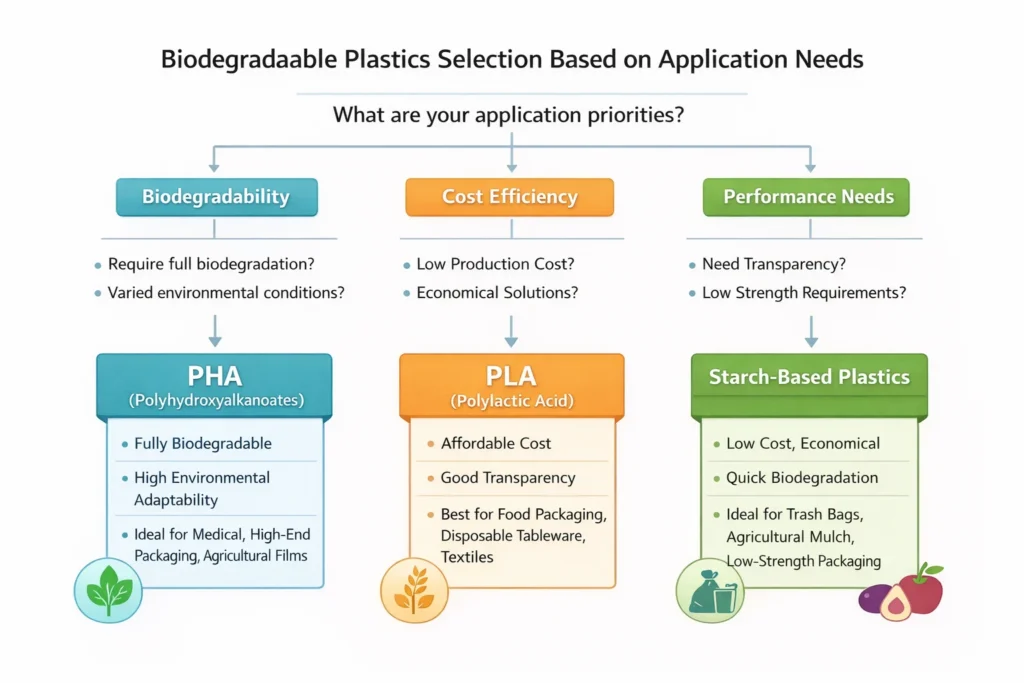

Application Scenario Matching: Which One Should You Choose?

Selecting the optimal resin is a balance between technical performance, regulatory compliance, and bottom-line profitability.

Decision Tree for Choosing PHA, PLA, and Starch-Based Biodegradable Plastics

Scenario 1: High-Clarity Retail & Food Service Packaging

Recommended Material: PLA (Polylactic Acid)

- The Logic: For products where visual appeal and structural rigidity are non-negotiable (e.g., deli containers, cold-drink cups, and transparent blisters).

- Advantage: PLA offers the closest aesthetic match to PET/PS, ensuring brand premiumization without sacrificing consumer experience.

Pro-Tip

- For hot-fill applications (up to 90°C), ask our team about CPLA (Crystallized PLA) formulations.

Scenario 2: High-Performance Industrial & Marine Applications

Recommended Material: PHA (Polyhydroxyalkanoates)

- The Logic: For specialized sectors like agricultural Mulch Films, medical devices, marine equipment, or high-end export goods where environmental leakage is a risk.

- Advantage: Marine & Soil Biodegradability serves as a powerful “insurance policy” against strict environmental regulations and potential microplastic liabilities.

Pro-Tip

- PHA’s superior moisture and gas barrier properties make it an excellent choice for long-term storage of sensitive contents.

Deep Dive: To understand the degradation curve and soil benefits, read our technical guide: PHA Biodegradable Mulch Film.

Scenario 3: High-Volume Flexible Logistics & Agriculture

Recommended Material: Starch-based Blends (TPS + PBAT)

- The Logic: For price-sensitive, high-turnover items like supermarket carrier bags, courier mailers, and disposable Cutlery (forks, spoons, knives).

- Advantage: Maximizes the use of renewable content at the lowest price point per unit, helping businesses meet “Bio-based Content” mandates while maintaining profitability.

Pro-Tip

- Our starch blends are optimized for high-speed blown film lines, reducing waste during the manufacturing transition.

The Distributor's Value: Beyond Just Material Supply

Transitioning to biodegradable resins involves technical risks. As your distributor partner, we de-risk the process to ensure your sustainability goals align with your bottom line.

Expert consultation can significantly reduce material selection and processing challenges

Technical Risk Mitigation

- Cycle-Time Optimization: We don’t just supply resin; we fine-tune your processing parameters to match traditional plastic cycle times, protecting your margins.

- On-Site Troubleshooting: Our engineers join your production trials to solve issues like warping, moisture sensitivity, or melt instability in real-time.

- Compatibility Audits: Assessment of your existing machinery (Injection, Extrusion, Blown Film) to minimize capital expenditure on new equipment.

Regulatory & Market Readiness

- Global Compliance Packs: Instant access to certification data (EN 13432, ASTM D6400, BPI) required for international market entry.

- Custom Compounding: If pure PLA or PHA doesn’t meet your specs, we develop custom blends to achieve the exact balance of toughness, heat resistance, and cost.

- Inventory Security: Buffer stock management to insulate your production from global raw material price volatility.

“Our goal is to eliminate the ‘Green Premium’ through processing efficiency. We ensure that your transition to PHA, PLA, or Starch-based materials is a competitive advantage, not a technical hurdle.”

Conclusion: Making Your Biodegradable Plastic Decision

Selecting between PHA, PLA, and Starch-based plastics is not a search for a universal “best” resin, but a strategic alignment with your business goals. Whether you prioritize high-end performance, cost-efficiency, or specialized biodegradation, the right material exists to meet your needs.

- PLA: The industry standard for clarity and rigid performance, offering the most seamless transition for high-volume food service packaging.

- PHA: The premium choice for “uncontrolled” environments, providing an eco-insurance policy for Agricultural Mulch Films and marine-sensitive products.

- Starch-based Blends: The pragmatic solution for large-scale logistics and everyday disposables, maximizing bio-content at the most competitive price point.

we don’t just supply resin; we provide tailored formulations and dedicated technical support to de-risk your sustainable transition. Our value lies in ensuring that your move toward biodegradable materials is both technically feasible and financially profitable.

How We Support Your Journey:

- Custom Formulations: We provide specific resin-blending advice to help you achieve the exact balance of heat resistance, flexibility, and cost.

- On-Site Technical Support: Our engineers assist with machine calibration and parameter optimization to ensure “plug-and-play” compatibility with your existing equipment.

- Regulatory & Certification Guidance: We navigate the complex landscape of global compostability standards so your products remain compliant in every market.

Frequently Asked Questions

PHA vs PLA vs Starch-based: which is better?

The “best” material is defined by your product’s lifecycle and performance goals. PLA is the industry standard for high-clarity, rigid packaging requiring industrial composting. PHA is our premium solution for environmental integrity, offering true marine and soil biodegradability where recovery is difficult. Starch-based resins provide a pragmatic, cost-effective entry point for high-volume flexible packaging.

Rather than a one-size-fits-all approach, we help you navigate these choices by evaluating mechanical requirements, environmental impact, and regional regulations to find your ideal sustainable match.

What is the cost comparison between PHA, PLA, and Starch-based plastics?

While bioplastics currently command a premium—typically ranging from Starch-based (1.5x–2.5x) to PHA (3x–5x) compared to conventional resins—the investment reflects long-term brand equity and regulatory compliance. Factors like carbon tax credits, plastic ban exemptions, and consumer loyalty significantly offset the initial material cost.

We leverage our supply chain to provide competitive volume pricing and help you optimize processing efficiency to reduce waste, ensuring your transition remains economically viable.

Can these biodegradable plastics be processed on conventional equipment?

Yes. Most of our resins are designed for seamless integration with existing injection molding, extrusion, and film-blowing machinery. PLA requires precise moisture control (≤50ppm), while PHA demands careful thermal management due to its narrower processing window. Starch-based materials often serve as excellent “drop-in” replacements with minimal adjustments.

We don’t just ship the resin; our technical team provides tailored processing profiles and on-site optimization to ensure your production line runs at peak performance from day one.