Material selection today is a high-stakes calculation where technical reliability meets aggressive margin optimization. While Polybutylene Terephthalate (PBT) remains the gold standard for dimensional stability, unpredictable feedstock costs and supply chain shifts are forcing engineers to re-evaluate not only material categories, but also supplier grade specifications within PBT itself.

Success now depends on identifying the precise tipping point where premium imported PBT grades justify their cost—and where high-performance domestic PBT grades can strategically lower the cost floor without compromising functional performance.

PBT Material Performance & Benchmarks

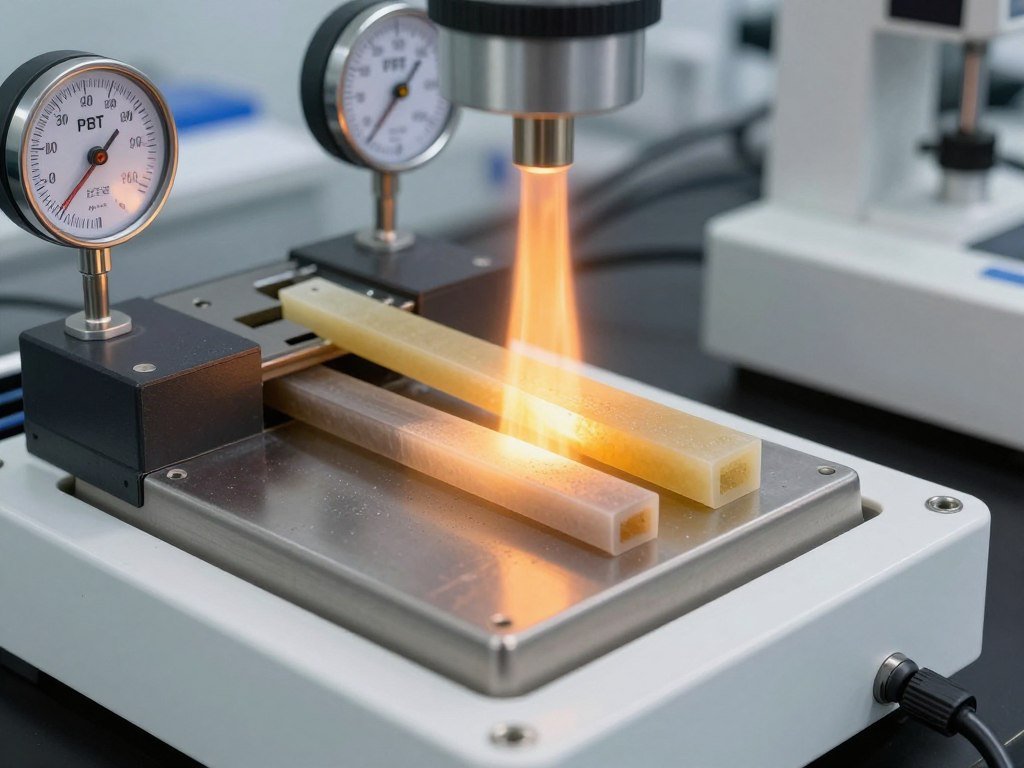

Figure 2: High-temperature performance testing of PBT

As a semi-crystalline engineering thermoplastic, PBT is defined by its rapid crystallization rates and exceptional environmental stability—offering a superior balance of performance and cost. Unlike many polyamides, PBT maintains its physical integrity in humid conditions, making it the industry standard for precision components.

The following benchmarks highlight why PBT is the preferred alternative for demanding applications:

Mechanical Strength & Versatility

While standard PBT offers a tensile strength of 50-60 MPa, glass fiber reinforcement (15-50%) can elevate this to 130 MPa. This scalability allows engineers to replace higher-cost specialty resins with customized PBT grades without sacrificing structural stiffness.

Thermal & Flame Performance

Reinforced PBT grades achieve a Heat Deflection Temperature (HDT) of 200-220°C. When compounded with flame retardants, PBT achieves UL94 V-0 ratings at 0.8mm, ensuring safety for thin-walled electrical housings.

Superior Electrical Integrity

PBT excels in insulation, featuring a Comparative Tracking Index (CTI) exceeding 600V and a dielectric strength of 15-20 kV/mm. Because saturated moisture absorption is consistently <0.1%, these electrical properties remain stable even in high-humidity environments.

Dimensional & Chemical Stability

With a low CLTE (20-40 × 10⁻⁶/K when reinforced) and high resistance to automotive fluids (oils, greases, and solvents), PBT ensures long-term dimensional accuracy. Its low mold shrinkage minimizes warpage, directly reducing scrap rates and per-part costs.

A High-Performance Domestic PBT Grade for Engineering Applications

Figure 3:PBT Raw Material – 25kg/Ton Bag Packaging

Addressing the increasing demand for supply chain resilience and cost optimization, Hengli has developed a specialized PBT portfolio specifically engineered to serve as a seamless “drop-in” replacement for established industry benchmarks like Chang Chun (CCP) PBT. By incorporating proprietary nucleating agents and optimizing molecular weight distribution, these grades bridge the gap between domestic cost-efficiency and the rigorous standards required by Tier-1 automotive and electronic manufacturers.

Unlike many regional compounders, Hengli’s integrated upstream petrochemical chain ensures a consistent supply of high-purity PTA and BDO feedstocks. This vertical integration allows for a level of batch-to-batch consistency that rivals premium Taiwanese market leaders (such as Chang Chun – CCP), ensuring that the molecular weight distribution remains stable—a critical factor for precision automotive connectors.

While we focus on high-performance alternatives here, you can explore the technical foundations of these specifications in our overview of PBT Material Grades: Types and Key Differences.

| Recommended Grade | Type | Key Features | Typical Applications | Key Metrics |

| PBT-G0 | Base Resin | High flow, easy to compound. | Fiber optic buffering, base resin. | MFI: 20-30 g/10min |

| PBT-GF30 | 30% GF | High strength & HDT. | Automotive connectors, housings. | Tensile: 125 MPa |

| PBT-FR15 | 15% GF FR | Balanced FR & Mechanics. | Switches, electronic connectors. | UL94: V-0 (0.8mm) |

| PBT-FR30 | 30% GF FR | Max FR & stiffness. | Power distribution, EV charging. | CTI: 600V |

| PBT-HR | Hydrolysis Res. | Long-term stability in heat/moisture. | Outdoor sensors, appliance parts. | 85/85 Test: 1000h+ |

Key Competitive Advantages of Hengli PBT:

- Superior Thermal Headroom: Features a Heat Deflection Temperature (HDT) 15-20°C higher than standard PBT.

- Precision Rheology: Optimized flow characteristics allow for a 12% reduction in molding cycle times and a wider processing window, matching the viscosity profiles of premium grades to ensure zero mold modifications.

- Hydrolysis Resistance: Engineered for stability in humid heat, making it a robust alternative for outdoor sensors and automotive connectors.

- Batch-to-Batch Consistency: Advanced automated polymerisation lines ensure that MFI and shrinkage rates remain within a tight ±3% tolerance, rivaling the stability of long-standing market leaders.

These enhancements position Hengli PBT as a strategic alternative to expensive imported grades, offering engineers a reliable path to cost balance without compromising on safety or precision.

Comparative Analysis: Performance, Processing, and Cost

Figure 4: Laboratory testing of mechanical properties for PBT comparison

To provide a data-driven evaluation framework, we conducted a head-to-head comparison between Hengli’s High-Performance PBT and a mainstream competitor(Chang Chun (CCP) grade. This analysis moves beyond raw data to examine the “Total Cost of Ownership” (TCO)—the true metric of profitability in high-volume production.

Technical Performance & Regulatory Benchmarks

The following metrics represent the critical evaluation criteria for engineering-grade polyesters:

| Property | Test Method | Hengli Grade | Chang Chun (CCP) Grade | Hengli Advantage |

| Tensile Strength | ISO 527 | 125 MPa | 118 MPa | Higher structural safety margin |

| Heat Deflection Temperature | ISO 75 (1.8 MPa) | 215°C | 205°C | 10°C higher thermal headroom |

| UL94 Rating | UL 94 | V-0 @ 0.8mm | V-0 @ 0.8mm | Equivalent high-tier safety |

| Melt Flow Index | ISO 1133 | 18 g/10min | 15 g/10min | Better thin-wall filling |

| Shrinkage Rate (Flow) | ISO 294-4 | 0.2-0.4% | 0.3-0.5% | More predictable precision |

| Relative Material Cost | – | 0.92 | 1.00 | 8% Direct Material Saving |

Enhancing Injection Molding Stability

Beyond static specifications, the Hengli grade is engineered to optimize the actual manufacturing environment. Injection Molding Stability is the cornerstone of this formulation:

- Consistent Shrinkage Rate: PBT is a semi-crystalline polymer prone to anisotropy. Hengli’s proprietary nucleating agents ensure a highly consistent Shrinkage Rate, minimizing post-molding warpage and ensuring that complex connectors meet tight tolerances consistently.

- Optimized Melt Flow Index: The increased Melt Flow Index does not just simplify filling; it allows for lower injection pressures and melt temperatures. This reduces internal stress in the molded parts and extends the maintenance intervals of the tooling.

- Thermal Endurance: With a significantly higher Heat Deflection Temperature, this grade maintains its mechanical Tensile Strength even during short-term thermal excursions, such as wave soldering or high-heat automotive environments.

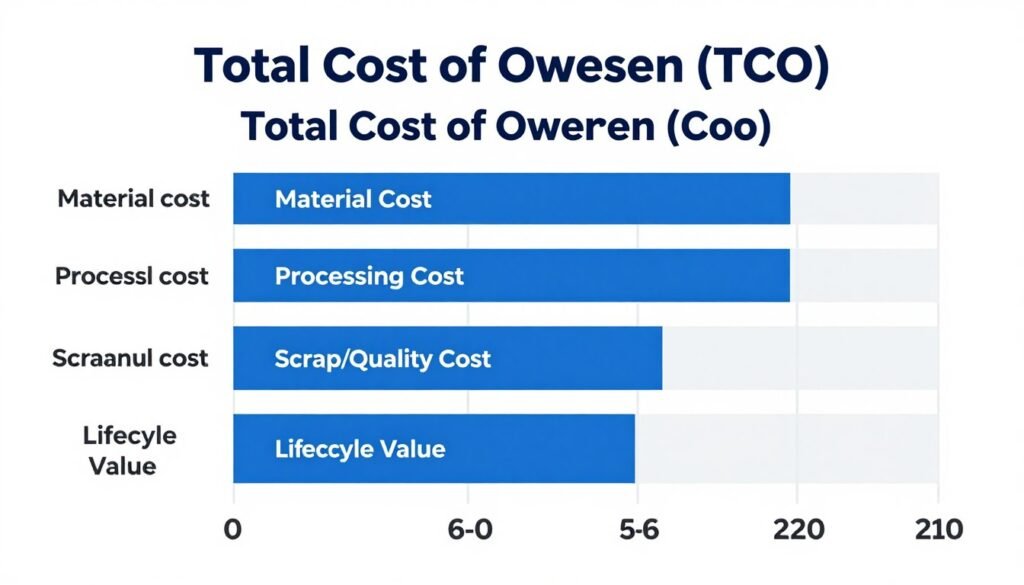

Total Cost of Ownership Analysis

Figure 5: Total Cost of Ownership comparison for PBT alternatives

A comprehensive TCO analysis reveals that the Hengli grade offers a 12-15% advantage in total production costs. This is achieved by compounding the 8% lower raw material cost with significant operational gains:

- Reduced Cycle Times: Faster crystallization kinetics reduce cooling time, increasing machine throughput by 10-12%.

- Part Miniaturization: Reliable UL94 Rating compliance at thinner wall sections (0.8mm) allows for lighter part designs and further material savings.

- Process Reliability: High Injection Molding Stability leads to a measurable drop in scrap rates, ensuring that your “cost per good part” remains the lowest in the competitive landscape.

Application Validation and Customer Feedback

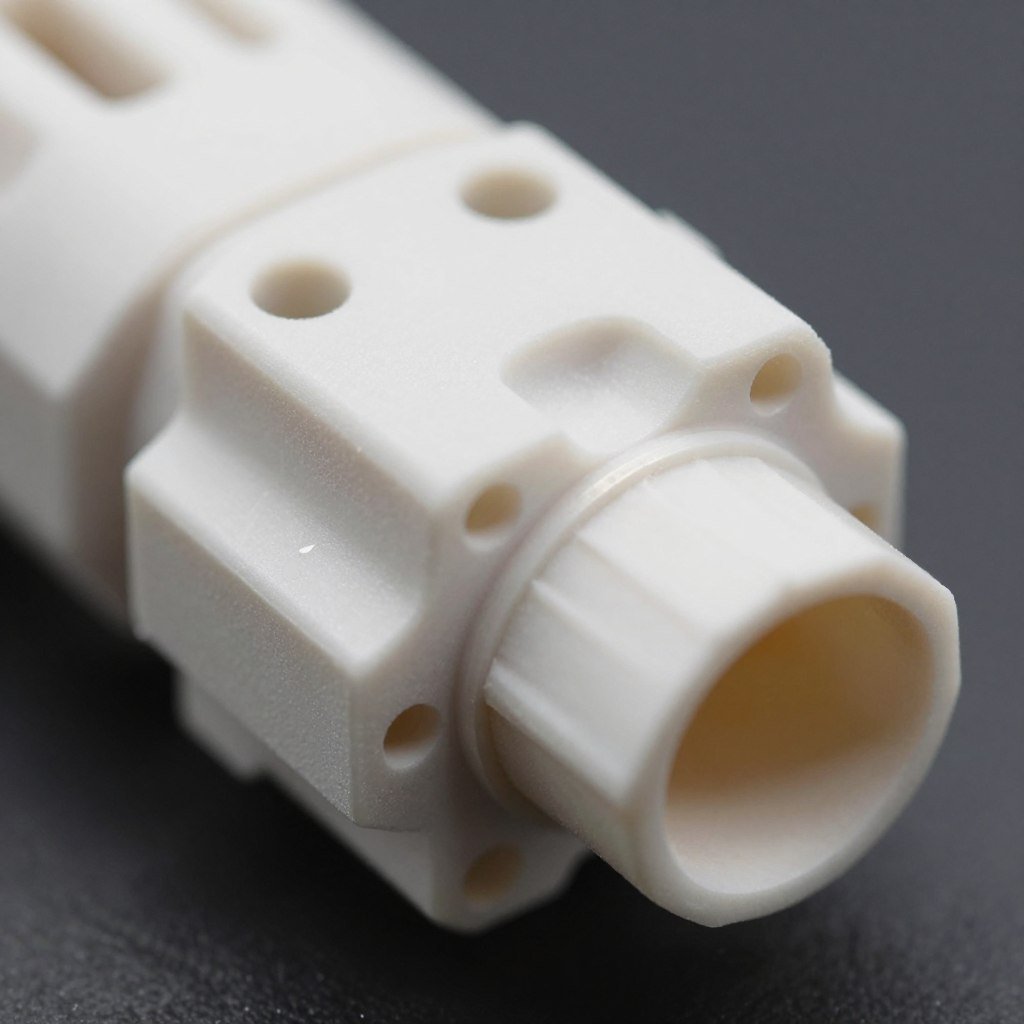

Figure 6: Automotive electrical connector using high-performance PBT

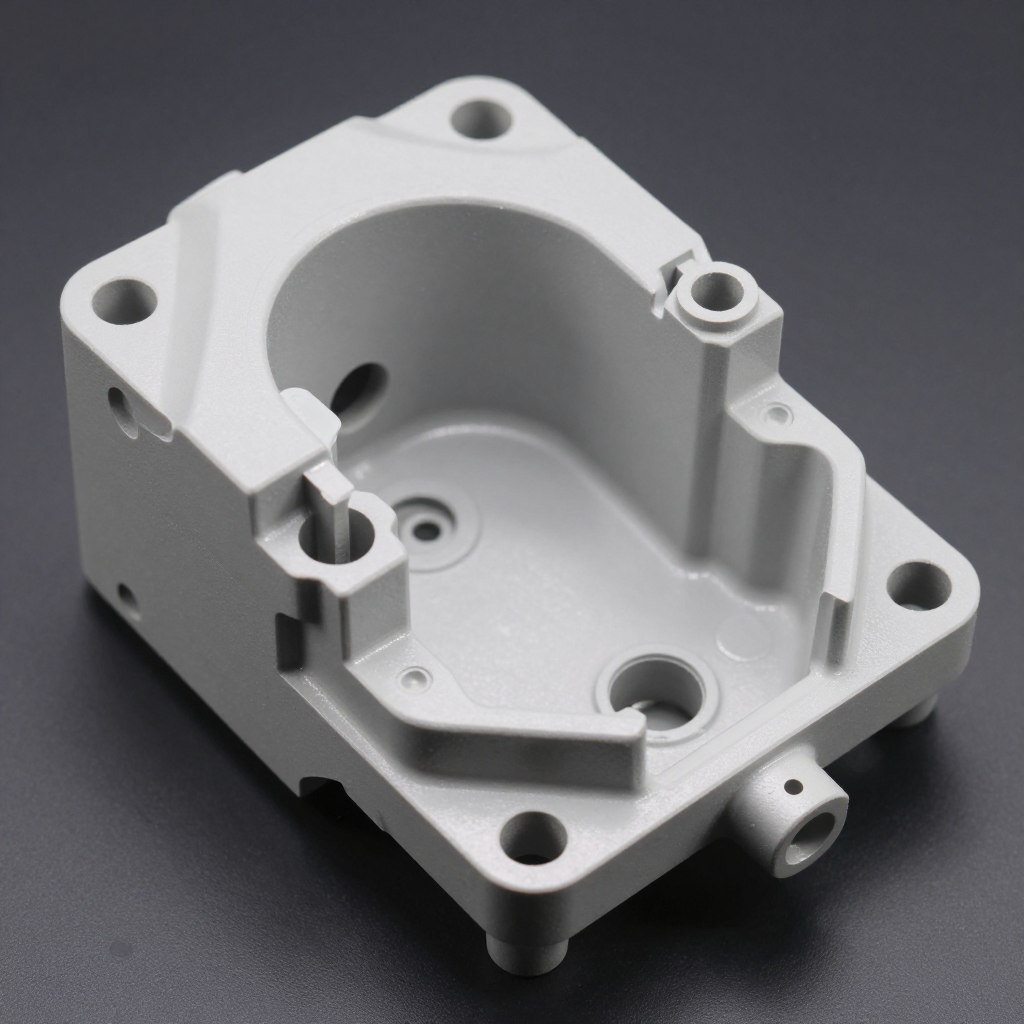

Figure 7: Electronic housing using PBT alternative

Theoretical benchmarks must translate into shop-floor results. The Hengli high-performance PBT grade has been rigorously validated in high-stakes environments, serving as a drop-in replacement for premium imported resins.

Automotive: Signal Integrity in Harsh Environments

A Tier-1 automotive connector manufacturer switched to Hengli PBT for high-voltage sensor housings.

- Challenge: Previous standard PBT exhibited warpage during thermal cycling, leading to signal leakage.

- Result: The enhanced Injection Molding Stability of the Hengli grade led to a 15% reduction in rejection rates. More importantly, it maintained structural integrity after 1,000 hours of 125°C aging, ensuring long-term vehicle safety.

Precision Electronics: Miniaturization & Finish

A global electronics leader utilized the material for ultra-thin sensor housings (0.5mm wall thickness).

- Validation: The material’s high Melt Flow Index and consistent Shrinkage Rate eliminated “short shots” and tiger striping, achieving a Class-A surface finish without secondary processing.

- Outcome: 100% batch-to-batch consistency in dielectric constant measurements across three global production sites.

Appliances: Chemical & Economic Efficiency

In high-volume appliance production, Hengli PBT replaced a competitor grade for detergent-contact components.

- Efficiency: Accelerated crystallization enabled a 11% cycle time reduction, effectively adding 2.5 hours of production capacity per day per machine.

- Durability: Superior hydrolysis resistance ensured zero stress-cracking after 5,000 washing cycles.

Customer feedback consistently underscores one key fact: Hengli PBT is not just a lower-cost option; it is a performance-equivalent alternative that simplifies supply chains while boosting the bottom line.

Ready to Optimize Your Production?

As your dedicated PBT distribution partner, we offer more than just resin. Contact our technical team today for:

- A Comparative Cost-Benefit Analysis for your current projects.

- Free Sampling of Hengli High-Performance PBT for mold trials.

- Technical Consultation on optimizing injection molding stability.

Conclusion: Balancing Performance and Cost in PBT Alternatives

Figure 11: Material evaluation in quality control laboratory

The evolution of the engineering plastics market has redefined the “Performance-Cost Balance.” Today, selecting the right material is no longer just about meeting technical specs—it is about optimizing the entire value chain.

- The Domestic Advantage: High-performance PBT grades like Hengli have bridged the quality gap, offering a drop-in alternative to premium imported resins that can reduce total production costs by up to 15% without sacrificing reliability.

- Holistic Evaluation: Engineering decisions must move beyond raw material price to a Total Cost of Ownership (TCO) model, accounting for cycle time efficiencies, lower scrap rates, and energy savings.

- Risk-Free Transition: While PBT remains the benchmark for dimensional stability and electrical integrity, the key to successful implementation lies in rigorous application-specific validation and expert technical support.

For engineers and procurement teams under pressure to reduce costs while maintaining 100% component reliability, the shift toward optimized domestic PBT is no longer an “alternative”—it is a strategic necessity.