Engineering success hinges on aligning precise material properties with demanding operational environments. Polybutylene Terephthalate (PBT) serves as a cornerstone thermoplastic, valued for its exceptional dimensional stability, chemical resistance, and dielectric strength. However, the transition from standard resins to high-performance variants—such as PBT-GF30, which leverages 30% glass fiber reinforcement to bridge the gap between plastics and metals—requires a nuanced understanding of grade-specific characteristics. Navigating these formulations involves balancing mechanical rigor against processing fluidities. This analysis provides a technical roadmap through diverse PBT grades, ensuring your material selection optimizes both long-term reliability and manufacturing efficiency.

What Is PBT?

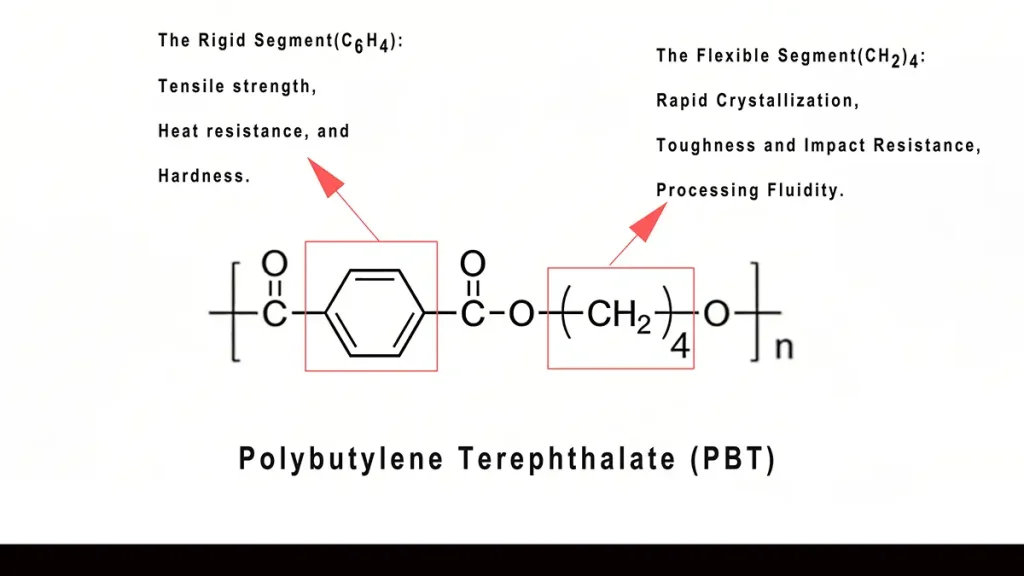

Molecular structure of Polybutylene Terephthalate (PBT)

Polybutylene Terephthalate (PBT) is a semi-crystalline engineering thermoplastic synthesized through the polycondensation of 1,4-butanediol with dimethyl terephthalate (DMT) or purified terephthalic acid (PTA). Its molecular architecture facilitates rapid crystallization during processing, yielding a material defined by the following core properties:

Core Properties of PBT Resin

- High Dimensional Stability:Low moisture absorption (0.1%-0.2%) ensures critical tolerances are maintained in humid conditions, outperforming most polyamides.

- Thermal Resilience: While neat resin has a modest HDT, glass-reinforced grades like PBT-GF30 elevate the heat deflection temperature to over 200°C.

- Electrical Excellence: Exceptional dielectric strength and arc resistance, essential for high-voltage insulation.

- Chemical Integrity: Robust resistance to aliphatic hydrocarbons, cleaning agents, and diverse automotive fluids.

- Mechanical Rigidity: High creep resistance and fatigue strength, which are further amplified in fiber-reinforced variants.

These technical advantages position PBT as the primary choice for precision-engineered components, ranging from automotive sensors to complex electronic housings. By integrating specific additives or reinforcements, the PBT family provides tailored solutions that balance mechanical toughness with efficient high-volume manufacturing.

Classification of PBT Resin Grades

Material selection optimization requires a granular understanding of how various formulations alter the base polymer’s behavior. PBT resins are categorized into distinct functional tiers based on their reinforcement levels, flame retardancy, and specialized chemical modifiers.

Different PBT resin grades showing variations in appearance based on additives and reinforcements

Unfilled PBT Grades

Unfilled or “neat” PBT consists of the virgin polymer matrix. These grades are prioritized for applications where aesthetic surface quality and tight dimensional tolerances are paramount, though they lack the mechanical rigors of reinforced variants.

| Property (Typical) | Value | Performance Benefits | Technical Constraints |

| Tensile Strength | 50-60 MPa | Superior surface gloss | Limited structural load capacity |

| Flexural Modulus | 2.3-2.8 GPa | Excellent flow for thin walls | Lower stiffness vs. reinforced |

| HDT @ 1.8 MPa | 55-65°C | Predictable isotropic shrinkage | Restricted high-heat exposure |

| Mold Shrinkage | 1.8-2.2% | Consistent processing | High shrinkage rate |

Glass Fiber Reinforced PBT Grades

Integrating glass fibers fundamentally transforms PBT into a structural powerhouse. While pure PBT is ductile, reinforced grades—particularly the industry-standard PBT-GF30—provide the modulus and thermal stability required for under-hood automotive environments.

How Glass Fiber Reinforced PBT is Made: Pure PBT + Glass Fibers

| Formulation | Tensile Strength | Flexural Modulus | HDT @ 1.8 MPa | Strategic Applications |

| PBT GF10% | 85-95 MPa | 3.5-4.0 GPa | 185-195°C | Precision precision gears |

| PBT GF15% | 100-110 MPa | 4.5-5.0 GPa | 195-205°C | Electronic connector shells |

| PBT GF30% | 130-150 MPa | 9.0-11.0 GPa | 210-220°C | Automotive structural parts |

| PBT GF50% | 160-180 MPa | 14.0-16.0 GPa | 220-230°C | High-stress metal replacement |

Among these, PBT-GF30 stands as the industry benchmark for balancing cost and performance. For an in-depth technical breakdown, explore our A Comprehensive Guide to PBT-GF30: Properties, Applications, and More.

Flame Retardant PBT Grades

Safety-critical electrical components necessitate FR grades, typically achieving UL94 V-0 ratings. These formulations inhibit combustion through halogenated or sustainable non-halogenated systems.

Flame retardant PBT resin undergoing UL94 vertical burn test to demonstrate fire safety properties

Advantages of FR PBT Grades

- Self-extinguishing properties

- Reduced smoke generation

- Compliance with international safety standards

- Available with various UL ratings (V-0, V-2, HB)

- Can be combined with glass fiber reinforcement

Considerations for FR PBT Grades

- Slightly reduced mechanical properties

- Higher cost than non-FR grades

- Potential environmental concerns with halogenated FR systems

- May affect colorability and surface appearance

- Processing window may be narrower

Common applications for flame retardant PBT grades include circuit breaker housings, electrical connectors, lighting components, and consumer electronics enclosures where fire safety is paramount.

Specialty and Modified PBT Grades

To address niche environmental stressors, specialty modifications extend the polymer’s functional envelope:

Diverse applications of specialty and modified PBT grades across various industries

Impact-Modified PBT

Incorporates elastomers to prevent brittle failure in cold-weather or high-velocity impact scenarios.

Hydrolysis-Resistant PBT

Specifically stabilized to prevent molecular chain scission in high-humidity, high-heat environments (e.g., USCAR-2 Class 3 automotive testing).

PBT Blends (e.g., PBT/PC)

Alloys that marry PBT’s chemical resistance with the superior impact strength and low shrinkage of Polycarbonate.

Functional Additives

Includes Laser-Markable grades for permanent traceability and FDA-Compliant resins for regulated food-contact interfaces.

Need help selecting the right PBT grade?

Our technical team can help you identify the optimal PBT grade based on your specific application requirements.

Key Performance Factors for PBT Grade Selection

Technical evaluation of PBT resins requires a holistic analysis of how specific parameters influence the final component’s lifecycle. Establishing a robust selection matrix ensures that the chosen grade—whether a base resin or a high-modulus PBT-GF30—aligns with environmental and mechanical stressors.

Materials engineer analyzing performance data to select the optimal PBT grade for a specific application

Mechanical Integrity and Load Bearing

- Tensile Strength & Modulus: Essential for structural rigidity. Reinforced grades provide the necessary stiffness to replace metal in housing applications.

- Impact Strength (Notched/Unnotched): Dictates the material’s energy absorption. Impact-modified grades are critical for parts exposed to mechanical shock or low-temperature environments.

- Creep and Fatigue Resistance: Vital for components under constant stress or cyclic loading, such as automotive gear systems or snap-fit connectors.

Thermal Dynamics

- Heat Deflection Temperature (HDT): A primary indicator for short-term heat exposure. PBT-GF30 offers an HDT of approximately 210°C, significantly exceeding the ~60°C threshold of unfilled grades.

- Continuous Use Temperature (RTI): Defines long-term thermal stability, ensuring the polymer matrix does not degrade during extended operational cycles.

- Thermal Expansion (CLTE): Critical for overmolding or multi-material assemblies to prevent delamination caused by mismatched expansion rates.

Electrical and Insulation Performance

- Dielectric Strength & Volume Resistivity: Fundamental for preventing current leakage in high-density electronic enclosures.

- Comparative Tracking Index (CTI): A key metric for electrical safety; high CTI grades (Plc 0 or 1) are mandatory for high-voltage EV components.

Chemical and Environmental Resistance

PBT’s semi-crystalline nature provides a robust barrier against hydrocarbons, lubricants, and automotive fluids. However, specific exposure requires tailored grades:

- Hydrolytic Stability: Standard PBT is susceptible to moisture-induced degradation at elevated temperatures; hydrolysis-resistant grades are required for humid under-hood environments.

- Chemical Compatibility: Careful assessment is needed when components interface with strong bases or oxidizing acids which can trigger chain scission.

Regulatory and Safety Compliance

Market-specific certifications act as the final filter for grade selection:

- Flammability Ratings: UL94 V-0, V-2, or HB based on safety requirements.

- Food & Health Safety: FDA or EU food-contact compliance for consumer appliances.

- Environmental Standards: Strict adherence to RoHS, REACH, and Halogen-free mandates.

How to Choose the Right PBT Grade

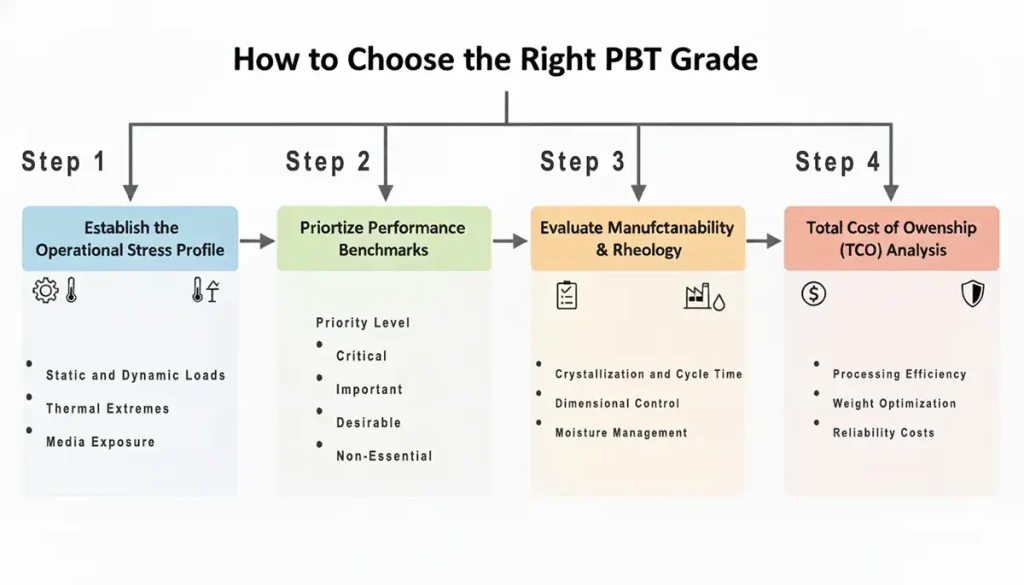

Material procurement and engineering design must converge through a systematic validation process to ensure the chosen PBT resin meets both functional and economic targets. This decision framework streamlines the transition from raw requirements to a finalized material specification.

Decision flowchart for systematic PBT resin grade selection based on application requirements

Step 1: Establish the Operational Stress Profile

Identify the environmental and mechanical boundaries the component will encounter. Documentation should prioritize:

- Static and Dynamic Loads: Determine if the application requires the structural reinforcement of PBT-GF30 or the ductility of an unfilled grade.

- Thermal Extremes: Map the peak excursion temperatures and long-term operating heat.

- Media Exposure: List specific contact with automotive fluids, industrial solvents, or high-humidity environments.

Step 2: Prioritize Performance Benchmarks

Rank properties based on their impact on part failure or success. High-modulus composites like PBT-GF30 are often the “Critical” choice for under-hood structural parts, whereas flame retardancy takes precedence in power distribution modules.

| Priority Level | Engineering Context | Industry Example |

| Critical | Mandatory for safety or core function | UL94 V-0 for EV battery housings |

| Important | Impacts longevity and reliability | Hydrolytic stability for outdoor sensors |

| Desirable | Enhances secondary characteristics | Laser markability for traceability |

| Non-Essential | Over-engineering to be avoided | Food-grade certification for industrial gears |

Step 3: Evaluate Manufacturability and Rheology

A material’s performance on a data sheet must be balanced against its behavior in the mold.

- Crystallization and Cycle Time: Leverage PBT’s rapid crystallization to optimize throughput.

- Dimensional Control: Account for the anisotropy (differential shrinkage) inherent in glass-reinforced grades to prevent warpage in large-format parts.

- Moisture Management: Ensure processing protocols guarantee a moisture content below 0.02% to prevent hydrolytic degradation during injection.

Step 4: Total Cost of Ownership (TCO) Analysis

Final selection should move beyond price-per-kilogram to evaluate systemic value:

- Processing Efficiency: Weigh the cost of high-performance grades against the savings gained from reduced cycle times.

- Weight Optimization: Assess if a 30% or 50% GF grade allows for thinner wall sections, reducing overall material consumption.

- Reliability Costs: Factor in the reduction of warranty claims by selecting stabilized grades (e.g., Heat-stabilized or Impact-modified) for aggressive environments.

Typical PBT Grade Selection Scenarios

Analyzing real-world applications clarifies how specific PBT grades solve complex design challenges. These scenarios demonstrate the technical alignment between polymer modification and operational demands.

Real-world applications of different PBT grades showing material selection based on performance requirements

Scenario 1: Automotive Powertrain Connectors

Environmental Stressors: Exposure to engine lubricants, thermal excursions up to 150°C, and constant vibration.

Recommended Grade: PBT 30% GF (Glass Fiber Reinforced)

Technical Rationale: This grade provides a high Heat Deflection Temperature (HDT) of 210°C, ensuring structural integrity during peak thermal loads. The 30% reinforcement offers the requisite creep resistance to maintain terminal retention force and prevent stress relaxation over the vehicle’s lifespan.

Scenario 2: Industrial Circuit Breaker Enclosures

Environmental Stressors: Arc-tracking risks, internal heat generation, and mechanical snap-fit requirements.

Recommended Grade: Flame Retardant PBT V-0 with 15-20% Glass Fiber

Technical Rationale: Achieving a V-0 rating is critical for electrical safety. A mid-range glass fiber loading balances the stiffness needed for arc-chamber stability with enough ductility to facilitate snap-fit assembly without brittle failure.

Scenario 3:High-Steam Appliance Components (e.g., Dishwashers)

Environmental Stressors: Sustained humidity, detergent alkalinity, and repeated wet/dry cycling.

Recommended Grade: Hydrolysis-Resistant PBT with 30% Glass Fiber

Technical Rationale: Standard polyesters can undergo molecular chain scission in hot, humid environments. Specialized hydrolysis-resistant grades utilize end-group capping or stabilizers to ensure long-term mechanical retention, preventing the part from becoming brittle after multiple wash cycles.

Scenario 4: Food Contact Precision Interfaces

Environmental Stressors: Regulatory scrutiny, frequent sanitization, and demand for low extractables.

Recommended Grade: FDA-Compliant Unfilled PBT (Food Grade)

Technical Rationale: Pure resin maximizes surface smoothness, reducing bacterial adhesion sites. The absence of glass fibers ensures compliance with global food-contact migration limits while maintaining PBT’s inherent resistance to common industrial cleaning agents.

Selection Tip: When performance boundaries overlap between two grades, such as PBT-GF20 versus PBT-GF30, functional prototyping and aging tests remain the most reliable methods to validate the safety margins under specific end-use conditions.

About Our PBT Resin Solutions

Advanced engineering requires more than just raw materials; it demands precision-engineered resin systems backed by technical expertise. Our high-performance PBT portfolio is strategically developed to bridge the gap between complex design specifications and large-scale manufacturing reliability.

Our technical laboratory conducting comprehensive testing of PBT resin properties for quality assurance

The PBT Solution Matrix:

Unfilled Precision Grades

Engineered for superior melt flow and surface aesthetics, these grades ensure isotropic shrinkage for components requiring the tightest dimensional tolerances.

Reinforced Structural Grades

Ranging from 10% to 50% glass fiber loading, our portfolio features the industry-standard PBT-GF30. This grade serves as a structural benchmark, offering an optimal balance of tensile modulus and thermal stability for metal-replacement initiatives.

Certified Flame Retardant Grades

Fully compliant with UL94 V-0 and V-2 standards, available in both traditional halogenated and sustainable non-halogenated chemistries for global market access.

Specialty Engineering Formulations

Our range extends to hydrolysis-resistant resins for high-humidity environments and elastomer-modified grades for superior energy absorption at low temperatures.

Lifecycle Engineering Support

Beyond material supply, our team provides data-driven selection guidance, rheological mold flow analysis, and on-site processing optimization to ensure seamless integration into your production line.

Whether your application demands the rigorous mechanical strength of PBT-GF30 or a customized alloy for unique environmental stressors, our technical experts are ready to assist in optimizing your material strategy.

Partner With Us For Your PBT Needs

Whether you need standard grades or custom formulations, our team is ready to help you select the optimal PBT solution for your application.

Conclusion

Optimizing the lifecycle and reliability of engineering components necessitates a rigorous alignment between PBT resin grades and their operational stressors. This guide underscores that the transition from a standard unfilled resin to a high-modulus PBT-GF30—or a specialized hydrolysis-resistant formulation—is a strategic move to manage thermal stability, mechanical loads, and environmental exposure.

The decision-making framework outlined here encourages a balanced evaluation of technical data against manufacturing realities. While high-performance grades offer superior heat deflection and creep resistance, successful implementation requires mitigating trade-offs in ductility and processing windows. As the industry pivots toward electrification and sustainable polymer chemistry, the emergence of low-carbon and high-CTI PBT variants offers new avenues for innovation in power electronics and structural housing design.

Leveraging the full potential of these advanced thermoplastics depends on continuous technical dialogue. For engineers aiming to refine part performance or troubleshoot complex molding challenges, navigating the nuanced differences between PBT grades is the first step toward achieving long-term market success.

Frequently Asked Questions

What are the different types of PBT?

PBT formulations are categorized into four primary technical tiers:

- Unfilled (Natural): Pure resin prioritized for precision and aesthetics.

- Reinforced: Specifically glass fiber variants (10% to 50%), including the high-modulus PBT-GF30.

- Flame Retardant: Grades engineered to meet UL94 V-0/V-2/HB safety benchmarks.

- Specialty Modifications: This includes impact-modified, hydrolysis-resistant, laser-markable, and high-flow grades, as well as high-performance alloys like PBT/PC for enhanced toughness.

What is PBT resin?

PBT (Polybutylene Terephthalate) is a semi-crystalline engineering thermoplastic synthesized via the polycondensation of 1,4-butanediol with either dimethyl terephthalate (DMT) or terephthalic acid (PTA). Characterized by rapid crystallization and a low moisture absorption rate of 0.1%, PBT resin offers a unique balance of dielectric strength, chemical resistance to hydrocarbons, and exceptional dimensional stability across a broad thermal envelope.

What is PBT 30% GF material?

PBT-GF30 is a composite resin integrated with 30% glass fiber reinforcement by weight. This modification acts as a structural benchmark, elevating the base polymer’s tensile strength to 130-150 MPa and the flexural modulus to 9-11 GPa. Crucially, it raises the Heat Deflection Temperature (HDT) to 210-220°C, making it an essential solution for load-bearing automotive under-hood components and high-stress electrical housings where neat resins would fail under thermal load.

What is PBT food grade?

PBT food grade designates resins formulated to meet strict regulatory mandates, such as FDA 21 CFR 177.1660 or EU 10/2011. These grades are synthesized with specific catalyst systems and additives that ensure minimal migration levels. Beyond legal compliance, food-grade PBT provides the chemical resilience needed to withstand aggressive sanitization agents and steam cleaning, maintaining structural integrity in kitchen appliances and food-processing equipment.

What is 100% PBT material?

In an industrial context, “100% PBT” refers to unfilled, neat virgin resin that has not been modified with reinforcements (glass/minerals) or alloyed with other polymers like PC or PET. While it may contain trace amounts of heat stabilizers or lubricants to facilitate processing, it retains the inherent isotropic shrinkage and high surface gloss of the base polyester. It is the preferred choice for high-precision components where uniform mold shrinkage and aesthetic finish are more critical than extreme mechanical rigidity.