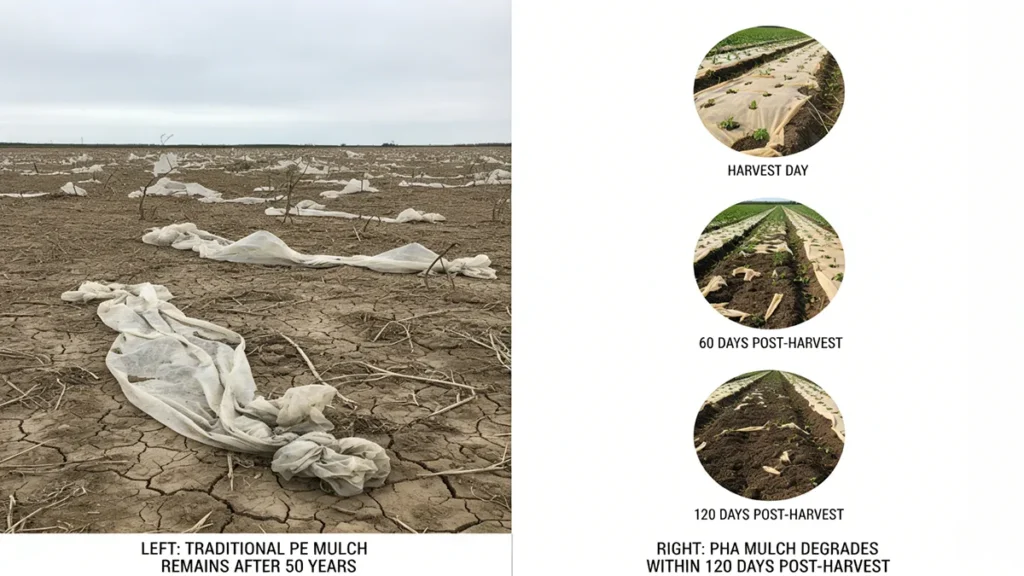

Global agriculture relies heavily on polyethylene (PE) mulch films, with millions of tons applied annually to boost productivity. However, this reliance has come at a staggering environmental and financial cost. Conservative estimates indicate that residual rates of traditional film reach 5-10% annually, leading to long-term accumulation that triggers severe soil compaction, disrupts microbial ecosystems, and interferes with crop root development. This “White Pollution” does not just stay in the field—it fragments into microplastics that infiltrate the global food chain.

For modern growers and enterprises, the burden is two-fold:

- Economic Drain: Traditional films demand intensive manual labor for post-harvest collection and disposal, significantly inflating operational costs.

- Regulatory Pressure: With tightening global “plastic bans” and ambitious carbon neutrality targets, conventional plastics are becoming a liability rather than an asset.

Is there a solution that maintains high crop yields while eliminating the need for removal? Imagine a mulch film or seedling pot that, after its functional life, can be simply plowed into the soil to undergo complete, natural biodegradation—leaving behind only water, CO2, and nutrient-rich biomass. This is the promise of PHA (Polyhydroxyalkanoates): the ultimate bridge between agricultural profitability and ecological integrity.

What is PHA? Why It's the Ultimate Solution for Soil-Biodegradable Agriculture

PHA (Polyhydroxyalkanoates) is a class of high-performance biopolyesters synthesized by microorganisms through the fermentation of renewable resources like plant oils and sugars. As a 100% bio-based material, PHA is not just a plastic substitute—it is a biological nutrient.

What truly sets PHA apart is its “All-Environment Biodegradability.” Unlike PLA (which remains largely intact in soil without industrial composting temperatures), PHA is recognized as “food” by indigenous soil microbes. It undergoes complete metabolic conversion into CO₂, water, and biomass within weeks to months, depending on film thickness and local climate. It is currently the only material that guarantees true, residue-free degradation in both soil and marine environments.

Comparative Performance: Why PHA Leads the Market

To understand why PHA is the premium choice for sustainable agriculture, we must compare it with existing materials:

| Material Type | Degradation Conditions | Soil Degradation Speed | Agricultural Suitability | Primary Drawback |

| Traditional PE | Non-degradable | Decades to centuries | Low (Requires removal) | Severe “White Pollution” |

| PLA | Industrial Composting | Extremely slow in soil | Limited | Leaves residues in nature |

| PBAT | Specific microbial conditions | Moderate to Good | Common but variable | Mechanical limitations; potential residue |

| Our PHA | Natural Soil/Water | Weeks to Months | Excellent (Premium) | None; Fully integrates into soil |

Empowering Sustainable Agriculture with Advanced Materials

We provide a comprehensive range of PHA resin solutions specifically engineered to address the most demanding agricultural challenges. Beyond supplying the raw material, we deliver:

- Tailored Degradation Profiles: We provide specific grades that allow for the “programming” of a product’s functional lifespan—ensuring mulch films maintain integrity for the exact duration of the crop cycle.

- High Processing Compatibility: Our materials are optimized for excellent melt strength, enabling seamless integration with existing blown film and injection molding equipment.

- Full Regulatory Support: We offer materials that meet the most stringent global biodegradability and bio-based certifications, ensuring your end products are ready for the premium green market.

Key Advantages of PHA in Agricultural Mulch Film Applications

Agronomic Performance & Yield Optimization

Our PHA resins enable the production of films that increase soil temperatures by 5-10°C and reduce irrigation needs by 20-30%. Meta-analyses confirm that crops under PHA mulch achieve yields and quality comparable to—and sometimes exceeding—traditional PE, ensuring early harvests and premium market entry.

"Zero-Labor" Economics

The “Zero-Burden” model eliminates the costly post-harvest recovery phase. By allowing direct plowing of residues, farmers save $10–$25 per acre in labor and disposal fees, while preventing plastic fragments from tangling in machinery or causing soil compaction.

The Science of Sustainability: Beyond Just Biodegradation

This is where PHA truly stands alone as the “Ultimate Solution”:

- Complete Elimination of “White Pollution”: Unlike oxo-fragmentable plastics, PHA undergoes 100% microbial mineralization. It doesn’t just break into pieces; it vanishes entirely.

- Active Carbon Sequestration: Derived from renewable biomass, PHA serves as a carbon source for beneficial soil microbes. It supports global “Carbon Neutrality” goals by returning atmospheric carbon back into the soil ecosystem.

- Total Bio-Safety: Our material is 100% bio-compatible and non-toxic to soil fauna, microbiota, and root systems, ensuring long-term land viability and supporting Green/Organic Certifications.

Proven Success Across High-Value Crops

Engineered for versatility, our resins provide a competitive edge in:

- Vegetables & Fruits: Strawberries, watermelons, peppers, and tomatoes.

- Strategic Crops: Tobacco and cotton.

- Advanced Agriculture: Greenhouse and facility farming systems.

Ready to Leading the Transition to Sustainable Agriculture?

Empower your production lines with our high-performance PHA resins. Partner with us to deliver zero-legacy solutions that meet the growing global demand for eco-friendly farming.

PHA Biodegradable Seedling Pots: Seamless Transplant with Zero Pollution

Beyond mulch films, PHA resin technology is transforming the nursery sector through direct-plant seedling containers. Traditional plastic pots are a logistical and environmental burden: they generate massive plastic waste and often trigger transplant shock when root systems are disturbed during removal. PHA containers provide an elegant, “one-touch” solution: plant the pot, save the plant.

Seamless Growth & Near-100% Survival Rates

Engineered for “Root-Through” performance, our PHA resins allow for the entire pot to be planted directly into the soil.

- Total Root Integrity: Seedlings remain undisturbed, eliminating the risk of transplant shock and ensuring vigorous early-stage growth.

- Enhanced Survivability: By preserving the complex root structure, farmers see a dramatic increase in survival rates, especially for delicate or high-value varieties.

Natural Degradation & Soil Enrichment

Once buried, the PHA pot is naturally colonized by soil microbes. The pot walls are calibrated to remain sturdy during the nursery phase but become porous and fully biodegrade into water, CO₂, and organic biomass once in the ground. Instead of creating a waste-disposal crisis, the container becomes a soil amendment, promoting healthy microbial activity around the root zone.

ersatile Solutions for High-Value Agriculture

Our PHA resin grades are specifically formulated to meet the nursery requirements of diverse sectors:

- Food & Cash Crops: High-value vegetables, peppers, and strawberries.

- Industrial Forestry: Rapid reforestation and commercial timber nurseries.

- Perennial Crops: Coffee, fruit trees, and ornamental floriculture.

“The combination of PHA mulch film with PHA seedling pots creates a fully integrated, zero-waste growing system. From the nursery to the final harvest, the grower manages a biology-based process rather than a waste-management crisis.

– Industry Sustainability Benchmarks

Real Evidence & Supporting Data:PHA Agricultural Mulch

The transition to PHA technology is backed by rigorous scientific validation and extensive field testing. Our PHA resins meet the world’s most stringent standards for biodegradability and environmental safety, providing manufacturers and growers with the confidence to move beyond petroleum-based plastics.

| Certification/Standard | Testing Parameters | PHA Performance | Environmental & Business Impact |

| OK biodegradable SOIL (TÜV Austria) | Biodegradation in natural soil at ambient temperatures | 90% biodegradation within 6-12 months | The “Gold Standard” for agriculture; guarantees zero microplastics in open fields. |

| EN 13432 / ASTM D6400 | Industrial compostability and disintegration | Rapid metabolic conversion | Simplifies global market access and compliance with international plastic bans. |

| Field Trials (Global Sites) | Multi-crop practical performance (Strawberry, Cotton, Maize) | Equivalent or superior yield; consistent mechanical strength | Eliminates 100% of collection labor costs; reduces irrigation water needs by 20-30%. |

| Ecotoxicity & GWP Testing | Earthworm survival & Global Warming Potential analysis | Passed (Non-toxic); Zero negative GWP impact | Supports carbon neutrality goals; ensures a safe habitat for soil microbiota. |

Synergistic Environmental Advantages

Beyond simple decomposition, our PHA solutions offer a synergistic approach to sustainable farming. By maintaining soil structure and moisture, they facilitate significant water conservation and emission reductions. Crucially, the life cycle of PHA in soil has zero negative Global Warming Potential (GWP), as the carbon released is part of the short-term biological carbon cycle, unlike the long-term carbon release from incinerating petroleum plastics.

Uncompromising Quality & Reliable Supply

We understand that for manufacturers and large-scale enterprises, consistency is as vital as performance. Our PHA resins are:

- Multi-Certified: Fully compliant with international biodegradability and bio-based standards.

- Batch Stability: Rigorous quality control ensures every shipment meets the required mechanical and processing specifications.

- Reliable Logistics: With a robust supply chain, we guarantee steady availability to support your year-round production and planting cycles.

Ready to Transition Your Production to PHA?

Leverage our certified, high-stability PHA resins to lead the sustainable market. Request our Technical Data Sheets (TDS) and Processing Guide to see how seamlessly our materials integrate into your existing lines.

Partner with Salesplastics

Transitioning to sustainable agriculture requires more than just high-quality resins—it demands a partner who understands the intricacies of biopolymer processing and the demands of the field. Salesplastics offers a robust bridge between innovative PHA technology and your large-scale manufacturing success.

Strategic & Stable Supply Chain

Global supply chain volatility is a major concern for bioplastic manufacturers. Salesplastics mitigates this risk by maintaining strategic, localized inventory. Our production partnerships ensure a consistent, year-round supply of premium PHA compounds, eliminating shortages during critical planting and manufacturing windows.

Technical Consulting & Formulation Optimization

We don’t just sell raw materials; we empower your production lines. Our team of polymer scientists provides:

- Customized PHA Blends: Tailoring thermal and mechanical properties to meet specific crop needs (e.g., 3-month vs. 12-month durability).

- Processing Precision: Assistance in optimizing blow-molding and injection-molding parameters to maximize output and minimize scrap rates.

On-Site Implementation & ROI Analysis

We support our partners from the lab to the field. Provides comprehensive implementation support, including equipment compatibility assessments and ROI modeling, ensuring that the transition to PHA is as profitable as it is sustainable.

Plug-and-Play Processing Support

We recognize that PHA behaves differently than Polyethylene under heat. To ensure a smooth transition, Salesplastics provides Grade-Specific Processing Profiles. Our technical team assists you in adjusting screw speeds and cooling temperatures, ensuring that our high-melt-strength resins run efficiently on your existing blown film lines with minimal downtime.

How does the total cost of Salesplastics’ PHA compare to conventional plastic?

While the per-kilogram price of PHA resin is higher than PE, the Total Cost of Ownership (TCO) often results in a net gain. By eliminating post-harvest collection, labor costs , and waste disposal fees, Our solutions deliver superior economic value while championing environmental sustainability.

Can our existing equipment process your PHA materials?

Yes. Salesplastics PHA resins are specifically engineered to be compatible with standard film-blowing and injection-molding machinery. Our technical team provides specific temperature and pressure profiles to ensure a seamless “plug-and-play” experience.

What is the shelf life of Salesplastics PHA resins?

When stored in original sealed packaging in a cool, dry environment, our resins maintain full functional properties for at least 12 months, allowing for confident inventory planning.

Does Salesplastics support small-scale R&D trials?

Certainly. We offer flexible Minimum Order Quantities (MOQs) for pilot trials and product development. We are committed to growing alongside our manufacturing partners.

Ready to Upgrade Your Production Line with Salesplastics PHA?

Join the future of bioplastic manufacturing. Contact our technical team today to request Resin Samples and our comprehensive Processing Parameter Guide.

Conclusion

PHA biodegradable mulch film represents more than a product—it is a pivotal advancement in agricultural technology that finally harmonizes peak productivity with environmental stewardship. By delivering the core agronomic benefits of traditional films without the ecological burden, PHA empowers growers to protect both their current yields and the long-term vitality of their land.

The transition to PHA is no longer just an environmental ideal; it is an economic and regulatory imperative. As global plastic mandates tighten and the demand for sustainable supply chains grows, early adopters of PHA technology secure a decisive competitive edge while future-proofing their operations against shifting environmental standards.

At Salesplastics, we are committed to being more than a supplier. Through our consistent material quality, technical mastery, and reliable logistics, we provide agricultural operations of all sizes the confidence to embrace this transformation. Together, we can achieve the dual goals of abundant harvests and a zero-waste future.