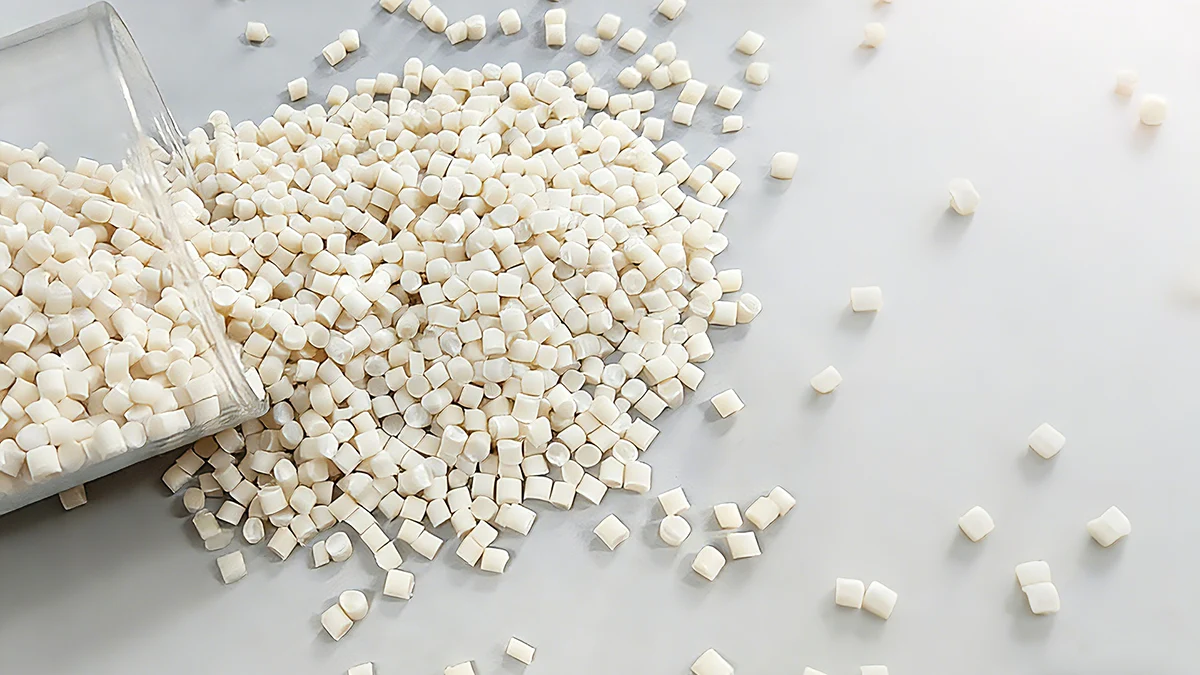

3D printing enables precise customization of tools, prototypes, and end-use products. Polylactic Acid (PLA), a biodegradable thermoplastic from renewable resources like corn starch or sugarcane, stands out for its low cost, printability, and reduced environmental impact. For food-contact uses, safety remains a critical concern. This post examines PLA’s suitability for food-safe 3D printing, covering benefits, limitations, regulations, and practical guidelines for additive manufacturing professionals.

What is PLA?

Polylactic Acid (PLA) originates from renewable resources, such as corn starch or sugarcane. This thermoplastic decomposes in industrial composting facilities within 3–6 months under conditions like 60°C and high humidity, unlike petroleum-based plastics. For 3D printing, PLA requires nozzle temperatures of 180–220°C, shows minimal warping, and yields detailed surface finishes.But how do these properties translate to food safety?

Key Properties of PLA:

- Biodegradability: Breaks down in industrial composting, but needs specific heat and humidity; unsuitable for home composting.

- Low Melting Point: Extrudes at 180–220°C, works with most desktop printers without a heated bed.

- Non-Toxic Base: Pure form meets food-contact standards, but additives like colorants may require certification.

- Mechanical Properties: Provides tensile strength but brittleness limits impact resistance compared to ABS or PETG.

- Versatility: Comes in standard, high-strength, or flexible variants for various printing needs.

- Environmental Impact: Relies on renewable sources, lowering fossil fuel dependence, though production uses energy and farmland.

These attributes suit PLA for prototyping and biodegradable packaging, provided heat resistance limitations—softening above 60°C—are addressed.

Is PLA Food-Safe?

PLA’s plant-based composition makes its base polymer non-toxic and suitable for food contact. The U.S. Food and Drug Administration (FDA) classifies pure PLA as Generally Recognized As Safe (GRAS) for food contact under certain conditions.

However, a 3D-printed object’s safety depends on more than just the base material. Commercial filaments often include uncertified additives (like colorants or strength enhancers) that could migrate into food, especially when exposed to heat or acidic substances. Therefore, the filament’s composition, the printing process, and post-use conditions all determine the final product’s safety.

Key Factors Affecting PLA Food Safety

To ensure a PLA print is food-safe, you must manage several critical factors throughout the manufacturing process.

- Filament Composition and Certification

The base PLA polymer holds GRAS status from the FDA and complies with EU Regulation 10/2011 for food contact. Additives such as colorants or fillers may leach under heat, violating standards. Select filaments with manufacturer Certificates of Compliance (CoC) confirming food-grade status. - Printer and Environmental Hygiene

Residuals from prior non-food-safe filaments, like ABS, contaminate nozzles or build plates. Airborne dust also poses risks. Dedicate printer parts to food-safe PLA and maintain clean environments to avoid cross-contamination. - Print Settings and Surface Characteristics

Layer lines in 3D-printed PLA create porosity that traps bacteria. Use high-resolution settings and food-safe coatings, like epoxy, to smooth surfaces. Verify coatings meet regulations. - Post-Processing and Usage

PLA softens above 60°C, limiting use with hot foods or dishwashers. Clean reusable items with food-safe agents and inspect for wear to prevent microbial growth.

Recommendations

Prioritize certified PLA, maintain hygiene, refine print settings for smoothness, and apply compliant post-processing. Refer to regulations and manufacturer data for verification. For extended contact, evaluate alternatives like stainless steel.

Food Safety Standards and Certifications for PLA

PLA for food-contact 3D printing must satisfy stringent regulatory requirements to ensure safety and compliance. These standards govern material composition, manufacturing processes, and intended use to prevent harmful substance migration into food. Regulatory bodies worldwide set specific limits and testing protocols for plastics like PLA. For manufacturers, providing granules that meet these standards is the first step in a safe supply chain. Key standards include:

Key Regulatory Standards

- FDA 21 CFR (USA): The Code of Federal Regulations, specifically parts 170-199, governs substances intended for food contact. It sets limits on what can migrate from the material into food based on temperature and duration of contact.

- EU Regulation (No) 10/2011 (Europe): This regulation establishes specific migration limits (SMLs) for substances used in plastic food-contact materials and requires a Declaration of Compliance (DoC).

- ISO 22000: This standard applies to the filament manufacturing process itself, focusing on food safety management systems to reduce the risk of contamination during production.

| Certification | Region | Description |

| FDA 21 CFR | USA | Ensures that components do not migrate into food at unsafe levels. |

| EU 10/2011 | Europe | Sets strict migration limits for plastics intended for food contact. |

| NSF/ANSI 51 | Global | Certifies materials for use in commercial food equipment. |

Export to Sheets

When sourcing material, always examine the Material Safety Data Sheet (MSDS) or CoC to verify adherence to these standards and note any usage limitations, such as for temperature or specific food types (e.g., acidic, fatty).navigating these complex regulations is critical. Our specialists can help you select the right certified granules to ensure full compliance.

Risks and Challenges of Using PLA in Food Applications

3D-printed PLA presents specific challenges for food safety and performance due to its material properties and manufacturing process. The base polymer’s non-toxic nature suits food contact, but practical applications reveal limitations that require careful management. These include risks from additives, processing conditions, and environmental factors affecting the material’s integrity. Key challenges include:

- Porosity and Bacterial Growth: The layer lines inherent in 3D prints create voids that can harbor bacteria, posing a significant contamination risk for reusable items.

- Low Heat Resistance: PLA’s glass transition temperature is around 60°C (140°F). It will deform and potentially leach chemicals if exposed to hot foods, liquids, or a dishwasher.

- Chemical Migration from Additives: Uncertified colorants, plasticizers, or other additives can leach into food, particularly with acidic or fatty foods.

- Material Degradation: High humidity or prolonged exposure to temperatures above 40°C can accelerate PLA’s degradation, potentially affecting its structural integrity and safety.

Mitigation Strategies

- Source Certified Filaments: Only use PLA filaments with documentation (CoC or MSDS) confirming they are food-grade.

- Apply a Food-Safe Sealant: Use an FDA-approved epoxy or polyurethane coating to seal surface pores. Ensure it is fully cured before use.

- Limit to Cold Applications: Restrict PLA items to contact with cold or lukewarm foods and liquids only (below 50°C).

- Design for Cleanliness: Create designs with smooth, sloped surfaces and avoid sharp corners or crevices where bacteria can accumulate.

By addressing these challenges with rigorous strategies, PLA’s reliability for food-safe 3D printing applications improves significantly, supporting safe and sustainable outcomes.

Best Practices for Ensuring Food-Safe PLA 3D Prints

PLA’s non-toxic base supports food contact, but safety depends on filament purity, printing hygiene, and post-processing. Regulatory compliance and proper handling are critical to prevent contamination or material failure. As a plastic pellet distributor, sourcing high-purity PLA granules ensures downstream safety for food applications. Follow these practices to ensure compliance and minimize risks.

- 1.Conduct Migration Testing

- Test for substance migration per FDA or EU standards, especially for repeated use with acidic or fatty foods.

- 2.Source Certified PLA

- Use filaments meeting FDA 21 CFR or EU 10/2011 standards; avoid pigmented types unless additives are compliant.

- 3.Maintain Dedicated Equipment

- Employ lead-free stainless steel nozzles and dedicate printers to food-safe prints to avoid cross-contamination.

- 4.Refine Print Settings

- Apply 100% infill and low layer heights to reduce porosity and bacterial buildup.

- 5.Apply Safe Coatings

- Seal surfaces with fully cured, certified epoxy or polyurethane to create non-porous barriers.

- 6.Clean Without Heat

- Wash with mild soap and lukewarm water; avoid dishwashers due to PLA softening at 55–60°C.

- 7.Incorporate Design Considerations

- Design with sloped surfaces and avoid crevices to ease cleaning; sand prints to smooth imperfections.

These practices ensure reliable food-safe PLA applications, supported by high-purity granules from certified suppliers. We specialize in sourcing and distributing compliant PLA pellets to meet your manufacturing needs. Get in touch to learn more about our certified materials.

Comparing PLA to Other Food-Safe 3D Printing Materials

PLA performs alongside other thermoplastics for food-contact 3D printing, evaluated by safety, performance, and usability criteria. The table below compares key properties, grounded in regulatory standards and material data, to guide material alignment with food safety and application needs.

Comparison of PLA with Other Food-Safe 3D Printing Materials:

| Material | Food Safety | Heat Resistance | Durability | Chemical Resistance | Printability | Relative Cost |

| PLA | Safe if certified. Additives are the main risk. | Low (~60°C) | Moderate (Brittle) | Low-Moderate | Excellent | Low |

| PETG | Generally safe; low VOC emissions. | Moderate (~80°C) | High (Tough) | Good | Good | Moderate |

| PP | Excellent (FDA/EU approved for containers). | High (~100°C) | High (Flexible) | Excellent | Challenging | Moderate to high |

| ABS | Not Recommended (emits styrene). | High (~105°C) | High (Strong) | Good | Moderate | Moderate |

Key Takeaways:

- PLA is excellent for low-heat, disposable, or single-use items like cookie cutters or prototypes, offering ease of printing and biodegradability.

- PETG provides a good balance of durability, chemical resistance, and higher heat tolerance, making it suitable for reusable items.

- PP (Polypropylene) is a top choice for demanding applications requiring high heat and chemical resistance, though it is difficult to print.

- ABS should be avoided for food-contact applications due to toxic emissions during printing and potential chemical migration.

This comparison clarifies material strengths and limitations, aiding manufacturers in aligning choices with food safety and application demands.

Real-World Applications of Food-Safe PLA

Food-safe PLA supports diverse applications due to its biocompatibility and environmental benefits. Its ability to meet regulatory standards while enabling customization makes it valuable across industries. Below are key uses, demonstrating PLA’s role in safe and sustainable food-contact solutions.Key applications include:

- Prototyping Food-Handling Tools: Engineers use certified PLA to rapidly fabricate molds, jigs, and custom utensils like cookie cutters, allowing for quick design iteration while maintaining safety standards.

- Custom Packaging: PLA is used to create biodegradable containers and trays for specific products, reducing plastic waste in single-use scenarios.

- Educational Aids: Non-toxic PLA models, such as portion guides or culinary stencils, are used in food science programs for safe, hands-on learning.

- Food Service Items: PLA can produce compliant disposable utensils, straws, and decorative items for events, offering a sustainable alternative to conventional plastics.

Case in Point: A small bakery switched to food-grade PLA for its custom cookie cutters. This move cut their tooling costs by 40% compared to metal alternatives and allowed them to quickly create new designs, all while adhering to FDA regulations.Inspired to innovate with PLA? Contact us to explore how our certified granules can support your specific application needs.

The Future of Food-Safe 3D Printing

Advancements in PLA formulations and 3D printing technology continue to enhance its potential for food-safe applications. New filaments are being developed with antimicrobial properties, incorporating natural antibacterial agents like silver ions to reduce microbial growth. Researchers are also creating enhanced PLA blends with improved thermal stability, which would expand their use to warmer applications like coffee cup lids. As high-precision printers achieve smoother surface finishes, the porosity that traps bacteria is minimized. As the technology becomes more common, regulatory bodies are also refining their oversight, ensuring all materials meet consistent and verifiable safety benchmarks. These innovations will position PLA as a leading material for sustainable and compliant food-safe applications.

Frequently Asked Questions (FAQs)

A:A: PLA is derived from renewable, plant-based sources like cornstarch, making its base polymer non-toxic. Unlike petroleum-based plastics like ABS, which can release harmful chemicals, pure PLA is inherently safer. The key is using a certified food-grade PLA to ensure no harmful additives are present.

A:Check for certifications like FDA 21 CFR or EU 10/2011 compliance on the product packaging or website. Request a Material Safety Data Sheet (MSDS) or Certificate of Compliance (CoC) from the manufacturer for official documentation.

A:No. PLA has a low glass transition temperature and softens above 60°C (140°F). It is unsuitable for hot foods, hot liquids, or cleaning in a dishwasher. For higher heat resistance, consider PETG or PP.

A:Wash them by hand with mild soap and lukewarm water. Avoid hot water and dishwashers, which will cause the object to warp or deform. Inspect prints regularly for any cracks or wear that could harbor bacteria.

A:While not always mandatory, a food-safe coating (like certified epoxy) is highly recommended for reusable items. It seals the porous surface, making it easier to clean and preventing bacterial growth. For single-use items like a cookie cutter, it is less critical.

A:Yes, PLA can be an excellent material for cookie cutters, provided you use a certified food-grade filament. Since cookie cutters have brief contact with dough and are not exposed to heat, the risks are minimal. Always wash them by hand after use.

Conclusion

PLA offers a cost-effective, biodegradable, and versatile option for 3D printing food-contact items. However, safety is not inherent to the material alone; it is a result of a controlled process.

By starting with certified, high-purity PLA granules, adhering to strict printing hygiene, optimizing print settings to minimize porosity, and respecting the material’s thermal limitations, you can safely leverage PLA for sustainable innovations in packaging, prototyping, and food service. As advancements in material science continue, PLA’s role in food-safe applications is set to expand, bridging the gap between customization and compliance.Contact us at jerry@salesplastics.com or +8618657312116 for high-quality, food-grade PLA granules to elevate your projects.