The environmental pollution caused by traditional cigarette filters has become a critical pain point for the tobacco industry. Historically, these filters have been essential for reducing the inhalation of harmful substances; however, their reliance on non-biodegradable Cellulose Acetate (CA) has led to a significant ecological crisis and increased pressure from global “Single-Use Plastics” (SUP) regulations.

To address this industry pain point, Polylactic Acid (PLA) has emerged as a game-changing solution. As a bio-based, fully compostable polymer derived from renewable resources like corn starch, PLA offers a high-performance alternative that bridges the gap between functional excellence and environmental responsibility.

This article explores the transformative potential of PLA as an innovative green raw material for cigarette filter production. We will delve into its unique advantages, practical application cases, and the promising market outlook that positions PLA at the forefront of the industry’s sustainable transition.

Overview of PLA Raw Material

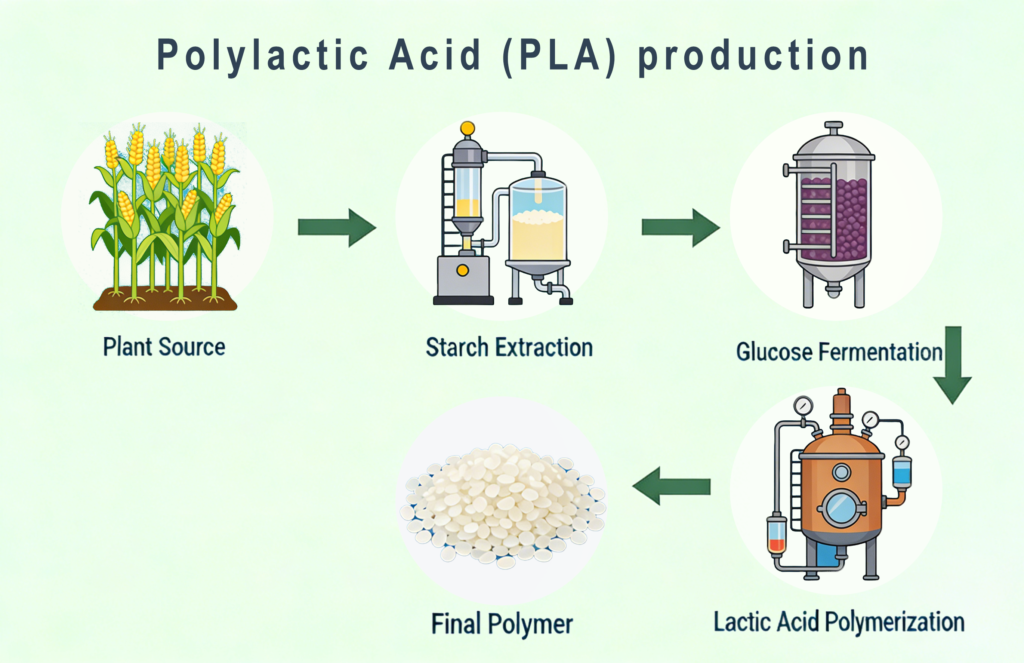

Polylactic Acid (PLA) is a high-performance bio-polyester synthesized through the fermentation of plant-derived sugars into lactic acid, followed by a sophisticated ring-opening polymerization process. Unlike petroleum-based plastics like PP or PET, PLA is entirely decoupled from fossil fuels, offering a significantly lower carbon footprint and a truly renewable lifecycle.

Production process of PLA from plant sources to final polymer

we provide PLA raw materials that set the benchmark for quality and safety through the following core characteristics:

Superior Environmental Profile

While traditional plastics persist in the environment for centuries, our PLA resins are designed for circularity. Under industrial composting conditions, PLA completely biodegrades into CO₂ and water within 90 days. To understand the science behind this process, you can explore our detailed analysis: Is PLA Biodegradable? The Ultimate Guide to Sustainable Plastics. This rapid decomposition effectively solves the persistent waste issue of traditional filter tows.

Compliance & Safety Certifications

Our materials meet the most stringent global standards, including EU REACH compliance and U.S. FDA food-contact grade certifications. This ensures that the raw material is non-toxic, biocompatible, and free from harmful additives or bleaches—critical for products involving inhalation and oral contact.

Performance vs. Tradition

Compared to conventional synthetic polymers, PLA provides excellent mechanical properties and high crystallinity. It maintains the necessary tensile strength for high-speed manufacturing while offering better thermal stability than many recycled alternatives.

Distributor Advantage & Customization

We supply high-purity pellets tailored for fiber extrusion. To understand the technical benchmarks, you can explore PLA Material: NatureWorks Injection, Extrusion & Fiber Grades.

Note: While NatureWorks offers world-class performance, we understand that every production line has unique requirements. That’s why we also carry a diverse portfolio of PLA resins from other global manufacturers to ensure the perfect balance of cost and performance for your specific needs.

Advantages of PLA in Cigarette Filter Mouthpieces

The application of PLA in cigarette filter production offers a synergistic balance between high-performance filtration and ecological responsibility. By analyzing its technical and market-driven benefits, it becomes clear why PLA is becoming the preferred raw material for the next generation of tobacco products.

Environmental Impact

The environmental advantages of PLA cigarette filters represent a significant improvement over traditional materials:

Environmental Benefits

- Complete biodegradation in soil within 3 months

- Derived from renewable plant resources

- Lower carbon footprint in production

- Reduced microplastic pollution

- Flame retardant properties reduce fire hazards

Environmental Challenges

- Requires specific conditions for optimal biodegradation

- Industrial composting facilities may be needed

- Land use considerations for source crops

- Energy requirements for processing

PLA tow material showing characteristic Y-shaped cross-section for enhanced filtration

Enhanced Filtration Efficiency

PLA fibers possess a unique molecular polarity and porous structure that optimize the adsorption of harmful substances.

- Targeted Removal: Technical studies indicate that PLA filters can improve the interception rate of formaldehyde and other carbonyl compounds by more than 20% compared to traditional cellulose acetate.

- Sensory Consistency: PLA is chemically stable and free from volatile substances, ensuring that the material does not introduce any off-flavors, thereby maintaining the original taste profile of the tobacco.

Environmental Compliance and Sustainability

- Circular Lifecycle: In alignment with global environmental mandates like the EU Single-Use Plastics Directive, PLA provides a definitive solution to the issue of cigarette butt litter. It is fully biodegradable under industrial composting conditions within 90 days, significantly reducing microplastic accumulation.

- Low Carbon Footprint: Derived from renewable plant resources, the production of PLA consumes less energy and emits fewer greenhouse gases than petroleum-based plastics like PP or PET.

Health, Safety, and Biocompatibility

- Non-Toxic Composition: PLA is inherently biocompatible and free from harmful chemical additives, bleaches, or plasticizers. This safety profile is particularly critical for products involving direct oral contact and inhalation.

- Reduced Secondary Risks: Its natural flame-retardant properties offer an added layer of safety, reducing the fire hazards associated with discarded filters.

Processing Stability and Economic Viability

- Manufacturing Compatibility: PLA exhibits excellent thermal stability and high tensile strength, making it highly adaptable to existing extrusion and melt-spinning processes.

- Cost Efficiency: As the global supply chain scales, the production costs of PLA have become increasingly competitive. When accounting for potential environmental taxes on plastics, PLA represents a cost-effective long-term alternative to traditional materials.

Innovation and Future Potential

The material’s versatility allows for the integration of natural fibers or aromatic capsules to enhance the user experience. With the global PLA market projected to maintain a 15% annual growth rate through 2030, the transition to bio-based filters is backed by strong market momentum and consumer demand.

Explore High-Performance Sustainable Materials

Access comprehensive technical data and certification profiles for our PLA filter-grade resins. See how bio-based raw materials can elevate your product’s environmental compliance without compromising filtration standards.

Market Cases, Comparisons, and Trends

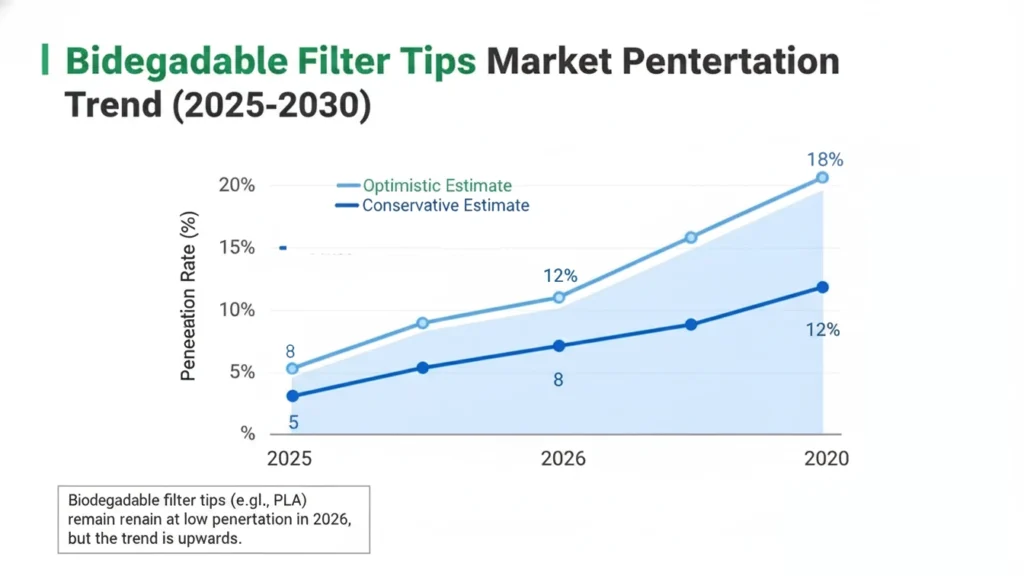

Market Penetration Trend of Biodegradable PLA Filter Tips (2025–2030)

The transition toward sustainable filter materials is no longer a matter of corporate choice but a strategic response to a changing global landscape. By analyzing current market data and technical benchmarks, it is clear that PLA is uniquely positioned to become the new industry standard.

Comparative Analysis

While cellulose acetate has been the historical norm, PLA offers superior long-term value, particularly as global “plastic taxes” and environmental levies begin to take effect.

| Key Factors | Cellulose Acetate (CA) | Polylactic Acid (PLA) | Strategic Advantage |

| Biodegradability | 10–15 Years | ~90 Days (Industrial) | Rapid Waste Turnover |

| Eco-Compliance | Subject to Single-Use Plastic Bans | Fully Compliant (Bio-based) | Future-Proof Regulatory Status |

| Durability | High | Comparable (High Crystallinity) | No Compromise on Shelf Life |

| Total Cost | Stable but rising due to taxes | Competitive & Decreasing | Long-term Price Stability |

Future Market Trends

The global tobacco industry is pivoting toward sustainability, with the PLA market projected to maintain a 15% CAGR through 2030.

Regulatory Pressure

Increasing global regulations on single-use plastics will continue to drive adoption of biodegradable alternatives like PLA in cigarette filters.

Technical Innovation

Ongoing research is improving PLA filter performance, biodegradation rates, and manufacturing efficiency, enhancing competitive positioning.

Cost Optimization

Economies of scale and production improvements are steadily reducing PLA filter costs, making them increasingly competitive with traditional options.

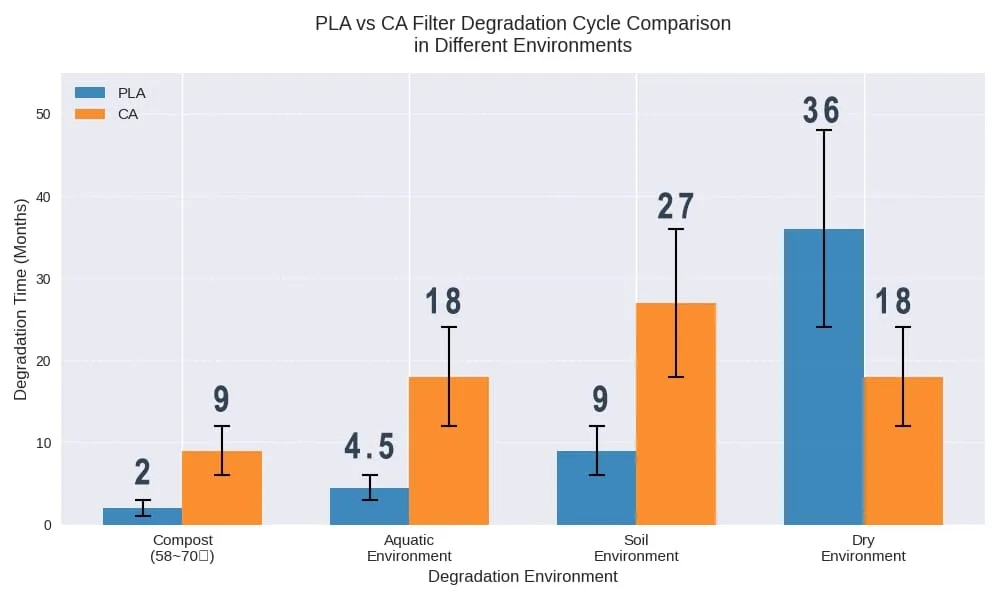

Environmental Degradation Periods of PLA and CA Filters

Overcoming Technical Challenges

While pure PLA can be sensitive to high-humidity environments, current material science provides effective solutions. As a specialized supplier, we offer Enhanced PLA Formulations that have been modified to improve moisture resistance and thermal stability. These innovations ensure that the raw material performs consistently during high-speed manufacturing and throughout the product’s storage life.

Why Partner with Us for Your Green Transition?

As a supplier of bioplastic raw materials, we provide more than just a product; we provide a bridge to a sustainable future:

- High-Purity Grades: Our PLA resins are specifically engineered for fiber extrusion, ensuring consistent tow quality.

- Competitive Supply Chain: We offer high-volume availability at competitive price points to support large-scale production.

- Technical & Sample Support: We offer comprehensive technical guidance and sample testing to help you seamlessly integrate PLA into your existing production lines without costly equipment overhauls.

Aligning your production with shifting market demands requires the right material specifications.

Explore the technical compatibility of various PLA resin grades and understand how they can be integrated into your existing manufacturing processes.

Conclusion

The adoption of Polylactic Acid (PLA) represents a landmark innovation in cigarette filter manufacturing, achieving a rare synergy between high-performance filtration and ecological responsibility. By integrating PLA into production, manufacturers are not merely swapping raw materials; they are revolutionizing the industry to align with a carbon-neutral future.

As global regulations tighten and consumer demand for “plastic-free” alternatives peaks, the trajectory is clear: PLA is set to become the industry standard. Its superior ability to intercept harmful compounds, combined with its 100% renewable origin and rapid biodegradability, positions it as the definitive choice for forward-thinking brands.

We invite you to take the next step in your sustainability journey. Our team is ready to support your transition with high-purity PLA raw material samples for performance validation and competitive quotations tailored to your specific production requirements. Contact us today to explore how our specialized resin grades can fit your manufacturing needs.Choosing PLA is more than a product upgrade—it is a commitment to a cleaner, more sustainable planet.

Ready for a Green Transition?

Access comprehensive technical data and certification profiles for high-purity PLA resins. Validate how our bio-based solutions can align your production with global sustainability standards while maintaining superior filtration quality.

Which regions are leading PLA cigarette filter adoption?

Asia-Pacific, particularly China, leads in PLA cigarette filter production and adoption, with European markets showing increasing interest driven by stringent environmental regulations. North American adoption remains in early stages but is expected to accelerate as sustainability initiatives gain momentum.

What market factors are driving PLA filter growth?

Key drivers include tightening environmental regulations on single-use plastics, corporate sustainability initiatives within the tobacco industry, increasing consumer environmental awareness, and technological improvements in PLA filter performance and cost-effectiveness.