With global plastic production exceeding 380 million tons annually and recycling rates stagnating below 9%, the industry is at a crossroads. For manufacturers and brand owners, PLA (Polylactic Acid) is no longer just an “alternative”—it is a strategic asset for decarbonizing supply chains and ensuring regulatory compliance in a circular economy.

Is PLA the right fit for your specific application? This article provides a technical comparison between PLA and conventional polymers, analyzing their environmental footprints, mechanical properties, and processing requirements to help you make a data-driven choice for your next project.

What is PLA and How is PLA Made?

PLA (Polylactic Acid) is a high-performance biopolymer derived from 100% renewable biomass, such as corn starch or sugarcane. Unlike traditional petroleum-based resins like PP or PET, PLA captures carbon dioxide from the atmosphere during the growth of its organic feedstock, significantly lowering its overall carbon footprint.

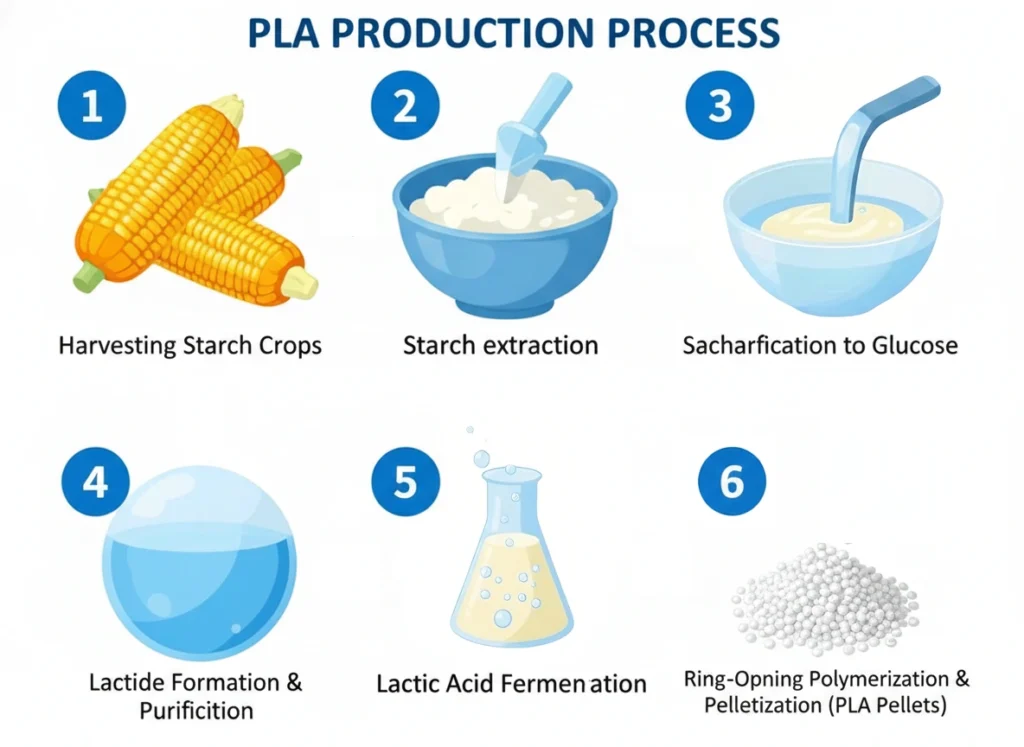

The manufacturing process follows a sophisticated multi-stage bio-refinery path:

- Saccharification: Plant starch is broken down into glucose.

- Fermentation: Specialized microorganisms convert sugars into high-purity lactic acid.

- Polymerization: Through advanced Ring-Opening Polymerization (ROP), lactic acid is transformed into PLA resin.

To ensure optimal mechanical properties in the final product. While PLA offers familiar functional results, it possesses a fundamentally different chemical structure that dictates its unique end-of-life behavior.

The PLA production process from plant starch to final polymer

Understanding these chemical nuances is key to determining how the material breaks down in various environments. To explore the complexities of its decomposition and certification requirements, read our dedicated analysis:Is PLA Biodegradable? The Ultimate Guide to Sustainable Plastics.

How PLA and Traditional Plastics Behave in the Environment

The environmental fate of polymers is a critical factor in material selection. Conventional petroleum-based resins (such as PE, PP, and PET) are designed for durability, which unfortunately leads to persistence for centuries. When mismanaged, they fragment into microplastics, creating long-term ecological challenges and complicating supply chain compliance.

PLA (Polylactic Acid) offers a circular alternative, but its advantages are environment-specific. Under industrial composting conditions (as defined by EN 13432 or ASTM D6400 standards)—where temperatures reach approximately 60°C (140°F) and humidity is controlled—PLA undergoes rapid hydrolysis, followed by microbial consumption. In these specialized facilities, it converts into CO₂, water, and nutrient-rich biomass within months.

- The Landfill Myth: In anaerobic landfill conditions, PLA remains largely inert, similar to traditional plastics.

- Infrastructure Dependency: The environmental “win” for PLA is only realized when paired with accessible composting infrastructure.

- Recycling Integrity: Because PLA has a lower melting point than PET, it must be clearly labeled to prevent contamination of existing mechanical recycling streams.

For our clients, we recommend PLA primarily for applications where food contamination makes traditional recycling difficult (e.g., food service ware), ensuring the highest environmental ROI.

PLA vs Traditional Plastics: Performance Comparison & Why Bioplastics Are Gaining Popularity

In the industrial sector, selecting the right resin requires balancing mechanical performance, processing efficiency, and regulatory compliance. While traditional petroleum-based plastics like PE, PP, and PET remain industry standards for durability, PLA has emerged as a high-performance alternative for sustainable applications.

| Property | PLA (Modified/High-Heat) | Petroleum-based (PE, PP, PET) |

| Common Uses | Eco-packaging, 3D printing, medical | PET (Bottles), PP (Containers), PE (Bags) |

| Origin | 100% Renewable (Corn/Sugarcane) | Non-renewable Petroleum |

| Heat Resistance | Up to 95°C (CPLA/Modified) | PE (80°C), PP (120°C), PET (75°C) |

| Barrier Properties | Breathable (Ideal for fresh produce) | Superior Oxygen/Moisture Barrier |

| Carbon Footprint | 75% Lower than fossil plastics | High (Significant CO₂ emission) |

| End-of-Life | Industrial Compostable (EN 13432) | Non-biodegradable; Recyclable |

Why the Industry is Shifting to PLA

The transition from traditional petroleum-based resins to bioplastics is a strategic business move driven by three critical factors:

Regulatory Compliance & ESG

With the expansion of Extended Producer Responsibility (EPR) and plastic taxes on non-recycled content, switching to PLA helps manufacturers bypass heavy penalties and meet strict export requirements for the EU and US markets.

Decarbonizing the Supply Chain

Traditional plastics like PE and PP are carbon-intensive. PLA captures CO₂ during the growth of its feedstock, allowing brands to claim a significant reduction in their product’s Scope 3 emissions.

Application-Specific Advantages

While PET is unbeatable for carbonated drinks, PLA’s natural breathability makes it superior for anti-fog food films and breathable agricultural mulch, where traditional PE would require expensive micro-perforation.

Common applications of PLA across various industries

Technical Insight: Manufacturers using PP or PET can often transition to PLA with minimal tooling adjustments. Our team provides specialized processing guides to help you optimize temperature profiles and prevent material degradation during the switch.

The Limitations & Challenges of Using PLA

Understanding the performance boundaries of PLA is essential for successful material integration. While PLA offers clear environmental wins, it presents specific technical hurdles that require professional guidance to overcome.

PLA Advantages

- Made from renewable resources

- Biodegradable under proper conditions

- Lower carbon footprint

- Non-toxic production process

- Suitable for food contact

- Compatible with existing manufacturing

PLA Limitations

- Low heat resistance (deforms above 60°C)

- More brittle than many conventional plastics

- Requires industrial composting facilities

- Higher production cost

- Limited barrier properties (gas/moisture)

- Agricultural land use concerns

Performance vs. Application

- Thermal Constraint: Standard PLA deforms above 60°C. Solution: We offer High-Heat PLA grades and crystallization technologies that extend thermal stability to 90°C+, making it viable for hot beverage lids.

- Brittleness: Its high modulus can lead to cracking. Solution: By blending PLA with bio-based toughening agents or PBAT, we can achieve the flexibility required for shopping bags and flexible films.

- Barrier Properties: PLA has higher gas permeability than PET. Solution: This is actually a benefit for fresh produce packaging (reducing condensation and mold), though not ideal for long-shelf-life carbonated drinks.

Industrial composting facilities are essential for proper PLA decomposition

The environmental ROI of PLA is highest when used in closed-loop systems (e.g., stadiums, offices) where industrial composting is accessible. Furthermore, while land use is a valid concern, our PLA feedstock is sourced from non-GMO industrial corn, utilizing only a tiny fraction of global acreage while driving the shift away from fossil-fuel extraction.

Choosing the Right Material

Not every application is a fit for PLA. Our technical team can help you analyze your product’s lifecycle to ensure you aren’t just buying “green,” but buying “smart.”

When PLA Makes Sense: Best Use Cases

we recommend PLA Resin for applications where its unique molecular properties provide a competitive edge over traditional polymers like PP or PET.

Food Service & High-Clarity Packaging

PLA excels in short-lifecycle applications such as cold-drink cups, deli containers, and fresh-cut produce packaging. Its superior clarity and stiffness provide a premium feel, while its natural origin ensures compliance with food-safety standards (FDA/EU Compliant). In closed-loop environments like stadiums or corporate cafes, it offers a seamless path to zero-waste.

Precision 3D Printing (Filament Grades)

For the additive manufacturing industry, PLA is the gold standard for prototyping and educational models. Its minimal thermal expansion ensures excellent dimensional stability and low warping. Our 3D-printing grades are optimized for consistent melt flow and zero odor.

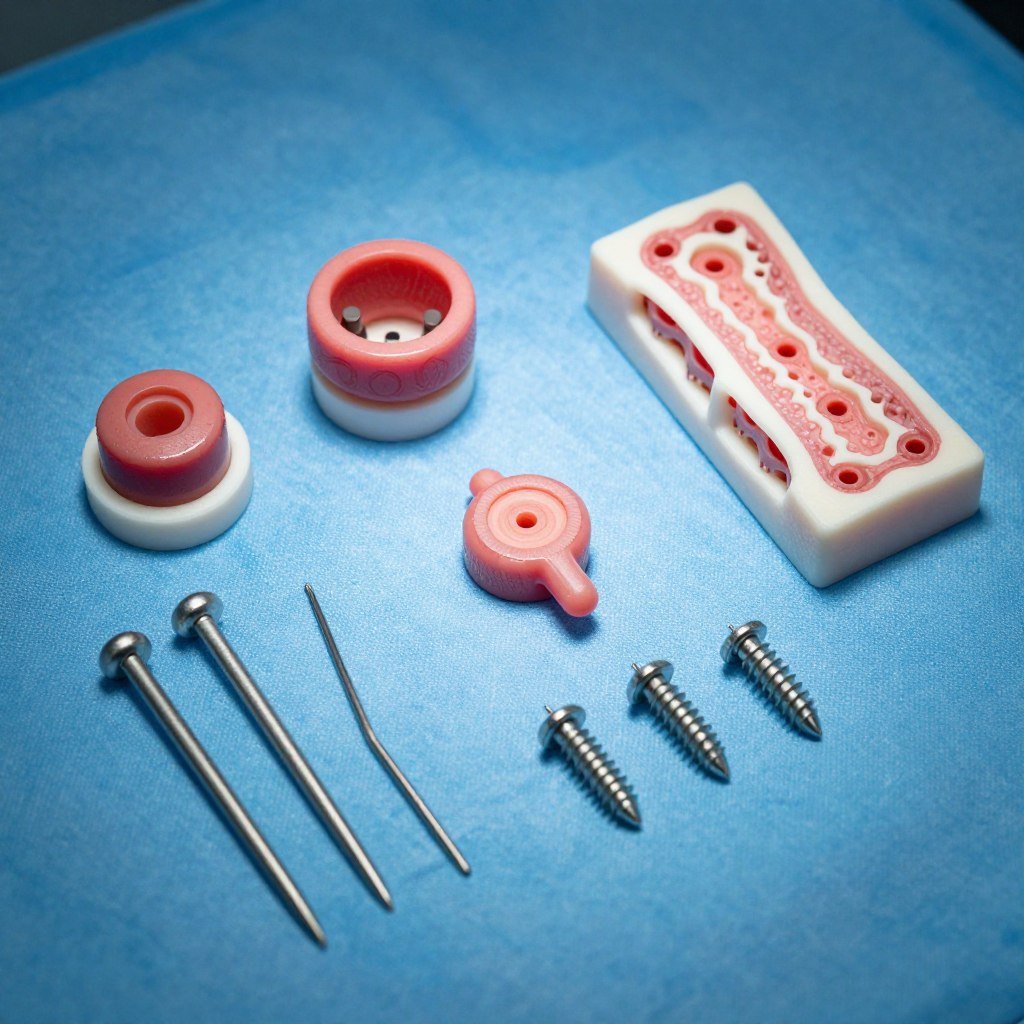

Advanced Medical & Bio-tech

PLA’s bioresorbable nature is revolutionary for medical devices. It is the material of choice for dissolvable sutures, bone screws, and drug-delivery scaffolds. Its ability to undergo controlled in-vivo degradation eliminates the risk and cost of secondary removal surgeries.

Technical Textiles & Non-wovens (The Growing Frontier)

Beyond rigid plastics, PLA is increasingly used in compostable tea bags, hygiene products, and agricultural mulch films. Its breathability and UV resistance make it a functional upgrade over traditional PE films in many agricultural contexts.

Greenwashing: How to Avoid Misleading Claims with PLA

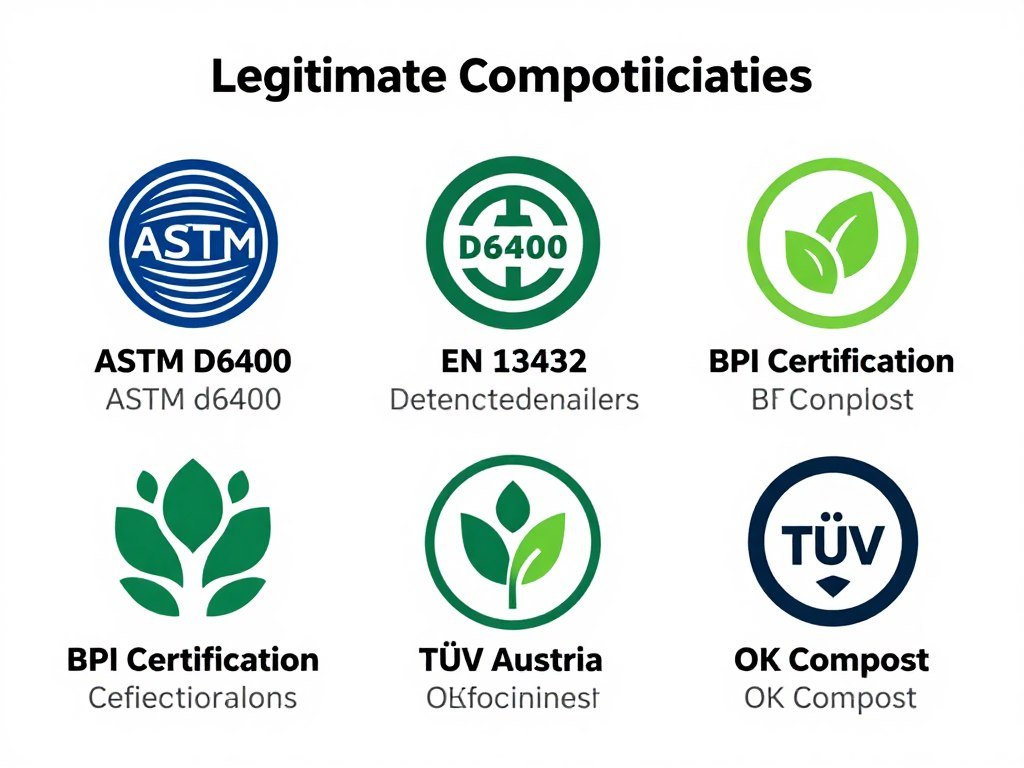

In the rapidly evolving bio-plastics market, terms like “eco-friendly” or “earth-safe” often lack legal weight. For professional buyers, relying on vague terminology can lead to significant regulatory risks. To ensure your product meets global sustainability mandates, you must look for verified industrial certifications:

- ASTM D6400 / EN 13432: The gold standards for compostability in the US and Europe.

- BPI & TÜV Austria (OK Compost): Crucial third-party verifications that guarantee the material leaves no toxic residues.

- ISCC PLUS: Ensures the biomass feedstock is sourced from sustainably managed land.

Our Commitment to Transparency: As your material partner, we provide full documentation for every batch of PLA resin we supply. We help our clients navigate the complexities of compostable labeling to ensure that end-consumers receive accurate information.

Remember: PLA is an environmental win only when its end-of-life path is clearly defined. Products that blend PLA with conventional resins without proper testing can contaminate recycling streams and damage your brand’s integrity.

The Future of PLA and Bioplastics

Research continues to improve PLA’s properties and processing methods

The bioplastics landscape is shifting from simple substitution to performance-driven innovation. As a forward-thinking distributor, we are tracking several key developments that will redefine material selection:

- Next-Gen Formulations: We are already seeing PLA blends that bridge the gap in heat resistance and impact strength, moving beyond simple packaging into automotive and consumer electronics.

- Alternative Feedstocks: The shift toward using non-food crops and agricultural waste ensures a more ethical and stable supply chain for the future.

- Circular Integration: Beyond composting, chemical recycling specifically for PLA is gaining traction, allowing the industry to move toward a truly circular economy.

Policy developments will play a crucial role in PLA’s future. Extended producer responsibility regulations, plastic taxes, and composting infrastructure investments could significantly impact adoption rates. As the true costs of plastic pollution become increasingly apparent, economic incentives may shift further in favor of bioplastics.

The most promising future likely involves a diverse materials approach – using PLA where its properties are ideal and proper disposal is available, while developing other sustainable materials for applications where PLA falls short. This pragmatic approach recognizes that no single material will solve all sustainability challenges.

Conclusion

The comparison between PLA and traditional plastics reveals that sustainability is not a binary choice, but a strategic decision. While PLA offers a breakthrough in renewable sourcing and biodegradability, its success depends on matching the material to the right application and disposal infrastructure.

Conventional plastics (PE, PP, PET) remain essential for their durability and cost-effectiveness, but the growing regulatory and consumer pressure makes exploring bio-based alternatives a business necessity.

At salesplastics, we believe the most sustainable approach is a pragmatic one. As your material partner, we don’t just supply resin; we provide:

- Technical Material Audits: Helping you determine where PLA can replace traditional plastics without compromising quality.

- Optimized Supply Chains: Ensuring consistent access to high-quality PLA pellets and Bio-blends.

- Compliance Support: Providing all necessary certifications (EN 13432, ASTM D6400) to protect your brand from greenwashing risks.

The most sustainable approach combines thoughtful material selection with system-wide improvements in waste management. PLA represents an important step toward more sustainable materials, but it must be part of a broader strategy that includes reduced consumption, improved recycling, and continued innovation.

Partner with Us for Your Sustainable Transition

Navigating the transition from traditional resins (PE, PP, PET) to PLA or other biopolymers requires technical expertise. Our team is ready to provide:

- Custom Grade Selection: Matching our PLA resins to your specific machinery.

- Compliance Documentation: Full certification support for global markets.

- Sample Testing: Fast-track your R&D with our latest modified grades.

Frequently Asked Questions

Is PLA actually better than plastic?

PLA offers significant environmental advantages over conventional plastics, particularly through its renewable plant-based sourcing and lower carbon footprint. However, whether it is “better” depends on your specific application and local infrastructure. PLA is the superior choice for short-lifecycle products (like food packaging) where industrial composting is available. For high-durability goods or regions lacking composting facilities, traditional resins may still be more practical.

What is the disadvantage of PLA plastic?

The primary technical challenges of standard PLA include low heat resistance (deforming above 60°C/140°F) and material brittleness. Additionally, it requires industrial composting facilities to biodegrade efficiently; it will not break down quickly in a standard landfill.

Note for Manufacturers: We offer modified high-heat PLA and impact-resistant grades to overcome these specific physical limitations.

Does PLA turn into microplastics?

Unlike traditional petroleum-based plastics that fragment into permanent microplastics, properly composted PLA breaks down completely into water, CO₂, and nutrient-rich biomass. While PLA can fragment into smaller pieces in sub-optimal environments (like the ocean), these fragments remain bio-available and will eventually undergo full biological decomposition, unlike conventional microplastics that persist indefinitely.

Is PLA a forever plastic?

No. PLA is chemically designed to return to nature. While conventional plastics can persist for centuries, PLA is certified to biodegrade in 3-6 months under industrial composting conditions. Even in less-than-ideal environments, it will decompose significantly faster than fossil-based polymers. It is a key tool for brands looking to exit the “forever plastic” cycle.