Nylon delivers reliable water resistance for demanding applications, from outdoor gear to medical textiles. Its tight weave repels light moisture, but achieving true waterproofing requires advanced coatings. As a trusted supplier of high-performance nylon granules, we empower manufacturers to create durable, water-resistant products for harsh conditions. This guide explores nylon’s properties, its water-repelling capabilities, and how our granules meet industry needs.

What Is Nylon?

Developed by DuPont in 1935, nylon, a synthetic polyamide, transformed industries with its strength, flexibility, and cost-effectiveness. Unlike natural fibers, it resists wear and performs reliably in extreme conditions, from freezing temperatures to high humidity.

Available in types like Nylon 6 and Nylon 6,6, it suits diverse needs, including outdoor gear, marine ropes, and automotive parts.

| Type | Melting Point | Tensile Strength | Common Uses |

|---|---|---|---|

| Nylon 6 | 428°F (220°C) | ~11,600–12,400 psi | Textiles, automotive components |

| Nylon 6,6 | 509°F (265°C) | ~12,000–12,500 psi | Ropes, gears, outdoor equipment |

Nylon’s water-resistant properties arise from its tightly packed polymer chains, which minimize water absorption compared to natural fibers. This makes nylon lightweight, strong, and ideal for:

- Weather-resistant outdoor gear

- Marine ropes and cords

- Protective industrial coatings

Nylon retains approximately 85% of its tensile strength at low temperatures, such as -40°F (-40°C), making it a reliable choice for demanding applications.Our nylon granules ensure consistent quality, enabling manufacturers to produce durable, water-resistant products tailored to demanding environments.

Nylon’s Water Resistance: Waterproof or Water-Resistant?

Nylon qualifies as water-resistant rather than waterproof. Its tightly woven fibers repel light water exposure, such as drizzle or minor spills, but prolonged or intense contact allows penetration. Seams and stitching serve as vulnerable points for water seepage, and untreated nylon absorbs water under heavy rain or high pressure.

Water resistance differs by nylon type, measured by water column ratings (in millimeters) that indicate pressure tolerance before leaking. Higher ratings signify better protection:

| Nylon Type | Water Column Rating (mm) | Protection Level | Common Applications |

|---|---|---|---|

| Untreated | 800–1,500 | Light rain resistance | Windbreakers, casual bags |

| PU-Coated | 3,000–5,000 | Moderate weather protection | Hiking gear, outdoor cushions |

| Laminated | 10,000+ | Heavy-duty water resistance | Technical outerwear, expedition tents |

Fabric thickness (denier), coating type, and seam construction govern water resistance. Higher-denier fabrics provide denser weaves for enhanced resistance. Polyurethane (PU) or laminated coatings improve performance, with laminates offering superior protection. Sealed seams prevent water ingress, unlike standard stitching.

Untreated nylon lacks waterproofing, and even coated versions may fail in extreme conditions. For heavy rain, use nylon with a hydrostatic head rating above 5,000 mm and sealed seams. Review manufacturer specifications, as “weatherproof” indicates strong resistance but not full waterproofing.

The Science Behind Nylon’s Water Resistance

Nylon’s water-repelling ability stems from its molecular structure. The polymer chains contain repeating amide groups that form strong hydrogen bonds with each other, creating a compact structure that resists water penetration. This makes nylon inherently hydrophobic, as water molecules cannot easily disrupt these bonds, causing water to bead up on the surface rather than soak in.

Fabric density, measured in denier (D), significantly influences nylon’s water resistance. Higher-denier fabrics with tighter weaves have smaller gaps, reducing water infiltration. The table below compares two common nylon fabrics:

| Denier | Thread Count (threads/in²) | Water Resistance | Common Uses |

|---|---|---|---|

| 40D | 120 | Moderate | Lightweight jackets |

| 70D | 210 | High | Backpacks, tents |

Higher-denier fabrics like 70D offer superior protection against heavy rain but add weight, requiring a balance of durability and portability.

Polymer chain alignment, hydrogen bond strength, and surface treatments drive water resistance. Tightly packed chains enhance hydrophobicity, stronger bonds limit penetration, and coatings improve performance without altering structure. Untreated nylon manages light moisture, but commercial products rely on coatings for extended exposure.

Enhancing Nylon’s Water Resistance

Manufacturers use advanced techniques to improve nylon‘s water resistance while maintaining its flexibility and strength. These methods include polyurethane coatings, silicone laminates, and Durable Water Repellent (DWR) finishes, which fill microscopic gaps in the material to block water penetration.

Polyurethane coatings form a robust barrier on nylon fibers. Specialized membranes allow vapor to escape while preventing water ingress, making them ideal for outdoor gear. For extreme conditions, silicone-based laminates combine with nylon to provide full waterproofing with enhanced breathability.

DWR finishes modify nylon’s surface to repel water, causing it to bead and roll off. While less durable than coatings, DWR is effective for revitalizing worn gear. Two common application methods are:

- Spray-on treatments: Applied post-purchase, these are cost-effective but require reapplication every few months.

- Factory-laminated finishes: Integrated during manufacturing, these are 15-30% more expensive but offer longer-lasting protection.

Innovative silicone and bio-based DWR blends offer eco-friendly waterproofing without harmful chemicals. Look for “fully seam-sealed” construction or hydrostatic head ratings for optimal performance. Reach out to discuss how our premium nylon granules can meet your industry’s waterproofing and durability requirements.

Applications of Water-Resistant Nylon

Water-resistant nylon, enhanced with polyurethane or silicone coatings, ensures robust durability and moisture protection in demanding environments. Its tight molecular structure and dense weave limit water penetration, making it ideal for applications requiring reliable hydrophobicity. These properties, amplified by advanced coatings, deliver superior performance, as detailed below with specific requirements and standards.

- Outdoor Gear: Nylon powers tents and jackets with robust water resistance. Polyurethane-coated nylon achieves a hydrostatic head rating of ≥1,500 mm, passing ISO 811 tests to ensure reliable waterproofing in heavy rain.

- Medical Drapes: Coated nylon surgical drapes deliver fluid resistance and breathability. These drapes meet ASTM F2407 standards, ensuring a sterile barrier for surgical procedures.

- Automotive Airbags: Nylon’s high tensile strength and lightweight nature make it ideal for airbags. It complies with FMVSS 208 regulations, ensuring rapid deployment and durability for vehicle safety.

- Printing and Packaging: Nylon serves as a substrate for waterproof labels and flexible food packaging. Its wet-rub resistance meets ISO 105-X12 standards, ensuring durability in humid or outdoor conditions.

- Marine Equipment: Nylon ropes and sails resist saltwater corrosion and abrasion. They meet ISO 9227 standards, ensuring performance in harsh marine environments.

| Application | Key Requirement | Standard Met |

|---|---|---|

| Outdoor Tents | Waterproofing under high pressure | ISO 811 (≥1,500 mm) |

| Medical Drapes | Fluid resistance & breathability | ASTM F2407 |

| Automotive Airbags | High tensile strength | FMVSS 208 |

| Printing/Packaging | Wet-rub resistance | ISO 105-X12 |

| Marine Equipment | Saltwater corrosion resistance | ISO 9227 |

Our nylon granules are tailored to these applications, delivering consistent quality and compatibility with advanced coatings for high-performance, industry-specific solutions.

Sustainability Considerations

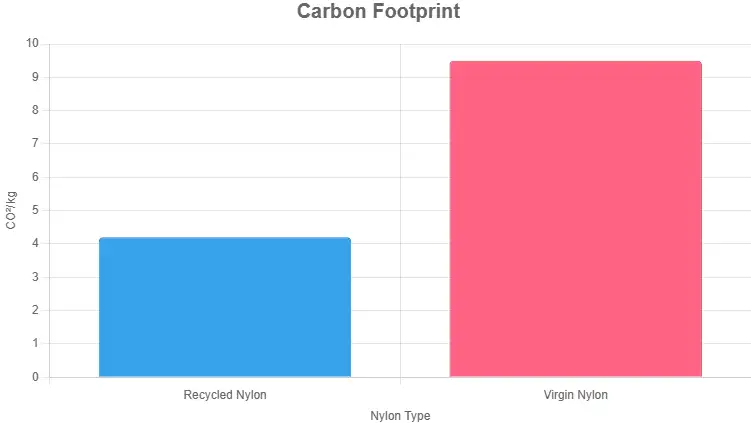

Recycled nylon, sourced from reclaimed fishing nets and fabric scraps, significantly reduces environmental impact. Compared to virgin nylon, it uses 60% less energy, 90% less water, and cuts carbon emissions from 9.5 kg CO2/kg to 4.2 kg. Our PFAS-free nylon granules support eco-friendly coatings, aligning with Global Recycled Standard (GRS) certifications. By integrating these granules, manufacturers meet rising demand for sustainable products while maintaining durability and water resistance for applications like outdoor gear and medical textiles.

| Factor | Virgin Nylon | Recycled Nylon |

|---|---|---|

| Energy Use | High | 60% lower |

| Water Use | 3,700 L/kg | 90% less |

| Carbon Footprint | 9.5 kg CO2/kg | 4.2 kg CO2/kg |

Conclusion

Nylon’s water-resistant properties, enhanced by advanced coatings, make it ideal for outdoor, medical, and industrial applications. Our high-performance nylon granules deliver superior weave density and coating compatibility, ensuring durability and sustainability. With years of expertise, we provide tailored solutions for manufacturers. Contact us at jerry@salesplastics.com or +8618657312116 to create reliable, eco-friendly products that meet industry standards.

FAQ

A:Nylon is naturally water-resistant, repelling light rain or spills due to its tight weave. It’s not fully waterproof unless treated with coatings like DWR or polyurethane. Check product specifications to confirm water-resistant or waterproof properties based on the treatment.

A:No material is inherently waterproof. Nylon, polyester, or vinyl can be waterproof with coatings like DWR or polyurethane. Waterproof performance depends on specific treatments or laminates. Always check product ratings for waterproof capabilities.

A:Both polyester and nylon are water-resistant, with nylon slightly better due to its tighter weave. Waterproofing depends on coatings like DWR or polyurethane, not the material itself. Check product specifications for treatment details to compare performance.

A:Nylon is wind-resistant due to its dense weave but not inherently windproof. Specialized weaves or coatings can make it windproof, as in windbreakers. Check product specifications for windproof performance based on construction.

A:Nylon alone isn’t warm, as it lacks insulating properties. Warmth comes from added linings or insulation, like fleece or down, in products like jackets. Check product design for warmth details.

A:100% nylon is water-resistant, handling light rain but not heavy exposure due to weave gaps. Coatings like DWR or polyurethane make it waterproof. Verify product specifications for its waterproof rating.

A:Yes. Technologies like Gore-Tex’s ePTFE membranes keep liquid water out while letting vapor escape. This makes nylon breathable and suitable for active use.