When picking a type of polyacetal—also called POM or acetal—you might wonder: Which one is best for my project, based on how well it works, how much it costs, and how easy it is to get? This guide compares popular brands like Delrin®, Hostaform®, and Duracon® with more affordable generic options from Chinese suppliers. Whether you’re designing parts or managing costs, we’ll help you choose wisely.

What is Polyacetal (POM)?

Polyacetal, also known as polyoxymethylene (POM) or acetal resin, is famous for its strength and rigidity. It’s a key thermoplastic in engineering plastics. This section explores its structure, importance in engineering, and common uses.

Basic Structure and Terminology

The terms polyacetal, polyoxymethylene, and acetal resin are often used together. They all refer to the same material. Polyacetal is a thermoplastic with a special structure. It has oxygen and carbon atoms linked together, making it very stable and strong.

Why It’s Used in Engineering Plastics

High-performance polyacetal is crucial in engineering plastics for several reasons:

- Stiffness: It has high mechanical strength, perfect for structural uses.

- Wear Resistance: It resists wear and abrasion well, lasting longer.

- Dimensional Stability: It keeps its shape well, even when temperatures or environments change.

Common Applications

Because of its great properties, acetal resin is used in many fields, including:

- Automotive: It’s used in fuel system parts, door handles, and mirrors.

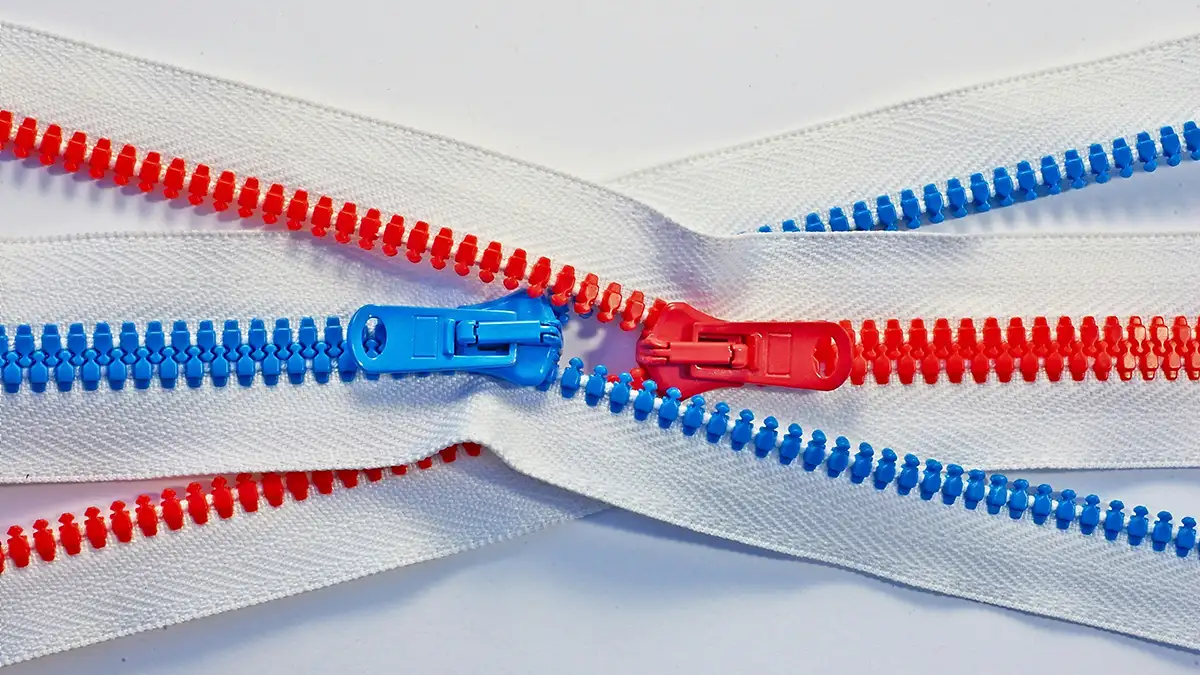

- 👖 Plastic zippers & buttons (clothing & accessories)

- 🧲 Snap locks & buckles (bags, shoes, uniforms)

- 🪑 Plastic fittings, clips, hinges (furniture, home hardware)

- 🧸 Toys, gears, sliders (low-load plastic components)

- ⚙️ Simple plastic bearings, wheels & rollers

Overview of the Major Polyacetal Brands

When choosing polyacetal products, engineers have many options. It’s important to know what makes each brand different. This helps make the right choice.

| Brand | Type | Manufacturer | Core Strength |

|---|---|---|---|

| Delrin® | Homopolymer | DuPont / Celanese | High strength, low friction, fatigue resistance |

| Hostaform® | Copolymer | Celanese | Chemical resistance, dimensional stability |

| Duracon® | Copolymer | Polyplastics (Japan) | Precision molding, high fatigue strength |

| Generic POM | Copolymer or Homopolymer | Chinese Suppliers | Cost-effective, customizable, fast delivery |

Homopolymer vs. Copolymer Acetal: Key Technical Differences

It’s important to know the difference between homopolymer and copolymer acetal. Each type has its own benefits for different uses. Let’s look at how they differ in key areas.

Molecular Structure

Homopolymers, like Delrin®, have a chain of formaldehyde units. This makes them strong and stiff. Copolymers, on the other hand, mix in another type of monomer. This makes them more stable at high temperatures.

This special POM polymer structure makes copolymers, such as Hostaform® and Duracon®, very useful in tough situations.

Mechanical Properties

Delrin® is known for its hardness and tensile strength because it’s a homopolymer. But, acetal copolymers are better at handling impacts and are more flexible. This makes them great for parts that face a lot of stress.

Chemical Resistance & Moisture Sensitivity

Both acetal types resist chemicals well, but copolymers are better against hot water and strong alkalis. This is because of their special chemical makeup. Homopolymers are strong but can absorb more moisture. This can affect their size over time.

Thermal Stability & Processing Window

Acetal copolymers have a wide range of processing options. This makes them easy to work with in complex settings. Homopolymers, like Delrin®, need more careful handling but offer unmatched stiffness and durability.

Grade-Level Comparison: What Do You Get?

Choosing the right polyacetal material is key. Different grades like Delrin grades, the Hostaform series, and Duracon specifications offer unique benefits. These differences can greatly affect how well a product works and meets standards.

Typical Grades of Delrin® (e.g., Delrin 150, 2700, AF, NC010)

Delrin® has various grades for different needs:

- Delrin 150: A general-purpose grade that balances strength and toughness well.

- Delrin 2700: Great for making thin, detailed parts because of its viscosity.

- Delrin AF: It has Teflon fibres for better wear and less friction.

- Delrin NC010: Ideal for applications needing low wear and friction.

Grade Examples of Hostaform® and Duracon®

The Hostaform series and Duracon specifications also offer a range of options:

Hostaform® Types:

Duracon® Types:

- M90-45: Strong and lasts long, good for everyday use.

- KH25: Quieter and steady even when temperatures change.

Common Specifications for Generic POM Resin

Generic POM resin meets basic engineering needs:

- It has good mechanical strength and stiffness.

- It has decent wear resistance.

- It has satisfactory dimensional stability.

- It resists chemicals like fuels, solvents, and more.

Certifications: FDA, RoHS, REACH, ISO, etc.

It’s important to choose a POM resin that meets regulatory standards. This ensures compliance in many industries:

- FDA: Approved for use in food contact.

- RoHS: Limits harmful substances in electronics.

- REACH: Ensures safe handling of chemicals.

- ISO: Follows international quality and safety standards.

When Should You Choose Branded vs. Generic POM?

Choosing the right polyacetal (POM) depends on several factors. These include the precision needed, the industry’s demands, the cost, and the reliability of the supply chain. We will look at when branded and generic POM are best used.

For High-Precision Mechanical Parts (e.g., gears, bushings)

For making precision acetal components like gears and bushings, branded POM is usually the top pick. Brands like Delrin®, Hostaform®, and Duracon® have better mechanical properties and stay stable in size. This is key for parts that face a lot of stress and need to last long.

For General Industrial Use (e.g., zippers, fasteners, handles)

For general industrial POM uses, where the need for precision is not as high, generic POM is a good option. Items like zippers, fasteners, and handles can use generic polyacetal at a lower cost. They still meet the necessary performance standards.

When Cost or Supply Chain is Critical

If keeping costs down and ensuring supply chain reliability is important, choose cost-effective polyacetal from generic suppliers. These options can help save money without losing too much quality. They work well in situations where the performance requirements are not too high.

For Customisation / OEM / White Label Needs

For custom, OEM, or white label projects, generic POM suppliers offer more flexibility. They often provide custom solutions and can quickly adjust to specific needs. This makes them great partners for unique manufacturing projects.

Why Choose Chinese POM over Delrin® / Hostaform®?

| Feature | Chinese POM (Export Grade) | Western Brands (Delrin®, etc.) |

|---|---|---|

| Price | ✅ 25–40% lower | ❌ Expensive |

| Supply Time | ✅ Fast from China ports | ❌ May involve longer logistics |

| Suitability | ✅ Perfect for low-medium tech parts | ✅ Better for high-end engineering |

| Certification | ✅ RoHS, REACH available | ✅ Full certs standard |

We Supply Polyacetal Resin—From Premium Brands to Cost-Effective Chinese Grades

Looking for a reliable polyacetal supplier who understands both performance-critical engineering needs and cost-sensitive procurement goals?

We’ve got you covered.

At SalesPlastics, we supply a full spectrum of POM materials:

- Branded resins like Delrin®, Hostaform®, and Duracon®—direct from original manufacturers or authorized channels.

- High-quality Chinese POM resins, tested and certified, offering 30–50% cost savings while maintaining consistent performance.

- OEM / white-label support, grade matching, and technical data for procurement audits and compliance checks.

📧 Contact us today at jerry@salesplastics.com

Let’s find the right material solution for your project—with the right performance, price, and delivery timeline.

FAQs

What is the difference between Delrin® and Acetal Copolymer?

Delrin® is a type of acetal with a unique molecular structure. It has a higher modulus of elasticity and tensile strength. On the other hand, acetal copolymers might have lower centreline porosity and better chemical resistance in some environments.

Is POM stronger than Nylon?

POM (polyoxymethylene) is generally more fatigue-resistant and dimensionally stable than Nylon. Yet, Nylon is often chosen for its better impact resistance and dampening properties.

Is Polyacetal the same as Polyoxymethylene?

Yes, polyacetal and polyoxymethylene refer to the same material. “Polyacetal” is more commonly used, mainly in Europe.

Are there different grades of Delrin®?

Yes, Delrin® comes in various grades. These include unfilled, filled, impact-modified, and UV-resistant types. Each is designed for specific uses, like Delrin® 150 for general use or Delrin® AF for enhanced wear resistance with Teflon fibres.

What makes POM suitable for engineering plastics?

POM is preferred for its high stiffness, wear resistance, and dimensional stability. It’s ideal for engineering due to its mechanical strength and low friction coefficient, making it perfect for precise parts.

What are common applications of polyacetal (POM)?

POM is widely used in the automotive sector, consumer goods, and precision manufacturing. It’s valued for its durability and mechanical properties in items like gears, zippers, and plastic fasteners.

How does Delrin® compare to Hostaform® and Duracon®?

Delrin® is a homopolymer acetal known for its high load-bearing capabilities. Hostaform® and Duracon® are copolymer acetals with lower centreline porosity and better hot water resistance. Duracon® also boasts excellent mechanical properties and is widely accepted globally.

When should I choose branded vs. generic POM?

Branded POM grades like Delrin®, Hostaform®, and Duracon® are best for high-precision and reliability needs, such as gears and bushings. Generic POM is suitable for general industrial use, cost-sensitive projects, or when customisation and OEM needs are important.

What are the key technical differences between homopolymer and copolymer acetal?

Homopolymers, like Delrin®, have higher strength and stiffness but are more prone to centreline porosity. Copolymers, with an additional comonomer, offer better high-temperature performance and chemical resistance, and a wider thermal processing window.

What are the typical certifications for polyacetal grades?

Polyacetal grades can meet various certifications, including FDA compliance for food contact, RoHS, REACH, and ISO standards. These ensure the material meets regulatory needs for different industries and regions.