Polyamide fabric, commonly known as nylon, represents a cornerstone of synthetic textile innovation, offering a compelling balance of durability, flexibility, and comfort that often surpasses traditional materials like cotton, wool, or silk. Its robust molecular structure, characterized by strong amide bonds, delivers exceptional resistance to abrasion and tensile stress, making it ideal for demanding applications. Simultaneously, its lightweight nature and soft texture enhance user comfort, addressing the dual needs of strength and wearability. This article explores polyamide’s composition, performance advantages, and diverse applications, providing insights into its critical role in modern manufacturing and its value for industries seeking high-performance materials.

In the 1930s, DuPont‘s pioneering research into synthetic polymers culminated in the development of nylon, the first commercially successful polyamide fiber, introduced in 1939. This breakthrough revolutionized textile production, enabling fabrics that withstand harsh conditions while maintaining versatility. Over decades, advancements in polymer chemistry have enhanced polyamide’s properties, from improved elasticity to eco-friendly production methods, such as bio-based polyamides. Key milestones include:

| Period | Key Development |

|---|---|

| 1930s | DuPont develops nylon, commercialized in 1939 |

| 1960s | Polyamide expands into automotive and medical sectors |

| 2000s | Introduction of sustainable, bio-based polyamide variants |

Compared to traditional materials, polyamide excels in mechanical strength—nylon’s tensile strength can reach up to 80 MPa, far exceeding cotton’s 15-40 MPa—while its low density (approximately 1.14 g/cm³) reduces transportation costs. Its moisture-wicking properties and ability to blend with other fibers further enhance comfort, making it a preferred choice for apparel, automotive components, and medical textiles. However, sustainability remains a critical consideration. Modern polyamides incorporate recycled materials and biodegradable options, addressing environmental concerns while maintaining performance.

For manufacturers and suppliers, polyamide’s consistent quality and adaptability ensure a reliable supply chain, particularly for high-grade plastic pellets used in fiber production. This guide details how polyamide’s unique properties drive its adoption across industries, offering practical insights for sourcing and utilizing this versatile.

Properties of Polyamide Fabric

Polyamide fabrics, exemplified by nylon, derive their exceptional performance from a robust molecular structure featuring strong amide bonds, which impart superior strength, flexibility, and durability. These properties enable polyamide to outperform traditional materials like cotton or wool in demanding conditions, making it a cornerstone for high-performance textiles. Key characteristics include:

- High Tensile Strength: Nylon exhibits tensile strength of 60-80 MPa, compared to cotton’s 15-40 MPa, enabling it to withstand heavy loads without deformation.

- Abrasion Resistance: Its resilient structure resists wear against rough surfaces, extending product lifespan in rugged applications.

- Lightweight Design: With a density of approximately 1.14 g/cm³, polyamide reduces material bulk and transportation costs.

- Elasticity: Polyamide’s elastic recovery ensures shape retention, ideal for form-fitting apparel and dynamic industrial components.

- Dimensional Stability: Stable across a wide temperature range (-40°C to 100°C), polyamide maintains integrity under thermal stress.

- Controlled Water Absorption: With a moisture absorption rate of 2-8% (vs. cotton’s 8-10%), polyamide retains strength in humid or wet environments.

These attributes make polyamide fabrics ideal for applications ranging from outdoor gear, such as backpacks and tents, to technical textiles like automotive upholstery and medical sutures. Unlike natural fibers, polyamide resists shrinkage (typically <1% after washing) and offers excellent dyeability, enabling vibrant, long-lasting colors. Recent advancements, such as recycled polyamide pellets, enhance sustainability without compromising performance, aligning with modern environmental standards.

Production of Polyamide Fabric

The production of polyamide fabrics, such as nylon, transforms raw materials into high-performance fibers through a series of precise, industrial processes. It begins with polymerization, where polyamide salts—typically adipic acid and hexamethylenediamine for nylon 6,6, or caprolactam for nylon 6—are mixed and heated to 250-270°C under controlled pressure in reactors. This forms long-chain polymers with strong amide bonds, ensuring the material’s durability and flexibility.

Next, the molten polymer is extruded through melt spinning, where it is forced through spinnerets to form fine filaments of precise thickness (typically 10-50 micrometers). Continuous production lines optimize energy efficiency, reducing consumption by up to 20% compared to batch processes. The filaments are then stretched and heat-set to enhance tensile strength (up to 80 MPa) and elasticity, critical for applications in apparel, industrial ropes, and automotive components.

Post-processing treatments, such as texturing or applying specialized coatings, improve surface smoothness and moisture resistance (absorbing 2-8% water, compared to cotton’s 8-10%). Rigorous quality control ensures consistency, involving tensile testing (to verify strength), thermal stability analysis (stable from -40°C to 100°C), and microscopic inspection for structural uniformity. These steps guarantee that the fibers meet industry standards for durability and performance.

| Stage | Key Process |

|---|---|

| Polymerization | Reacting polyamide salts at 250-270°C to form polymers |

| Spinning | Extruding molten polymer into filaments via melt spinning |

| Finishing | Stretching and coating to enhance strength and smoothness |

Applications of Polyamide Fabric

Nylon‘s exceptional strength and flexibility make it a cornerstone for high-performance textiles across multiple industries. In athletic wear, its moisture-wicking capability (absorbing 2-8% water vs. cotton’s 8-10%) and tensile strength (60-80 MPa) enable durable, comfortable products like running leggings and breathable jerseys, enhanced by micro-porous weaving for 20% better air permeability. Outdoor gear, such as hiking backpacks and tents, leverages nylon’s lightweight structure (density 1.14 g/cm³) and abrasion resistance to withstand rugged conditions.

In the automotive and aerospace sectors, nylon’s thermal stability (-40°C to 100°C) and durability support critical components like airbags, upholstery, and lightweight structural parts, reducing vehicle weight by up to 10% compared to metal alternatives. Medical applications benefit from its biocompatibility, with nylon 6,6 used in surgical sutures and protective gowns meeting FDA standards. Industrial sectors utilize nylon for high-performance filters and technical textiles, resisting chemical and mechanical stresses in harsh environments.

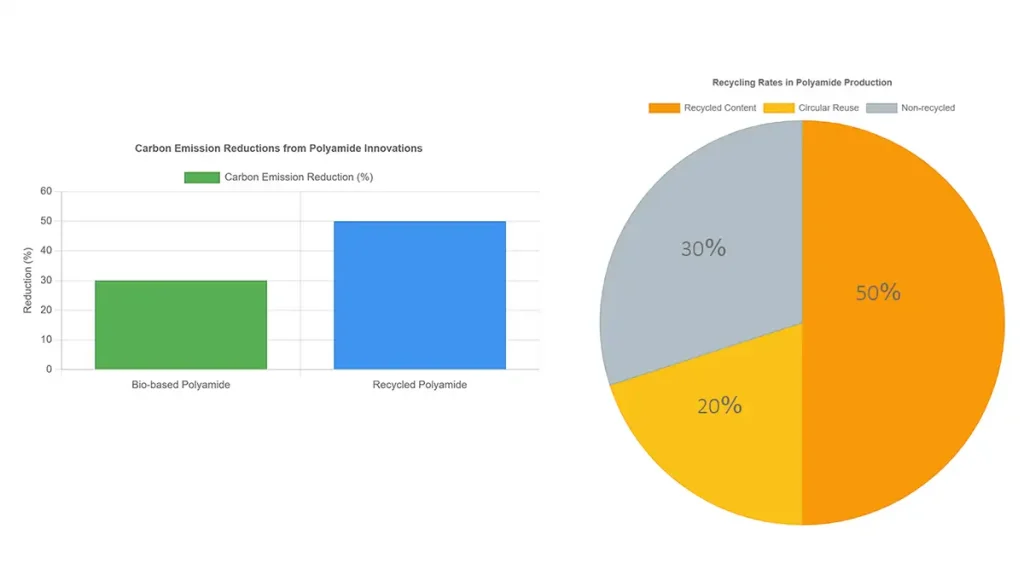

Advancements in polymer technology, such as BASF’s Ultramid® bio-based polyamides (reducing emissions by 20-40%) and recycled variants (up to 50% recycled content), enhance sustainability and impact resistance for eco-friendly apparel and 3D-printed components. Nylon’s superior dyeability (colorfastness rating 4-5, AATCC standard) ensures vibrant, fade-resistant textiles for aesthetically demanding applications like fashion and sportswear.

Environmental Impact and Sustainability

Sustainable textile production drives advancements in nylon and other polyamide fibers, addressing environmental challenges through innovative practices. Manufacturers prioritize resource efficiency, reducing water consumption by up to 30% and energy use by 20% in continuous polymerization processes compared to traditional methods. Recycling initiatives transform post-consumer textiles and industrial scraps into high-quality yarn, with companies like BASF achieving up to 50% recycled content in select polyamide products, significantly lowering raw material demand and carbon emissions.

Bio-based polyamides, derived from renewable sources like castor oil, offer a reduced carbon footprint—potentially cutting emissions by 20-40% compared to fossil-based counterparts. Advanced wastewater treatment systems, such as membrane filtration, minimize ecological impact by removing up to 95% of contaminants, protecting local water systems. Circular economy strategies further enhance sustainability, enabling up to 70% of polyamide waste to be repurposed into new fibers, supporting applications in eco-friendly apparel, automotive components, and industrial textiles.

These efforts align with global trends in polymer research, which emphasize sustainable materials as critical to modern textile engineering. Ongoing innovations, including biodegradable polyamide variants, promise further reductions in environmental impact.

Care and Maintenance of Polyamide Textiles

Proper maintenance of nylon and other polyamide textiles ensures lasting durability, vibrant colors, and optimal performance. Gentle cleaning preserves the fabric’s shape and mechanical properties, such as its tensile strength (60-80 MPa), making it ideal for applications from apparel to industrial components.

For washing, use mild, bleach-free detergents and water at 30-40°C to prevent damage to the amide bonds. A low spin cycle (600-800 RPM) minimizes stretching and shrinkage (typically <1% for nylon). Sort garments by color to avoid dye transfer, and use a soft-bristled brush with lukewarm water for spot cleaning stubborn stains, reducing the risk of pilling. Avoid harsh chemicals, such as chlorine-based cleaners, which can degrade the fiber’s structure.

To manage static cling, common in low-humidity environments, maintain 50-60% relative humidity or apply a minimal amount of silicone-based fabric softener. For wrinkle removal, iron at a low setting (110-130°C) with a pressing cloth to protect the fabric’s surface. Proper storage involves folding garments neatly and keeping them in a cool, dry place to prevent creasing and UV-induced fading.

These practices, endorsed by industry leaders like DuPont, extend the lifespan of polyamide textiles, ensuring they retain their strength and aesthetic appeal in demanding applications, such as sportswear, medical textiles, and industrial filters.

Market Trends and Future Outlook for Polyamide Textiles

The global polyamide market, valued at approximately $8 billion in 2023, is projected to reach $12 billion by 2030, driven by a compound annual growth rate (CAGR) of around 6%. Industry leaders like DuPont and BASF are advancing polyamide performance by blending it with specialized polymers, such as glass-reinforced or carbon-fiber composites, to enhance strength (up to 100 MPa tensile strength) and thermal stability for demanding applications.

Emerging smart textiles integrate conductive fibers and sensors, enabling functionalities like real-time health monitoring in wearables and temperature regulation in sportswear. These innovations leverage nylon’s flexibility and durability, with breathability improved by up to 20% through advanced weaving techniques. In parallel, 3D printing with polyamide filaments, particularly nylon 6 and 6,6, allows for customized, lightweight components with minimal material waste—reducing production scrap by up to 30% compared to traditional methods. Sustainable finishing processes, such as water-based coatings and bio-based sizing agents, further minimize environmental impact by cutting volatile organic compound (VOC) emissions by 40%.

Rising demand from the automotive and aerospace sectors, where polyamide is used in lightweight parts like gears and insulation, underscores its versatility. Emerging applications in energy storage (e.g., battery casings) and construction (e.g., reinforced membranes) signal broader market potential. These trends align with a focus on eco-friendly production, building on recycled and bio-based polyamide innovations.

Polyamide Textiles Compared to Other Fibers

Nylon and other polyamide textiles excel in demanding applications due to their superior tensile strength (60-80 MPa) and elasticity, maintaining shape under high stress. As synthetic fibers, they ensure consistent quality, with minimal batch-to-batch variation, making them a reliable choice for manufacturers seeking dependable performance in products like industrial filters, sportswear, and medical textiles.

Compared to natural and other synthetic fibers, polyamide offers distinct advantages:

- Cotton: Absorbs 8-10% moisture, providing breathability but prone to 5-10% shrinkage after washing, limiting durability in rigorous applications.

- Wool: Offers excellent insulation (thermal conductivity ~0.04 W/m·K) but is heavier (density ~1.3 g/cm³ vs. nylon’s 1.14 g/cm³) and costly to maintain due to special cleaning needs.

- Rayon: Delivers a soft texture but has lower tensile strength (~20-40 MPa), making it susceptible to tearing under stress.

- Polyester: Resists wrinkles and is 10-20% less expensive than nylon, but its lower elasticity (Young’s modulus ~2-4 GPa vs. nylon’s 3-7 GPa) reduces stretchability. For a detailed comparison, refer to our article “Nylon vs Polyester“, which explores performance differences in depth.

Polyamide’s durability and versatility make it ideal for applications where strength and flexibility are critical, unlike cotton’s comfort-driven uses or wool’s insulating roles. Its recyclability (up to 50% recycled content) also enhances its appeal over less sustainable options like rayon.

| Fiber Type | Key Performance Indicators | Drawbacks | Comparison to Polyamide (Nylon) |

|---|---|---|---|

| Polyamide (Nylon) | Tensile strength 60–80 MPa; excellent elasticity; high batch consistency; up to 50% recycled content | Slightly higher cost than some synthetics | Superior strength and flexibility; ideal for high-performance applications |

| Cotton | Moisture absorption 8–10%; breathable | Shrinks 5–10% after washing; lower durability | More comfort-oriented; not suitable for demanding environments |

| Wool | Excellent insulation (thermal conductivity ~0.04 W/m·K) | Heavier; high maintenance cost | Warmer but bulkier and harder to care for |

| Rayon | Soft hand-feel | Low tensile strength (20–40 MPa); tears easily | Comfortable but mechanically weaker than nylon |

| Polyester | Wrinkle-resistant; 10–20% cheaper than nylon | Lower elasticity (Young’s modulus 2–4 GPa vs. nylon’s 3–7 GPa) | More economical, but less stretchable and flexible |

Why Choose Our Polyamide Pellets?

Partnering with leading factories, we supply premium PA6 and PA66 polyamide pellets, delivering exceptional performance for textiles, automotive, and industrial applications. PA6 pellets, with a tensile strength of ~70 MPa and melting point of ~220°C, enable durable sportswear fibers and lightweight automotive gears. PA66 pellets, offering ~80 MPa strength and a ~255°C melting point, support high-stress components like engine parts and flame-retardant electrical connectors. Limited quantities of bio-based PA11 and low-moisture PA12 are available for specialized needs, such as fuel lines.

Our pellets ensure consistent quality through rigorous testing, maintaining uniform 2-4 mm pellet size and a defect rate below 1%. Sustainability drives our offerings, with up to 50% recycled content in PA6 and PA66, reducing carbon emissions by 20-30% (Textile Exchange). We provide customized formulations, including glass fiber reinforcement (GF15-GF35) or flame retardants, tailored to your manufacturing requirements. Direct factory sourcing ensures competitive pricing and rapid delivery within 7-15 days, supported by expert guidance to optimize injection molding and extrusion processes.

Contact us to explore our PA6 and PA66 pellets for your next project.

Types and Specifications of Our Polyamide Pellets

Our PA6 and PA66 pellets deliver robust performance for crafting durable polyamide fabrics used in high-demand applications. Tailored formulations with additives like glass fibers or flame retardants ensure versatility in textile and automotive manufacturing. Limited quantities of bio-based PA11 and PA12 support specialized uses, such as medical tubing and fuel lines. Adhering to ISO 9001 standards, our pellets meet rigorous quality requirements. Our dedicated support team responds swiftly to customize solutions for your needs.

Main Products: PA6 and PA66 Pellets

PA6 and PA66 pellets are our core offerings, engineered for durability and versatility. PA6 excels in textile fibers and automotive gears, while PA66 supports high-stress components like engine parts and electrical connectors.

| Pellet Type | Melting Point | Tensile Strength | Density | Key Applications |

|---|---|---|---|---|

| PA6 | ~220°C | ~70 MPa | 1.13-1.14 g/cm³ | Sportswear fibers, automotive gears, 3D printing filaments |

| PA66 | ~255°C | ~80 MPa | 1.14-1.15 g/cm³ | Airbags, engine parts, flame-retardant connectors |

Specialty Offerings: PA11 and PA12

Limited quantities of bio-based PA11 (180°C melting point, ~50 MPa strength) and low-moisture PA12 (190°C melting point, ~60 MPa strength) are available for niche uses like fuel lines and medical tubing.

Unique Selling Points

- Consistent Quality: Rigorous testing ensures defect rates below 1%.

- Sustainable Options: Up to 50% recycled content in PA6/PA66, reducing emissions by 20-30%.

- Custom Formulations: Additives like glass fibers or flame retardants tailored to your needs.

- Expert Support: Guidance on processing optimizes production efficiency by 10-15%.

Conclusion

Polyamide textiles, driven by PA6 and PA66 pellets, power industries from sportswear to automotive, with a market projected to grow from $8 billion in 2023 to $12 billion by 2030 (CAGR 6%). Innovations in smart textiles and 3D printing expand their potential, while sustainable options align with eco-conscious demands. Contact jerry@salesplastics.com or call +8618657312116 to source our premium PA6 and PA66 pellets for your manufacturing needs.

Frequently Asked Questions

A: Polyamide is a broad category of synthetic fibers with amide-linked polymers, encompassing nylon as its most recognized type, developed by DuPont in 1939. Nylon, such as nylon 6 (caprolactam-based) or nylon 6,6 (adipic acid and hexamethylenediamine-based), offers high tensile strength (60-80 MPa) and elasticity. Other polyamides, like aramid fibers (e.g., Kevlar), provide specialized properties such as flame resistance. While all nylon is polyamide, not all polyamides are nylon, as formulations vary for specific performance needs.

A: Polyamide, including nylon, is non-toxic and safe for most applications under normal conditions, as it is chemically stable with no significant release of harmful substances. Approved by regulatory bodies like the FDA for medical uses (e.g., sutures) and compliant with EU REACH standards, polyamide poses minimal health risks. However, during production, trace volatile compounds may be managed through proper ventilation to ensure worker safety. For consumer and industrial applications like apparel and automotive components, polyamide’s safety profile supports its widespread use.

A: Polyamide fabrics, like nylon, have moderate breathability due to their low moisture absorption (2-8%, compared to cotton’s 8-10%). Advanced weaving techniques, such as micro-porous structures, enhance air permeability (up to 20% higher than standard weaves), making polyamide ideal for moisture-wicking sportswear and outdoor apparel. While less breathable than cotton, polyamide’s quick-drying properties (20-30% faster than cotton) ensure comfort in activewear, balancing ventilation with durability.

A: Polyamide (e.g., nylon) and polyester are distinct synthetic fibers with different chemical structures and properties. Polyamide, formed from amide bonds, offers superior elasticity (Young’s modulus 3-7 GPa) and tensile strength (60-80 MPa) compared to polyester’s lower elasticity (2-4 GPa) and strength (40-60 MPa). Polyamide is ideal for stretchable, durable applications like sportswear and automotive parts, while polyester’s wrinkle resistance suits casual apparel. Polyamide is typically 10-20% more expensive but offers higher recyclability (up to 50% recycled content). For a detailed comparison, refer to our article “Nylon vs. Polyester“.

A: Polyamide fabric encompasses synthetic fibers formed from amide-linked polymers, known for their strength and flexibility. Nylon, a subset of polyamide, was pioneered by DuPont in 1939, with variants like nylon 6 (based on caprolactam) and nylon 6,6 (based on adipic acid and hexamethylenediamine). While all nylon is polyamide, not all polyamides are branded as nylon, as manufacturers develop proprietary formulations with unique properties, such as enhanced elasticity or thermal stability.

A: Polyamide production is energy-intensive, similar to polyester, but innovations like recycled polyamide (e.g., BASF’s Econamid® with 50% recycled content) and bio-based variants (reducing emissions by 20-40%) enhance its sustainability. Compared to polyester, polyamide’s higher recyclability (up to 70% waste reuse) offers environmental advantages.

A: Advanced finishes, such as silicone-based water-repellent coatings and anti-static treatments, improve polyamide’s performance in harsh conditions. These enhance moisture resistance (repelling up to 90% of water) and reduce static cling in low-humidity environments, making polyamide suitable for outdoor gear, workwear, and technical textiles.