The global plastic crisis demands more than just incremental change; it requires a material revolution. While conventional plastics persist for centuries, Polyhydroxyalkanoates (PHA) offer a truly circular solution.As a bio-polyester synthesized through microbial fermentation, PHA is not just another bioplastic—it is the only mass-produced polymer that is 100% home-compostable and marine-biodegradable.

Designed to match the high-performance standards of PP and PE, PHA provides a seamless “drop-in” transition for manufacturers.Stop compromising between performance and the planet. Transition to PHA—the ultimate zero-waste polymer.

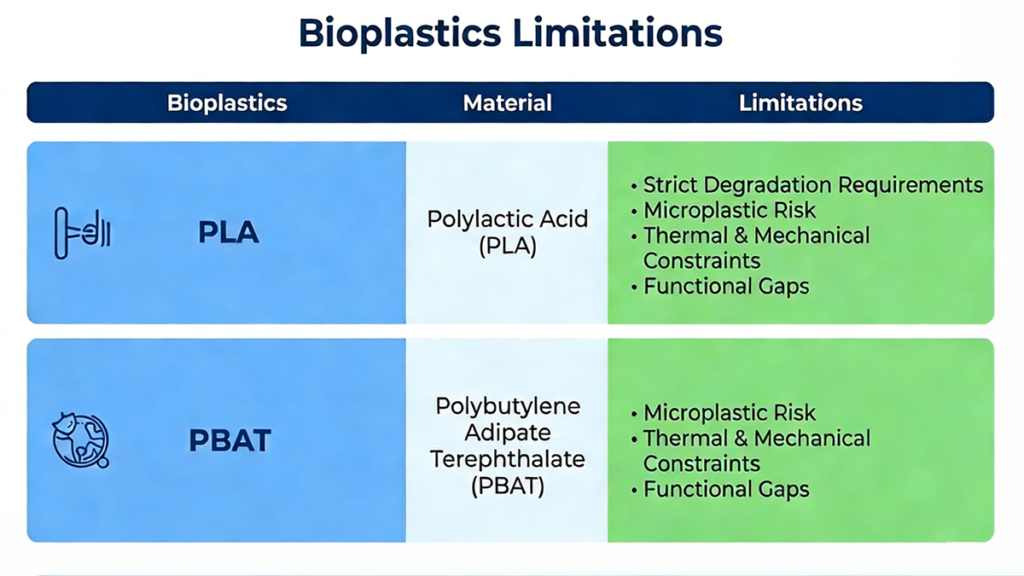

Why PLA and PBAT Are Not the Final Answer?

Comparative Limitations of PLA and PBAT Bioplastics

While PLA (Polylactic Acid) and PBAT (Polybutylene adipate terephthalate) have paved the way for bio-based materials, they remain “conditional” solutions rather than universal ones. For high-stakes applications and true environmental circularity, their limitations are becoming increasingly clear:

Current Bioplastic Benefits

- Reduced carbon footprint compared to conventional plastics

- Made from renewable resources rather than petroleum

- Can be processed using existing manufacturing equipment

Current Bioplastic Limitations

- Require industrial composting facilities to properly break down

- May produce microplastics in natural environments

- Limited feedstock options, often competing with food sources

- Restricted performance characteristics for many applications

PHA: Nature’s Biological Solution Unlike “conditional” bioplastics, PHA achieves complete mineralization in soil, freshwater, and marine environments. It is a product of nature’s biology, recognized by microorganisms as a food source, leaving zero microplastics behind.

Why Now? Overcoming the Historical Scaling Bottlenecks

Historically, PHA was sidelined by cost and processing instability.Today’s PHA industry—and our current supply chain—has entered a new era of maturity. By utilizing second-generation feedstocks (such as organic waste and industrial by-products) and high-efficiency CRISPR-optimized strains, we have achieved:

- Regulatory Compliance: With the tightening of EU’s SUPD and Global Plastic Treaties, PHA is a compliance necessity to avoid hefty non-recyclable plastic levies.

- Processing Stability: Modern PHA grades feature improved crystallization rates, addressing the “sticky mold” issues and enabling cycle times comparable to traditional injection molding.

- Cost-Performance Balance: While pure PHA is a premium material, we offer specialized PHA-based alloys that bridge the gap, providing the functionality of PHA at a price point that facilitates mass-market adoption.

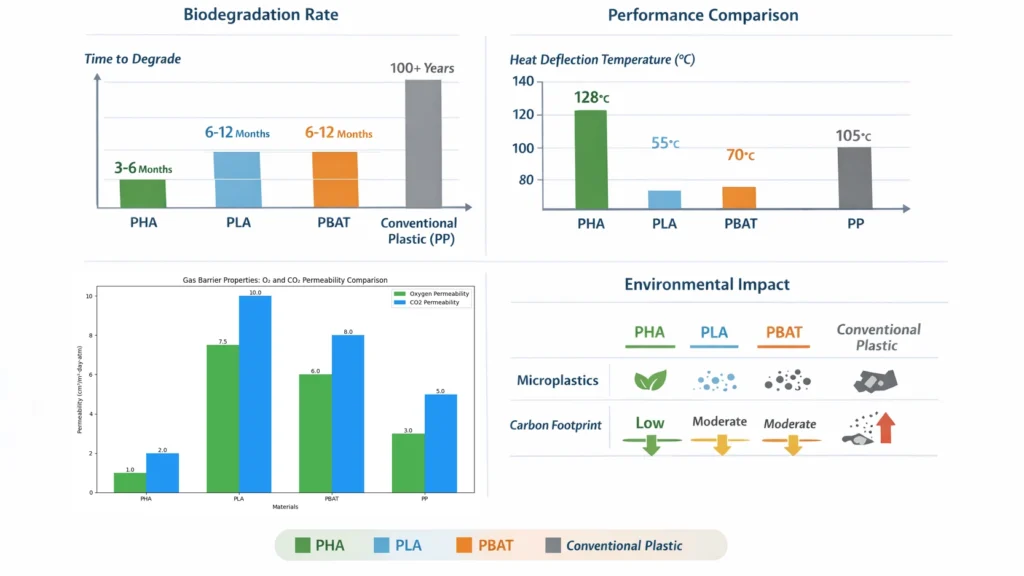

Performance Comparison: PHA vs. Traditional and Other Bioplastics

To understand PHA’s market value, we must look beyond biodegradability. PHA bridges the functional gap where PLA and PBAT fall short, offering mechanical properties comparable to—and in some cases exceeding—petroleum-based resins like PP and PE.

| Property | PHA (Our Grades) | PLA | PBAT | Traditional PP |

| Marine Biodegradability | Complete (<6 months) | Very Limited | Limited | None |

| Soil Biodegradability | Complete (3-6 months) | 2+ Years | 12+ Months | None |

| Heat Deflection (HDT) | 80-140℃ | ≈ 55℃ | ≈ 60℃ | ≈ 100℃ |

| Oxygen Barrier | Excellent (Low O₂ TR) | Moderate | Poor | Moderate |

| Water Vapor Barrier | Good to Excellent | Poor | Poor | Excellent |

| Mechanical Profile | Tunable (Rigid to Elastic) | Rigid & Brittle | High Ductility | Semi-rigid |

Comparison of Biodegradable Plastics: PHA, PLA, PBAT, and Conventional Plastics

Beyond performance, our PHA grades are backed by global certifications (e.g., TÜV AUSTRIA Marine Biodegradable, OK Compost Home), ensuring your products meet the world’s strictest “Single-Use Plastic” (SUP) bans.

Real-World Applications Already Transforming Industries

PHA is no longer a laboratory curiosity. It is a mature, high-performance resin already replacing traditional polymers in critical industrial value chains. As a leading distributor, we offer specific grades tailored for the following sectors:

PHA applications in food service, agriculture, and medical industries

Food Service: The "Premium" Alternative to PP/PS

- Applications: Heat-resistant coffee lids, straws, injection-molded cutlery, and moisture-barrier food trays.

- The Edge: Unlike PLA, our PHA grades handle hot beverages (up to 100℃) and are Certified Home Compostable, allowing brands to bypass strict single-use plastic (SUP) bans globally.

Precision Agriculture: Eliminate Collection Costs

- Applications: High-tenacity mulch films, tree protectors, and controlled-release seed coatings.

- The Edge: PHA biodegrades in situ through soil microbial activity. This eliminates the labor-intensive removal and expensive disposal costs of conventional PE films, effectively reducing total operational costs for farmers.

Medical & Healthcare: Bio-Resorbable Excellence

- Applications: Bio-compatible sutures, tissue engineering scaffolds, and drug-delivery micro-spheres.

- The Edge: Because PHA is a natural metabolite in the human body, it offers exceptional biocompatibility. It is absorbed at a controlled rate, eliminating secondary surgeries for implant removal.

🏥 Learn More: Medical Grade PHA – The Future of Biocompatible Biomaterials

Packaging & Films: High-Barrier Circularity

- Applications: Stand-up pouches, shrink wraps, and paper coatings (replacement for PE-lamination).

- The Edge: PHA provides a superior aroma and oxygen barrier, keeping food fresher for longer while ensuring the entire package can be composted along with food waste.

Marine & Technical Textiles

- Applications: Fishing nets, aquaculture cages, and non-woven fibers.

- The Edge: Designed to “disappear” if lost at sea. PHA is the only material that meets the stringent Marine Biodegradability standards, mitigating the risk of “ghost fishing” and ocean microplastics.

3D Printing & Additive Manufacturing: Beyond PLA

- Applications: Functional prototypes, architectural models, and custom eco-friendly jigs and fixtures.

- The Edge: PHA offers superior impact resistance and layer adhesion compared to standard PLA. It delivers a premium matte finish and higher thermal stability, making it the ideal sustainable choice for industrial-grade additive manufacturing.

🔗 Learn More: Revolutionizing 3D Printing with PHA Filament

Discover how PHA can transform your products

Our experts can help you identify the perfect PHA solution for your specific application needs.

Comprehensive Product Portfolio: Tailored PHA Solutions

As a specialized PHA distributor, we provide a complete ecosystem of materials—from raw resins for R&D to high-performance compounds ready for mass production. All our materials are supplied in high-quality standard form (Pellets/Powder) for easy handling, with custom masterbatches available to meet your specific branding and aesthetic needs.

PHA Raw Materials: Powder and Granules

A. Industrial Grade Resins (Pellets)

Our base resins are designed for manufacturers who require high-purity biological materials as a foundation for their own proprietary conversion processes.

- Key Grades:

PV3000G,PB3000G,PB3430G. - Compatible Processes: Injection Molding, Cast Film, Extrusion, Fiber Spinning, 3D Printing, and Thermoforming.

- Form Factor: Available in both pellets and powder to suit different feeding systems.

B.Process-Specific Solutions (Compounds & Blends)

Pure PHA can be technically challenging to process due to its narrow thermal window. Our Modified Compounds (Alloys) are pre-engineered to provide a wider processing window and enhanced melt strength, ensuring “Plug-and-Play” compatibility with standard equipment.

Coating & Paper-Plastic Composites

- Aqueous Emulsions: Ideal for sustainable paper coatings (grease/water resistance).

- Extrusion Coating: PB1002LA (Our Best-Seller) is formulated for standard lamination lines to ensure stable adhesion and eliminate the “edge-tear” issues of bio-polymers.

Injection Molding & Straw Solutions

PB2001IM(Injection Grade): A high-performance compound for rigid items (cutlery, caps).PB1001ST(Straw Grade): Optimized for high-speed straw extrusion, balancing heat resistance with home-compostability.

3D Printing Solutions (3DESIGN)

We offer everything from Pure PHA for maximum biodegradability to Enhanced Blends that prevent warping.

- Pure PHA (Natural): For users seeking maximum biodegradability and biological authenticity.

- PHA Blends (Compounds): Enhanced with biodegradable modifiers to prevent warping and improve interlayer adhesion.

C.Specialty & High-Precision Grades

For partners at the forefront of bio-medical and polymer research, we provide ultra-specialized materials that meet the highest regulatory standards.

- Medical Grade: 3 specialized grades with ultra-high purity for bio-compatible implants, sutures, and drug delivery.

- R&D/Scientific Library: A massive repository of 60+ molecular structures (PHB, PHBV, PHBHx, etc.) for research institutions and advanced product development.

Why Source Your PHA From Us?

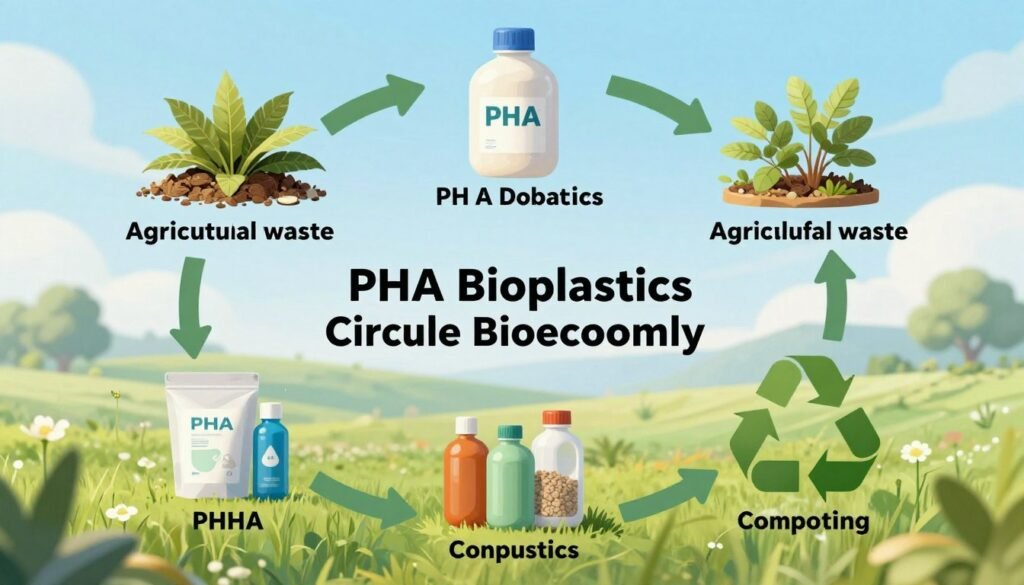

PHA’s role in creating a truly circular bioeconomy

🧪 Custom Compounding

We don’t just sell off-the-shelf products. We can develop bespoke PHA alloys (e.g., PHA+PLA) tailored to your specific mechanical and degradation requirements.

📦 Form Factor Flexibility

Whether your feeder requires pellets for consistency or powder for specialized compounding, we can supply the material in the form that fits your process.

🛠️ Technical Consultation

Our experts assist with “Drop-in” testing, helping you adjust temperature gradients and cycle times to minimize downtime during your transition to PHA.

Conclusion: The PHA Revolution Has Begun

PHA bioplastics are no longer a theoretical promise; they are a market-ready reality. By moving beyond “less harmful” alternatives to a truly circular solution, PHA allows your brand to lead the transition toward a plastic-free future without compromising the performance your customers expect.

As the global regulatory environment tightens and consumer demand for authentic sustainability peaks, the question is no longer if you should switch to PHA, but how fast you can integrate it. This is where we come in.

Partner with us to transform your supply chain:

- Proven Performance: Experience material that works in harmony with nature and your existing production lines.

- Expert Guidance: Leverage our technical team to navigate processing, customization, and certification.

- Zero-Waste Legacy: Join a growing list of industry leaders who are choosing materials that flow in cycles rather than ending as waste.

The PHA revolution is here. Let’s start your trial today.

Ready to Transition to PHA?

We are your dedicated partner for high-performance, fully biodegradable materials.

Frequently Asked Questions

What are PHA bioplastics?

PHA (Polyhydroxyalkanoates) is a high-performance family of bio-polyesters synthesized by bacteria. Think of it as “Nature’s Energy Reserve.” Microorganisms produce PHA as a storage molecule (similar to how humans store fat) through the fermentation of renewable feedstocks. As a plastic resin, it is a 100% bio-based “drop-in” solution that provides the durability of conventional polymers during use, but returns completely to nature—without leaving microplastics—once its lifecycle is over.

What is the difference between PLA and PHA bioplastics?

The core difference is Environmental Versatility.

- PLA (Polylactic Acid) is a “conditional” bioplastic; it requires industrial composting (>58℃) to degrade. In the ocean or backyard soil, it acts similarly to traditional plastic, persisting for decades.

- PHA is the gold standard of biodegradability. It is Home-Compostable and Marine-Biodegradable. It breaks down in ambient natural conditions just as wood or cellulose would. Furthermore, PHA offers a wider thermal window (higher heat resistance) and superior gas barrier properties, making it much more suitable for food packaging than PLA.

Is PHA eco-friendly?

Absolutely. PHA represents the pinnacle of the circular economy. Its carbon footprint is significantly lower than petroleum-based plastics because it is derived from renewable biomass (and increasingly from waste streams like used cooking oil or CO₂). Unlike other materials that merely “break into smaller pieces,” PHA achieves complete mineralization into H₂O,CO₂, and biomass, actively contributing to soil and aquatic health rather than polluting it. It is the ultimate insurance policy against the global “Plastic Tax” and ESG regulatory pressures.

What are the cons of PHA plastic?

While PHA is the ultimate material, we believe in full transparency with our partners regarding current challenges:

- Cost Efficiency: Currently, PHA carries a premium over PE/PP. However, when considering the Total Cost of Ownership—including plastic taxes, brand loyalty, and the elimination of waste disposal fees—the value proposition is highly competitive.

- Process Precision: PHA has a narrower thermal processing window. (This is where we help: Our technical team provides on-site support to calibrate your existing machinery for seamless production).

- Supply Scale: While global capacity is lower than fossil-fuels, our strategic partnerships ensure supply security for our contracted clients. We view these not as “cons,” but as technical parameters that we, as your distributor, help you manage and optimize.